-

iestinstrument

Model Coin Cell in-situ Swelling Test System

1. Preface

Model coin cell battery is a kind of battery used by lithium researchers, it is composed of a single layer of positive and negative electrode and diaphragm, but due to the binding of the positive and negative electrode steel shell, the electrode of the swelling cannot be measured. If the influence of positive and negative electrode steel shell is excluded and the model coin battery is used to explore the swelling behavior of single layer battery, it can more directly analyze the swelling performance of active material, which is helpful to evaluate the feasibility of material modification and process formula optimization.

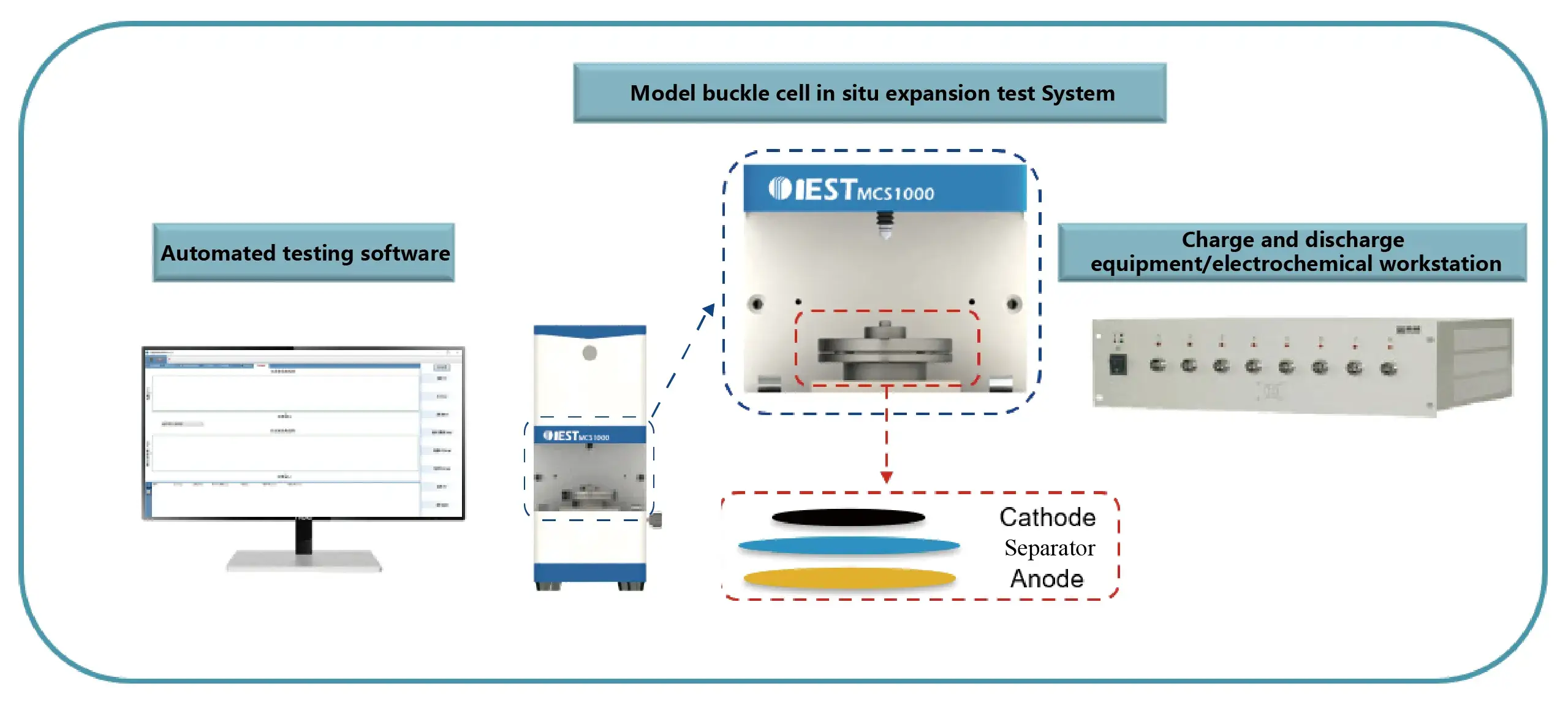

Scheme of Model Coin Cell

- Automated testing software

- IEST Model coin cell in-situ swelling test System

- Charge and discharge equipment/electrochemical workstation

2. Main Features

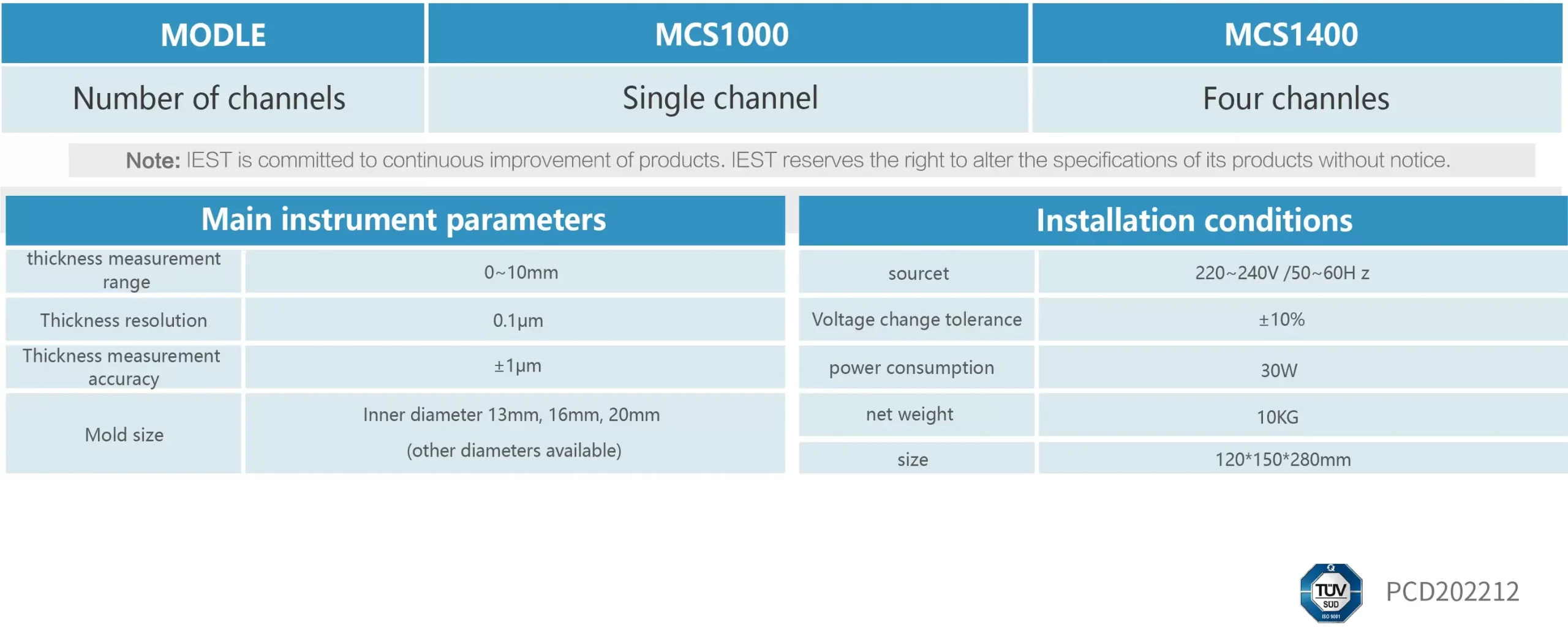

- The instrument size is small (length * width * height: 120 * 150 * 280mm), which can be placed in the glove box;

- The model coin cell can be used to assemble various types of full coin cell;

- Good tightness can ensure long-term test stability and obtain more reliable test results;

- High-precision thickness measurement system, thickness measurement resolution 0.1 µm precision ±1 µm.

- In-situ test of the full-cell expansion thickness curve;

- Ion conductivity of the solid electrolyte can be measured;

- The software can automatically combine the thickness change of the model coin cell with the charging and discharge data (compatible with partial charging and discharge tester), and output the report involving all testing data.

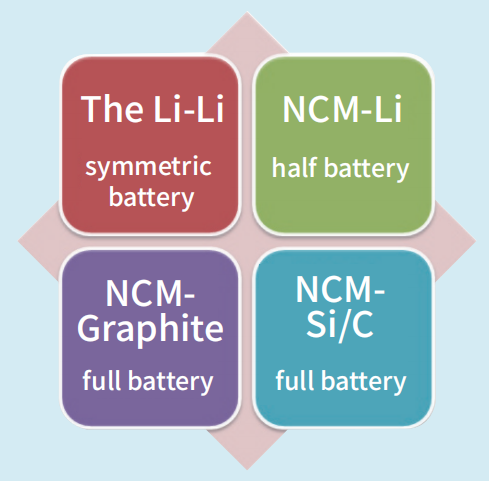

3. Application Case

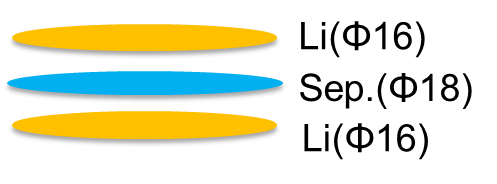

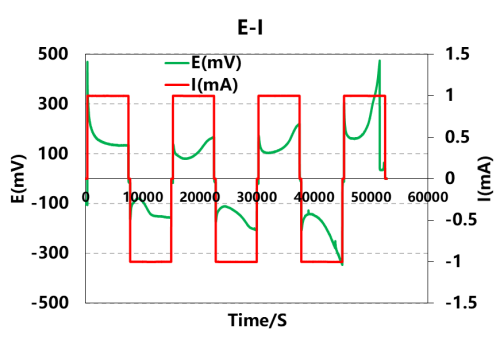

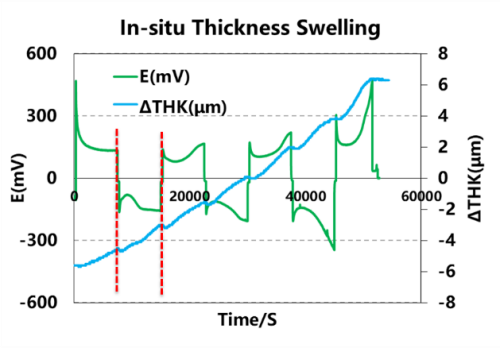

3.1 The L i-L i Symmetric Battery

Assemble Li-Li symmetrical battery to test the thickness change during lithium deposition; test parameters: current density is 0.5mA / cm2, charged and discharging for 2h and rest for 5min. During lithium plating, the total thickness of the battery gradually increased, and per 2mAh of lithium plating, the total battery thickness increased by 2 μm, corresponding to a volume swelling of about 0.76mm3/mAh.

|

|

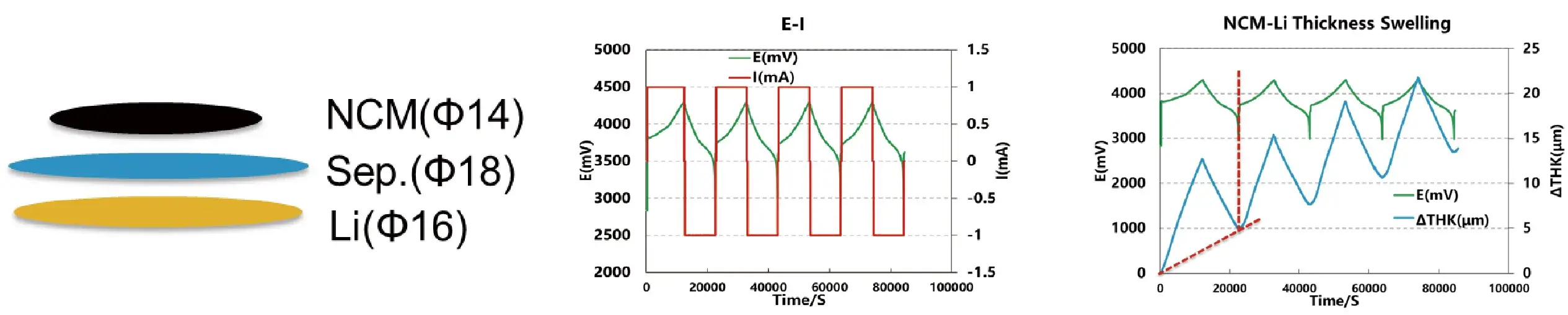

3.2 NCM-Li Half Battery

Assemble the NCM-Li battery to test the thickness change during charge and discharge; test parameters: the current density is 0.6mA / cm2,3~4.3V. During the charging process, the battery thickness swelling is about 4 μm / mAh, and the volume swelling is about (0.6mm3 / mAh), mainly caused by the deposition of lithium in NCM surface of the lithium sheet. During discharge, the thickness shrinkage is about 3 μm / mAh, and the volume shrinkage is about (0.5mm3/mAh), mainly due to the continuous removal of lithium from the lithium sheet embedded ternary, the thickness of the lithium sheet decreases;

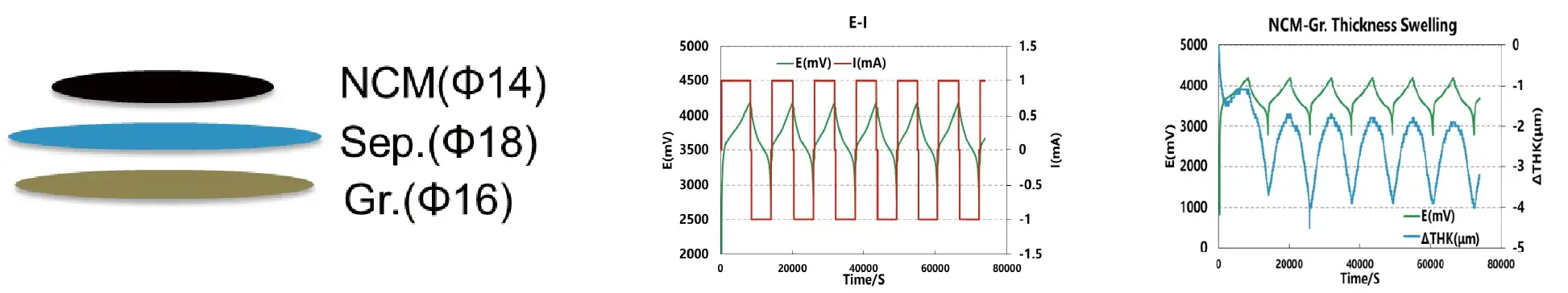

3.3 NCM-Graphite Full Battery

Assemble the NCM-Graphite battery to test the thickness change during charge and discharge; test parameters: the current density is 0.6mA / cm2,2.8~4.2V. The thickness of the battery decreases in the first circle of charging, mainly due to the rest stage after assembly, under a certain pressure condition, the interface contact between the positive and negative electrodes will gradually close, so it is necessary to start the charging time as far as possible for more than 3h before testing the thickness swelling. During the late charge and discharge process, the thickness change of both charging and discharge was about 1.33 μm / mAh, with a corresponding volume change of 0.2mm3/ mAh, which is mainly caused by lithium removal of graphite; the thickness of graphite coating is about 100μm. If the swelling of positive electrode is ignored, the percentage of thickness expansion of graphite is 2%.

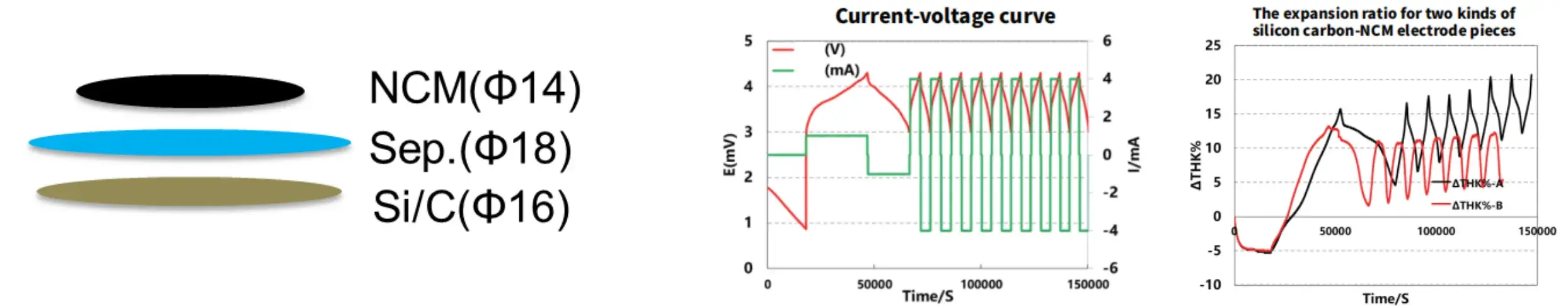

3.4 NCM-Si/C Full Battery

Assemble NCM-Si/C battery and test the thickness change during charge and discharge; test parameters: current density is 0.6mA / cm2,3~4.3V. When the thickness of the test model battery expands, the swelling of the positive NCM plate is ignored, the total swelling is mainly the swelling of the negative SiC, and then deducting the thickness of copper foil, the swelling percentage can be calculated. Compared with two kinds of materials, swelling of A material is greater than B, and the first circle full, the difference is smaller, and subsequent cycle, B maximum swelling thickness will decrease compared to the first circle, the subsequent slow increase, for A material, each circle of the maximum swelling thickness has been increasing, this is related to the two material modification way.

4. Main Instrument Parameters

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.