-

iestinstrument

Effect Of External Stress On Battery Cycle Life

Lithium-ion battery charging and discharging cycle is a complex physicochemical reaction process, and battery cycle life is affected by a variety of factors. On the one hand, it is related to the characteristics of the battery itself, such as material properties, electrode design and battery manufacturing process; on the other hand, it is also related to the external influences on the battery during the use process. In this paper, we focus on finding the most suitable conditions for battery cycle life by changing the external stress, which can provide some guidance for the use of cells and mold PACK.

1. Experimental equipment and test methods

1.1 Experimental equipment

In-situ swelling analyzer, model SWE2110 (IEST), as shown below

Figure 1. Appearance of SWE2110 device

1.2 Test Information and Procedure.

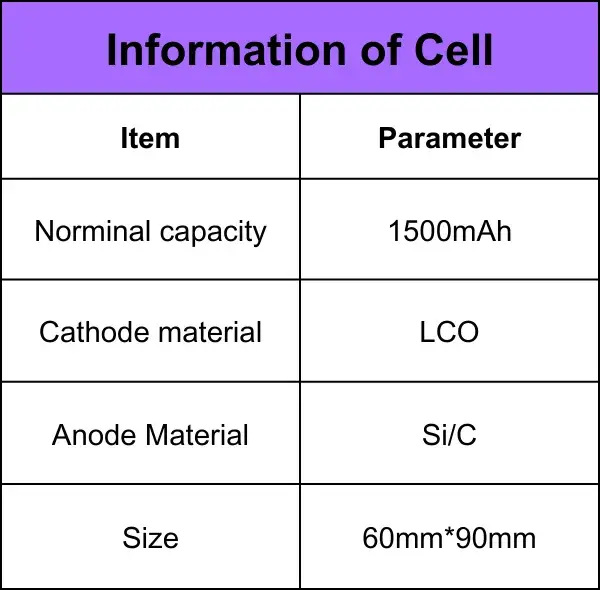

1.2.1 The cell information is shown in Table 1.

Table 1. Test cell information

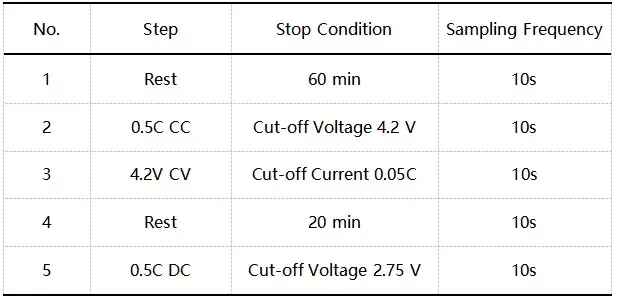

1.2.2 Charging and discharging process:

Table 2. Charging and discharging process

1.2.3 Experimental process

Cell thickness expansion test: Place the battery to be tested into the corresponding channel of SWE2110, start the MISS software, set different test pressures, sampling frequencies, charge and discharge processes, etc. The software automatically reads the cell thickness, thickness change, test temperature, current, voltage, capacity and other data.

2. Experimental Results And Analysis

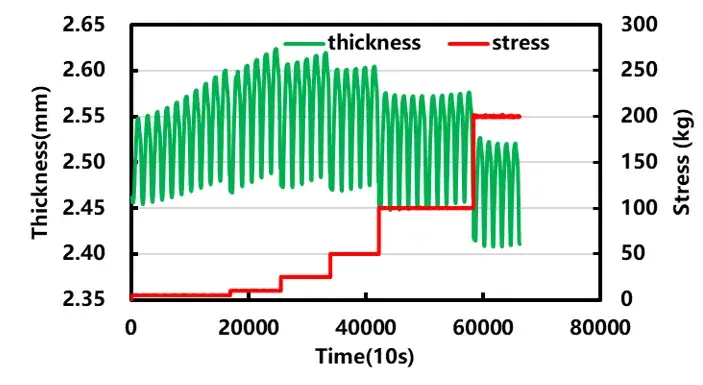

The in-situ swelling analyzer (SWE2110) was turned on in constant pressure mode, and the pressure was set to 5.0kg, 10kg, 25kg, 50kg, 100kg and 200kg respectively, and the pressure was held for 1h each before charging and discharging the battery cell for cycling, and at the same time, the thickness change was monitored in-situ during the whole process. As shown in Figure 2, during the whole cycling process, due to the de-embedded lithium phase transition of the positive and negative materials, the cell as a whole exhibits a trend of expansion in charging and contraction in discharging. This is mainly due to the expansion of the embedded lithium in the SiC negative electrode, and the volume recovery after delithiation, which is caused by this reciprocal reversible volume change. The thickness of the cell is different under different pressures, and the maximum thickness of the cell gradually decreases as the externally applied pressure increases. External stress increases the relative density and contact area between the active material and the diaphragm, which not only minimizes the interfacial resistance, but also ensures uniform current distribution during charging and discharging, and thus the degree of decay in the cycle life of the cell varies under different pressures. Under the same pressure, the maximum expansion of the cell in each cycle rises with the number of cycles, which indicates that there is irreversible expansion of the cell in the process of charging and discharging, and the amount of irreversible expansion increases with the number of cycles (extract the initial thickness of charging and the end thickness of discharging in each cycle and calculate the difference between the two thicknesses, which is the thickness of irreversible expansion).

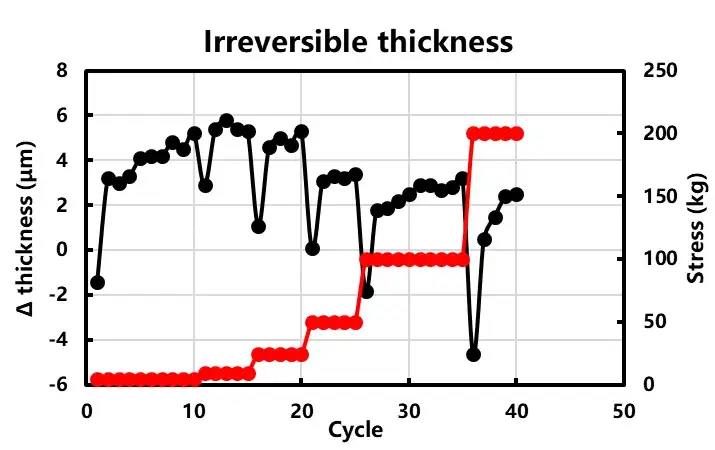

Figure 3 shows the change of irreversible expansion thickness with pressure: with the increase of pressure, the irreversible expansion of the cell charging and discharging has a certain change, i.e., the appropriate pressure helps to inhibit the irreversible expansion. During the pressure switching process, the irreversible expansion shows a sudden change point, and the sudden change is more obvious with the increase of pressure, which may be related to the different time needed for the cell to reach the stable state with the pressure switching. The thickness of irreversible expansion is the formation of permanent plastic deformation and cracks during the lithiation/delithiation process, which mainly includes the structural change of anode materials, the crushing and dissolution of active materials, the growth of SEI film due to a variety of side reactions, analytical reasoning, and the gas production of the cell , etc. Because the experiment uses a silicon-carbon negative electrode, and the charge/discharge current is only 0.5C, the irreversible expansion of the experiment is mainly caused by the anode material’s cracking and SEI membrane reorganization. As the cycle proceeds, these side reactions and attenuation continue to accumulate, resulting in the irreversible thickness of the cell also increasing.

Figure 2. Thickness variation curve of different pressure cycles of the cell

Figure 3. Irreversible thickness variation curve of the cell

Appropriate external stress can increase interfacial contact, reduce the loss of active lithium during cycling, and slow down the decay of battery capacity. At the same time, the positive and negative electrodes and the diaphragm of lithium-ion batteries are porous structures, and with the increase of pressure, the porosity of the electrodes and the diaphragm, as well as the tortuosity and other parameters will be changed to affect the diffusion of Li+, from causing the capacity decay[1].

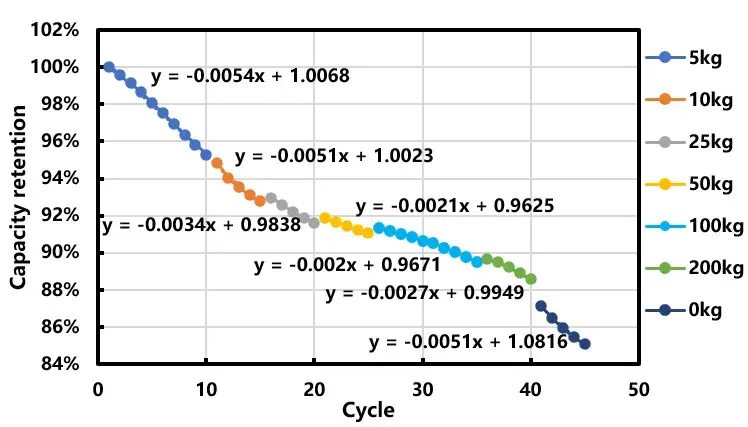

Pressure affects the electrical contact resistance, porosity and effective surface area of the electrodes, as well as the morphology of the diaphragm. Therefore, external compression on the cell affects the electrochemical performance, including battery cycle life. The discharge capacity of the cells under each pressure point at different numbers of cycle turns was extracted and linearly fitted, and the results are shown in Figure 4: with the increase of pressure, the slope of the linear fitting curve of the capacity of the cells increases and then decreases, i.e., the decay rate of the discharge capacity shows a tendency of decreasing and then increasing. The effect of mechanical pressure on batteries has been studied in several ways and it is clear that it has a significant impact on battery performance. Applying a certain amount of pressure to the cell can help to minimize irreversible swelling and maintain cell performance with graphite anodes and silicon-based anodes. However, applying too much pressure on the cell can negatively affect capacity retention. Studies have shown that the measured initial cell thickness is approximately 5-15% higher than the theoretical thickness, and this discrepancy is mainly due to electrolyte filling resulting in binder and diaphragm swelling, chemosynthesis gas production, and the presence of voids at the electrode interface. External stress can reduce the electrode interface voids and increase the contact area. As a result, the cell is compressed at lower pressures and the thickness is reduced, which can reduce the contact resistance and improve the battery cycling performance. Subsequently, when the pressure continues to increase, the porosity of the electrodes and diaphragm, as well as the tortuosity, will be changed to affect Li+ diffusion, from resulting in a faster capacity decay. The capacity degradation of the cell is minimized at an external stress of 50kg~100kg, i.e. this pressure is the optimal external stress for this cell.

Figure 4. Capacity decay curves of battery cells at different pressures

3. Summary

In this paper, the optimal cyclic external stress conditions for LCO/SiC system batteries were explored by using the in-situ swelling analyzer (SWE) of IEST. The capacity degradation and irreversible cycling expansion are minimized when the long cycling of the cell is performed under an external stress of 50kg~100kg, which also provides relevant technicians with ideas to improve the silicon-based system battery cycle life and further enhance the use of silicon-based system in practice.

4. References

[1] A.S. Mussa,M. Klett,G. Lindbergh, and R.W. Lindstrom, Effects of external pressure on the performance and ageing of single-layer lithium-ion pouch cells. J. Power Sources 385 (2018) 18-26.

[2] D.J. Li, D.L. Danilov, J. Xie, L. Raijmakers, L. Gao, Y. Yang and P.H.L. Notten, Degradation Mechanisms of C6/LiFePO4 Batteries: Experimental Analyses of Calendar Aging. Electrochim. Acta 190 (2016) 1124-1133.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.