-

iestinstrument

In-situ Analysis of Silicon-Carbon Composite Cell Swelling Performance During Formation Process

1. Abstract

This study characterizes thickness expansion during formation of silicon-carbon composite cells with different silicon loadings (450 Si/C vs 800 Si/C) using an in-situ cell swelling tester (IEST SWE2110). Continuous thickness, voltage, current and capacity monitoring during controlled formation reveals that higher silicon content produces larger irreversible and reversible thickness increases driven by SEI formation, gas evolution and Li–Si alloying. Differential capacity analysis links lithiation features to the onset and magnitude of swelling. The results provide practical guidance for silicon-carbon electrode formulation and module design to mitigate silicon carbon battery swelling while preserving energy density.

2. Intoduction

Formation is the critical first electrochemical conditioning step in cell manufacture. During formation the negative electrode forms the solid electrolyte interphase (SEI) and lithium inserts into active particles; both phenomena increase electrode and cell thickness. SEI growth may also produce gaseous byproducts that accumulate in pouch side-gaps under formation jigs and contribute to net pouch expansion. Silicon-containing anodes are particularly susceptible to volumetric change because silicon undergoes large alloying-induced expansion upon lithiation. Understanding and quantifying silicon carbon battery swelling during formation is therefore essential for cell stacking, module compression design and long-term mechanical reliability.

This work compares formation swelling for two silicon-carbon composite cells (labelled 450 Si/C and 800 Si/C, representing differing gravimetric silicon capacities) under an identical formation protocol, and draws links between electrochemical signatures and thickness change.

![]()

Figure 1. Comparison of Expansion for Silicon-Carbon Composite cells with Different Ratios

3. Experimental Setup and Method

3.1 Experimental Equipment:

The In-Situ Cell Swelling Testing System (IEST SWE2110) was used to monitor real-time thickness variation under controlled temperature and pressure. This system provides high-precision measurements of thickness, voltage, current, and temperature throughout the formation process. The external appearance of the equipment is shown in Figure 2.

Figure 2. External View of the SWE2110 Device

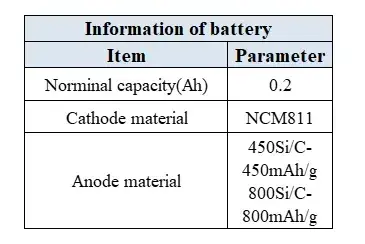

3.2 Cell Specifications

Two silicon-carbon composite cells with different gravimetric capacities (450 mAh/g and 800 mAh/g) were tested to compare expansion behaviors relative to silicon content(Table 1)

Table 1. Test Cell Specifications

3.3 Formation Process

The formation protocol included:

-

Rest at 25°C for 5 minutes

-

Constant current (CC) charge at 0.01C for 2 minutes

-

CC charge at 0.1C until 3.9V

3.4 Data acquisition and analysis

Thickness and electrochemical data were sampled synchronously via the SWE2110 MISS software. Differential capacity (dQ/dV) curves were calculated from the charge data to identify lithiation features. Thickness expansion was compared directly against dQ/dV peaks to correlate phase transitions with mechanical response.

4. Results and Discussion

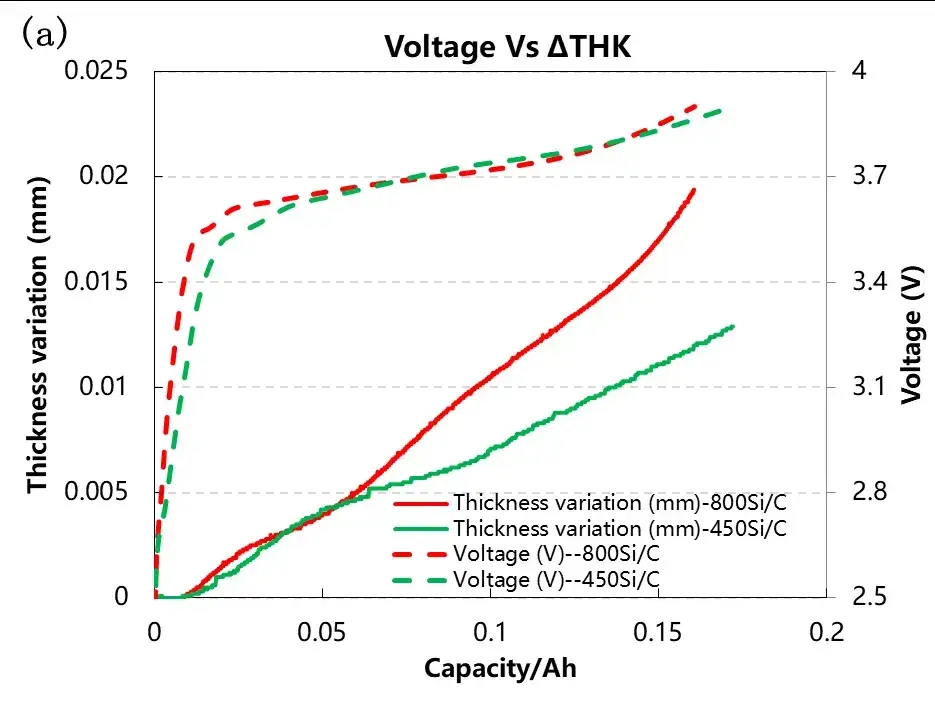

4.1 Formation charge and thickness expansion profiles

Figure 3 (charge curve) and Figure 4 (thickness curve) show the coupled electrochemical and mechanical response during formation. Both cells exhibit gradual thickness increase during charge; however, the 800 Si/C cell shows substantially greater net expansion than the 450 Si/C cell. The divergence grows during the lithiation region where Li–Si alloying occurs.

Figure 3. Formation Charging Curves

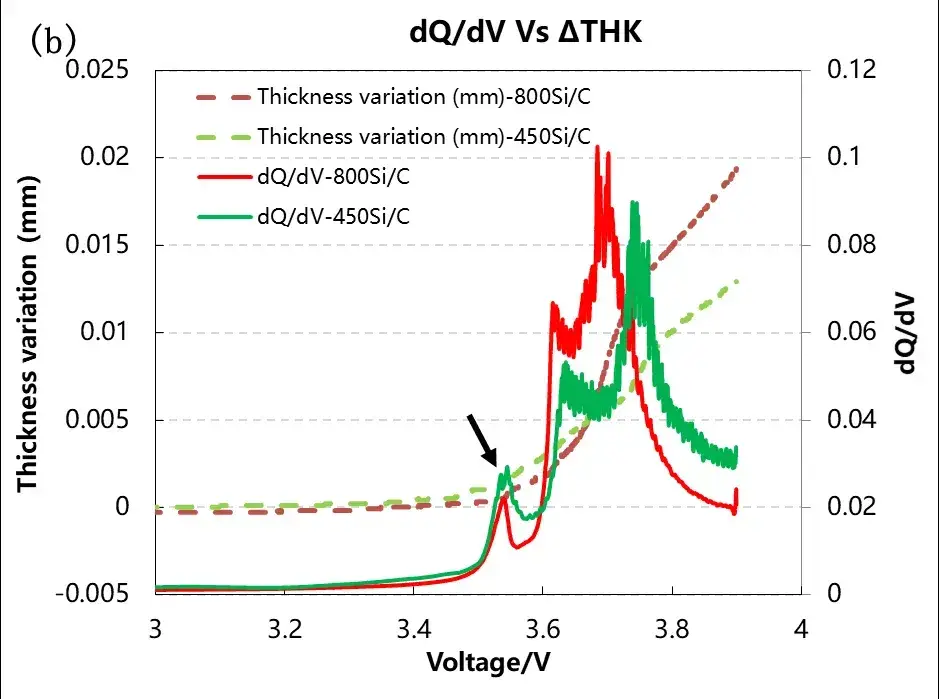

4.2 Differential capacity vs. thickness change

Overlaying dQ/dV and thickness reveals notable inflection points: the 800 Si/C cell demonstrates earlier onset of lithiation peaks and higher peak intensity relative to 450 Si/C. These electrochemical signatures indicate more extensive LiₓSi formation and explain the increased swelling observed for higher silicon loading.

Figure 4. Thickness Expansion Curves

5. Discussion

5.1 Mechanisms driving formation swelling

Key contributors to thickness expansion during formation are:

-

SEI formation and associated volume — inorganic/organic SEI components accumulate on the anode surface, increasing thickness.

-

Gas generation — electrolyte decomposition during SEI formation produces gas that is trapped in pouch side gaps under jig pressure.

-

Li–Si alloying — silicon expands mechanically when forming LiₓSi phases; higher silicon content magnifies this effect.

-

Mechanical boundary conditions — applied pressure and pouch geometry affect whether expansion translates to thickness increase or pouch deformation.

5.2 Implications for cell and module design

-

Electrode formulation: Increasing silicon content raises energy density but at the cost of larger irreversible and reversible swelling during formation. Optimizing the Si/C ratio is necessary to balance capacity and mechanical stability.

-

Material engineering: Silicon microstructure (nano-sizing, yolk-shell, porous or carbon-coated Si) and binder/conductive additive systems can accommodate Si expansion and reduce net swelling.

-

Formation protocol: Slower or multi-step formation (lower C-rate holds) and gas-management strategies can limit rapid gas evolution and reduce trapped gas volume.

-

Module/preload design: Module clamping forces and cell side-gap allowances must account for initial formation swelling to avoid mechanical stress and pouch rupture.

6. Recommendations to Mitigate Silicon Carbon Battery Swelling

-

Optimize silicon architecture: adopt yolk-shell, porous, or carbon-encapsulated Si particles to provide internal free volume for expansion.

-

Control silicon loading: select Si/C ratios that meet energy targets while keeping manageable swelling (consider grading Si content across cells).

-

Advanced binders and conductive networks: use elastic polymer binders (e.g., SBR/CMC blends, elastomeric polymers) and robust conductive frameworks (carbon nanotubes, graphene) to maintain electrode integrity during expansion.

-

Formation process tuning: include low-rate preformation and stepped CC-CV holds to reduce fast gas evolution and SEI shock formation.

-

Thermal and pressure control: perform formation under controlled temperature and apply optimized preload to minimize side-gap gas trapping and uneven deformation.

-

Electrolyte additives: select additives that form stable SEI with lower gas generation (e.g., FEC, VC for Si-containing anodes) to reduce formation swelling.

7. Conclusion

Using the IEST SWE2110 in-situ swelling analyzer, this study demonstrates that silicon content strongly influences formation-stage thickness expansion in silicon-carbon composite cells. The 800 Si/C cell showed a larger thickness increase than the 450 Si/C cell, with differential capacity analysis confirming earlier and stronger Li–Si alloying signals that correlate with mechanical swelling.

These findings highlight the need for optimized silicon-carbon ratios and advanced material engineering—such as core-shell structures or porous silicon designs—to mitigate swelling. The SWE2110 system offers valuable insights for evaluating and refining electrode materials under realistic conditions.

8. References

[1] Andressa Y. R. Prado, Marco-Tulio F. Rodrigues, Stephen E. Trask, Leon Shaw, and Daniel P. Abraham, “Electrochemical Dilatometry of Si-Bearing Electrodes: Dimensional Changes and Experiment Design,” Journal of The Electrochemical Society, 167 (2020) 160551.

[2] Peng Li, Hun Kim, Seung-Taek Myung, Yang-Kook Sun, “Diverting Exploration of Silicon Anode into Practical Way: A Review Focused on Silicon-Graphite Composite for Lithium Ion Batteries,” Energy Storage Materials, 35 (2021) 550–576.

[3] Sujong Chae, Minseong Ko, Kyungho Kim, Kihong Ahn, and Jaephil Cho, “Confronting Issues of the Practical Implementation of Si Anode in High-Energy Lithium-Ion Batteries,” Joule, 1, 47–60, September 6, 2017.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.