-

iestinstrument

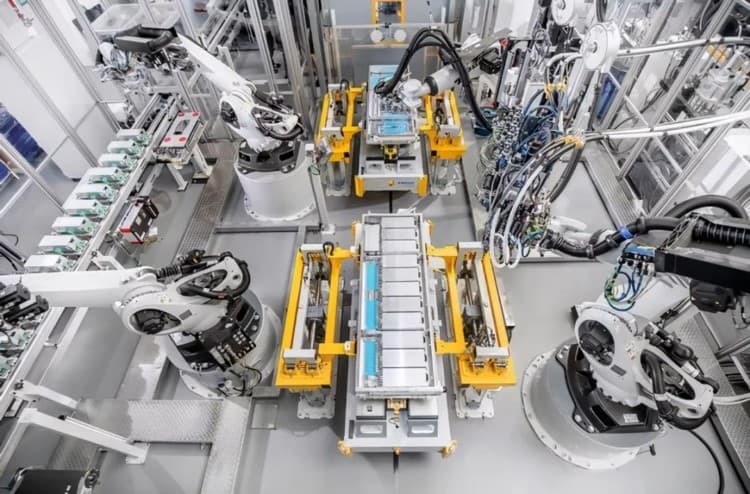

CATL Launches Condensed Matter Batteries, Pioneering Electrification of Passenger Aircraft and EVs

1. CATL launches condensed matter batteries to help electrify passenger aircraft

Chinese power battery giant Contemporary Amperex Technology Co., Limited (CATL) has unveiled a groundbreaking innovation in energy storage—the Condensed Matter Battery. This new battery technology promises to reshape the landscape of electric mobility, from passenger vehicles to electric aircraft, with its ultra-high energy density and superior safety profile.

During a recent update on an interactive platform, CATL announced that it is currently collaborating on the development of civil electric manned aircraft. The company is implementing stringent aviation-grade standards and testing protocols to ensure the condensed matter batteries meet the highest levels of safety and quality required for aerial applications. In parallel, CATL confirmed that a vehicle-grade application version will also be introduced, with mass production expected within 2023.

2. What Are Condensed Matter Batteries?

CATL Condensed Battery technology represents a major evolution in lithium-based energy storage. It utilizes a unique condensed state electrolyte, which exists in a gel-like form—bridging the gap between liquid batteries and all-solid-state batteries. This innovative material system allows the battery to achieve a remarkable single-cell energy density of up to 500 Wh/kg, doubling that of mainstream ternary lithium batteries (~250 Wh/kg) and far surpassing lithium iron phosphate batteries (~180 Wh/kg).

Key Advantages of Condensed Matter Batteries:

2.1 Ultra-High Energy Density

With an energy density of 500 Wh/kg, the CATL condensed battery significantly extends the driving range of electric vehicles and, critically, enables the electrification of regional aircraft. It is estimated that condensed matter batteries could power sub-100-seat electric aircraft for distances between 600 km and 1,200 km on a single charge.

2.2 Enhanced Safety

Through the use of an adaptive micron-scale network structure, CATL’s condensed matter batteries effectively regulate inter-chain interactions during electrochemical reactions. This design greatly improves structural stability and reduces the risk of thermal events, making these batteries suitable for high-stakes applications including aviation.

2.3 Innovative Material and Process Design

The battery incorporates a high-energy cathode, a new anode material, and upgraded separator technology—all developed through proprietary manufacturing processes. These innovations not only support ultra-high energy density but also ensure long cycle life and reliability under demanding conditions.

3. Energy density: up to 500 Wh/kg? How that compares

The most attention-grabbing claim is an energy density of ~500 Wh/kg at the cell level — roughly double that of many current mainstream power cells (~200–260 Wh/kg) and significantly above typical LFP cells (~160–190 Wh/kg). For context:

-

Typical high-energy NMC/NCA power cells today: ~220–260 Wh/kg.

-

Advanced semi-solid or high-nickel demonstrations: often reported in the 350–400 Wh/kg range (lab or prototype).

-

CATL’s claim of 500 Wh/kg would place condensed matter batteries at the top end of reported cell energy densities, if validated at scale.

Higher specific energy directly translates to longer range for electric vehicles or larger mission capability for electric aircraft, assuming weight, packaging and thermal management are all optimized.

4. Safety and cycle life — CATL’s emphasis

CATL emphasizes safety engineering: the condensed electrolyte chemistry and mesh structure are intended to reduce thermal runaway risk and improve mechanical/chemical stability. The company says the design targets aviation-grade safety, which would imply rigorous qualification (thermal abuse, mechanical shock, cell containment and redundancy). However, safety performance and cycle life must be proven across many cycles and under realistic abuse and ageing scenarios before aviation or mass-market automotive deployment can be confirmed.

5. Applications: from EV cars to electric passenger aircraft

CATL positions condensed matter batteries for two broad application families:

-

Automotive (car-grade) — a mass-production vehicle variant that would offer much greater range or smaller pack weight. CATL has stated plans for a car-grade version and indicated production readiness timelines.

-

Aviation (civil electric aircraft) — CATL is reportedly collaborating on manned electric aircraft projects and working to meet aerospace standards. For small regional aircraft (sub-100 seats), the company has suggested the technology could enable fully electric ranges in the order of hundreds to over 1,000 km, depending on aircraft design and pack integration.

If verified, condensed matter batteries could accelerate electrification beyond ground vehicles into aviation niches where weight is a primary constraint.

6. Challenges & what to watch for next

-

Independent validation: Look for third-party tests or peer-reviewed data on cycle life, thermal abuse resistance, and pack-level behavior.

-

Scalability: Pilot lines and mass production demonstrations will reveal whether the claimed densities are achievable at scale with acceptable yields.

-

Cost trajectory: Materials and process complexity will determine whether condensed matter batteries can be cost-competitive for consumer EVs or primarily targeted at premium / aerospace segments.

-

Regulatory & certification pathways for aviation: Even with impressive metrics, aerospace adoption requires long validation cycles and certification.

7. Conclusion

The CATL condensed battery technology marks a pivotal advancement in the global battery industry. By combining unprecedented energy density with rigorous safety standards, it opens new possibilities for electric aviation and enhances the performance and appeal of electric vehicles. As CATL moves toward mass production, it reinforces its leadership in electrification innovation and sustainable energy solutions.

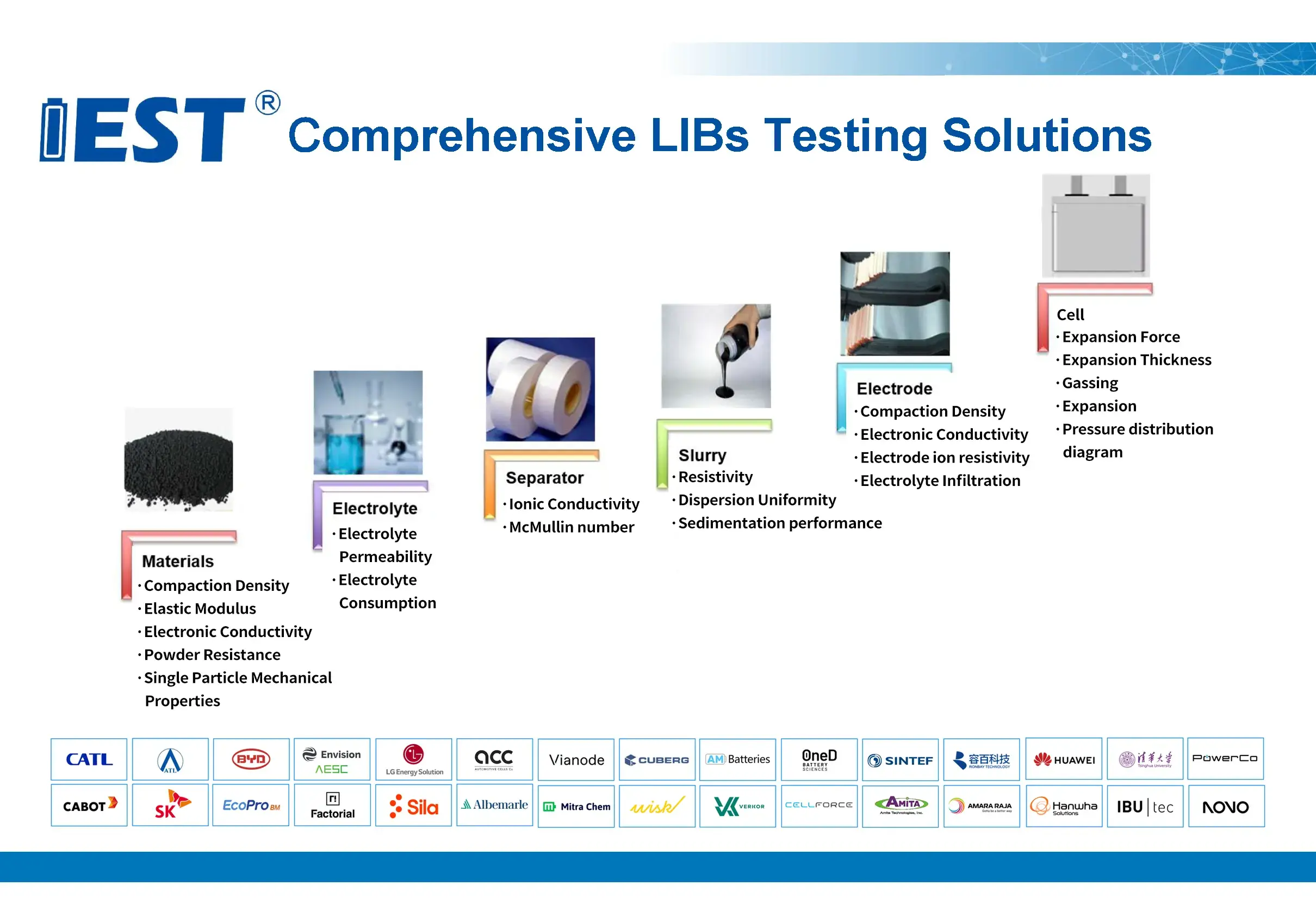

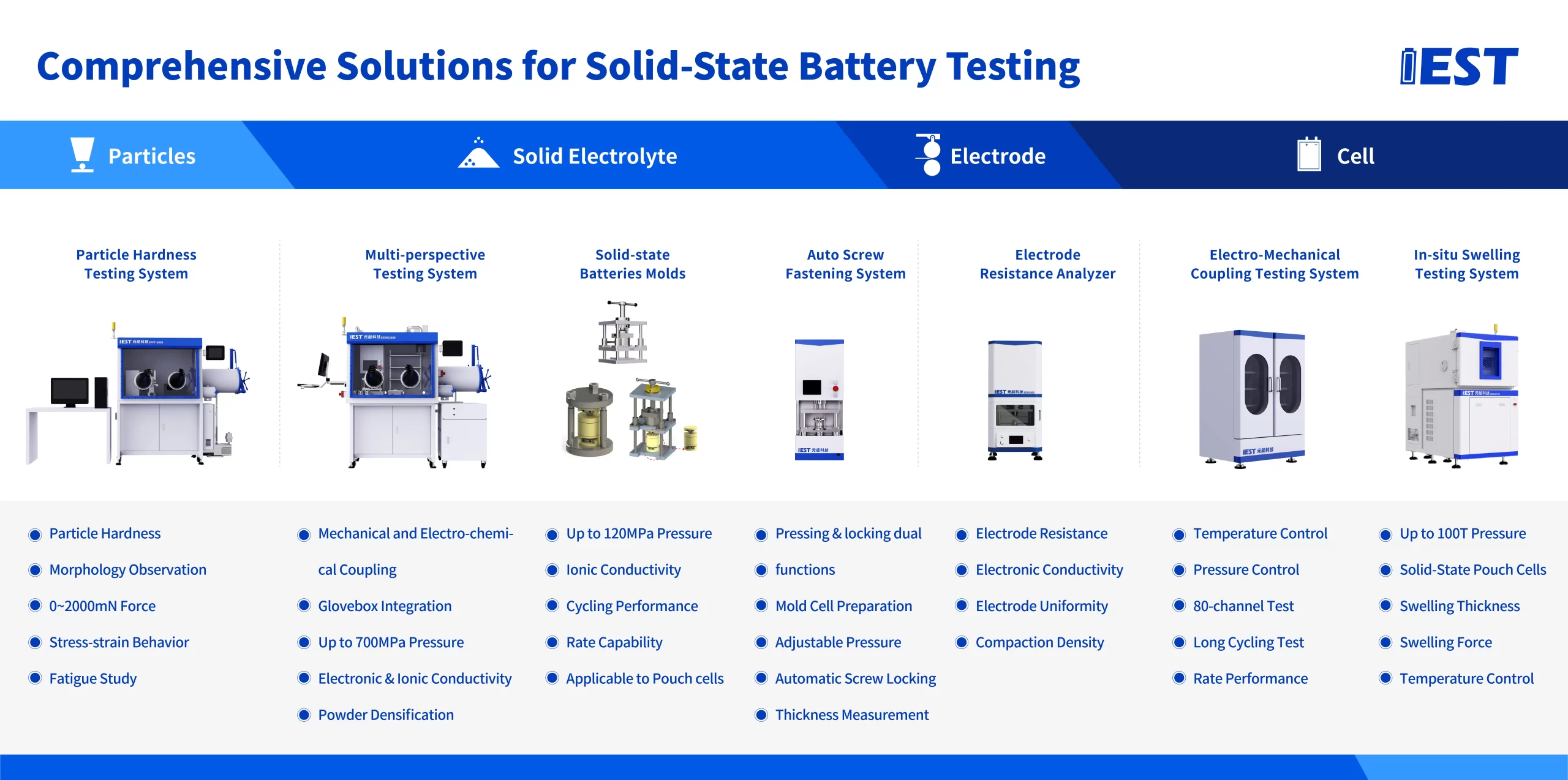

8 . Lithium Battery Testing Solutions Recommend:IEST Instrument

IEST is a high-tech enterprise focusing on R&D and production of lithium ion battery tester. IEST is a professional manufacturer that integrating laboratory instrument R&D and production, method development, instrument sales and technical services. Committed to providing leading testing solutions and services for the global new energy field, IEST company serves key clients like CATL, BYD, Huawei, Svolt, GM, Leyden, Sintef, Factorial, Cabot, Cuberg.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.