-

iestinstrument

High-Precision Battery Cycler Systems: Analysis of Accuracy and Stability Verification Methods

1. Abstract

With the rapid development of electric vehicles, grid-scale energy storage and premium consumer electronics, the demand for accurate and stable battery characterization has risen sharply. High-precision battery cycler systems are indispensable tools for battery R&D, quality validation and state assessment. This article explains the core technologies and verification methods used to validate the accuracy and stability of high-precision battery cycler systems, and discusses their role in improving battery quality, accelerating R&D and ensuring safety.

2. Why Can Battery Characterization Not Do Without High Accuracy and Stability?

Traditional battery cycler systems might have sufficed for basic capacity sorting. But now, tiny current/voltage measurement deviations or momentary control instability can lead assessment results astray.

-

R&D Perspective: Even subtle differences in charge-discharge curves can correspond to different electrode materials, electrolyte formulations, or SEI film characteristics. High-precision data is the foundation for exploring internal battery mechanisms.

-

Quality Perspective: Accurate measurement of key indicators like capacity, internal resistance, and Coulombic efficiency directly impacts battery grading, pricing, and even market competitiveness.

-

Safety & Lifespan Perspective: If the system is unstable, overcharge, over-discharge, or even thermal runaway can occur. In cycle life testing, minor energy accumulation errors are amplified over cycles, leading to severely inaccurate lifespan predictions.

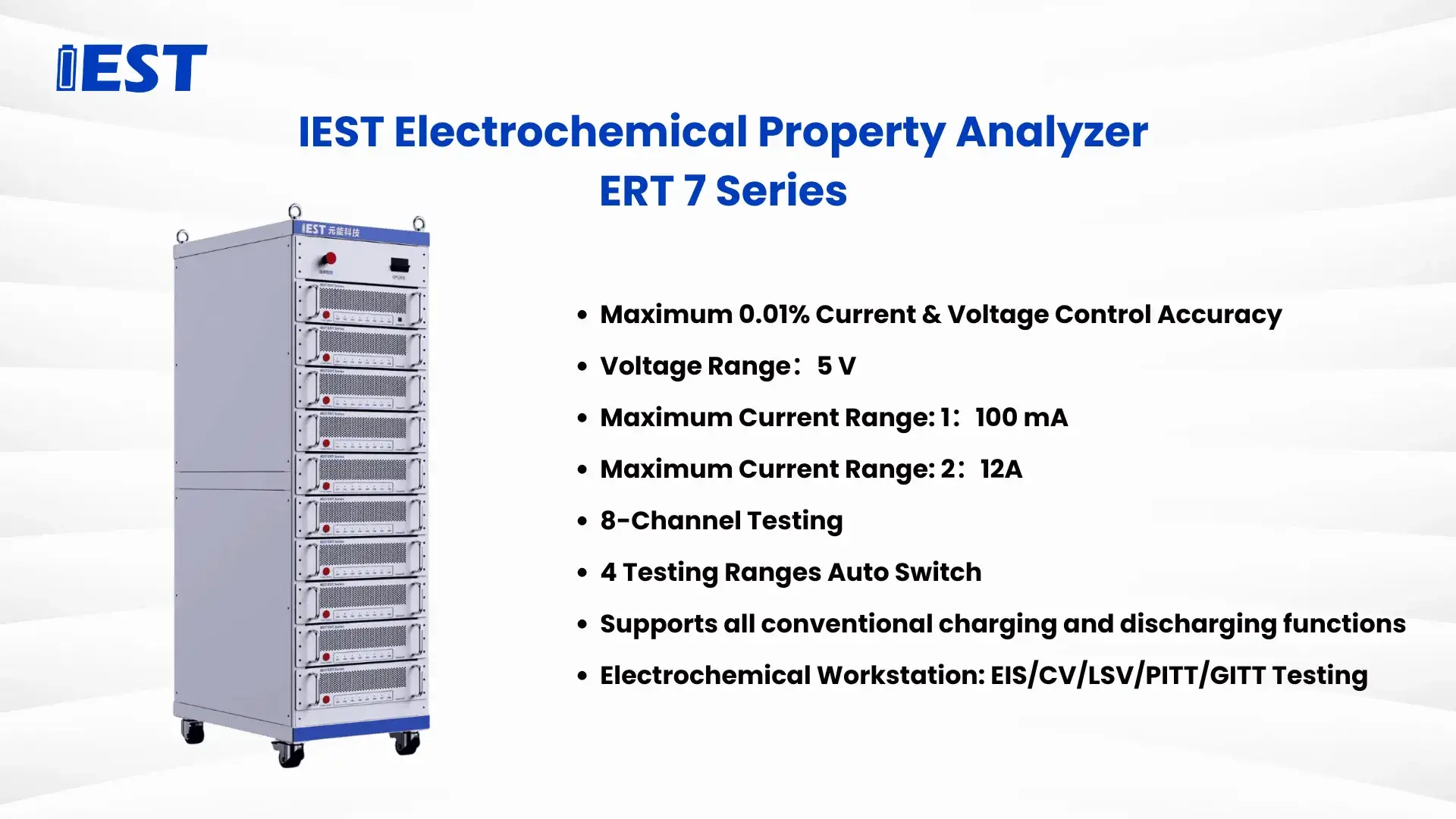

Figure 1. IEST High-Precision Battery Cycler Systems ECT6008 (0.01% F.S.)

3. What is Accuracy? How is it Verified?

Accuracy refers to how close a device’s measurement value is to the “true value.” For battery cycler systems, accuracy is divided into Control Accuracy and Measurement Accuracy. Control Accuracy characterizes how close the equipment’s actual output parameters are to the set values; Measurement Accuracy characterizes how close the equipment’s measured values are to the actual output values.

-

Key Parameters of Muotech Equipment:

-

Current Accuracy: ±0.01% F.S.

-

Voltage Accuracy: ±0.01% F.S.

-

In practical applications, battery cycler systems often requires multiple current ranges to adapt to different testing needs. For example, Muotech’s ECT6008-5V100mA series provides four current ranges: 100mA, 10mA, 1mA, and 0.1mA. Different ranges suit different scenarios:

-

100mA, 10mA: Suitable for routine tests like coin cells, stacked cells.

-

1mA, 0.1mA: More suitable for material-level research or fine experiments like electrocatalysis.

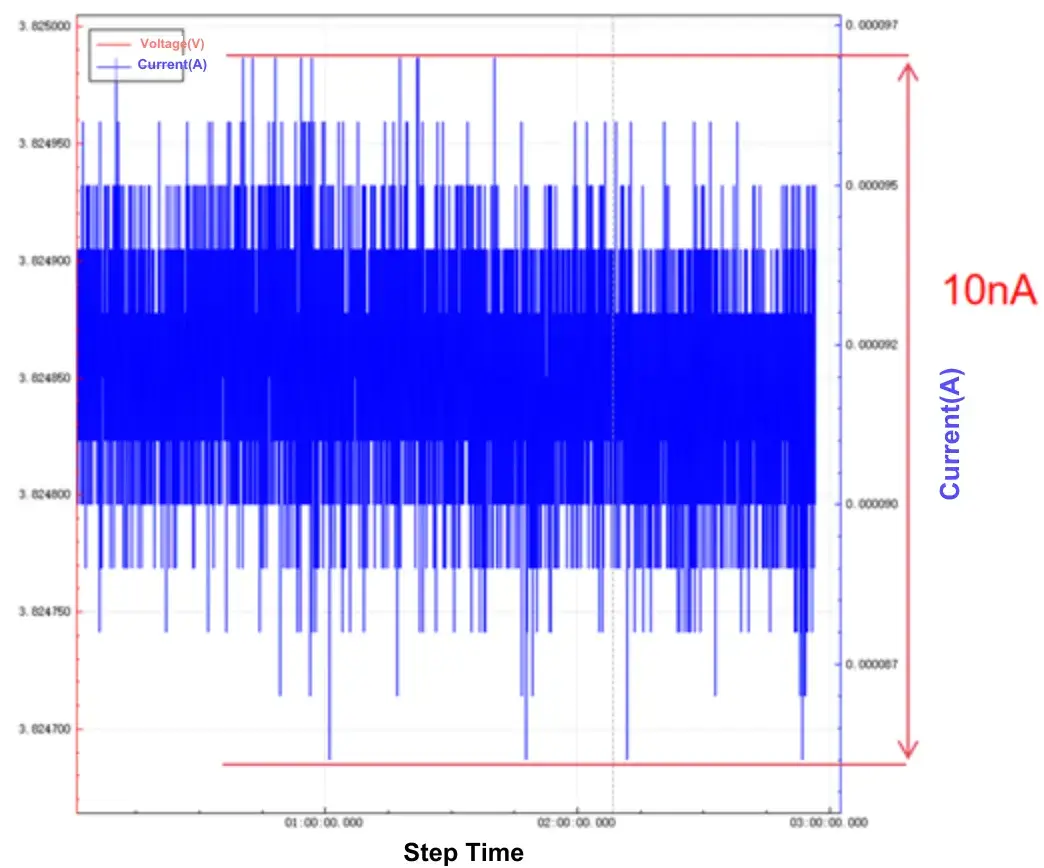

The specified current accuracy refers to the relative accuracy within its respective range. For instance, at the minimum range of 0.1mA, with an accuracy of 0.01% F.S., the corresponding resolution capability is 10nA. This means the equipment can detect current changes at the 10nA level in this range.

Figure 2. IEST High-Precision Battery Cycler System – Current Measurement down to 10nA level

Figure 3. IEST ECT & ERT6008 Equipment CNAS Certification

4. How to Verify Battery Cycler Systems Accuracy?

-

Use measurement instruments with an order of magnitude higher accuracy than the device under test (e.g., a 6½ digit digital multimeter – DMM).

-

Voltage Verification: Input reference voltages within the device’s range (typically ±20% and ±80% of full scale – four reference points), record the corresponding DMM voltage values, and calculate the error.

-

Control Accuracy = (DMM Measured Value – Set Value) / Full-Scale Range

-

Measurement Accuracy = (Software Read Value – DMM Measured Value) / Full-Scale Range

-

-

Current Verification: Output reference currents within the device’s range (typically ±20% and ±80% of full scale – four reference points). For currents ≤10A, measure current directly with a DMM. For currents >10A, pass the current through a high-precision shunt resistor, measure the voltage across it using the DMM’s voltage mode, and calculate the current. Use the same calculation logic as voltage verification to determine the error.

-

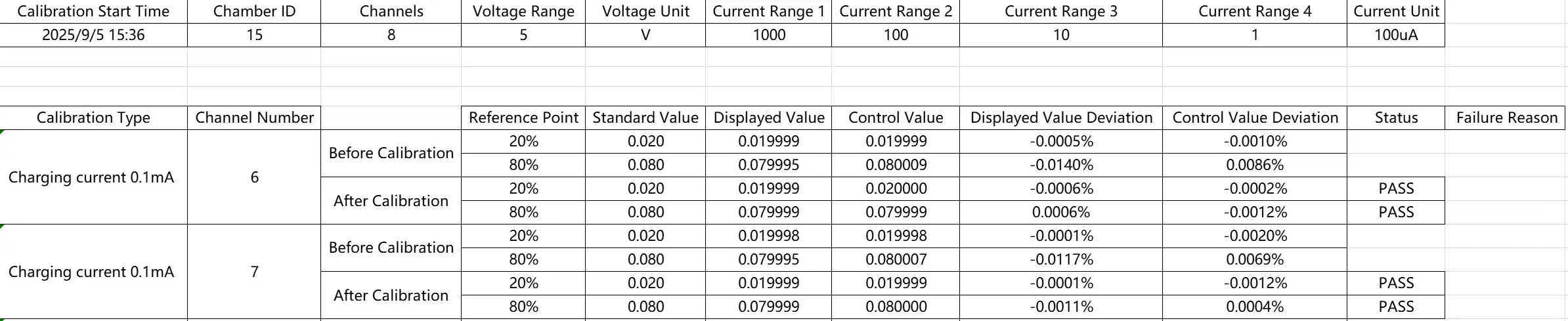

Data Presentation: Generate a calibration report containing each measurement point, standard value, device reading, and error.

Figure 4. IEST Automated Calibration Fixture – Large-Scale Channel Calibration

Figure 5. IEST Professional Channel Calibration Report

5. What is Stability?

For cell R&D, quality certification, and lifespan testing, the stability of battery cycler system is as crucial as accuracy, if not more so. Stability directly determines the repeatability, consistency, and reliability of test results, especially in long-term cycling and micro-signal measurement. Current Stability and Voltage Stability are the two most critical dimensions for assessing equipment performance.

-

Current Stability Determines Capacity Measurement Credibility:

-

Capacity is calculated by integrating current over time (Ah = I * t). Any minor current drift or fluctuation is integrated and amplified over long charge-discharge periods, causing significant errors in capacity calculation. This is detrimental for precise Coulombic Efficiency (CE) calculation (often required to be above 99.99%).

-

-

Voltage Stability Determines Accuracy of Key Characteristic Points:

-

Plateaus and inflection points on a cell’s charge-discharge curve (e.g., in dV/dQ curves) correspond to important electrochemical phase transition reactions. Noise or drift in voltage measurement can obscure these subtle features, preventing researchers from accurately identifying reaction mechanisms.

-

Cycle life test termination conditions are defined by voltage thresholds (e.g., charge to 4.2V, discharge to 3.0V). Unstable voltage control leads to inconsistent Depth of Discharge (DOD) per cycle, introducing extra capacity fade variables and distorting lifespan data.

-

-

Stability is the Cornerstone of Safety Testing:

-

During extreme condition testing (e.g., fast charging, overcharge tests), loss of current or voltage control (e.g., current overshoot, voltage overshoot) can directly trigger cell thermal runaway, causing safety incidents.

-

6. How to Verify Battery Cycler System Stability?

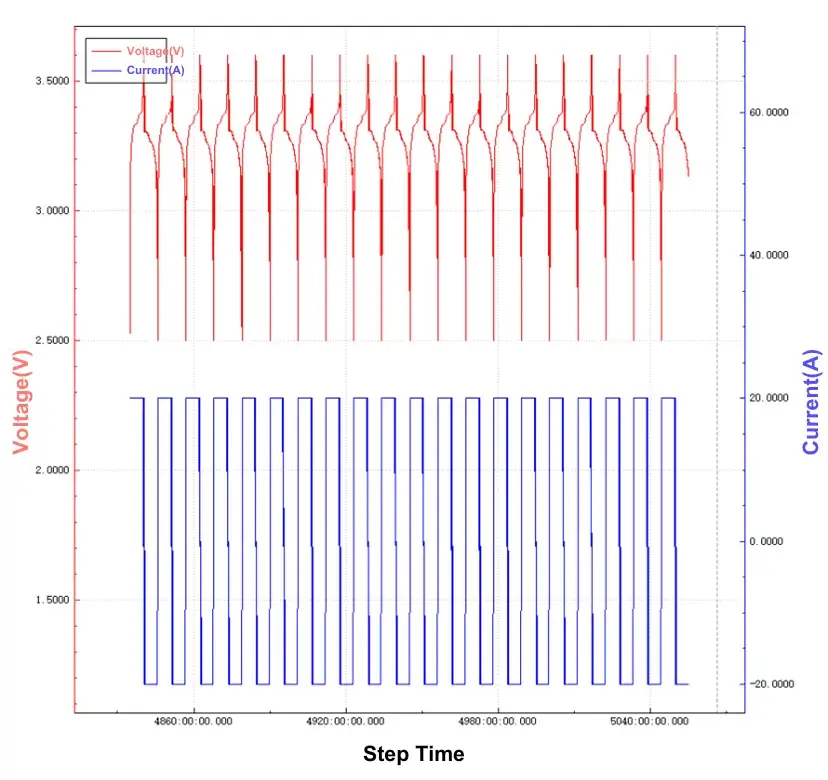

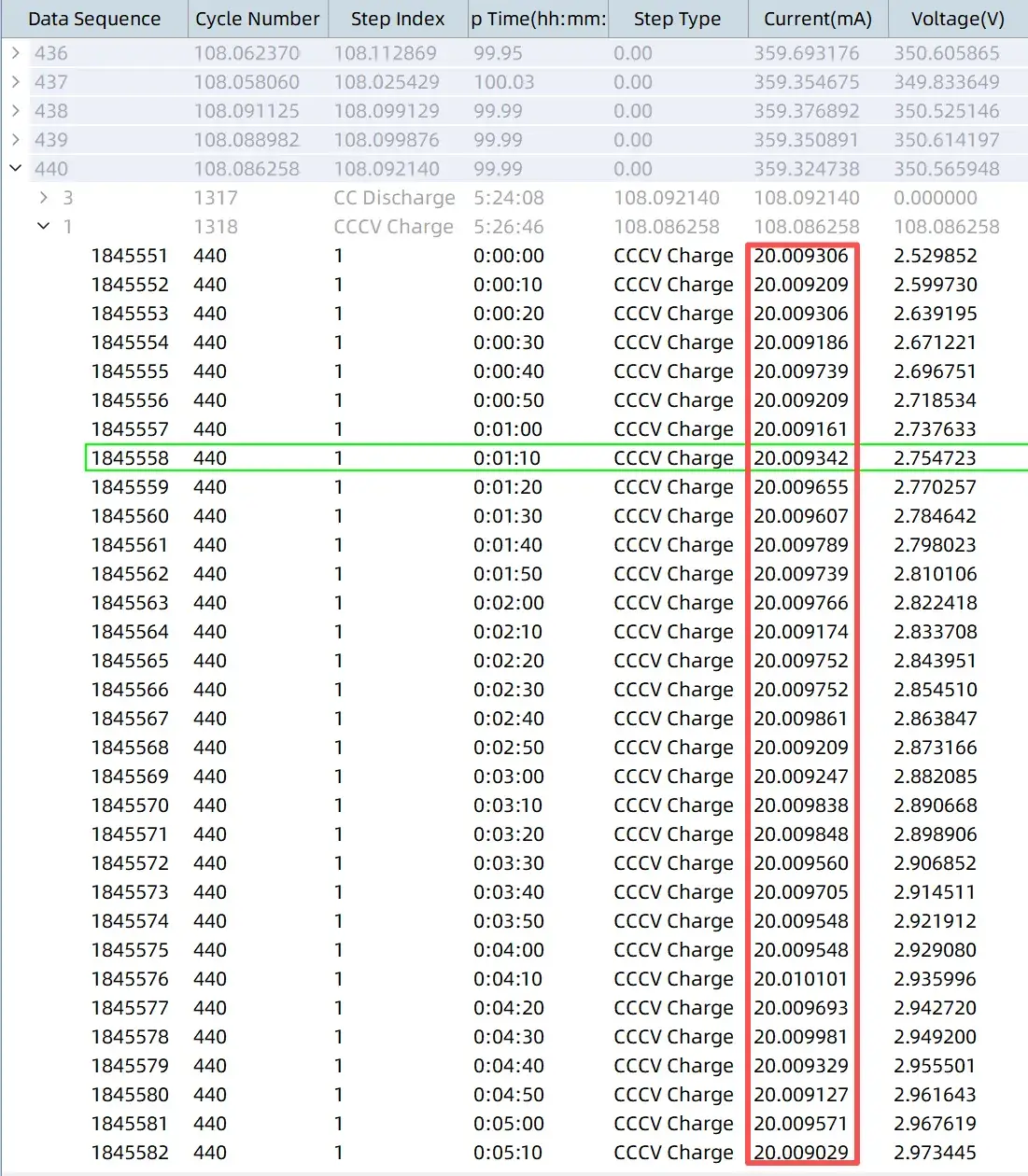

The stability of a charge-discharge channel can be assessed via long-term cycling: observing the consistency of curves and key parameters during repeated charge-discharge cycles. IEST Battery Cycler System, using Constant Current-Constant Voltage (CC-CV) charging mode for long-term cycle testing, has safely operated for 250 days of cycling. Verified results show the equipment’s current and voltage accuracy remains within the 0.01% F.S. specification.

Figure 6. IEST Long-Term Cycle Stability Test Data(~250 days)

7. Summary

The accuracy and stability of high-precision battery cycler systems are not just “marketing slogans” but are provable hard indicators. They bridge the gap between the physical characteristics of batteries and digitized test data. Their reliability determines the accuracy of R&D conclusions, product quality, and lifespan predictions.

For any enterprise pursuing the forefront of battery technology and high-quality manufacturing, investing in test equipment with comprehensive accuracy and stability verification is an absolute strategic necessity. As battery technology advances towards higher energy density and faster charging, the requirements for test equipment will continue to escalate.

If you are looking for a high-precision battery cycler system, feel free to contact us for more details!

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.