-

iestinstrument

A Method for Rapid Prediction of Cell Lifetime Degradation: Correlating Li Plating and Thickness Expansion

1. Abstract

Li plating (lithium metal deposition) is both an accelerator of capacity fade and a latent safety hazard in lithium-ion pouch cells. We demonstrate a fast, non-destructive method that correlates intermittent low-rate capacity loss with in-situ thickness expansion measured during accelerated high-rate cycling. By inserting periodic 0.3C diagnostic cycles into a 2C/1C stress program and continuously logging cell thickness with an SWE2100 expansion analyzer, engineers can quickly map a cell’s Li Plating → thickness expansion → capacity fade relationship and thereby estimate lifecycle progression for similarly designed cells.

2. Background

Due to its advantages such as high energy density, relatively long lifespan, and environmental friendliness, the application of lithium-ion batteries has covered multiple fields including consumer electronics, electric vehicles, and energy storage systems. When the potential of the negative electrode approaches or falls below the deposition potential of metallic lithium, lithium ions may precipitate on the surface of the negative electrode in the form of metallic lithium. The continuous growth of precipitated lithium metal can lead to the formation of lithium dendrites, which in turn may induce internal short circuits, posing safety risks. Additionally, the precipitated lithium metal may react slowly with the electrolyte, significantly reducing the onset temperature of thermal runaway [1,2]. Among the various lithium ion degradation mechanisms, Li Plating is considered one of the most detrimental factors. This is because the occurrence of Li plating not only accelerates battery aging but also poses safety hazards during later stages of usage. The phenomenon of Li plating is primarily related to the materials and design of the battery cell, including the negative electrode material, the ratio of negative to positive electrode capacity, electrolyte formulation, etc.

When the cathode electrode material possesses a higher reversible equilibrium potential (relative to the Li Plating potential), Li plating reactions are less likely to occur. Regarding the ratio of negative to positive electrode capacity, lithium-ion batteries are typically designed with an excess of negative electrode capacity to avoid depleting the lithium-ion-insertable capacity in the negative electrode, thereby reducing negative electrode overpotential. Insufficient negative electrode material would result in insufficient space for lithium ions to deintercalate from the positive electrode, leading to Li plating. However, an excess of negative electrode material would reduce the battery’s energy density and power density, leading to material waste and increased costs. The composition of the electrolyte has a more pronounced effect on Li plating in lithium-ion batteries because it directly influences the kinetic properties of lithium ions, thereby impacting the rate of lithium intercalation in the negative electrode to some extent. Li plating phenomena, in addition to being associated with the materials and design of the battery cell, typically occur more readily in low-temperature environments, high state of charge (SOC), high-rate charging conditions, and aged batteries.

Regardless of whether it is in low-temperature conditions, high state of charge, high-rate charging conditions, or in aged batteries accompanied by the continuous thickening of the passivation film on the negative electrode surface, the fundamental reason is that the rate of lithium-ion accumulation on the negative electrode surface is faster than the rate of lithium-ion diffusion into the graphite interior. This results in high polarization of the negative electrode, known as unfavorable electrode kinetics, forcing the potential of the battery’s negative electrode (usually graphite) to be lower than the equilibrium potential of lithium/lithium ions, leading to Li plating. Conducting Li plating tests on lithium-ion batteries based on actual usage conditions and operational parameters requires a long time and cannot meet the demands of product development. Therefore, research on accelerated Li plating testing for lithium-ion batteries has become extremely important and urgent.

3. Detection Approach

Existing non-destructive online detection technologies for Li plating [3] can be categorized into four types:

-

Detection methods based on lithium-induced cell aging, such as the Arrhenius curve method and Coulombic efficiency method

-

Impedance-based methods (EIS, ACIR growth).

-

Electrochemical signatures (differential voltage/dQ/dV, voltage relaxation, small-current discharge).

-

Physical property changes (thickness/expansion, acoustic signatures, gas evolution).

The deposition of lithium metal layer on the negative electrode during Li plating reactions leads to changes in electrode morphology and microstructure. In situ physical methods can not only detect the growth of lithium metal layer but also obtain the distribution of lithium deposition at different locations. Physical property detection methods include thickness measurement, acoustic detection, etc. Regardless of the detection method, increasing the charge/discharge cycle rate of lithium-ion batteries can significantly accelerate capacity degradation and shorten cycle test time, making it an effective method for accelerating aging tests.

4. Testing Information

4.1 Test Equipment

In-situ Swelling Analyzer, Model SWE2100 (IEST), capable of applying pressure ranging from 50 to 10000N, with temperature control adjustable from -20°C to 80°C.

Figure 1: Schematic Diagram of SWE2100 Swelling Equipment

4.2 Test Parameters

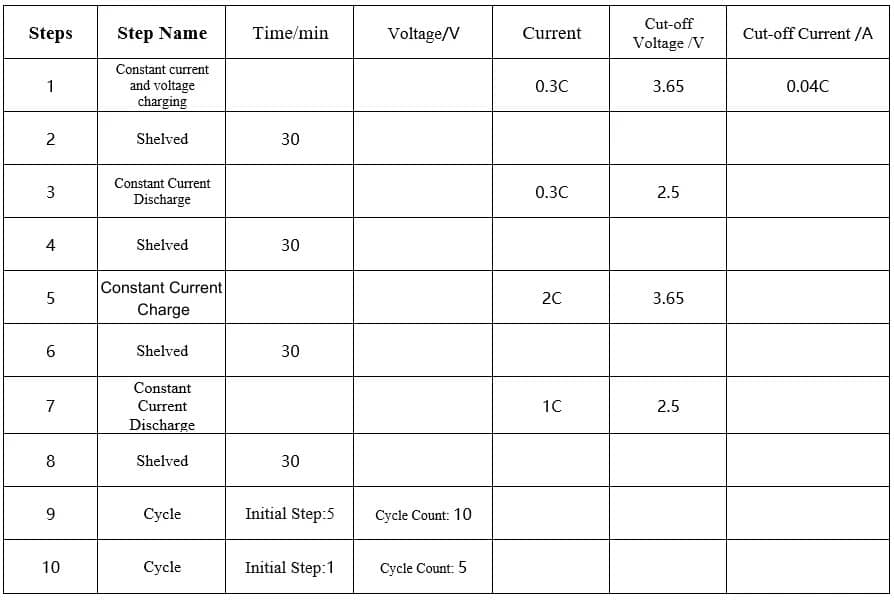

A specific cycling protocol was designed to accelerate degradation and probe the cell’s state:

-

Cycling Procedure: The primary regimen consisted of 2C charge / 1C discharge cycles. Every 10 cycles of this fast protocol, a 0.3C charge / 0.3C discharge step was inserted. This low-rate cycle serves to minimize polarization and assess the underlying capacity and thickness changes. The specific process is as Table 1 follows:

-

Thickness Expansion Measurement: The test cell was placed in the analyzer, and parameters including a 500N applied force and a 1-second sampling frequency were set via the MISS software. The system automatically recorded cell thickness, thickness variation, temperature, current, voltage, and capacity throughout the test.

Table 1. Charging and discharging process

5. Test Results Analysis

5.1 Capacity Fade under High-Rate Cycling

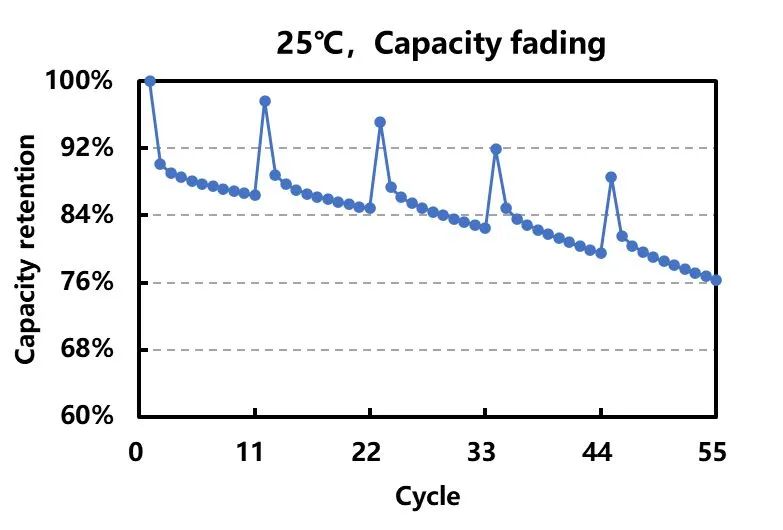

Figure 2. Cycle number vs. capacity fade curve

Figure 2 shows the cell’s capacity fade throughout the test. At room temperature, the discharge capacity during the 2C/1C cycles was only about 90% of that delivered during the intermittent 0.3C/0.3C cycles. This is primarily attributed to significant concentration polarization during fast charging, where the rate of Li⁺ migration within the electrode particles lags behind the surface electrochemical reaction rate, leading to considerable polarization-induced capacity loss.

5.2 Identifying Irreversible Expansion Linked to Li Plating

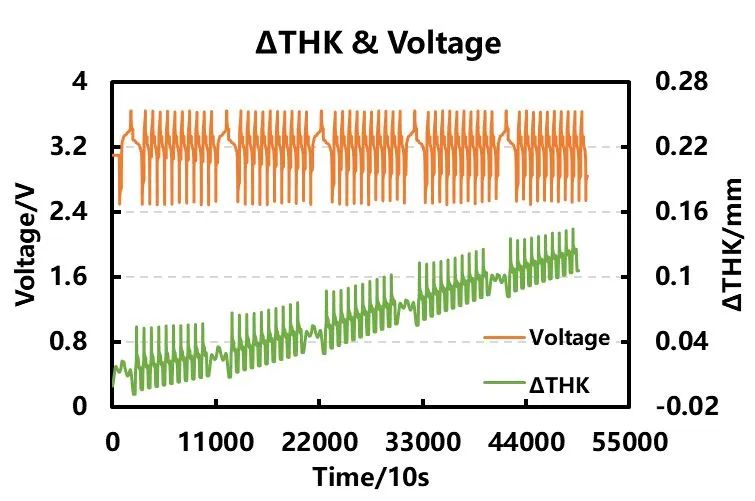

Figure 3. Cycling charge/discharge curves and thickness expansion curves

The voltage and thickness variation curves over time, encompassing both the 2C/1C and 0.3C/0.3C cycles, are presented in Figure 3. A key observation is the gradual increase in cell thickness at full charge as cycling progresses. Critically, the thickness increase during high-rate (2C) charging was significantly more pronounced than during low-rate (0.3C) charging.

This differential expansion points directly to processes unique to high-rate charging. While reversible thickness changes from Li-ion intercalation are normal, the additional, irreversible expansion is strongly linked to lithium plating. The plated metallic lithium layer and the subsequent formation of a new Solid Electrolyte Interphase (SEI) on its surface contribute to permanent thickness gain.

Conventional point-measurement tools like dial gauges are inadequate for detecting this phenomenon, as lithium deposition is often random and unevenly distributed across the electrode. The SWE2100 system, by measuring the overall average thickness of the pouch cell, effectively captures these global changes, providing a comprehensive view of plating-induced expansion.

5.3 Quantifying the Correlation: Capacity Fade and Thickness Expansion

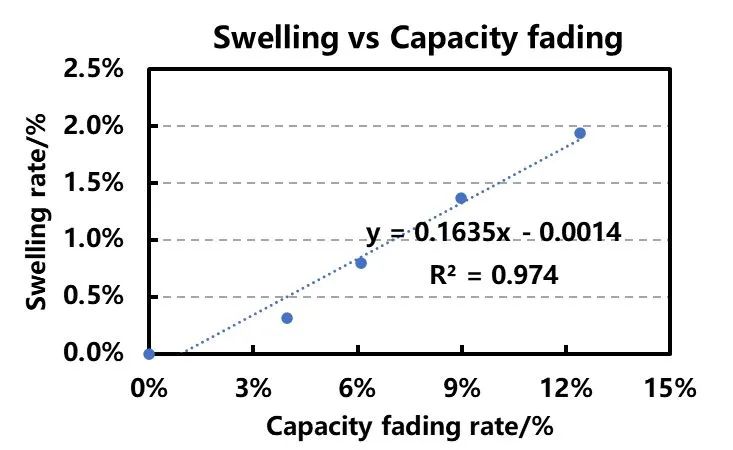

Figure 4. Correlation between low-rate capacity fade rate and thickness expansion rate

The analysis further quantified the relationship between capacity fade and thickness expansion. Figure 4 plots the capacity fade rate from the 0.3C discharges against the thickness expansion rate during the 0.3C charges.

The data reveals a strong positive correlation. This indicates that during high-rate cycling, significant polarization induces lithium plating on the anode surface. This plating is responsible for both the irreversible capacity loss (increased fade rate) and the permanent increase in cell volume (increased expansion rate) observed during the low-rate probe cycles.

Under these kinetically-limited conditions (e.g., high-rate cycling), the low-rate capacity can be considered largely free from polarization effects. Therefore, neglecting active material loss, the correlation between the low-rate capacity fade rate and the expansion rate can be approximated as a relationship between the amount of plated lithium and the resulting physical swelling. This allows for the fitting of a model that describes the correlation between Li plating and expansion throughout a cell’s life, enabling rapid assessment of the plating severity in similarly designed cells at different stages of aging.

6. Summary

This paper utilizes an in-situ swelling analyzer (SWE) to analyze the capacity and expansion thickness of cells during cycling. It is found that conducting depolarized low-rate charge-discharge tests at certain intervals can straightforwardly quantify the correspondence between lithium deposition and expansion rate in cells. This approach provides a novel and efficient strategy for accelerating lifetime testing of lithium-ion batteries and offers a practical, non-destructive metric for evaluating Li plating.

7. References

[1] Waldmann T, Hogg B I, Wohlfahrt-Mehrens M. Li plating as unwanted side reaction in commercial Li-ion cells-A review. Journal of Power Sources, 2018, 384: 107-124.

[2] Smith A J, Burns J C, Zhao X, et al. A High Precision Coulometry Study of the SEI Growth in Li/Graphite Cells. Journal of The Electrochemical Society, 2011, 158(5): A447.

[3] Deng Linwang, Feng Tianyu, Shu Shiwei, Guo Bin, Zhang Zifeng. Research Progress on Non-Destructive Detection of Lithium Plating in Lithium-Ion Batteries. Energy Storage Science and Technology. 2023, 12(1): 263-27

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.