-

iestinstrument

Analyzing the Relationship Between Electrode Resistance and Calendering Compaction in Li-ion Batteries

1. Introduction: Calendering Compaction as a Key Lever for Electrode Resistance

Electrode resistance is a key indicator of electronic conductivity within the coating, closely linked to parameters such as compaction density, porosity, and formulation. During electrode manufacturing, the calendering process, which applies different pressure levels, alters the electrode’s surface roughness and compaction density. While this generally improves conductive contact between active material particles and enhances cell volumetric energy density, the process involves not just vertical compression but also lateral shear forces, leading to particle rearrangement.

Sheet resistance measurement involves applying a vertical electrical signal through the electrode thickness between two opposing probes. This measures both the intrinsic conductivity of the particles and the contact resistance between them. Consequently, whether sheet resistance decreases as expected with increasing calendering compaction density requires verification. This article presents experimental validation for various cathode and anode systems.

2. Experimental Equipment and Test Methods

2.1 Experimental instrument

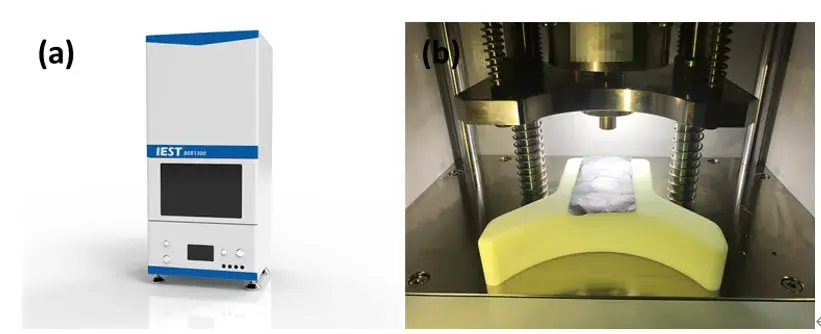

Battery Electrode Resistance Tester: BER1300 (IEST), electrode diameter 14mm, can be applied to the pressure of 5~60MPa.

Figure 1. (a) BER1300 appearance; (b) BER1300 structure

2.2 Measurement principle and what the test captures

The test applies a current perpendicular to the electrode surface and measures through-thickness resistance. Thus, the reading contains multiple contributions:

-

Intrinsic particle conductivity (active material and conductive additive).

-

Contact resistance between particles (active–active, active–carbon, carbon–carbon).

-

Coating-to-current-collector interface resistance.

-

Probe-to-coating contact resistance (sensitive to surface roughness and probe pressure).

Because all of the above appear in the single measured value, interpreting resistance changes with calendering pressure requires correlating electrical trends with microstructure and surface measurements.

2.3 Sample preparation

Single-sided electrodes were prepared. The slurry formulations were:

-

Anode: Graphite Powder : SP : CMC = 90 : 5 : 5

-

Cathode: Cathode Powder (NCM/LCO/LFP) : SP : PVDF = 96.5 : 1.5 : 2

After coating and drying, the electrodes were rolled with different pressures by a roller press to prepare electrodes with different roll compaction density.

2.4 Test method

the electrodes to be tested before and after roller pressing were cut into rectangular sizes of about 5cm×10cm, placed on the sample stage, set the parameters of test pressure and holding time on the MRMS software, and started the test, and the software automatically read the data of the thickness of the electrodes, electrical resistance, resistivity, conductivity, and so on.

3. Results and Discussion

3.1 Calendering compaction and cathode (NCM/LCO/LFP) resistance trends

Electrode resistance data for single-sided anodes and cathodes, both before and after calendering at different pressures, are shown in Figure 2.

From the trend of the results, the graphite anode exhibits a general increase in resistivity with rising compaction density, only slightly decreasing after exceeding 1.63 g/cm³. The uncalendered NCM cathode, with a compaction density of 1.60 g/cm³, shows relatively low resistivity. However, after calendering, cathode resistivity initially increases before decreasing. LCO and LFP cathodes show similar trends, though the initial calendering step has a less pronounced effect on LCO resistivity.

Conventionally, calendering is expected to increase compaction density, enhance inter-particle contact area, and thus improve conductivity. However, our experimental results reveal a more complex picture, analyzed below using SEM and surface roughness measurements.

Figure 2. Electrode sheet resistance trend before and after calendering at different pressures

3.2 Graphite Anode Analysis

Cross-sectional SEM images of graphite anodes at three different compaction densities (Figure 3) show that increasing calendering pressure causes initially randomly oriented graphite layers to align more parallel to the electrode surface.

Figure 3. Cross-section of graphite electrodes with different compaction densities

Figure 4. Graphite crystal structure and morphology

Graphite crystal structure consists of carbon hexagon layers stacked parallel, defining distinct basal planes and edge planes (Figure 4). Most Li-ion intercalation occurs via the edge planes. Electrically, graphite exhibits significant anisotropy: high conductivity along the basal planes due to mobile π-electrons, but poor conductivity perpendicular to them. Consequently, when calendering aligns more basal planes parallel to the electrode surface, it becomes more difficult for the test current—applied perpendicularly to the sheet—to penetrate the coating, leading to increased resistance. Conversely, higher compaction density also promotes tighter contact between graphite and conductive agent particles, which tends to decrease resistance. These opposing effects make the overall impact of calendering on anode sheet resistance complex and highly dependent on specific material morphology and electrode microstructure. Measuring anode sheet resistance helps analyze electronic transport characteristics and assess coating uniformity.

3.3 Cathode Analysis

For all three cathode types, sheet resistance initially increases after low-pressure calendering compared to the uncalendered state.

In cathode slurries, conductive agents (e.g., SP) form a well-connected, percolating 3D electron transport network after coating and drying. The uncalendered electrode, despite potentially poor contact between active material particles, benefits from this intact conductive network, resulting in low sheet resistance. Initial, low-pressure calendering can disrupt this carefully constructed network. SEM surface images and carbon element mapping for NCM cathodes (Figure 6) suggest that lateral shear forces during calendering may displace conductive carbon particles coating the active material, breaking conductive pathways and increasing resistance.

Figure 5. Surface roughness trend for three cathode types

Figure 5. Surface roughness trend for three cathode types

Figure 6. SEM surface images and carbon element distribution for NCM cathodes at different calendering pressures

Additionally, this initial resistance increase may relate to decreasing surface roughness (Figure 5). The two-probe measurement inherently includes contact resistance between the probes and the electrode surface. Smoother surfaces post-calendering might worsen this contact, increasing the measured total resistance.

As calendering pressure increases further, active particles are compacted more densely, forcing conductive carbon particles back into contact and re-establishing a connected 3D network. Consequently, sheet resistance decreases. Therefore, sufficient calendering pressure is crucial for cathodes; insufficient pressure can degrade the conductive network and increase resistance, adversely affecting battery performance. When comparing cathode sheet resistance, consistent surface state is essential for evaluating different formulations or processes. It also enables assessment of coating uniformity across an electrode.

4. Practical Tips for Optimizing Calendering Compaction and Minimizing Electrode Resistance

-

Target sufficient calendering pressure — avoid minimal calendering that can break conductive networks without restoring them. For the studied cathode systems, higher pressures ultimately lowered resistance.

-

Monitor surface roughness — maintain consistent probe contact conditions when using electrode-resistance tests; consider using guarded probes or correction methods to isolate coating bulk resistance.

-

Balance morphology and pressure for graphite — if through-plane conductivity is critical, limit flake reorientation by controlling roll nip temperature, roll speed, and calendering schedule, or consider particle morphology tuning.

-

Formulation levers — optimize carbon type, content and dispersion; better-dispersed conductive carbon can better tolerate shear during calendering.

-

Map spatial uniformity — measure resistance at multiple locations to assess coating homogeneity; use COV or similar statistics to quantify uniformity.

5. Summary

This study characterized the sheet resistance of anodes and cathodes at different calendering compaction levels. Results show distinct trends: anode resistance generally increased, attributed primarily to particle orientation, while cathode resistance exhibited a non-monotonic ‘increase-then-decrease’ pattern, linked to the disruption and reformation of the conductive agent network and changes in surface roughness. Consequently, when using sheet resistance to evaluate electrode conductivity and uniformity, careful consideration of active material particle orientation and electrode surface state consistency is paramount.

6. References

[1] Henrik Lyder Andersen, Lisa Djuandhi, Uttam Mittal, Neeraj Sharma, Strategies for the Analysis of Graphite Electrode Function, Adv. Energy Mater., 2021, DOI:10.1002/aenm.202102693

[2] Hiroki Kondo et al. Influence of the Active Material on the Electronic Conductivity of the Positive Electrode in Lithium-Ion Batteries[J]. Journal of the Electrochemical Society, 2019,166 (8) A1285-A1290.

[3] B.G. Westphal et al. Influence of high intensive dry mixing and calendering on relative electrode resistivity determined via an advanced two point approach[J]. Journal of Energy Storage 2017, 11, 76–85.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.