-

iestinstrument

How To Improve Electrolyte Wetting Level

1. Preface

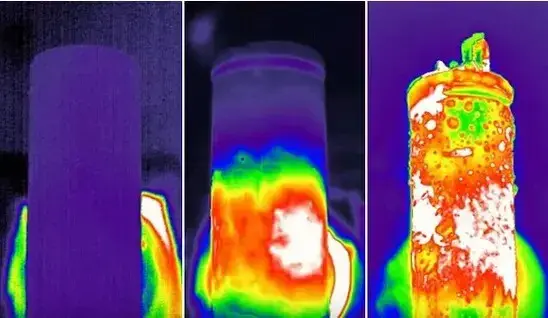

The degree of electrolyte wetting is one of the key factors affecting the performance of lithium-ion batteries such as kinetics, cycle life, and safety and reliability, etc. A good wetting effect can form a uniform interface between the solid-liquid, which is favorable for the electrochemical reaction, and reduce the interfacial resistance between the positive and negative electrode materials and the electrolyte. This interface contributes to the generation of (Solid Electrolyte Interface) SEI film, which enhances the cycling stability and safety of the battery cell[1-3]. If the wetting effect of the electrolyte is not satisfactory, it will make the transport path of lithium ions farther during the charging and discharging process, reduce the shuttling efficiency of lithium ions between the positive and negative electrodes, and affect the kinetic performance of the battery cell. Incomplete infiltration may lead to problems such as active substance stripping and lithium dendrite growth, which will lead to an increase in internal resistance and a decrease in capacity of the core, accelerating the aging process of the core, and more seriously, may cause the core to become locally overheated during the charging and discharging process, resulting in thermal runaway that leads to safety problems such as fires and explosions (Figure 1).

Figure 1. Thermal runaway of battery cell

2. Electrolyte Wetting Improvement Program

For the problem of poor electrolyte wetting, it can be improved by adjusting the electrolyte formulation, modifying the parameters of the production process of the electrode core and other programs:

2.1 Electrolyte formulation improvement

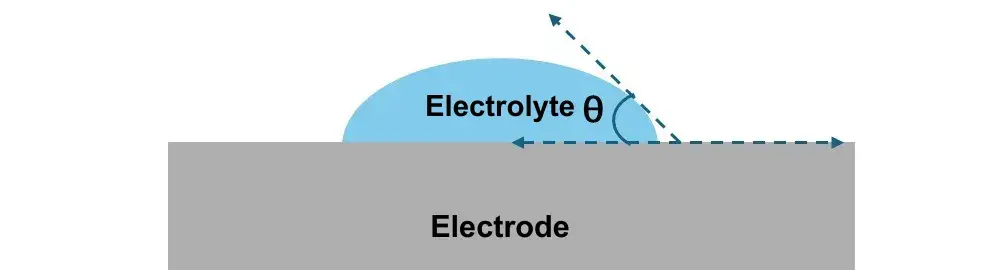

The chemical composition and physical state of the electrolyte (e.g., solvent, solute, viscosity and surface tension, etc.) affect its ability to wet the electrode[4]. When the electrolyte is not compatible with the positive and negative electrodes, and the isolation film material, the contact angle θ between the electrolyte and the surface of the material will be large (Figure 2), the interaction force between the two is small, and the electrolyte can not adequately infiltrate the entire material. Therefore, R&D personnel usually improve the compatibility between the electrolyte and electrode materials by adjusting the solvent, solute or adding some specific additives to improve the wetting ability of the electrolyte and enhance the life of the battery cell.

Figure 2. Schematic diagram of the contact angle between the electrolyte and the electrode

2.2 Improvement of pre-process technology

The positive and negative electrode materials with different shapes and particle sizes, conductive carbon and binder, etc. have different infiltration effects on the electrolyte. Usually, the larger the specific surface area of the material, the faster the penetration rate of electrolyte and the better the penetration degree. Therefore, for different materials, it is necessary to adjust the corresponding core production process parameters to ensure that the electrolyte is fully infiltrated.

2.3 At the level of electrode

The compaction density will directly affect the degree of electrolyte infiltration. Although increasing the compaction density can reduce the internal resistance of the cell and improve the volumetric energy density of the cell, when the compaction density of the pole piece is too large, the porosity inside the pole piece will be reduced, which is not conducive to the infiltration and penetration of the electrolyte. Therefore, it is necessary to adjust the appropriate compaction density to obtain a low impedance while ensuring adequate infiltration of the electrolyte.

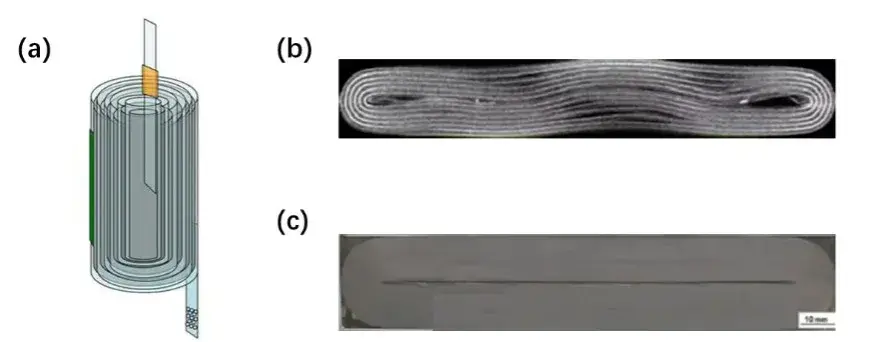

2.4 At the battery cell level

The winding tension of the bare core pole piece, the isolation film, and the degree of hot pressing will also affect the electrolyte infiltration (Figure 3). When the bare core winding hot pressing is too tight, the gap between the pole piece and the isolation film is very small, and the electrolyte can not be fully infiltrated into the interior of the core, which is likely to lead to the core in the cycle process in the middle of the purple spot, lithium precipitation and other problems. When the structure of the bare core is relatively loose, on the one hand, it will lead to difficulties in shelling the bare core, and abnormalities such as deformation of the core during the cycling process, and on the other hand, it will make the gap between the positive and negative electrodes and the isolation film increase, which will lead to the electrolyte not being able to be uniformly distributed in the core, which in turn will affect the performance of the core.

Figure 3. (a) Schematic diagram of the battery cell, (b) Schematic diagram of the cross-section of the battery cell before hot pressing (c) after hot pressing

2.5 Improvement of liquid injection process

One of the most conventional ways to improve the wetting effect of electrolyte is to adjust the liquid injection process. From the liquid injection method, liquid injection static temperature and time, liquid injection conditions and other aspects can effectively improve the electrolyte wetting effect. For example, the electrolyte wettability of lithium-ion batteries can be improved by vacuum liquid injection. Liquid injection under vacuum conditions is not only conducive to discharging the gas in the core, but also reduces the resistance of the gas to electrolyte injection, so that the electrolyte is in direct contact with the pole piece, thereby reducing the wetting time and improving the degree of wetting. After liquid injection, the electrolyte is usually left to stand at high temperature, under which the electrolyte can better penetrate into the interior of the core and the pores of the electrode material, thus improving the contact area between the electrolyte and the electrode and the reaction activity.

3. Electrolyte Wetting Test System(EWS)

Based on the importance of electrolyte wetting for battery cells, IEST has developed an electrolyte wetting test system, which can quantify the difference of electrolyte wetting between different electrode and battery cells, and provide an effective means of evaluating electrolyte wetting.

3.1 Electrode Electrolyte Capillary Wetting System

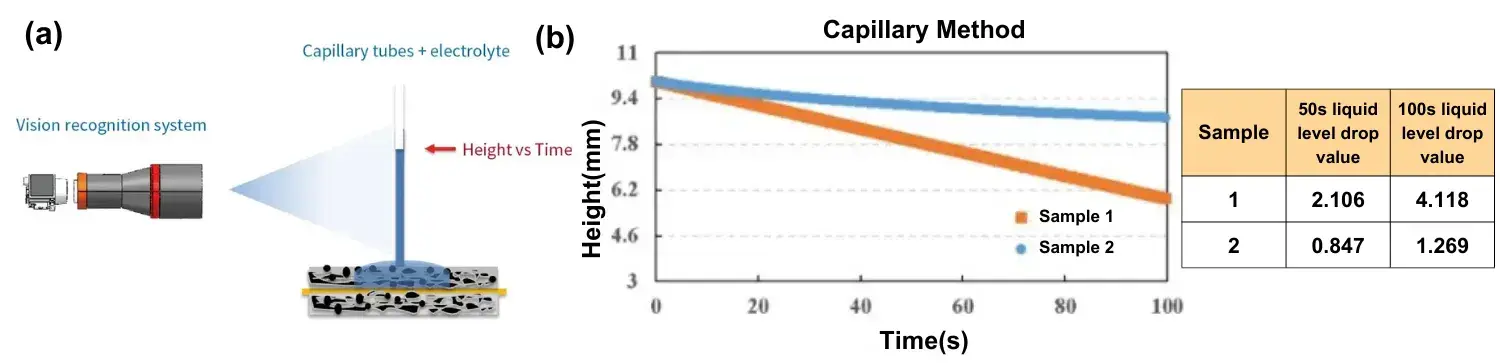

Figure 4a shows the schematic principle of the capillary infiltration method. The electrolyte is injected into the capillary tube, and after the capillary glass tube is vertically contacted with the surface of the pole piece, the capillary liquid level decreases as the electrolyte continues to infiltrate the coating. The visual recognition system records the capillary liquid level height in real time, and the dynamic evolution of the liquid level height is the electrolyte infiltration process in real time, and the amount of height change is the amount of electrolyte infiltration. As shown in Fig. 4b, the values of electrolyte liquid level decrease in 50s and 100s for sample 1 are significantly larger than those for sample 2, which indicates that the electrolyte has a better infiltration ability in sample 1.

Figure 4.(a) Schematic diagram of the principle of capillary infiltration method, (b) Capillary infiltration curves for different cathode electrodes

3.2 Electrolyte weight infiltration system

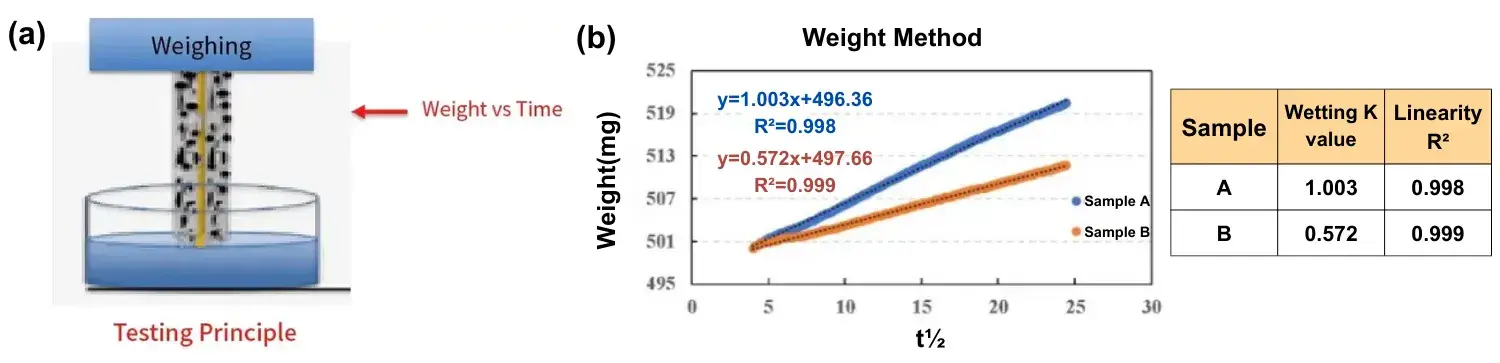

Figure 5a shows the schematic diagram of the weight infiltration method. The electrode/battery cell is suspended under the corresponding balance and infiltrated in the electrolyte, which will climb upward with the increase of time, at which time the weight change of the balance can be used to characterize the electrolyte infiltration amount and infiltration rate of the pole piece and bare core in real time. Measurements were made on pole pieces with different compaction densities, in which the compaction density of sample A was smaller than that of sample B. From the measurement results (Figure 5b), the immersion K value of sample A was larger than that of sample B, i.e., the larger the compaction density the worse the electrolyte immersion.

Figure 5. (a) Schematic diagram of the principle of the weight infiltration method, (b) Infiltration curves of the weight method for electrodes with different compaction densities

3.3 Electrolyte height infiltration system

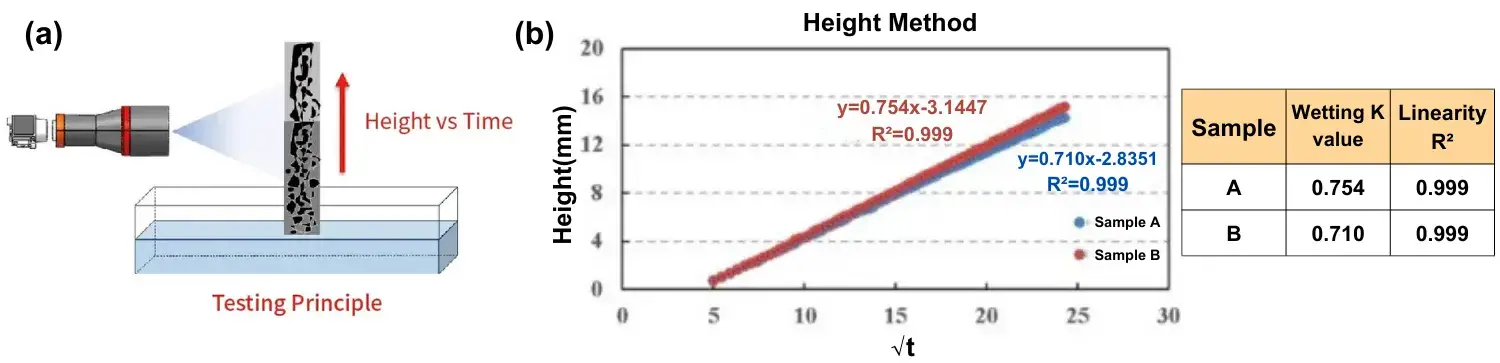

Figure 6a shows the schematic principle of the height infiltration method. The pole piece is placed vertically and infiltrated in the electrolyte, and the infiltration height of the electrolyte in the pole piece is recorded in real time by the equipped high-precision visual acquisition system to characterize the infiltration rate of the electrolyte in real time. Figure 6b shows the measurement results of the height method for different negative electrodes, from which the height method can also distinguish the difference in electrolyte infiltration of different electrodes.

Fig. 6.(a) Schematic diagram of the principle of the height infiltration method, (b) Infiltration curves of the height method with different cathode electrodes

4. Summary

Poor electrolyte wetting will lead to black spots, lithium dendrite growth, increased internal resistance, capacity discount, and in severe cases, localized overheating of the core, causing thermal runaway leading to fire and explosion and other safety issues. Therefore, evaluating the wetting effect of electrolyte is one of the core concerns in the research and development of the battery cell system and the process of production. IEST has developed an electrolyte wetting test system, which can evaluate the wetting ability of electrolyte from the level of electrode and battery, thus providing certain theoretical guidance for the design of electrolyte and the production and manufacturing process of the battery cell.

5. References

[1] Zheng Honghe et al. eds. Electrolytes for lithium ion batteries. Beijing: Chemical Industry Press, 2007.01.

[2] Wang B L, Wang J P, Zhang L, et al. Adsorptive Shield Derived Cathode Electrolyte Interphase Formation with Impregnation on LiNi0.8Mn0.1Co0.1O2 Cathode: A Mechanism-Guiding-Experiment Study[J]. ACS Applied Materials & Interfaces, 2024:16, 38, 50747-50756.

[3] Zhang Shuanghu. Progress in Electrolyte Wetting for Lithium Ion Battery [J]. Chemistry World,2021,62(03):129-136.

[4] Yao N, Yu L, Fu Z H, et al. Probing the origin of viscosity of liquid electrolytes for lithium batteries[J]. Angewandte Chemie International Edition,2023:e202305331.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.