Description

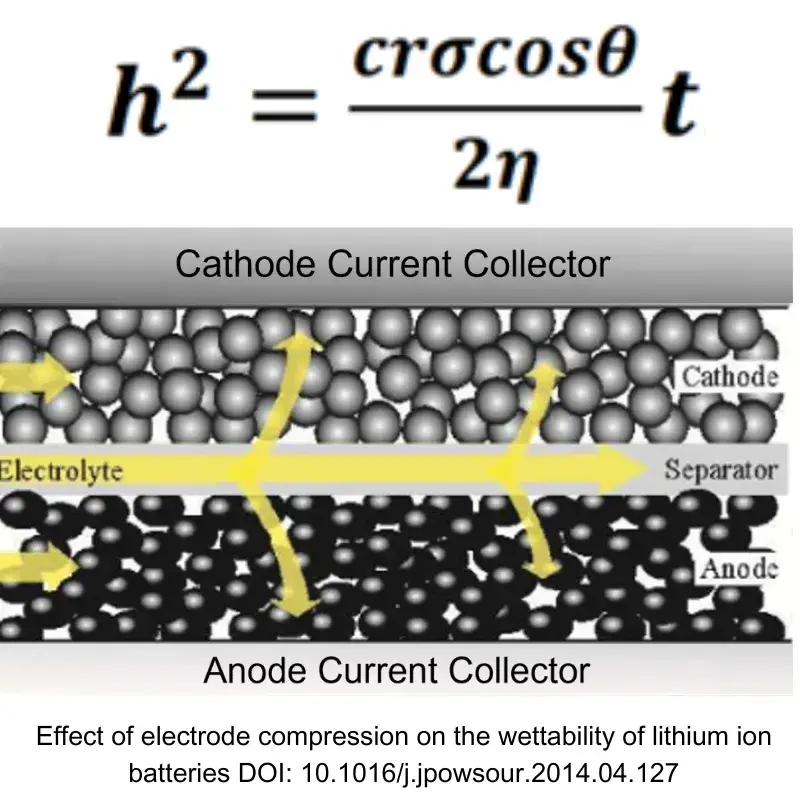

1. Principle of Electrode Wetting

The Lucas–Washburn Equation is commonly used to describe the dynamic of liquid absorption in electrode pores, as represented by the equation below:

- r represents the radius of the capillary (m),

- σ represents the surface tension of the imbibition fluid (N/m),

- η represents the viscosity of the imbibition fluid (Pa*s),

- θ represents the contact angle of the wet phase (°),

- h represents the liquid suction height (m),

- t represents the liquid suction time,

- cr represents a fixed value, called the formal radius.

2. Applications

- Electrolyte: Performance Evaluation

- Electrode: Consistency Assessment

- Optimization of material: Electrode Surface Treatment Processes

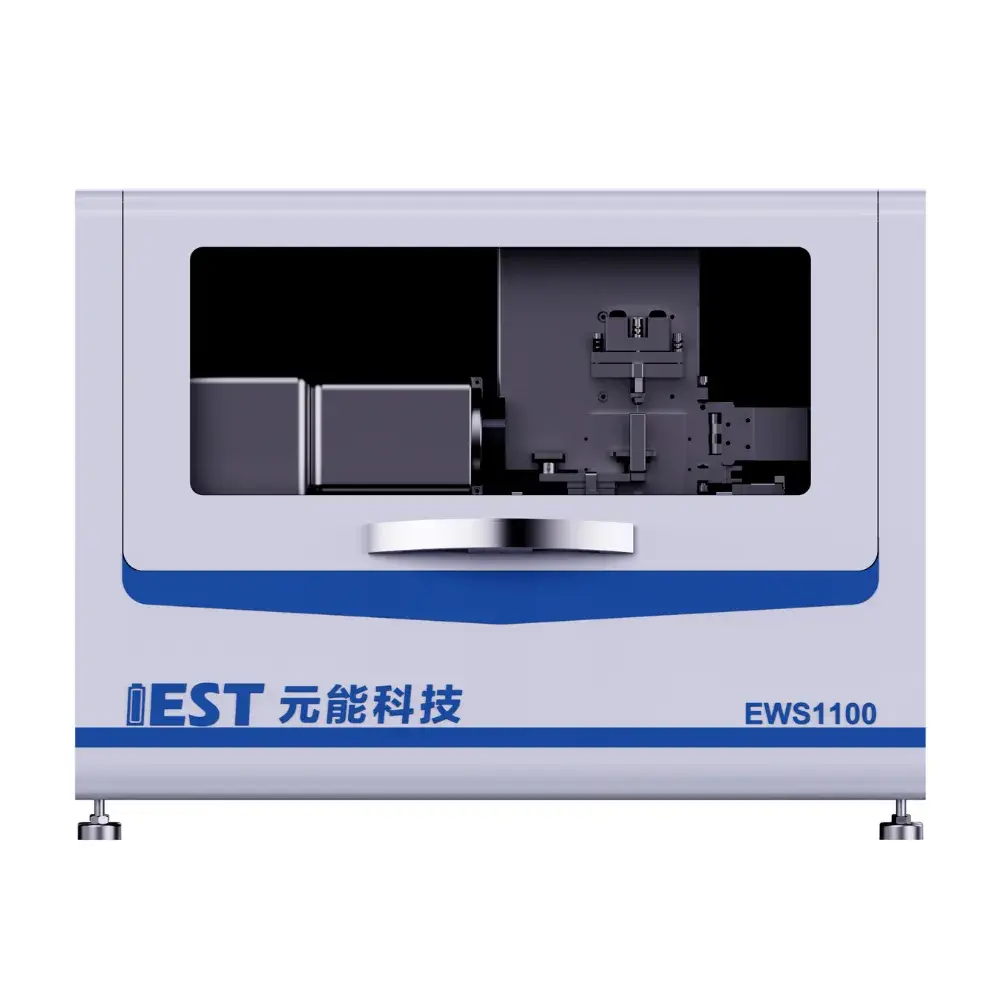

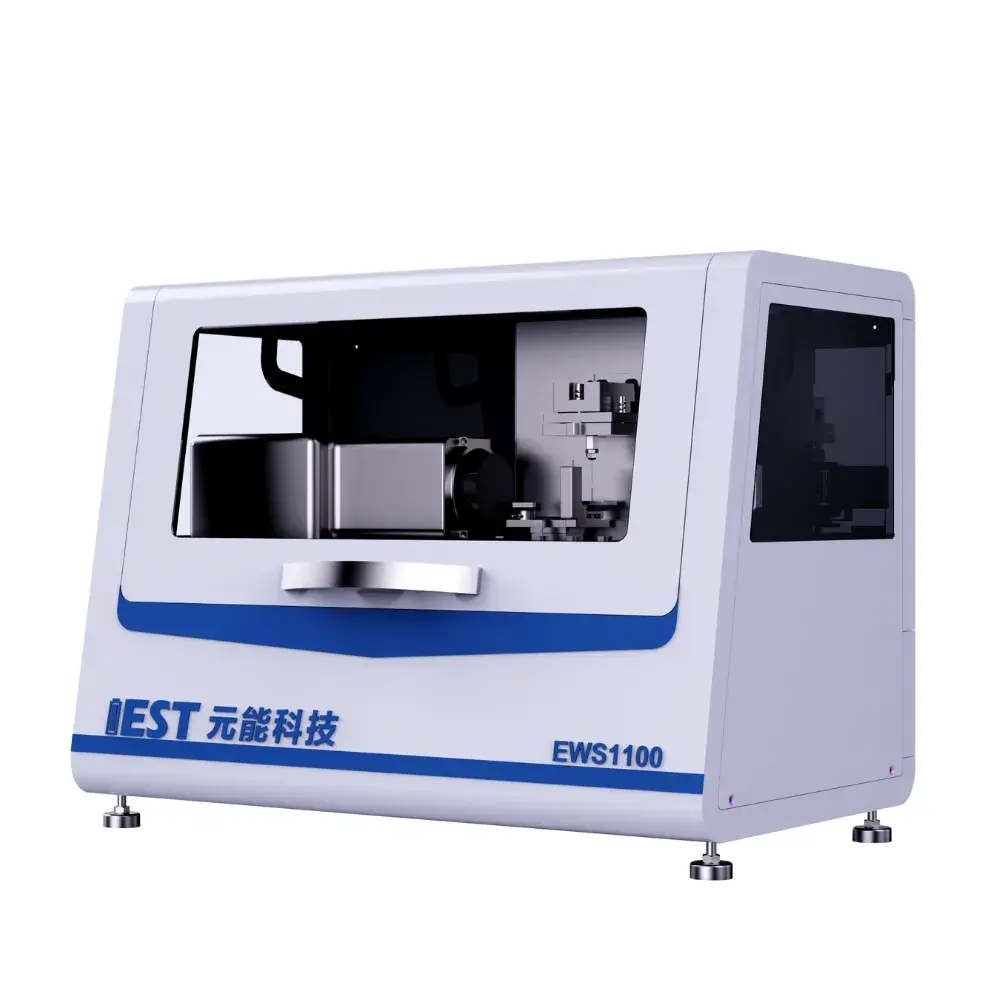

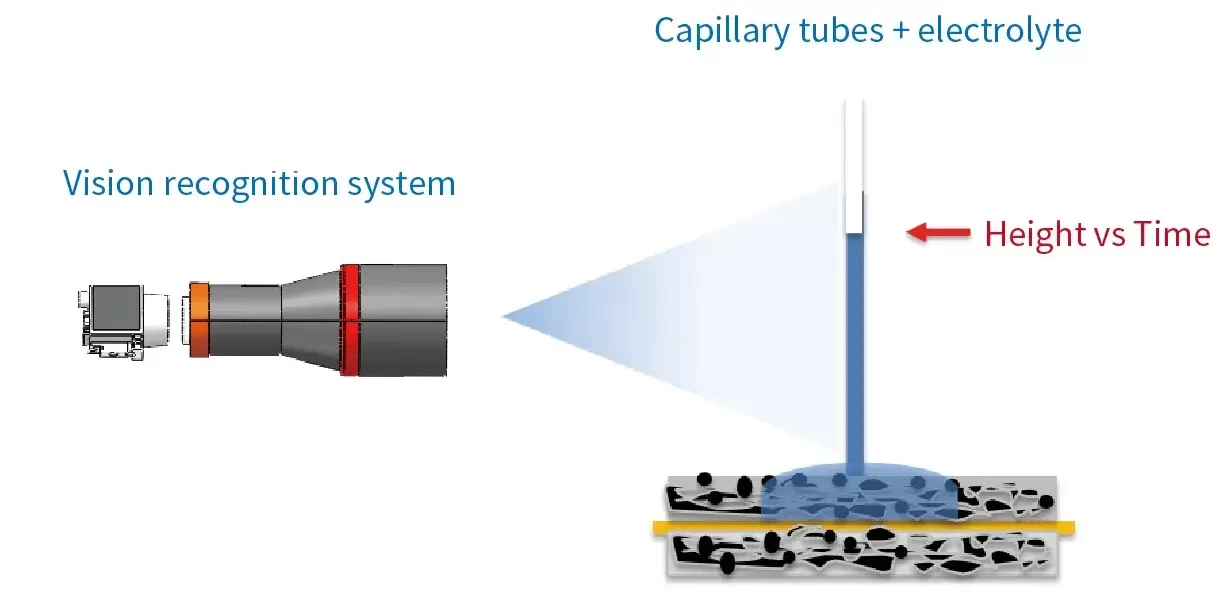

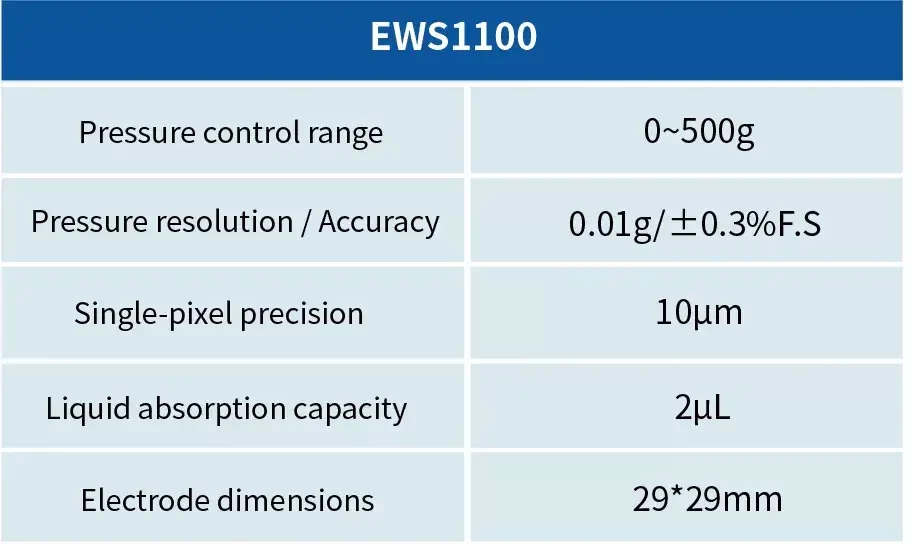

2.1 Capillary Wetting System-EWS Series

Key Features:

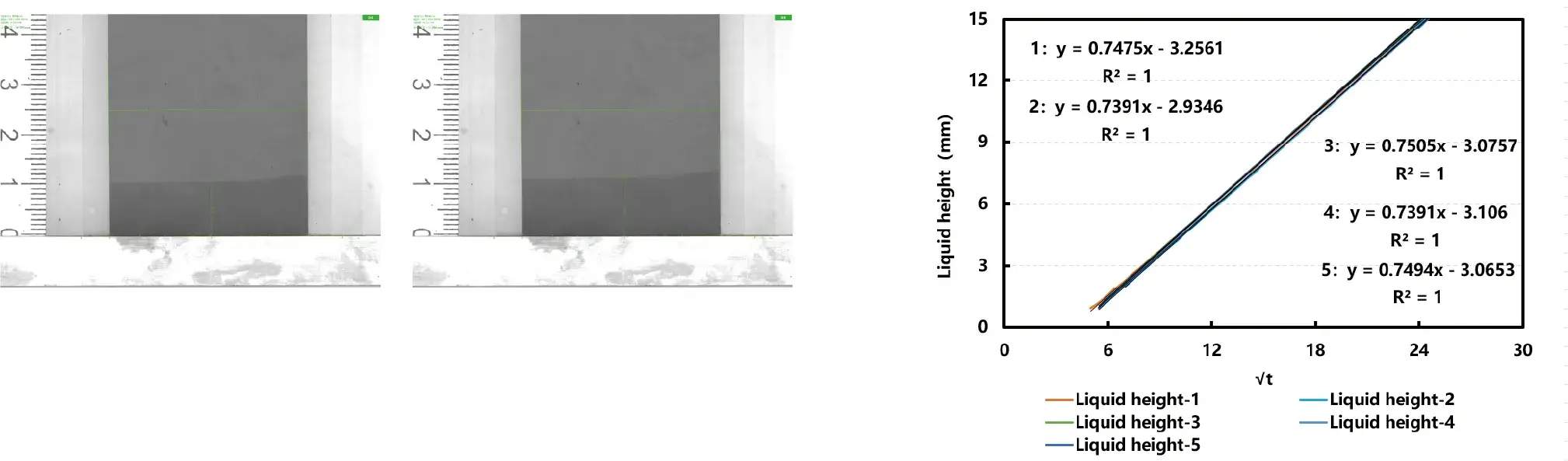

- Equipped with a high-precision vision testing system for stable and efficient testing repeatability.

- In-situ real-time characterization of electrolyte wetting rateon negative electrode sheets of lithium-ion batteries.

- Applicable Samples: Negative electrode sheets.

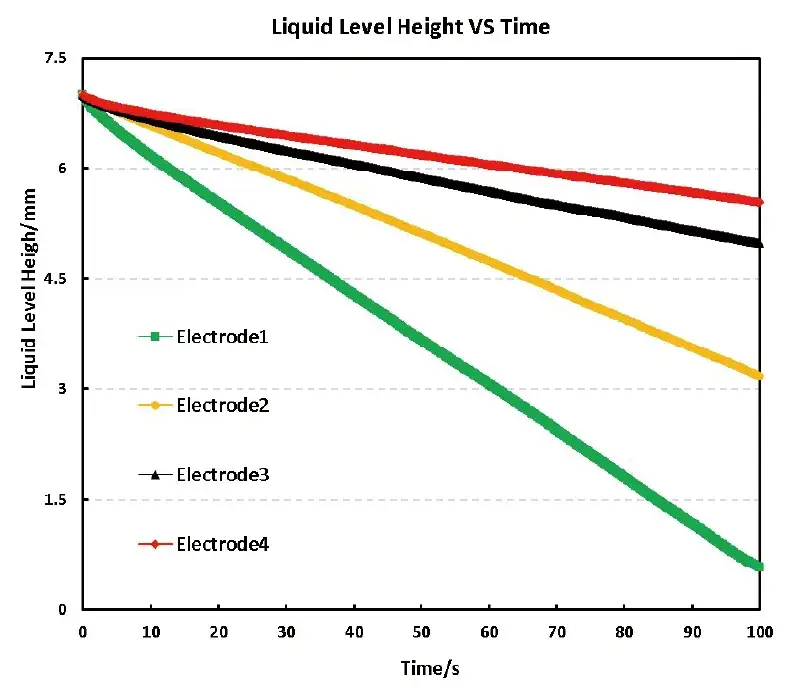

- The greater the compacticion of the electrode sheet, the lower the porosity, resulting in poorer electrolyte wetting.

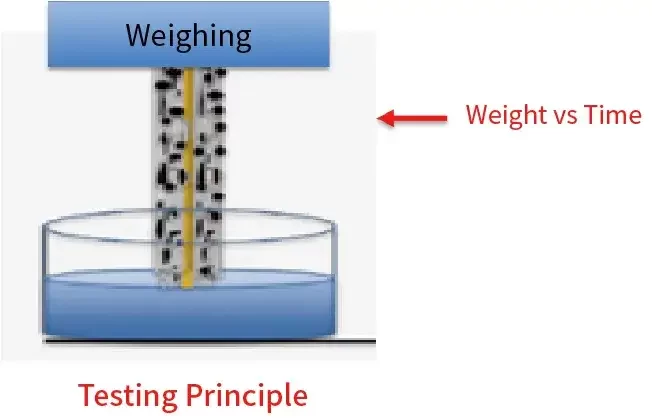

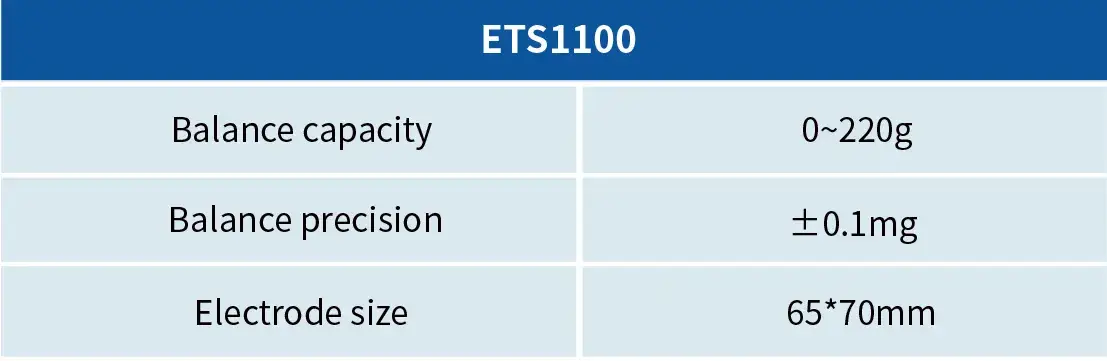

2.2 Weight Wetting System-ETS Series

Key Features:

- Equipped with a high-precision weighing system for stable and efficient testing repeatability.

- In-situ real-time characterization of electrolyte wetting rate on positive and negative electrode sheets of lithium-ion batteries.

- Applicable samples: Anode electrodes & Jelly Cells

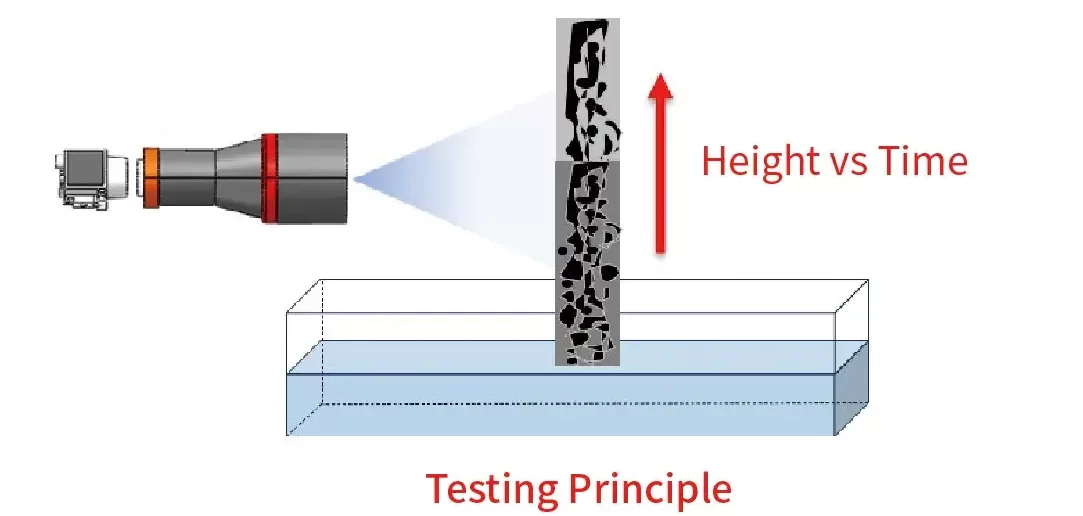

2.3. Height Wetting System-CHT Series

Key Features:

- Equipped with a high-precision vision acquisition system for stable and efficient testing repeatability.

- In-situ real-time characterization of electrolyte wetting rate on positive and negative electrode sheets of lithium-ion batteries.

- Applicable samples: Anode electrodes

Applications

1. Capillary Wetting System-EWS Series

- The greater the density of the electrode, the lower the porosity and the worse the electrolyte wettability.

2. Weight Wetting System-ETS Series

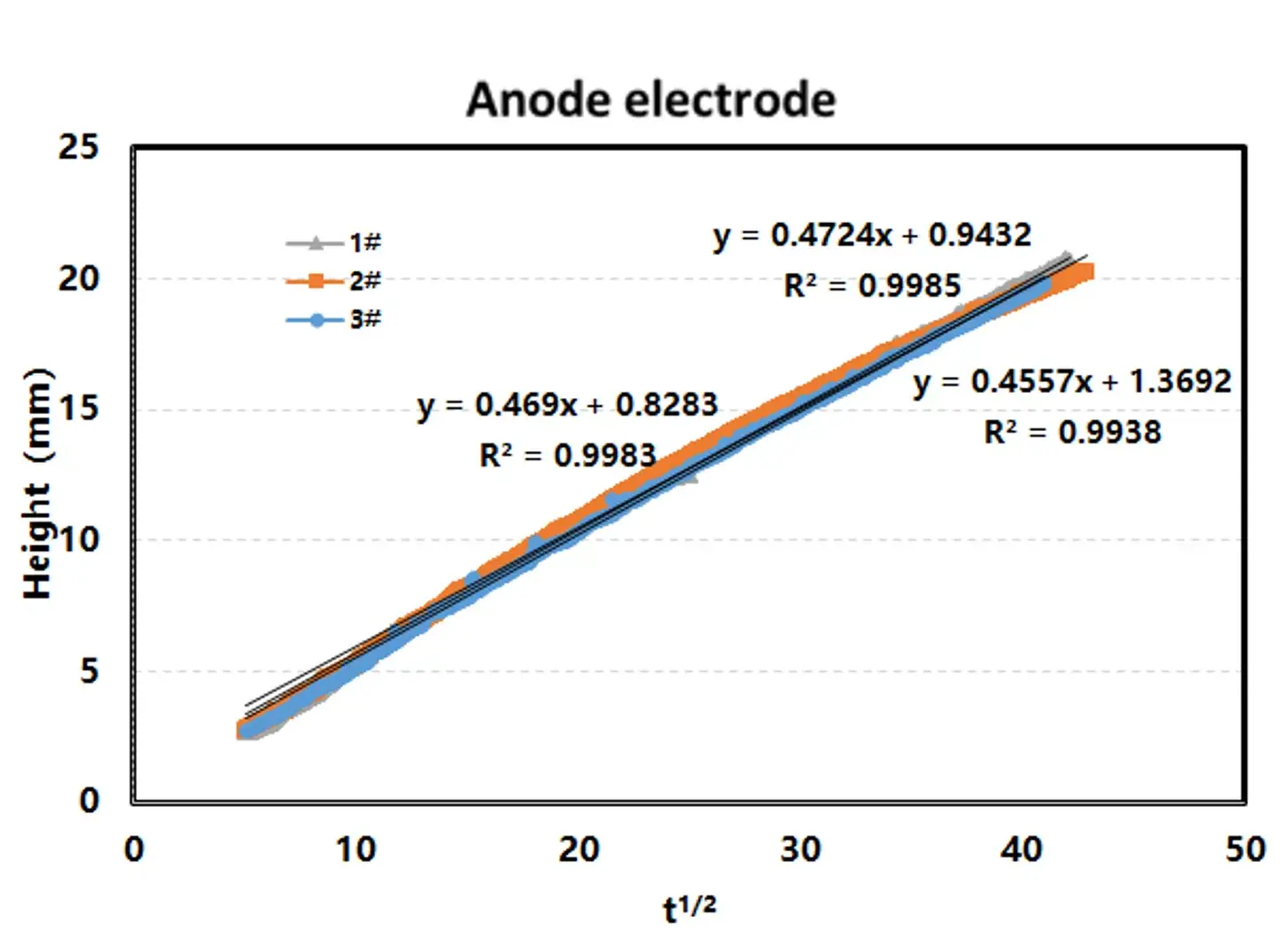

- Trimming three sets of negative electrode sheets from the same batch (65*70mm)

3. Height Wetting System-CHT Series

- The slopes of the 3 tested electrodes are consistent with each other, so is the wetting consistency of their electrolytes.

Video

Specifications

Capillary Wetting System-EWS Series

Weight Wetting System-ETS Series

Height Wetting System-CHT Series