-

iestinstrument

Effect of Deionized Water on Gas Production in Silicon-Based Slurry at Different Temperatures

1. Introduction

With the rapid development of the lithium-ion battery industry, silicon-based anode materials have gained attention due to their high theoretical specific capacity. Silicon-based slurry typically use deionized water as a solvent, with techniques like surface modification and elemental doping employed to enhance material performance. However, these techniques may introduce instability, such as surface alkalinity or incomplete coating, leading to exposure of nanoscale silicon. This exposure can result in gas generation during the slurry mixing process, potentially causing production anomalies that affect battery performance and safety.

Despite these challenges, there has been limited research on gas generation in silicon-based slurries and the influence of deionized water, possibly due to limitations in testing equipment precision. The in-situ gas volume monitoring analyzer(GVM2200) developed by IEST Company, enables real-time and quantitative monitoring of gas generation in silicon-based slurries. Its high-precision sensors can detect minute changes in gas volume, providing valuable data for evaluating silicon materials and their modifications, thereby supporting technological advancements in silicon material applications.

2. Test Information

2.1 Testing Equipment: The in-situ gas volume monitoring device, model GVM2200 (IEST Company), operates within a temperature range of 20°C to 85°C. The appearance of the device is shown in Figure 1.

Figure 1. Schematic diagram of in-situ battery gassing volume Analyzer (GVM2200)

2.2 Testing Procedure

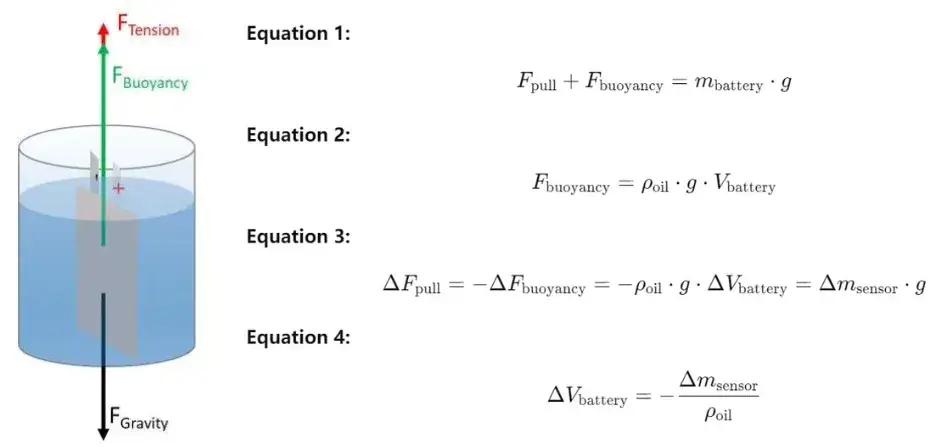

The GVM2200 utilizes Newton’s theorem and Archimedes’ buoyancy principle, measuring volume changes in samples through high-precision mechanical sensors. The test principle is as follows:

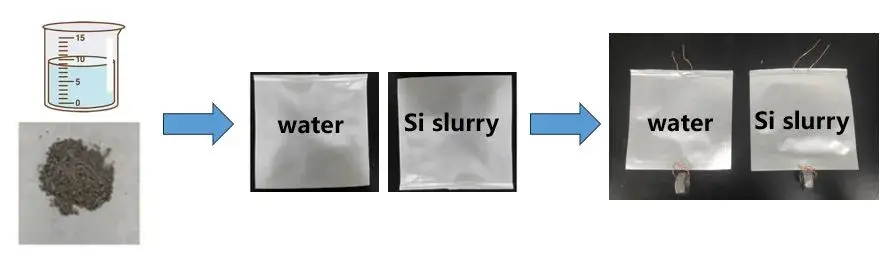

For this experiment, equal masses of deionized water and silicon-based slurry were encapsulated in aluminum-plastic films, weighted, and placed on the GVM2200’s two channels to monitor gas volume changes at various temperatures.

Figure 2. Sample Preparation Process

To verify the impact of deionized water on gas generation in silicon-based slurries, the slurries were prepared and monitored at different temperatures according to the ratios specified in Table 1.

Table 1. Slurry ratio

3. Testing Process and Results Discussion

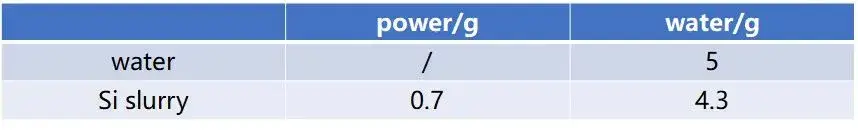

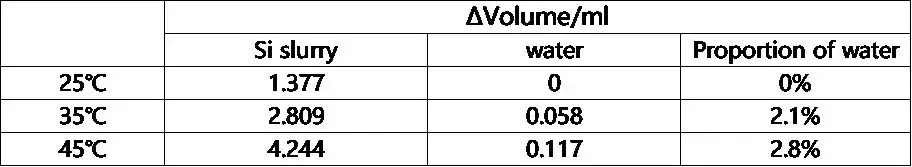

The experiment involved placing deionized water and silicon-based slurry from a room temperature of 25°C into chambers set at different temperatures. As shown in Figure 3 and Table 2, the volume of deionized water increased by 0.058 mL at 35°C compared to 25°C and by 0.117 mL at 45°C. This increase is primarily due to thermal expansion, where molecules gain more energy and move more vigorously as temperature rises. This volume increase is continuous until the deionized water reaches a new thermal equilibrium.

Figure 3. Volume Changes of Deionized Water at Different Temperatures

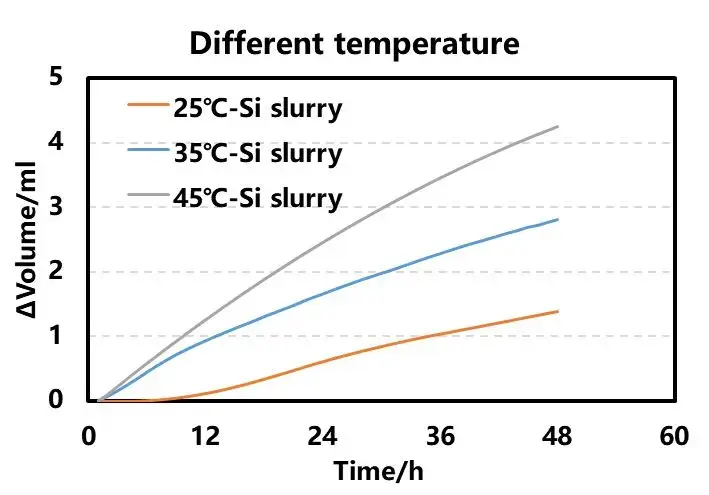

Figure 4. Volume changes of silicon-based slurry at different temperatures

Table 2. Volume changes of deionized water and silicon-based slurry at different temperatures

The experiment involved placing deionized water and silicon-based slurry from a room temperature of 25°C into chambers set at different temperatures. As shown in Figure 3 and Table 2, the volume of deionized water increased by 0.058 mL at 35°C compared to 25°C and by 0.117 mL at 45°C. This increase is primarily due to thermal expansion, where molecules gain more energy and move more vigorously as temperature rises. This volume increase is continuous until the deionized water reaches a new thermal equilibrium.

From Figure 4 and Table 2, it is evident that at 35°C, the gas volume generated by deionized water within 48 hours accounted for 2.1% of the total gas generated by the silicon-based slurry; at 45°C, this percentage rose to 2.8%. As the temperature increased, the gas volume generated by the slurry also increased significantly, far exceeding the volume change in deionized water. This could be due to several factors:

3.1 Surface Modification or Elemental Doping

These processes might introduce instability, such as surface alkalinity or incomplete coating, leading to the exposure of nanoscale silicon, which reacts with hydroxide ions during slurry preparation, generating gas.

3.2 Pre-Magnesium or Pre-Lithiation Treatment

To address issues like low initial discharge efficiency, poor conductivity, and poor cycle performance of silicon-based anode materials, extensive research on prelithiation techniques has been conducted. By introducing a small amount of lithium source beforehand, the lithium consumed during side reactions and solid electrolyte interphase (SEI) formation is replenished, while surface modifications further enhance the material. However, prelithiation agents are water-sensitive and may react to produce gas. Additionally, elemental silicon is prone to hydrolysis, generating combustible hydrogen gas as a byproduct:

Si+2H2O→SiO2+2H2↑

4. Conclusion

This study used the IEST GVM2200 in-situ battery gassing volume Analyzer to characterize the gas generation behavior of deionized water and silicon-based slurry at different temperatures. As temperature increased, the volume of deionized water stabilized after reaching a new thermal equilibrium, while the gas volume generated by the silicon-based slurry continued to rise over time. The GVM2200‘s precise measurements allow for continuous and automated gas volume testing, providing robust technical support for material development and the study of gas generation mechanisms in slurries.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.