Description

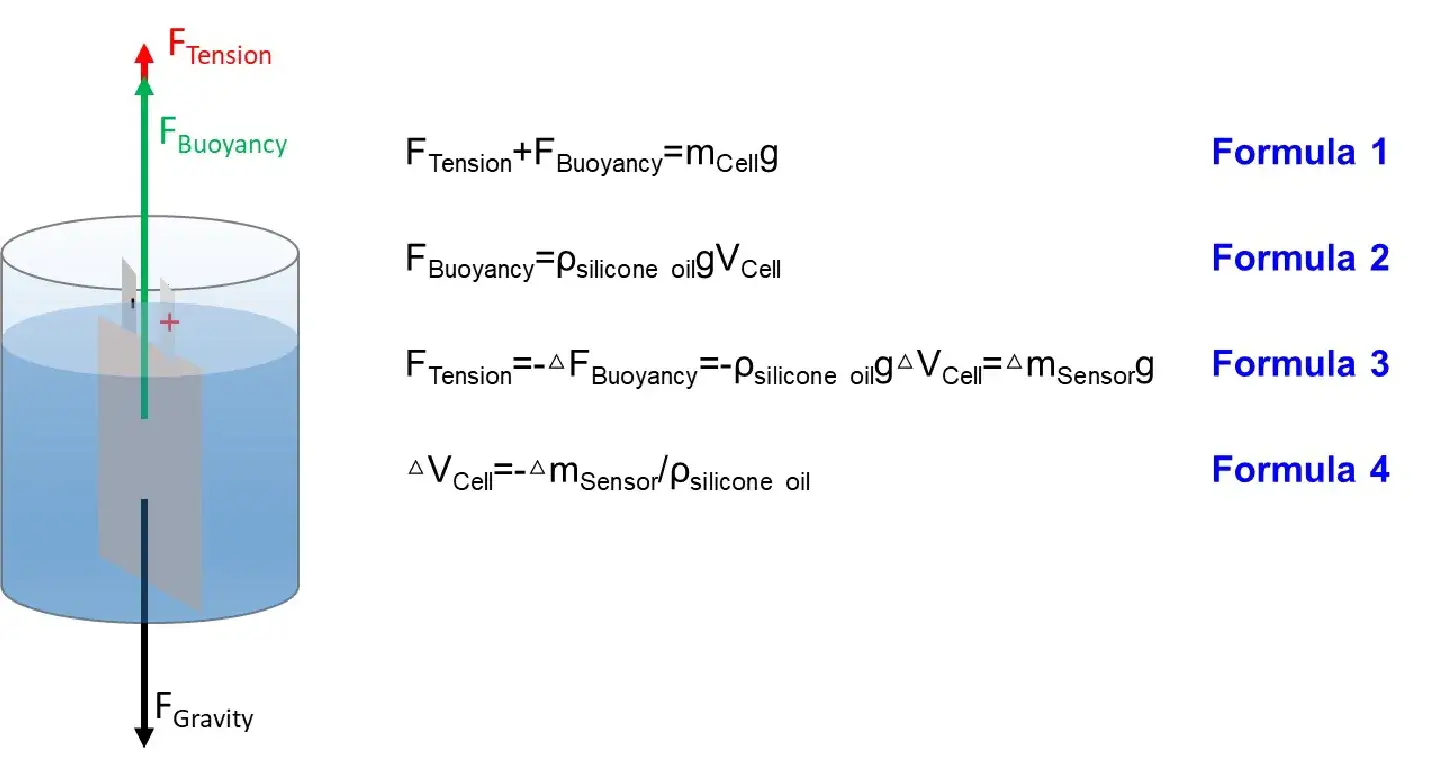

1. Instrument Principles

By combining Newton’s law (formula 1) and Archimedes’ buoyancy principle (formula 2), specialized sensors are used to measure the real-time mass changes of the cell during the charge & discharge process, and then the cell’s volume changes can be further calculated(formula 3 and 4).

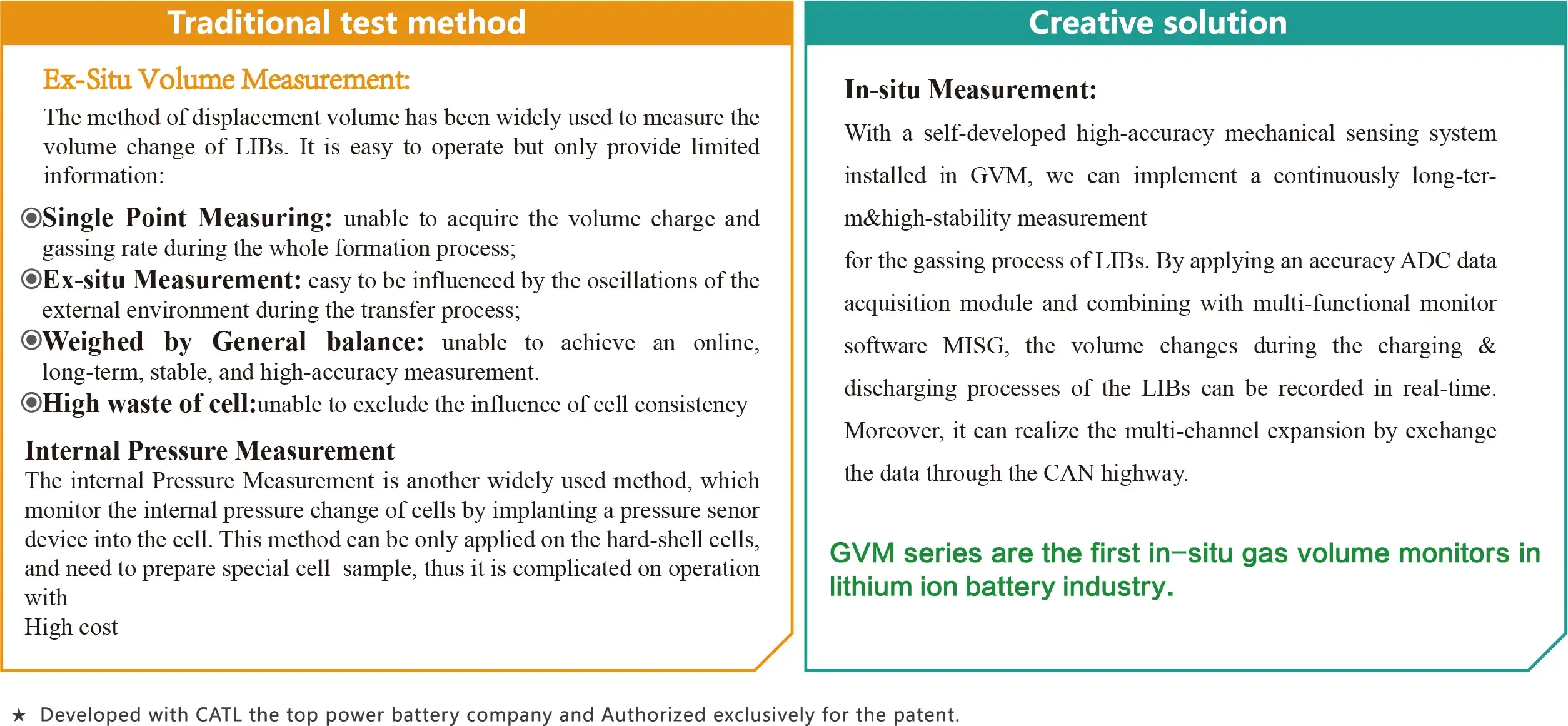

2. Product Features

- Multi-Level Gassing Testing: Material Gassing → Single-Layer Stacked Cell Gassing → Small Pouch Cell Gassing → Cylindrical & Prismatic Cell Gassing

- Multi-Channel Gassing Testing: Single channel → 2-channel → 8-channels Testing

- Multiple Temperature Settings: Room Temperature Testing → High and Low Temperature Testing (RT to 85℃ with Water Bath Control)

- Comprehensive Gassing Analysis: Gassing Volume → Gassing Pressure → Gassing Composition Analysis

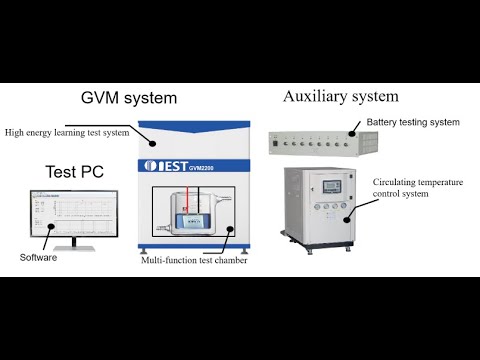

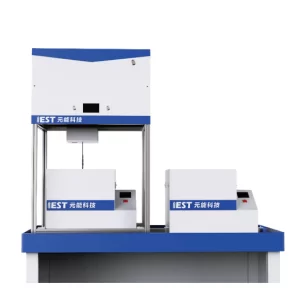

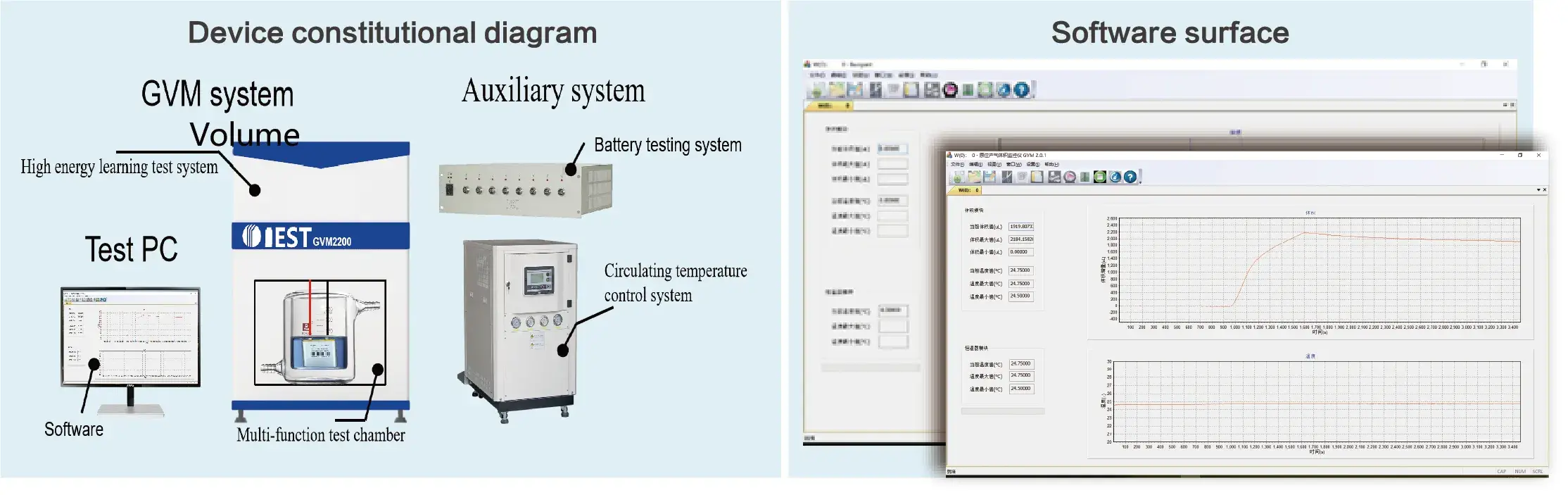

3. Device Constitutional Diagram and Software

3.1 High-energy Learning Test System

long-term in-situ online monitoring, and meet the accuracy requirements;

3.2 Dedicated Test Software

Real-time collection and display of mechanical test system data, and automatically draw volume change curves;

3.3 Auxiliary System

Special structure design, convenient to intervene in supporting auxiliary system, realize test temperature adjustment control.

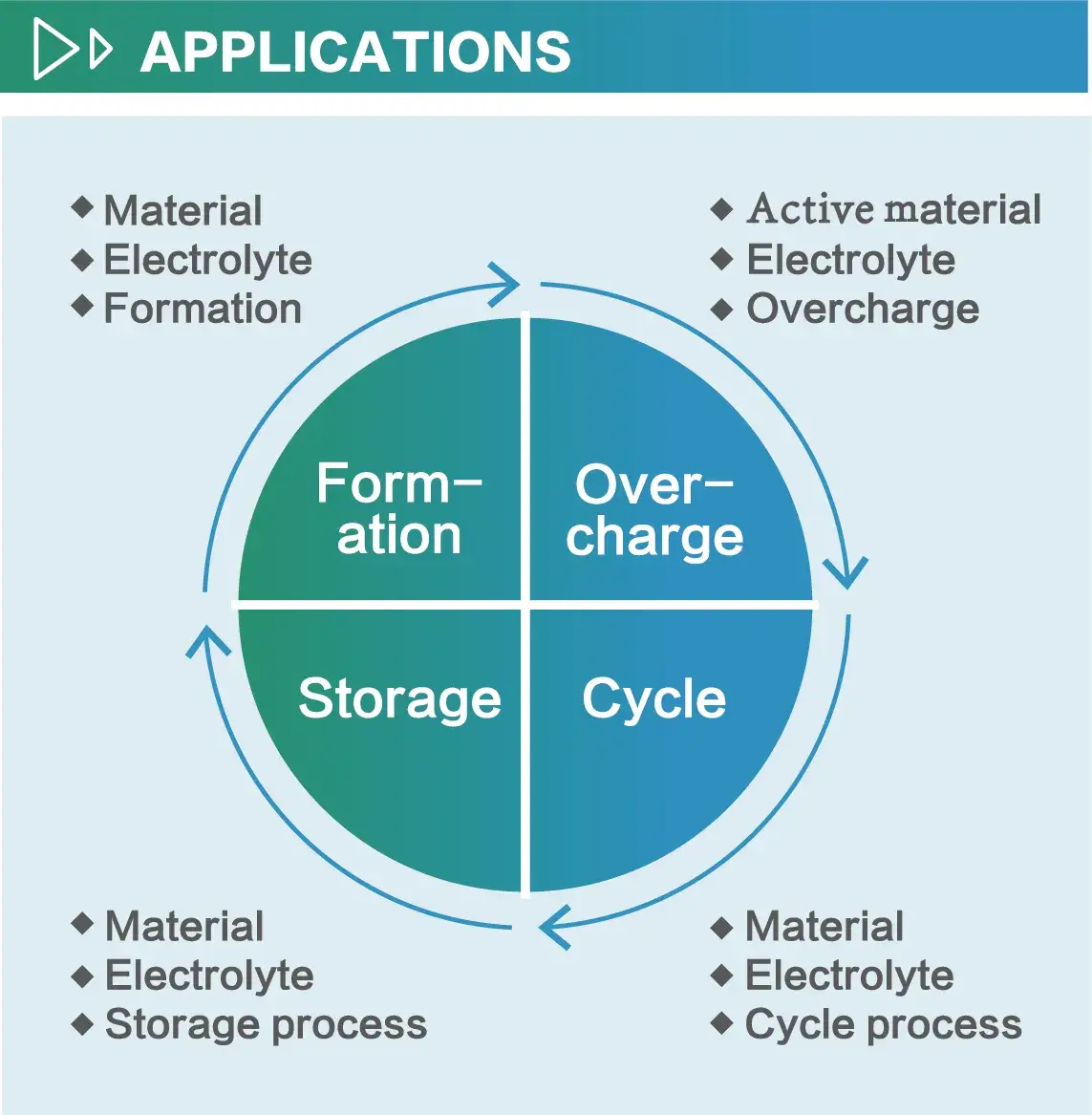

4. Applications

- Overcharge Gassing

- Cycle Gassing

- Storage Gassing

- Formation Gassing

Applications

1. Application Case: Formation Gassing

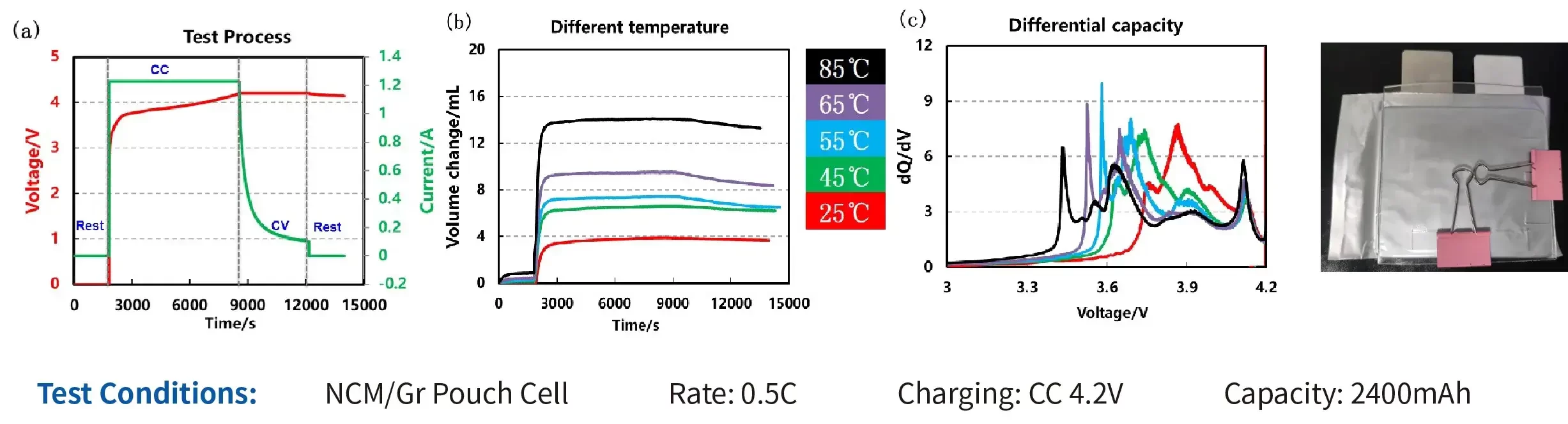

1.1 Formation at different temperatures

Conclusion:

- The gas production increases gradually with the increases of formation temperature, and when formationtemperature is around 55°C, the first phase transition reaction peak will be more acute.In addition, from the differential capacity curve, as the formation temperature increases, the polarization decreases.

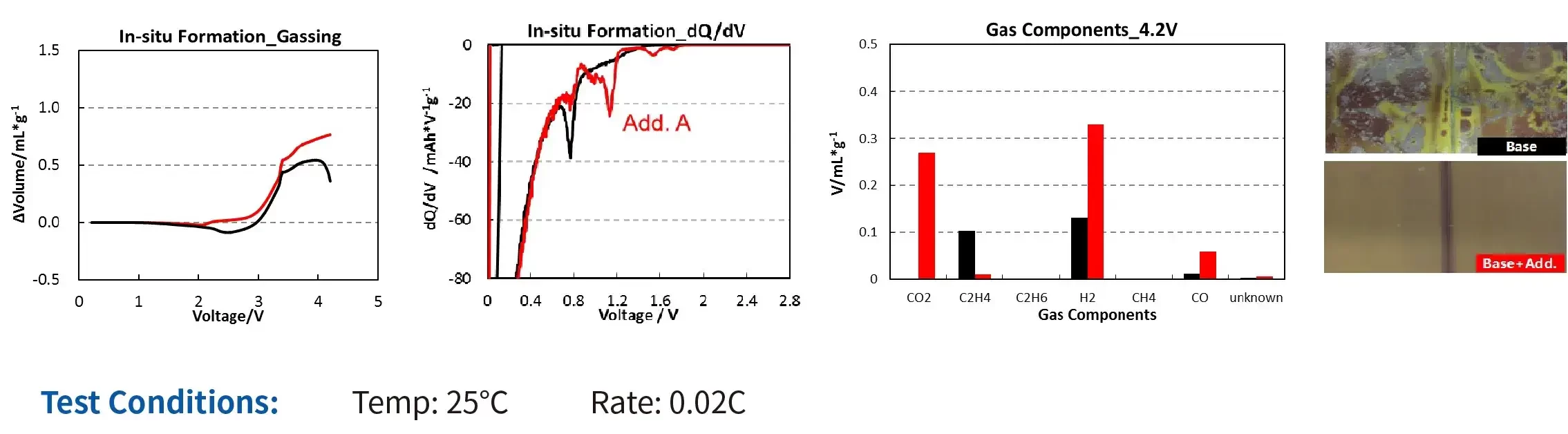

1.2 Formation with different electrolyte additives

Conclusion:

- The gas production & gas production rate of the cells with additive A(red) are greater than those without the additive, which means this additive enables a more complete SEI formation in the cells.

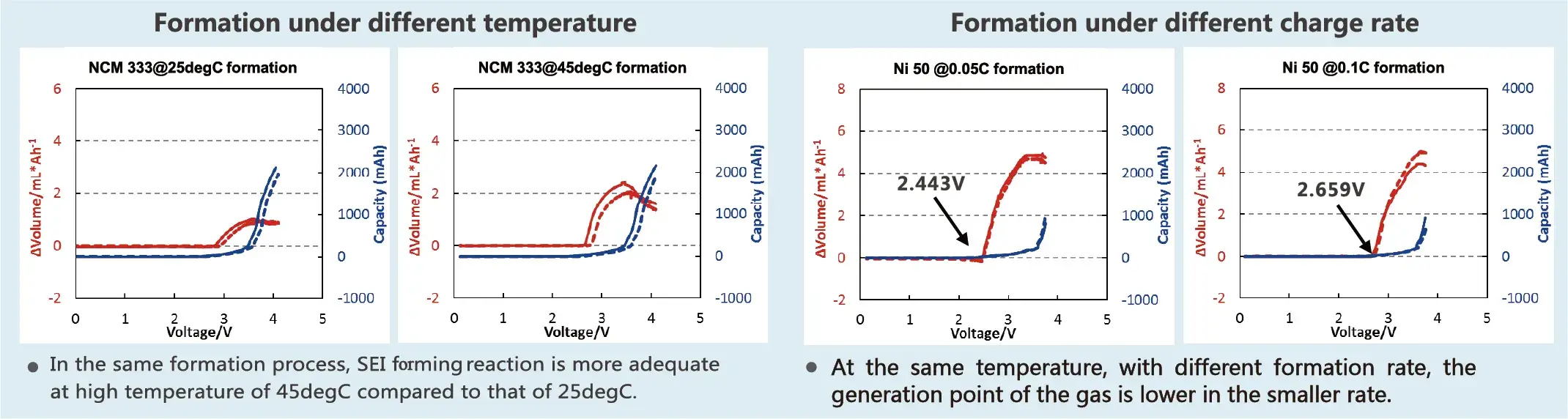

1.3 Different temperature and rate of formation conditions

- By setting different formation conditions, it can quantitatively obtain the starting voltage of the gas production under different formation conditions, as well as the gassing quantity and the gassing rate of different stage of the formation process, which can help to guide the improvement ofthe formationprocess and the technology of LIBs and raise the production efficiency of the enterprise.

2. Application Case: Overcharge Gassing

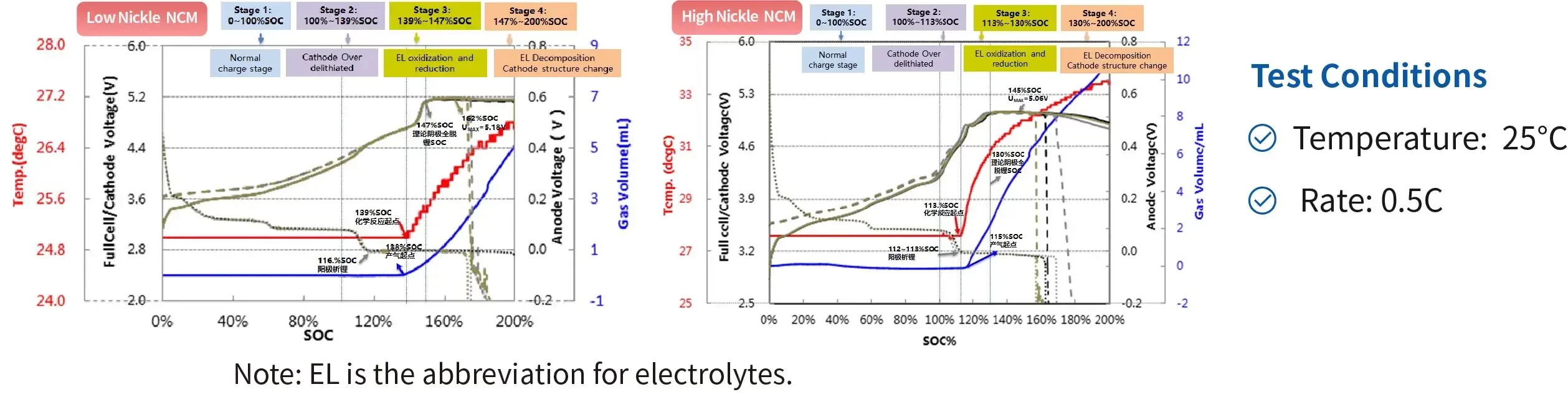

2.1 NCM cells with different Ni contents

Conclusion:

- The slope of the volume change curve suddenly increases when overcharged to a certain potential, then the surface temperature of the cell increases sharply, and gas generation starts instantly from there;

- As the nickel content increases, the state of charge (SOC) at the onset of gas generation shifts from 138% to 115%

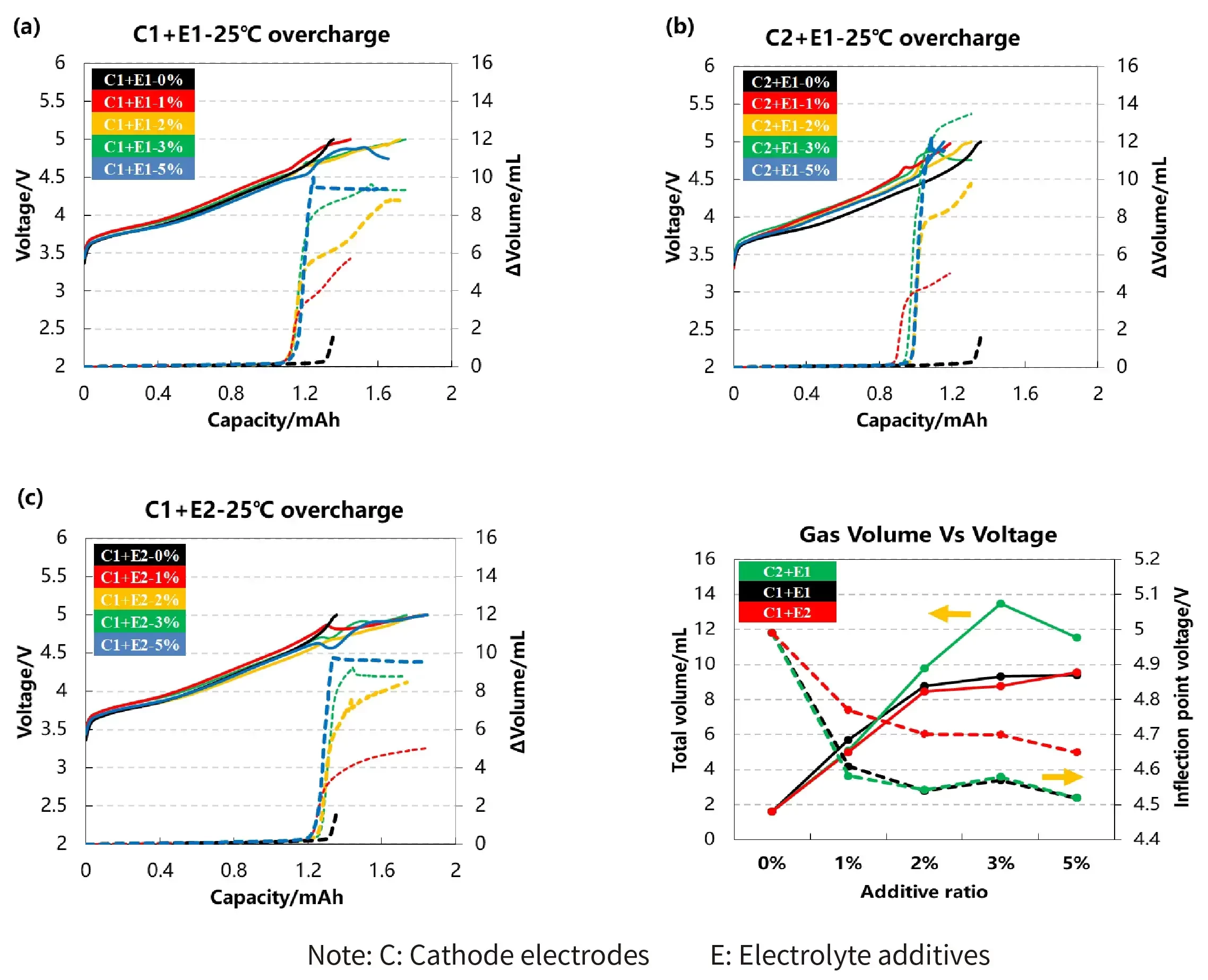

2.2 Cells with different cathodes and contents of electrolyte additives

Conclusion:

Conclusion:

- Both cathode electrodes and the contents of electrolyte additives afect gas production, while the type of additives mainly affects the potential of gas production.

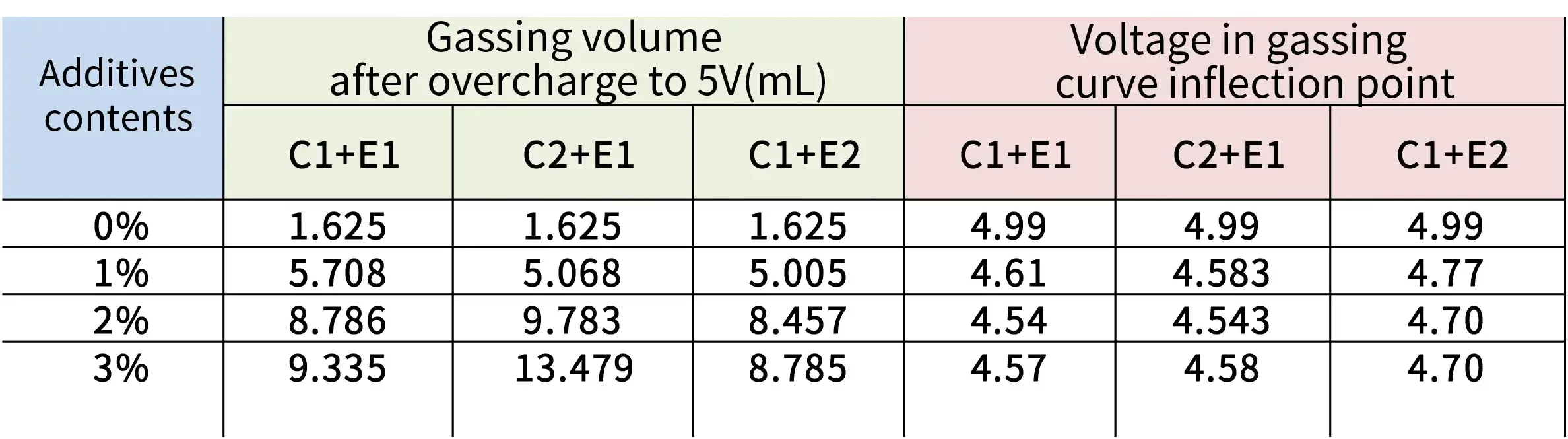

2.3 Overcharge and overdischarge of LFP batteries

Conclusion:

- As the cell is overcharged or overdischarged, the starting point of gas production can be detected in real time;

- Gas chromatography analyzes the gas composition under these two working conditions. in addition to the same gas type as the over-discharge cell, a relatively high content of CO and CO2 gas is also detected

3. Application Case: Cycling Gassing

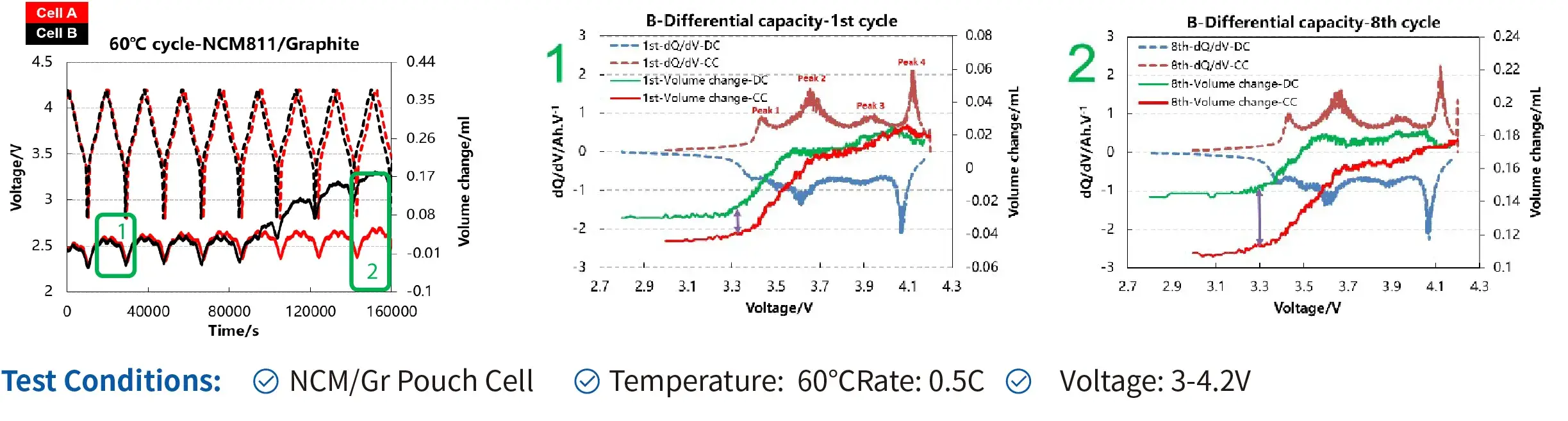

3.1 Cycle performance ofdifferent NCM cells

Conclusion:

- Cell-A and Cell B are made by diferent NCM matemals. The volume change of Cell-B is larger than that of Cell-A during the long-term cycling and the irreversible volume change also increase from 0.01 mL to 0.04 mL.

- It can help to quantitatively analyze the cycling performance of diferent materials, modify the materials in a targeted manner, and improve the R&D efficiency.

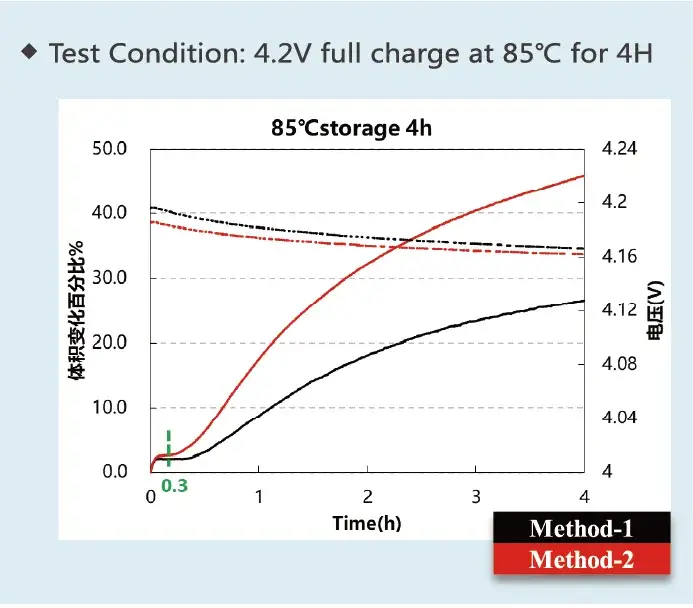

4. Application Case: Storage Gassing

4.1 Comparing NCM811 modified conditions

- At 85°C, both the voltage drop and the gas production of NCM811 modified by Method-1 arelarger than that of NCM811 modified by Method.

- It can used to compare the advantages of different modification methods of materials by using this in-situ method to continuously monitor the gas production during storage, which can help toimprove the efficiency of R&D.

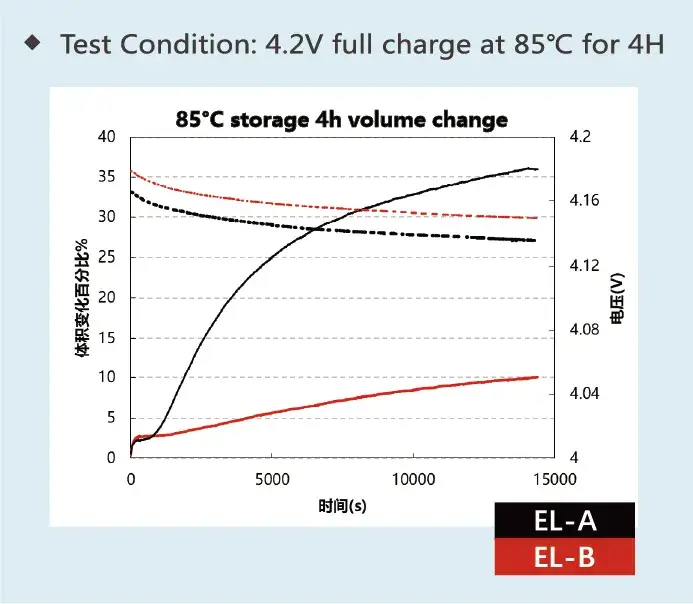

4.2 Comparing different type of electrode

- Cell-A and Cell-B are made by different electrolyte systems. From the volume change curves during the full-charge storage, it can be found that Cell-A produce more gas than Cell-B, indicating that the electrolyte of EL-A is much easier to produce the gas under high temperatre and high voltage.

- Help to quantitatively analyze the gas production performance of different electrolytes, modify the electrolytes in a targeted manner, and improve the R&D efficiency.

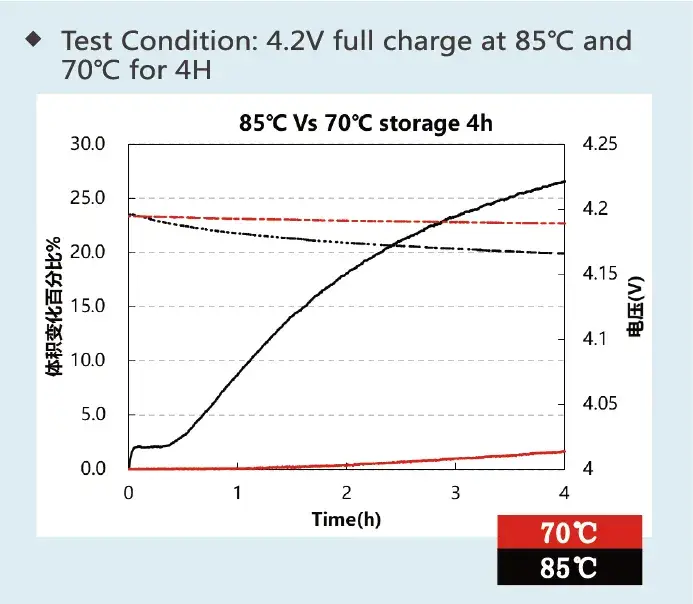

4.3 Comparing different storage temperature

- This cell has better storage performance at 70°C, while it produce more gas at 85°C

- By using in-situ method to continuously monitor the gas production during, the storage point and maximum point of gas production can be obtained, which is helpful for researchers to carry out the next step of R&D work in a targeted manner.

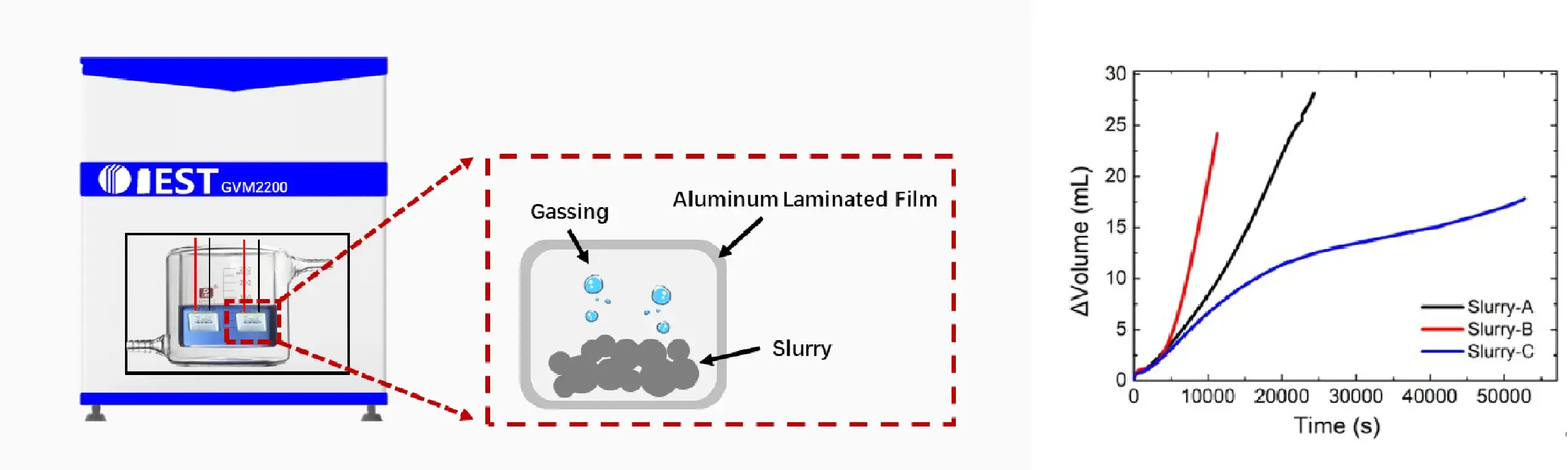

5. Application Case: Gassing from silicon-based slurries

Conclusion:

- Pre-magnesium or pre-lithiation treatment of silicon monoxide results in gas generation in the slurry.

- Lithium compensation additives in the cathode tend to decompose and generate gas during the actual slurry and lithium compensation process.

Video

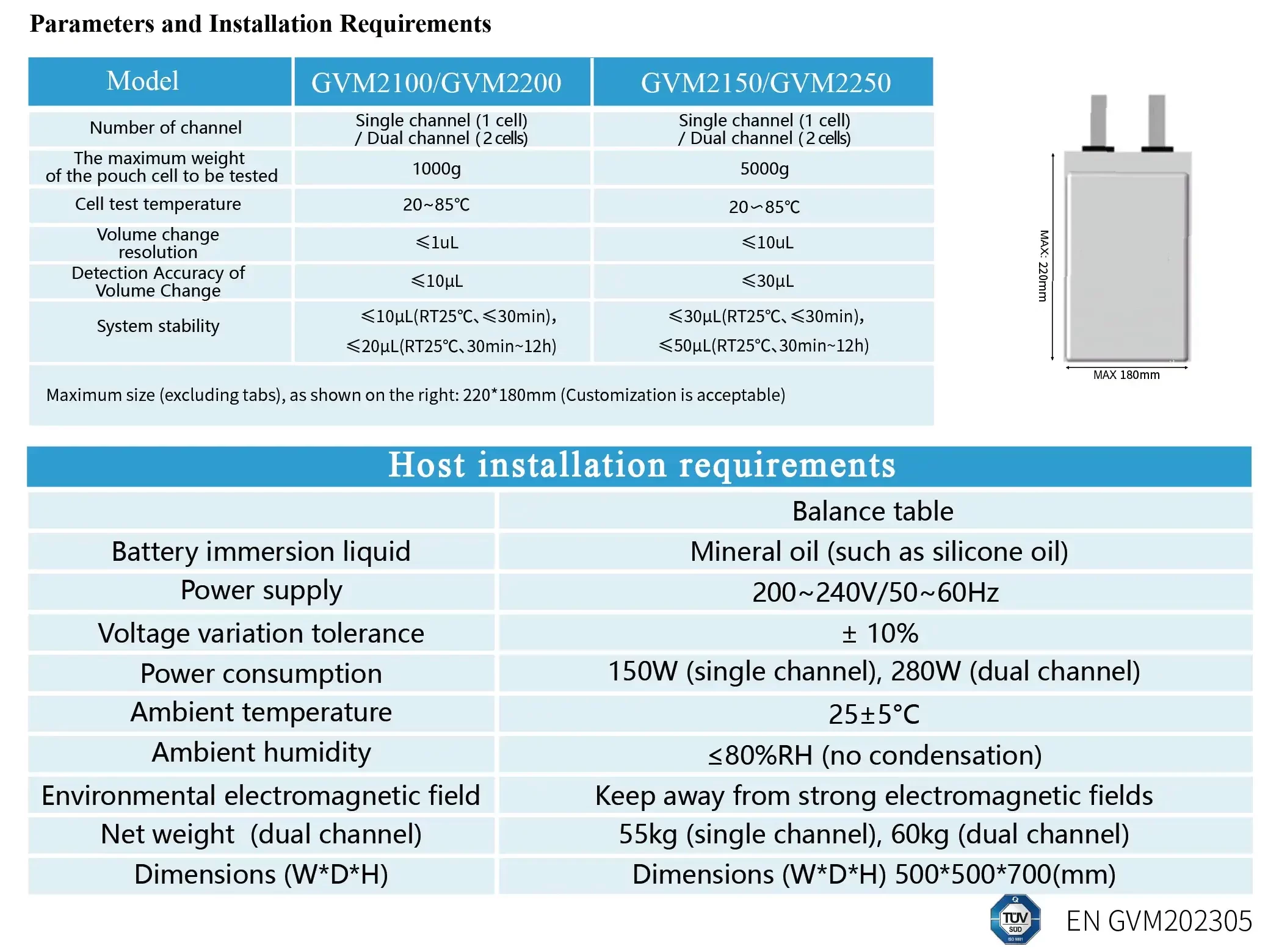

Specifications