-

iestinstrument

Analysis Silicon-carbon System Cells’ Cyclic Expansion and Capacity Decay

1. Preface

With the continuous improvement of the endurance requirements of new energy vehicles, battery anode materials are also developing in the direction of high energy density. Although the traditional graphite anode material has mature technology and low cost, its development in terms of energy density is close to its theoretical maximum (372mAh/g). Silicon has gradually entered people’s field of vision due to its ultra-high gram capacity (4200mAh/g) and low lithium intercalation potential (0.4V), but the significant volume swelling (~300%) of the silicon anode during charge and discharge greatly limits process of its large-scale commercialization. In order to overcome these defects, researchers often use composite technology to buffer the volume expansion of silicon. Among them, carbon materials are often regarded as composite materials with silicon because of their advantages such as small volume change during charging and discharging, good cycle stability, and high conductivity. preferred matrix [1].

In this paper, the in-situ swelling analyzer (SWE2110) developed and produced by IEST was used to comparatively study the swelling behavior of silicon-carbon system soft-pack batteries with different silicon contents, and reveal the relationship between the volume swelling and capacity decay of silicon-carbon system batteries. It also provides research ideas for subsequent material optimization and modification, and helps to promote the commercialization of silicon-based anodes.

2. Experimental Equipment and Test Methods

2.1 Experimental Equipment

In-situ swelling analyzer, model SWE2110 (IEST), the appearance of the equipment is shown in Figure 1:

Figure 1. Appearance of SWE2110 Equipment

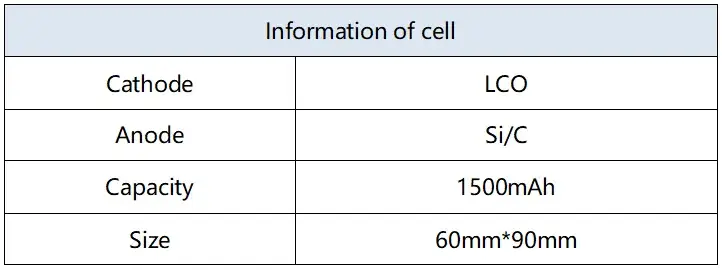

2.2 The test battery information and charging and discharging process are shown in Table 1 and Table 2 respectively:

Table 1. Information of Test Cell

Table 2. Charge and Discharge Process

2.3 Cell Thickness Swelling Test Process

Put the cell to be tested into the corresponding channel of SWE2110, open the MISS software, set the cell number and sampling frequency and other parameters corresponding to each channel, the software will automatically read the thickness of the cell, thickness variation, and test temperature during the charging and discharging process , current, voltage, capacity and other data for subsequent comparative analysis.

3. Results and Analysis

3.1 Comparison of Swelling Behavior of Silicon-carbon System Cells with Different Proportions

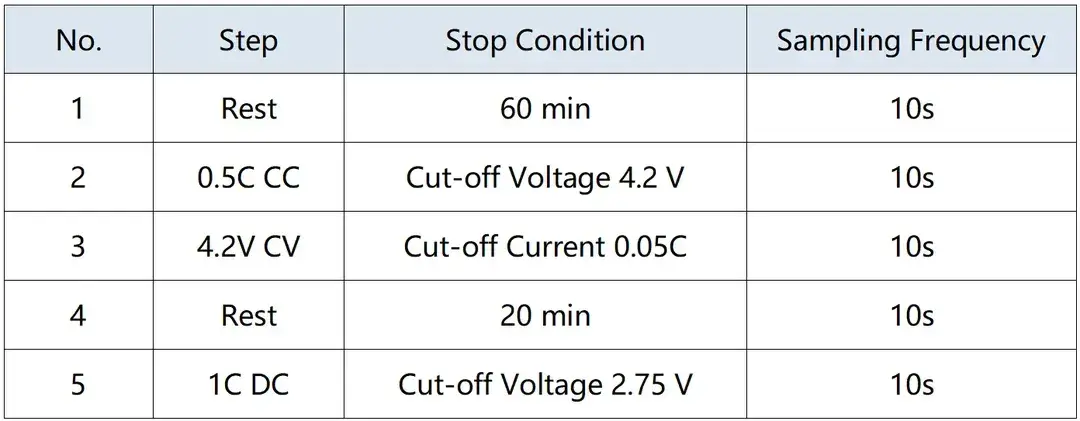

Set the in-situ swelling analyzer (SWE2110) to the constant pressure mode (the pressure value is 5.0kg), and monitor the thickness change of different proportion of silicon-carbon system (silicon content is 3 wt.% and 5 wt.% respectively) soft core under long cycle (50 cycle), the results are shown in Figure 2. Through the initial thickness normalization, it can be found that with the increase of the number of cycles, the thickness swelling curves of both are also rising, and the higher the silicon content, the more obvious the swelling growth.

Compared with the initial state, 3wt.% after 50 cycles And 5 wt.% The thickness swelling percentage of the silicon content cell is 8.8% and 11.2% respectively, indicating that both of them have accumulated a lot of side reaction products after long cycle, resulting in the continuous increase of the total volume of the cell. Due to the serious volume swelling of the silicon particles in the cathode during the lithium intercalation process, the active material particles will be broken and pulverized, and the existing SEI film on the particle surface will be destroyed, while the exposed new silicon particle surface will further react with the electrolyte to form a new SEI film. This repeated rupture and regeneration of the SEI film will not only accumulate many side reaction products and make the total volume of the cell expand continuously, but also easily cause the internal resistance and polarization of the cell to increase continuously, and finally aggravate the capacity attenuation of the cell [2,3].

Figure 2. Cell charging curve and thickness expansion curve

In addition, in addition to the comparison and analysis of the total swelling thickness changes of the two silicon-carbon system cores, we also carried out a detailed analysis of the irreversible swelling amount of each cycle during the cycle. The specific operation is as follows: subtract the change of volume shrinkage during discharge from the change of charging swelling thickness of a single cycle, and the difference is the irreversible swelling thickness of the cycle. Due to the process of alloying lithium intercalation of silicon-carbon anode during charging, if the reaction is completely reversible during discharge, the irreversible swelling thickness should be close to zero, so this parameter can reflect the lithium intercalation capacity of silicon-carbon anode under different aging conditions. The results of the irreversible swelling thickness of the two groups of silicon-carbon system cores with different proportions as the number of cycles are shown in Figure 3. It can be seen that the irreversible swelling thickness of the two groups of cores increases with the number of cycles, and the irreversible swelling amount of the two groups is almost the same before 35 cycles, but as the cycle aging continues, 5 wt.% The irreversible swelling of the silicon content cell is more serious, indicating that the increase of silicon content will greatly affect the swelling performance of the cell at the later stage of the cycle.

![]()

Figure 3. Curve of irreversible expansion thickness of two groups of silicon-carbon system cores (silicon content is 3wt.% and 5wt.% respectively) with the number of cycles

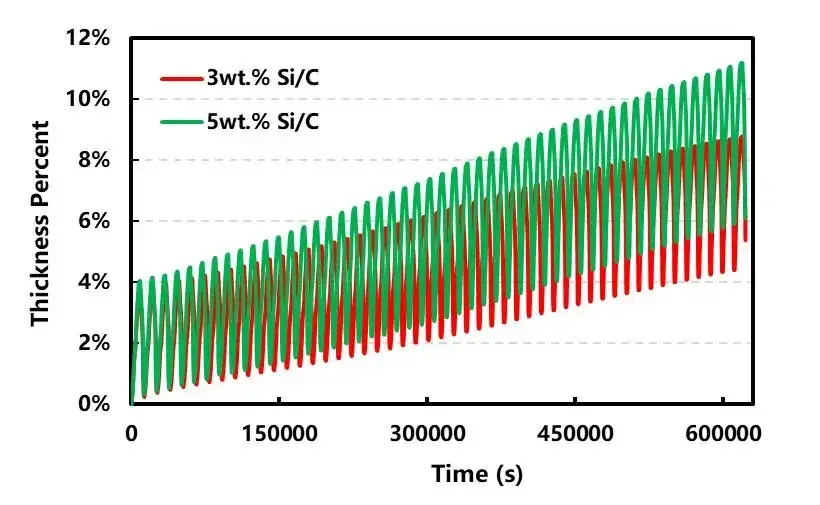

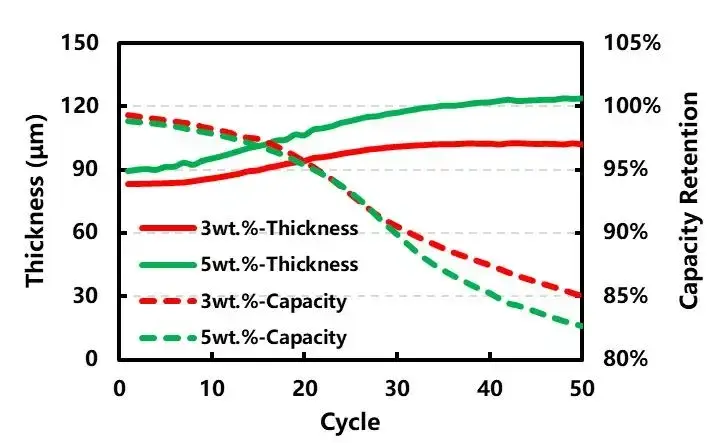

3.2 Correlation Between Swelling Thickness and Capacity

In order to further analyze the correlation between swelling thickness and capacity, we extracted the thickness swelling and corresponding capacity of each cycle of charging stage, as shown in Figure 4. It can be seen that with the increase of the number of cycles, the thickness swelling of the two groups of cells shows a trend of increasing first and then becoming flat, while the capacity retention rate of the two groups of cells is also decreasing. This is due to the continuous accumulation of irreversible thickness swelling of the two groups of cores during the cycle aging process, which leads to the continuous rise of the expansion thickness curve of the cores at the early stage of the cycle, and the irreversible alloying reaction and the pulverization of silicon particles and other factors will reduce the active sites on the silicon-carbon cathode electrode, making the capacity of the silicon-carbon negative electrode to play is also decreasing with the cycle. At the later stage of the cycle (after 35 cycles), due to factors such as particle pulverization, electrolyte consumption and the reduction of active lithium concentration, the thickness increase caused by lithium intercalation reaction of silicon-carbon anode gradually decreases, so the thickness swelling curve becomes relatively flat, but the capacity attenuation at this time is still continuing. In addition, 5 wt.% The thickness increase and capacity attenuation of silicon-carbon system core are higher than 3wt.% The silicon-carbon system core is serious, so the optimization and modification of high silicon anode still need further swelling by researchers.

Figure 4. Correlation curve between core thickness swelling and capacity retentiond

In addition, in order to explore the effect of the side reaction products accumulated by the irreversible reaction at the later stage of the cycle on the cell polarization, capacity decay and lithium intercalation reaction of silicon-carbon, we also compared and analyzed the differential capacity curves of two groups of silicon-carbon system cells before and after the long cycle, and the results are shown in Figure 5 (a) and (b). It can be seen that no matter 3wt.% Or 5 wt.% The dQ/dV curve (black line) of the silicon-carbon system core after 50 cycles shifted to the right as a whole, indicating that the internal polarization of the two cores increased at the end of the cycle. In addition, the characteristic peak intensity and peak area of dQ/dV curve after 50 cycles at 3.72V and 3.81V decreased significantly, indicating that the phase transformation reaction at these two potentials after 50 cycles did not fully exert its due capacity, which led to the attenuation of the overall capacity of the cell. If you observe carefully, you can also find that the dQ/dV curve after 50 cycles lacks some small characteristic peaks compared with the first cycle (red line), that is, some phase change reactions gradually disappear with the aging of the cell, which is also one of the important factors that lead to the capacity attenuation of the cell at the end of the cycle.

![]()

Figure 5. (a) and (b) are 3 wt.% respectively And 5 wt.% DQ/dV curve of the 1st and 50th cycle of silicon-carbon system core

According to the above experimental results, the capacity attenuation of the silicon-based electrode is closely related to the volume swelling of the silicon particles. Figure 6 shows the attenuation diagram of the silicon-based electrode [4]. The main effects include: (1) the volume change will cause the particles to crack and break, which will lead to the falling of the active material or the deterioration of the electronic transmission performance; (2) Active lithium is lost due to the continuous formation of SEI film on the continuously exposed fresh surface of particles; (3) The increase and thickening of SEI film will also cause the increase of electrode impedance and polarization, and change the electron and lithium ion transport characteristics of the interface layer; (4) The volume swelling of the electrode and the continuous formation of the SEI film will also lead to changes in the porosity of the electrode, thus affecting the transmission of electrons and ions. Therefore, the strategies to improve the cycling performance of silicon-carbon composite electrode include: (1) material structure modification, such as reducing the size of silicon particles, or synthesizing nanostructured silicon electrode; (2) Potential control to avoid the formation of crystalline Li-Si alloy; (3) Develop self-healing adhesive to make better combination between active materials; (4) The oxide using silicon has less specific volume swelling than crystalline silicon when lithium-ion is embedded/removed.

![]()

Figure 6. Attenuation diagram of silicon-based electrode [4]

4. Summary

In this paper, the in-situ swelling analyzer (SWE2110) developed by IEST is used to analyze the swelling thickness changes of two silicon-carbon system cores with different silicon content under long cycle and the correlation between the swelling thickness and the capacity attenuation. It is found that the volume swelling of silicon particles will lead to the continuous rupture and regeneration of the SEI film[3], which not only consumes a large amount of electrolyte and active lithium, but also accumulates a large number of side reaction products in the cell, thus increasing the overall thickness of the cell, while the available capacity of the cell is also declining. In addition, the volume swelling and capacity retention rate of high silicon system cells are lower than that of low silicon system cells, which also indicates that the optimization and modification of high silicon system cells still have a long way to go.

5. References

[1] M. Ashuri, Q.R. He and L.L. Shaw, Silicon as a potential anode material for Li-ion batteries: where size, geometry and structure matter. Nanoscale 8 (2016) 74–103.

[2] S. Chae, M. Ko, K. Kim, K. Ahn and J. Cho, Confronting issues of the practical implementation of Si anode in high-energy lithium-ion batteries. Joule 1 (2017) 47-60.

[3] X.H. Shen, R.J. Rui, Z.Y. Tian, D.P. Zhang, G.L. Cao and L. Shao, Development on silicon/carbon composite anode materials for lithium-ion battery. J. Chin. Cream. Soc. 45 (2017) 1530-1538.

[4] I. Choi, J.L. Min, S.M. Oh and J.J. Kim, Fading mechanisms of carbon-coated and disproportionated Si/SiOx negative electrode (Si/SiOx/C) in Li-ion secondary batteries: Dynamics and component analysis by TEM. Electrochim. Acta 85 (2012) 369-376.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.