-

iestinstrument

Electrical Conductivity and Compression Performance Evaluation of Single/Double-sided Electrode Sheets

1. Preface

This article comprehensively analyzes the single and double-sided electrode conductivity and compression properties of different active materials, which can effectively distinguish the performance differences of electrodes in different coating states, it provides an effective means to more precisely control the electrode in the design and manufacturing process of lithium-ion batteries to improve overall performance, and can also further promote the improvement of the overall electrical performance of the battery.

Lithium-ion batteries have become one of the leading energy storage solutions in the consumer, power and energy storage markets due to their long cycle life and high-rate performance. Currently, lithium-ion batteries still have challenges in reducing production costs and improving performance and durability. Therefore, it is of great significance to have an in-depth understanding of the impact of the production process on batteries and the assessment of special needs during the production process, future trends and directions depend not only on changes in lithium-ion battery materials, but also on production processes. As the core components of lithium-ion batteries, the preparation process of positive and negative electrode sheets, such as coating, rolling and other processes, is a key process to ensure that the lithium electrode sheets achieve the required compaction density and design capacity. To increase battery capacity, improve electrode conductivity and electrochemical performance, battery cell manufacturers usually use different coating and rolling processes for production. In-depth study and understanding of the evolution of the electrode microstructure during the coating and rolling processes, as well as the impact of process parameters on the final structure and performance of the electrode, it is conducive to more refined control of electrodes and improvement of overall performance, which is of great significance to the design and production control of lithium-ion batteries [1].

2. Experimental Instrument and Test Methods

2.1 Experimental Equipment

Test instrument model BER2500 (IEST), electrode diameter 14mm, applicable pressure range 5~60MPa. The equipment is shown in Figures 1(a) and 1(b).

Figure 1. (a) BER2500 appearance; (b) BER2500 structure diagram

2.2 Sample Preparation and Test

2.2.1 Sample Preparation

Prepare lithium cobalt oxide (LCO) and ternary material (NCM) material slurries with the same formula, at the same time, prepare graphite (GR) slurry, apply LCO and NCM slurry on aluminum foil, apply GR slurry on copper foil, and apply two sheets of each electrode. After the electrode is dry, select one of them and apply it on the reverse side to make a double-sided electrode. Single-sided and double-sided electrodes of three different active materials were thus obtained.

2.2.2 Sample Test

Combined with the BER2500 equipment independently developed by IEST, single-point mode, transformer mode and steady-state mode were used for testing, and the electrode resistance and compression performance of single and double-sided samples of the three materials were compared. The test process is as follows, single point mode: Under the pressure of 25MPa (positive electrode)/5MPa (negative electrode), select 6 points evenly on the electrode to apply pressure. After the pressure reaches the specified pressure, hold the pressure for 15 seconds; Variable pressure mode and steady state mode: Select a point on the electrode to apply pressure. When the pressure reaches 5MPa, hold the pressure for 15S. After the pressure holding is completed, the pressure is increased to the next pressure point. The pressure is maintained at an interval of 5MPa, test the electrode resistance and electrode thickness changes of 5-60MPa, and the test ends in the 60MPa transformer mode. After the variable pressure mode ends, gradually reduce the pressure at the same pressure interval (5MPa) and read the data at the corresponding pressure point for 15 seconds. When the pressure drops to 5MPa, the steady-state mode ends. During the test process, the software will record the electrode thickness and real-time resistance at the same time and output the data file.

3. Data Analysis

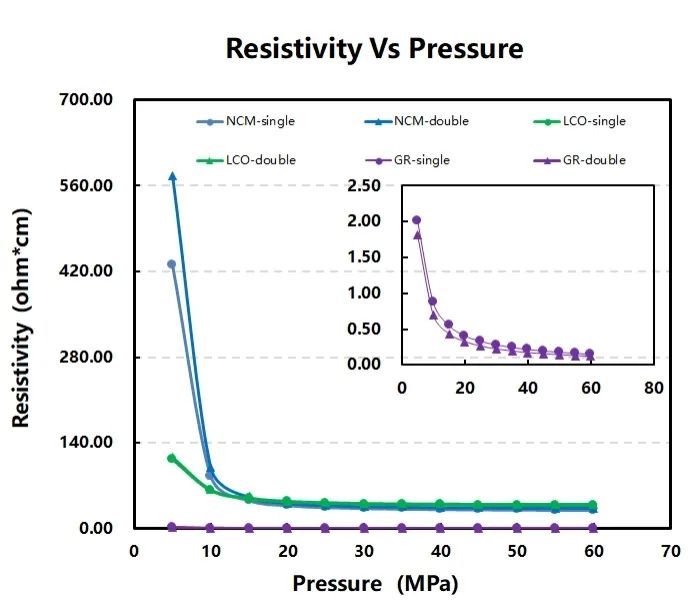

Conduct resistivity tests at different pressures on single and double-sided electrodes of three different active materials, as shown in Figure 2 (taking NCM as an example), the test results show that there is a difference in the resistivity of single-sided NCM and double-sided NCM under small pressure. As the test pressure increases, the resistivity of the two tends to be consistent. A similar trend can be observed in the resistivity test results of LCO and GR. Comparing the resistivity of single and double-sided electrode and the resistivity of double-sided electrode at the same pressure point, the resistivity of double-sided electrode under low pressure of LCO and NCM materials is slightly larger than that of single-sided electrode, and the resistivity is close to the same as the pressure increases, this trend is mainly due to the difference in contact resistance of the single and double-sided electrodes tested. The resistivity of GR samples at different pressure points is relatively consistent.

The results obtained by the traditional four-probe test method can only describe the resistance of the coating, because the direction of current transfer is parallel to the coating, the interface resistance between the substrate and the coating is ignored, and the coating gradient of the electrode is ignored, so the electrode resistance value cannot be fully characterized. In the test method we use, the electron conduction path is basically the same as that of the real battery electrode, and the Cu foil, Al foil and probe materials are all high electrode conductivity materials, so the bulk resistance of the positive electrode and probe accounts for a small part. However, the contact resistance between the probe and the coating cannot be ignored. For a single-sided electrode, the probe on one side is in direct contact with the positive electrode, for electrodes coated on both sides, the probe is in contact with the coating. This difference in contact results in a difference in resistivity. When the test pressure increases, the contact pressure between the probe and the coating or current collector is also greater, the proportion of contact resistance will decrease, and the resistivity difference between single and double-sided electrodes becomes smaller. Therefore, in the subsequent single-point mode, LCO and NCM were tested using a pressure of 25MPa, and GR was tested using a pressure of 5MPa.

Figure 2. Resistivity change curves of three single and double-sided electrodes

Figure 3(a), Figure 3(b), Figure 3(c) shows three groups of single- and double-sided electrodes with different active materials under the same pressure, six different locations were selected for testing to obtain resistance, resistivity, and electrode total thickness data. From the overall results, the resistivity COV of single-sided and double-sided electrodes of the same material at different test positions are not much different; However, comparing the three different materials, The COV of resistivity shows a trend of GR > LCO > NCM, which is related to the properties of the active material and the electrode microstructure, on the one hand, the resistivity of the material itself will affect the test COV. The smaller the resistivity, the greater the impact of contact resistance, which will affect the test results. The resistivity of the DR sample is very low, so the COV of the resistivity is larger. In addition, the softness and hardness of the material itself may also affect the test results. Under pressure, the interface contact of easily deformed materials may be closer, resulting in better test consistency. For both LCO and NCM samples, LCO is more difficult to deform (Figure 4), and the COV of resistivity is larger. The graphite sample was tested with a smaller pressure, which may also be a reason for the larger COV; On the other hand, it is related to the dispersion properties of the slurry during the slurry preparation process. The more uniform the slurry is dispersed, the smaller the resistivity COV of the single-sided or double-sided electrode. From Figure 3(a), the resistance of the three double-sided electrodes is approximately twice the resistance of the corresponding single-sided electrode, the sample thickness of the three double-sided electrodes is slightly less than twice that of the corresponding single-sided electrode (Figure 3(c)), therefore, the resistivity of single- and double-sided electrodes (Figure 3(b)) is not significantly different due to the thickness of the sample. Moreover, when tested under greater pressure, the contact pressure between the probe and the coating or current collector is also greater, and the proportion of probe contact resistance of single-sided and double-sided electrode is also relatively low, the difference in resistivity between single and double-sided electrodes is relatively small.

Figure 3. Consistency of three single and double-sided electrodes at different positions

The steady-state mode was used to conduct loading compression-unloading rebound tests on the electrode under different quantified pressure conditions, and the thickness changes were recorded. The thickness deformation was normalized and calculated based on the initial pressure point of 5MPa, the stress-strain curves of different electrodes are obtained (as shown in Figure 4), and their deformation conditions are summarized (as shown in Table 1).

Figure 4. Stress-strain (compression performance) curves of three single- and double-sided electrode.

Table 1. Summary of deformation conditions of three single- and double-sided electrodes

It can be seen from the result chart that the maximum deformation, reversible deformation and irreversible deformation trends of the single and double-sided electrode thickness of the three active materials are consistent, and the change in thickness of the double-sided electrode is not much different from that of the single-sided electrode, since the coating mainly deforms during the compression process compared to the metal material current collector, this difference between the single and double sides is only caused by the different proportions of the thickness of the current collector in the electrode, it shows that the compression performance of electrode is mainly determined by the properties of the active material.

4. Summary

This article uses BER2500 series electrode resistance testing equipment to test the conductive performance and compression performance of single-sided and double-sided coated NCM, LCO, and GR electrodes. It can effectively distinguish the performance differences of electrodes under different coating states, in the actual production process, the choice of the number of coating surfaces must be rationally selected based on the specific process formula. While increasing the battery capacity, it can also effectively improve the overall electrical performance of the battery. This electrode conductivity testing method can quickly study the impact of the process on the electrode resistivity, and even complete the test directly in the production line.

5. References

[1] Lu Zhaocai, Wang Yuxi, Wang Zhitao, Sun Xiaohui, Li Jingkang. Influence of heated calendering process on cathode film performance of lithium-ion batteries.[J]. Energy Storage Science and Technology.

[2] Zhang Caixia. Research on correlation of artificial graphite processing performance.[J]. Power Supply Technology, 2022, 46(11): 1256-1260.

[3] Song Lan, Xiong Ruoyu, Song Huaxiong, Tan Penghui, Zhang Yun, Zhou Huamin.Multiscale nonuniformity of lithium-ion batteries.[J]. Energy Storage Science and Technology, 2022, 11(02): 487-502.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.