-

iestinstrument

Electrode Fatigue Testing | Evaluation of Anode Electrode Recoverability

1. Background

Electrode flexibility can be categorized into recoverability (the ability to bend repeatedly) and bendability (the ability to bend once without fracturing). Electrode recoverability specifically focuses on the restoration capability and long-term stability of an electrode after undergoing deformation during multiple bending cycles. For evaluating recoverability, IEST Battery Electrode Flexibility Testing System (BEF1000) supports fatigue mode testing. This enables the measurement of stress-strain curve variations during multiple compression-recovery cycles, assessing the electrode’s ability to return to its initial state upon removal of the external force. This provides deeper insights into the electrode recoverability and overall flexibility.

2. Test Protocol

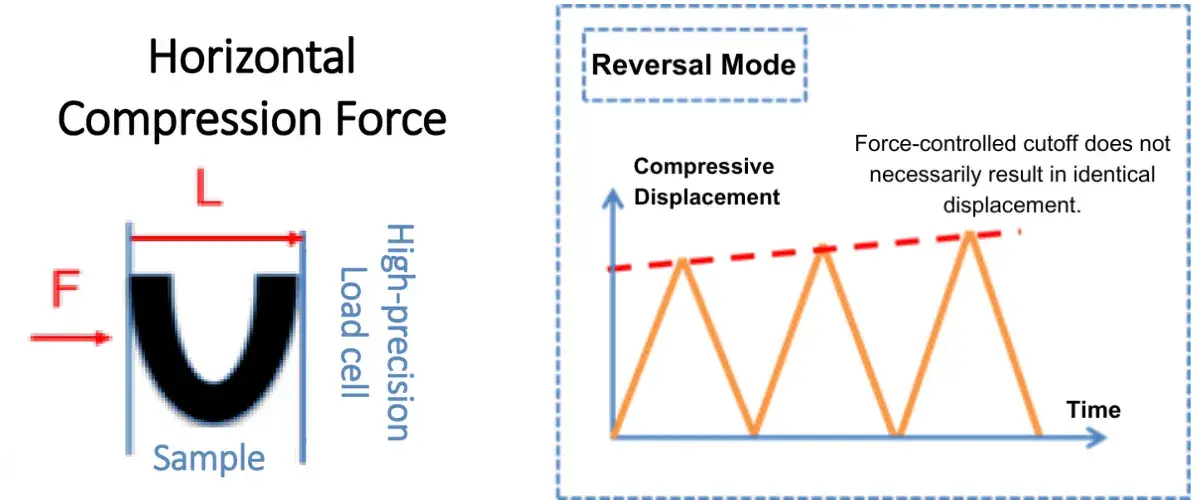

Based on the definition and application of electrode recoverability, this study selected two anode samples with different active materials: Anode 1 and Anode 2. Both anodes were cut into small rectangular specimens measuring 8 cm x 4 cm. Fatigue testing was performed by bending the long edge of each specimen to a specific angle and securing it within the test fixture (Figure 1). A total of 10 compression-recovery cycles were performed. In each cycle, compression proceeded to the same stress cut-off point, followed by recovery to the displacement zero point. The test employed transverse force application with a constant platen displacement rate of 0.5 mm/s.

Figure 1. Schematic Diagram of the Battery Electrode Flexibility Testing System Test Mode

3. Test Results

3.1 Cycle 1: First Compression-Recovery

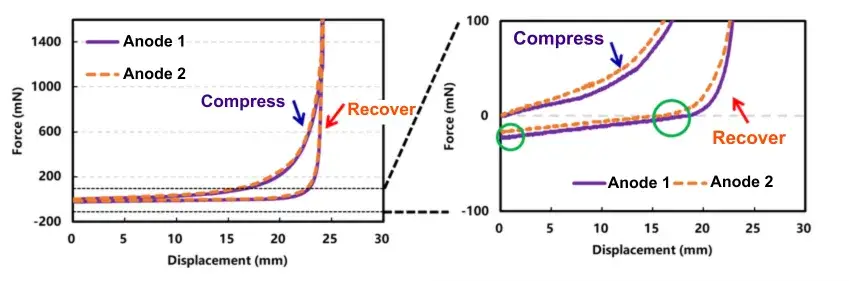

Figure 2. First Compression-Recovery Curves for Anode 1 and Anode 2 (Left) and Local Magnification (Right)

As shown in Figure 2, the first compression-recovery curves for Anode 1 and Anode 2 are very similar. Neither exhibited significant fracture behavior, and the area enclosed by their respective compression-recovery curves is also comparable, indicating no major difference in their fundamental mechanical properties. During compression, the material on the inner side of the bend undergoes compressive deformation. Comparing the initial segments of the compression curves, Anode 1 exhibits a slightly lower slope than Anode 2. In stress-strain curves, the slope typically correlates with the material’s elastic modulus, reflecting its resistance to elastic deformation. This suggests Anode 1 has a lower elastic modulus. However, elastic modulus alone does not directly determine flexibility. Flexibility is a broader concept encompassing both bendability and recoverability. It involves the material’s ability to deform under external force and return to its original shape (recoverability), as well as its capacity to withstand significant deformation without fracturing (bendability). Flexibility is closely related to elastic deformation, plastic deformation, fracture behavior, etc., reflecting the electrode’s adaptability, toughness, and ability to maintain structural integrity during deformation.

Further analysis of curve details reveals:

-

Residual Strain at Zero Stress (Initial Stress Zeroed): At the point where the stress recovers to the initial value (zero, initial stress zeroed), the corresponding displacement value is larger for Anode 1 than for Anode 2. This indicates that to return to the initial stress state, Anode 1 requires greater deformation (displacement). In other words, Anode 1 retains a larger deformation after the external force is removed. This deformation primarily consists of plastic deformation occurring after the material yields, which cannot be recovered upon force release.

-

Residual Stress at Zero Displacement (Initial Displacement Zeroed): At the point where the displacement recovers to the initial value (zero, initial displacement zeroed), the corresponding stress value is smaller for Anode 1 than for Anode 2. This indicates that when returning to the initial displacement state, Anode 2 maintains a larger tension (stress), closer to its initial state.

These observations suggest Anode 2 exhibits better flexibility characteristics.

3.2 Cycle 10: 1st to 10th Compression and Recovery

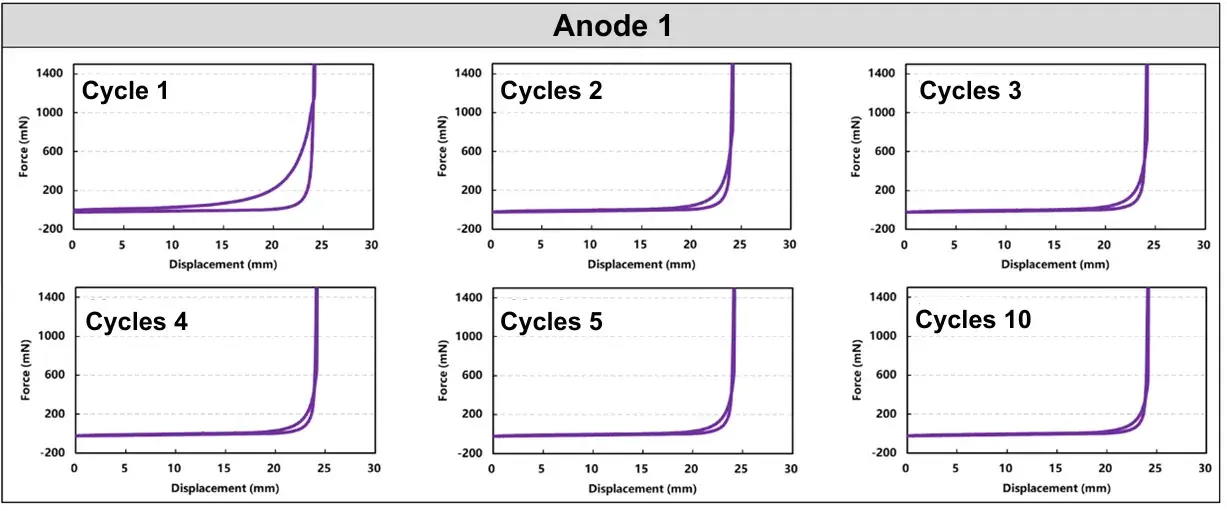

Figure 3. Compression-Recovery Curves for Cycles 1-5 and 10 (Anode 1)

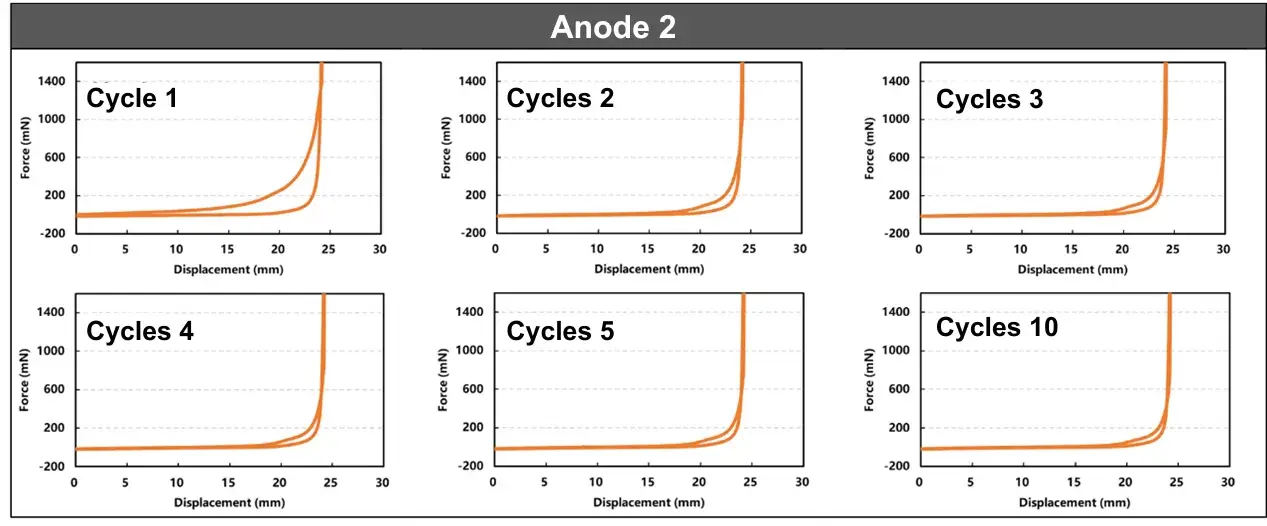

Figure 4. Compression-Recovery Curves for Cycles 1-5 and 10 (Anode 2)

Evaluating electrode recoverability through cyclic compression-recovery curves is an effective method. It quantifies the electrode’s mechanical behavior during repeated compression-recovery, revealing the strength of its flexibility. As shown in Figures 3 and 4, both anodes were subjected to 10 compression-recovery cycles (curves for cycles 6-9 are omitted). It is evident that both anodes experienced fatigue damage or performance degradation after the first cycle. Cycles 2-10 remained relatively stable, with no significant differences or changes observed in the curves.

Following the analytical approach described earlier, we analyzed the residual strain at zero stress and the residual stress at zero displacement for each cycle.

-

Residual Strain: Reflects the extent of deformation the electrode cannot recover after undergoing compression. Smaller residual strain indicates better recoverability, meaning a stronger ability to restore the original shape.

-

Residual Stress: Represents the stress state retained by the electrode after recovery. Residual stress closer to the initial stress value (zero) indicates the electrode can more effectively return to its original state after compressive deformation, also signifying better recoverability.

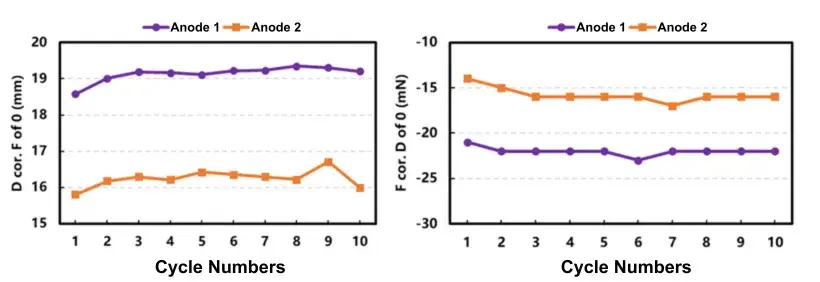

Figure 5. Residual Strain (Left) and Residual Stress (Right) vs. Cycle Number for Anode 1 and Anode 2

Figure 5 clearly shows that the compression-recovery curves for Anode 2 exhibit smaller residual strain across cycles 1-10 compared to Anode 1. Furthermore, Anode 2’s residual stress is closer to the initial stress value (zero). The fatigue test provides a more intuitive and compelling demonstration that Anode 2 possesses superior elastic recovery capability and stress relaxation ability, consequently exhibiting better flexibility.

4. Summary

In the process of evaluating electrode flexibility, fatigue testing, specifically the analysis of multiple cyclic compression-recovery curves, proves to be a highly intuitive and effective method. This approach not only aids in understanding the behavioral patterns of electrodes under repeated mechanical stress but also quantifies their recovery capability during cyclic compression and recovery. This provides a more comprehensive assessment of the relative merits of electrode recoverability and overall electrode flexibility.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.