-

iestinstrument

Analysis of Five Critical Impacts of Electrode Flexibility on Battery Performance

1. Introduction

The performance of modern energy storage, from electric vehicles to smart devices, hinges on lithium-ion batteries. At the heart of these batteries lies the electrode, whose electrode flexibility is a critical factor influencing both cycle life and safety. Brittle electrodes can crack and pulverize during charge-discharge cycles, leading to rapid capacity fade and potential safety hazards. How can electrode sheets achieve both strength and pliability? This article unveils the technical key behind battery performance: electrode flexibility, and deciphers IEST Instrument advanced testing solutions.

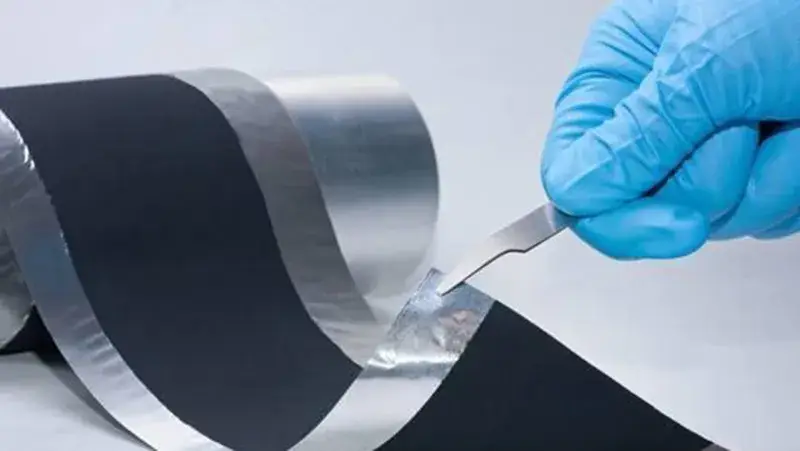

Figure 1. Lithium Battery Electrode Sheet

2. Electrode Flexibility: The Hidden Arbiter of Battery Performance

2.1 A Determinant of Cycle Life

-

Stress Fluctuations During Cycling: During charge/discharge, electrode materials undergo repeated expansion and contraction (e.g., volume changes in cathode materials like NCM and LFP during Li-ion intercalation/deintercalation). Poor electrode flexibility increases susceptibility to crack initiation and fracture under cyclic stress (Figure 1), degrading electrical contact between the active material and current collector. This elevates internal resistance (IR), ultimately shortening cycle life and potentially triggering safety incidents.

-

Powdering Issue: Electrodes with inadequate flexibility are prone to powdering during cycling, causing active material detachment from the current collector and accelerating performance degradation.

Figure 2. Fractured Battery Electrode Sheet Post-Cycling

2.2 A Critical Factor in Manufacturing Yield

-

Slitting and Winding Processes: Electrode sheets undergo demanding processes like slitting, calendering, winding, or stacking. Electrodes with insufficient flexibility can develop burrs, micro-cracks, or breaks during these steps, reducing production yield and increasing costs.

-

Electrode-Separator Interface: flexible electrode sheets conform better to the separator, minimizing gaps within the cell stack. This improves both energy density and cell-to-cell consistency.

2.3 An Indicator of Electrical Performance

-

Internal Resistance & Power Performance: Brittle electrodes readily develop cracks during cycling, increasing contact resistance at the active material/current collector interface. This raises the cell’s overall IR, degrading power performance.

-

Energy Density: While increasing areal density boosts energy density, insufficient flexibility can cause electrode failure during cycling, paradoxically reducing the practical usable energy density.

2.4 A Key Consideration in Design Trade-offs

-

Electrode Thickness Design: High-energy-density designs often require thicker electrodes with higher areal loadings, which can compromise flexibility. Engineers must therefore balance energy density with mechanical robustness, ensuring the electrode possesses sufficient strength and electrode flexibility for its intended use.

-

Material Selection: Flexibility is intrinsically linked to the ratios of binder, conductive additive, and active material. Optimizing formulations and selecting high-performance binders can enhance flexibility without sacrificing energy density.

2.5 A Requirement for Diverse Applications

-

Power Batteries: Electric vehicles encounter complex road conditions (vibration, impacts) imposing mechanical stress on battery packs, potentially causing safety incidents (Figure 3). Flexible electrodes can better absorb this mechanical energy, reducing the risk of damage and enhancing both safety and longevity.

-

Flexible Batteries: Emerging fields like wearables and flexible electronics demand batteries capable of conforming to device deformation. Here, superior electrode flexibility is not just an advantage but a fundamental requirement.

Figure 3. Thermal Runaway Following Impact Damage to EV Underbody

3. How is Electrode Flexibility Measured?

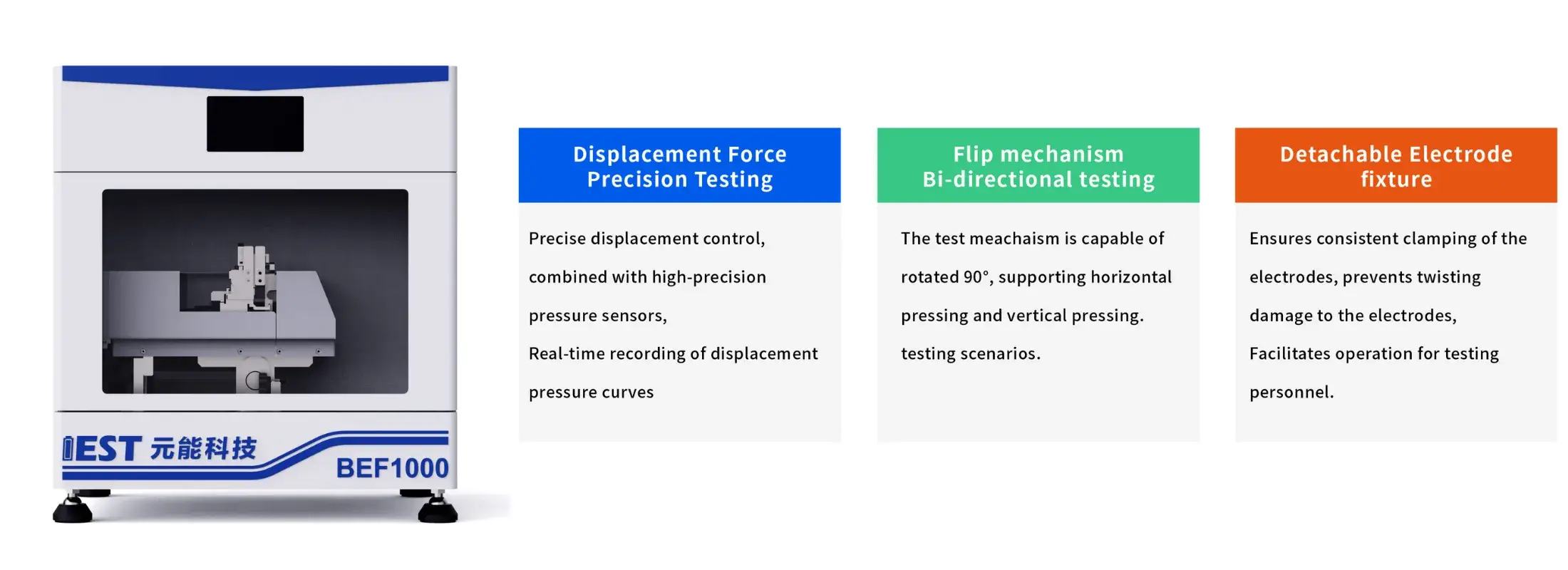

Quantifying electrode flexibility requires a reliable, standardized test. The IEST Battery Electrode Flexibility Testing System(BEF1000) provides a solution based on fundamental stress-strain analysis.

In this method, an electrode strip is bent to a specific angle and secured in a fixture. A controlled displacement is then applied to deform the sample further, while the resulting force is measured. This generates a force-displacement (or stress-strain) curve that characterizes the electrode’s mechanical behavior.

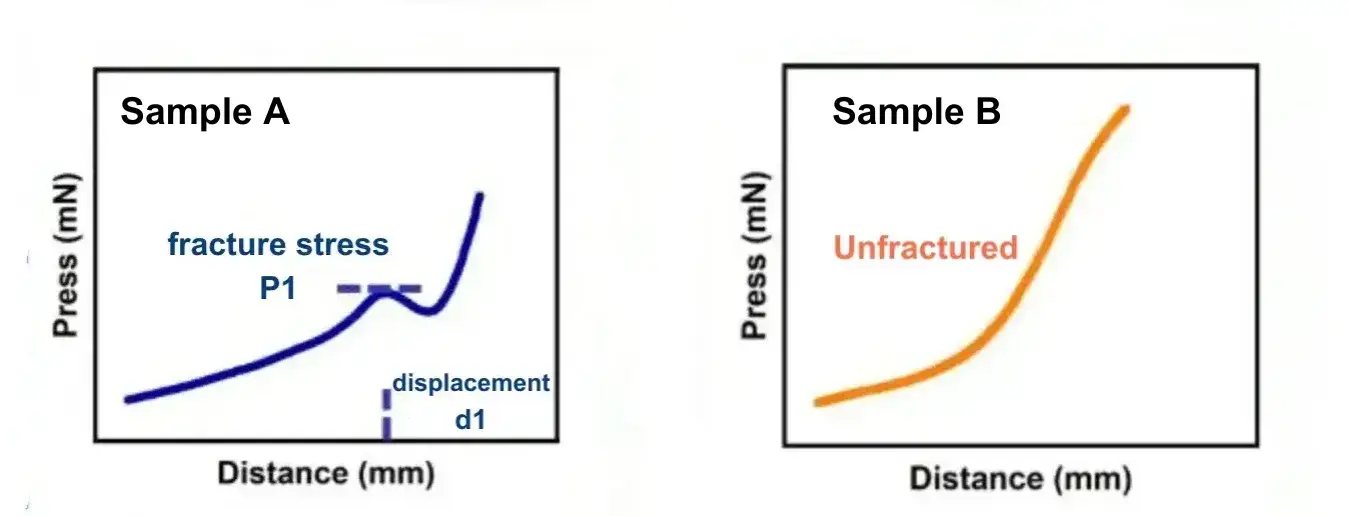

As shown in Figure 3B, a high-quality, flexible electrode (Sample B) produces a smooth, continuous curve. A poor-quality, brittle electrode (Sample A) exhibits a sharp drop or discontinuity, indicating fracture. The difference is clear and quantifiable.

For detailed case studies on electrode flexibility testing, please refer to the article: Novel Battery Electrode Testing Solution | Electrode Flexibility Tester BEF1000

Figure 4.IEST Battery Electrode Flexibility Testing System (BEF1000) Equipment

Figure 5. Flexibility test data for two electrode samples, showing the distinct curve of a brittle sample (A) versus a flexible one (B).

4. Conclusion

Electrode flexibility is a non-negotiable property for high-performance, safe, and durable lithium-ion batteries. It influences decisions from material formulation and process optimization to lab testing and production control. IEST Instrument innovative testing instrumentation provides the industry with a precise “flexibility scale,” supporting the development of next-generation batteries that are both energy-dense and mechanically robust.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.