-

iestinstrument

A Guide to Scientifically Evaluating Electrode Flexibility for Lithium-Ion Batteries

1. Introduction

In battery research and development, electrode flexibility is a critical performance indicator. It acts like the “skeletal resilience” of a battery, requiring sufficient strength to support volume changes during charge/discharge cycles, along with good ductility to withstand repeated mechanical stresses. Numerous methods exist for assessing electrode flexibility. Different manufacturers may adopt various approaches based on product specifics and testing needs, such as manual folding over a roller to check light transmission, wrapping around a needle to observe active material shedding, or three-point bending tests. However, these manual methods often suffer from significant test errors, poor consistency, and yield limited information.

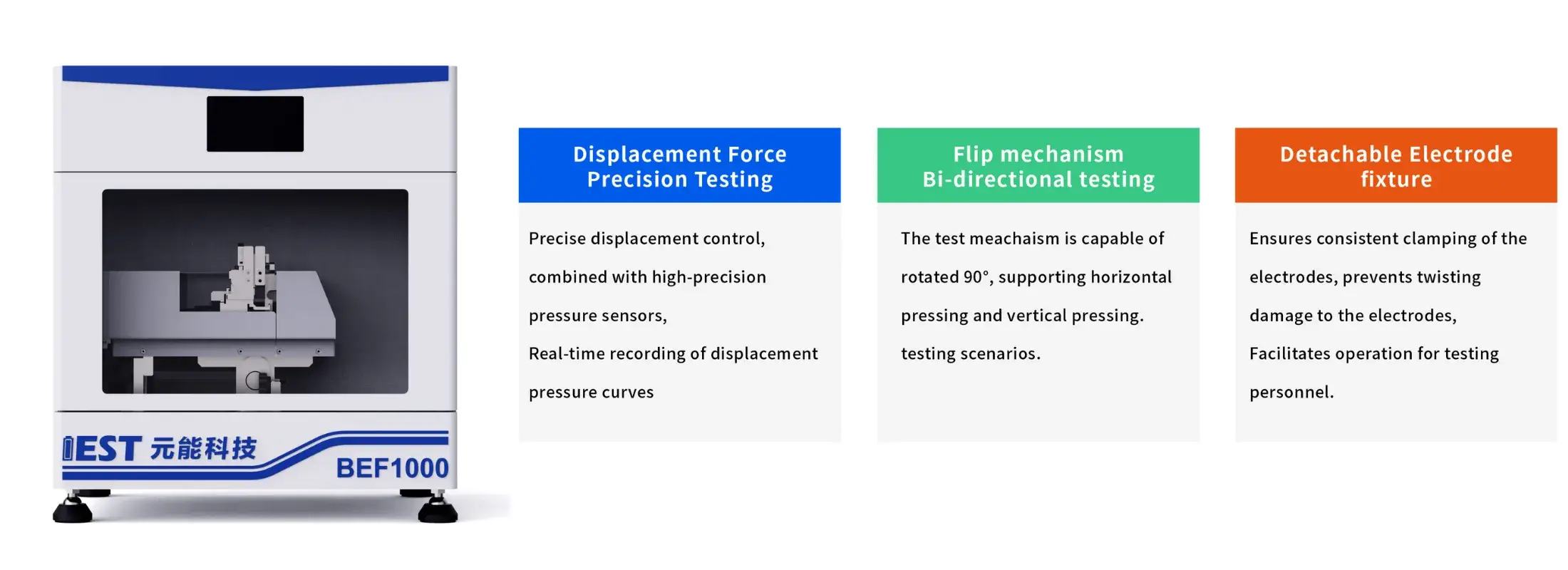

IEST Electrode Flexibility Testing System(BEF1000) employs a different methodology. This device clamps the electrode strip and bends it at a specific angle within a fixture. A controlled displacement is then applied to deform the electrode, and the resulting force-displacement curve is measured. By analyzing this force-displacement relationship, the electrode flexibility of different samples can be precisely quantified and compared. Notably, cathode and anode materials exhibit substantially different mechanical behaviors, typically necessitating distinct testing and analysis strategies:

-

Cathode: Evaluated for bendability via single-cycle compression.

-

Anode: Evaluated for recoverability via cyclic testing.

Figure 1. IEST Battery Electrode Flexibility Testing System (BEF1000) Equipment

2. Cathode Electrode Flexibility Testing: Identifying the “Critical Point” in Single-Cycle Bending

Cathode electrodes are generally more brittle, often exhibiting coating cracking during testing. Therefore, a single-cycle, constant-speed test mode is typically employed. The resulting force-displacement curve is analyzed to evaluate the cathode’s bendability, a key aspect of its flexibility.

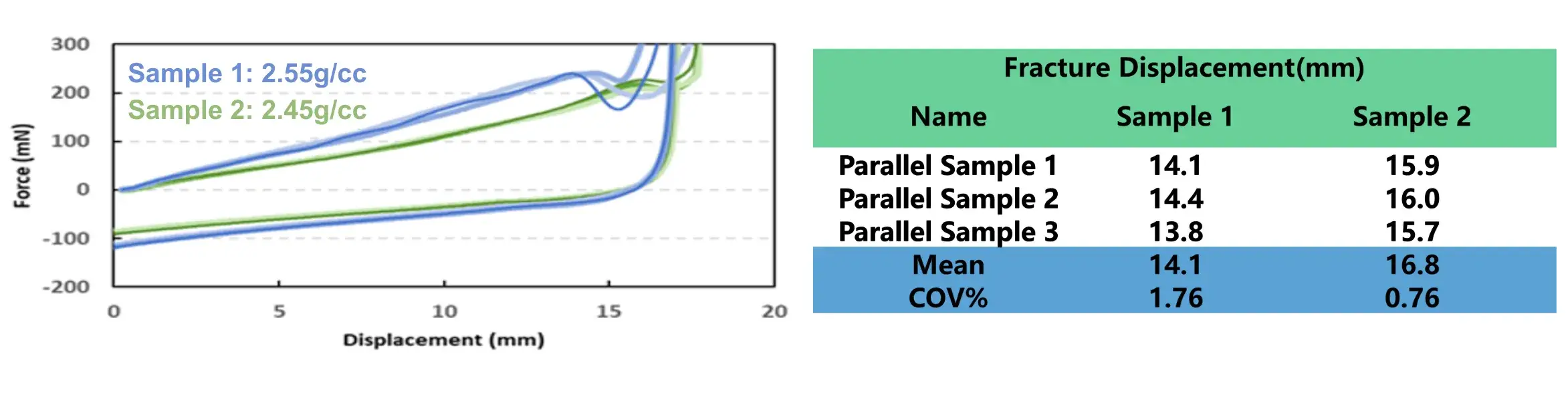

Figure 2 shows test data for two LFP cathodes with different compaction densities. Both curves exhibit a sudden drop or inflection point, indicating a release of stress. This stress release primarily originates from cracking within the electrode coating. Generally, a shorter displacement to fracture indicates poorer bendability and, consequently, inferior flexibility.

Figure 2. Force-Displacement Curves for Cathodes with Different Compaction Densities

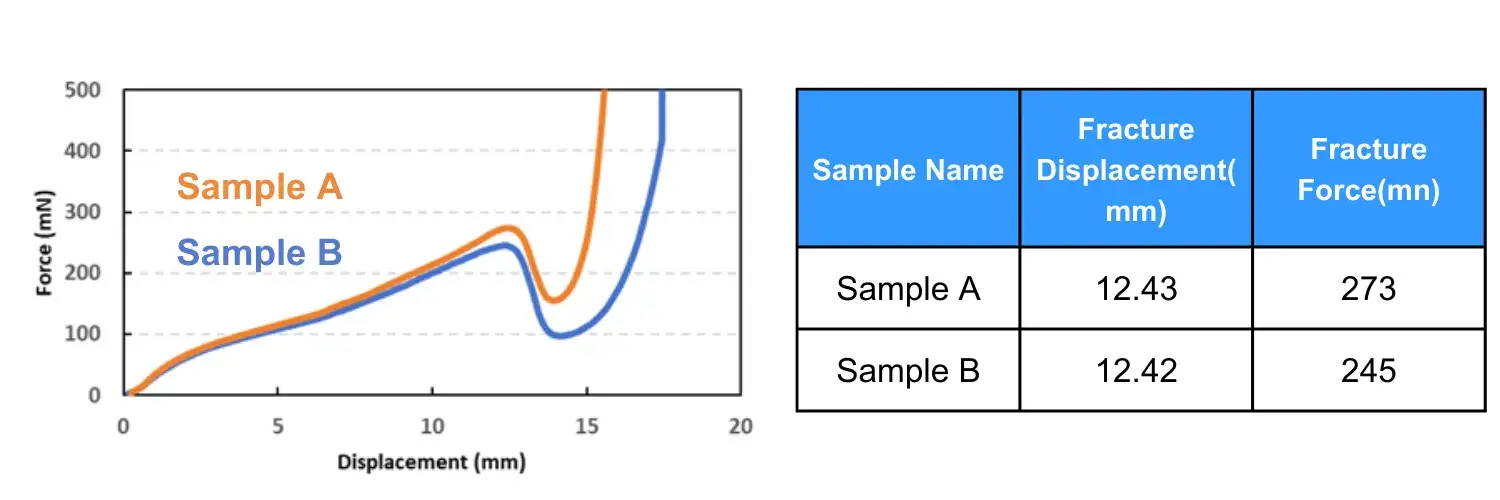

When the fracture displacements of two samples are similar, how can we further differentiate them? Parameters like fracture force and curve slope become crucial. As shown in Figure 3, under the same applied displacement, a higher measured force indicates greater resistance to bending deformation—meaning the electrode is “stiffer.” But does a stiffer electrode automatically mean worse flexibility? Stiffness reflects a material’s resistance to localized deformation, while flexibility describes its ability to deform before fracture. These properties are governed by different factors and may not always trend together. Typically, electrode stiffness and flexibility show a negative correlation. A stiffer electrode (e.g., due to high active material content, high compaction density, low or inherently stiff binder content) often tends to be more brittle, cracking or shedding more easily during bending, winding, or impact. However, the strength and direction of this correlation are complex, influenced by a combination of factors including binder properties, active material, conductive additives, compaction density, porosity, and microstructure.

Figure 3. Force-Displacement Curves for Sample A and Sample B

3. Anode Electrode Flexibility Testing: Assessing “Fatigue” and Recoverability Through Cycling

Compared to cathodes, anode electrodes are typically softer and may not show obvious coating cracking during a single bending test. Thus, analysis focuses on a different dimension: the electrode’s recoverability (its ability to return to its original shape after the removal of an external force).

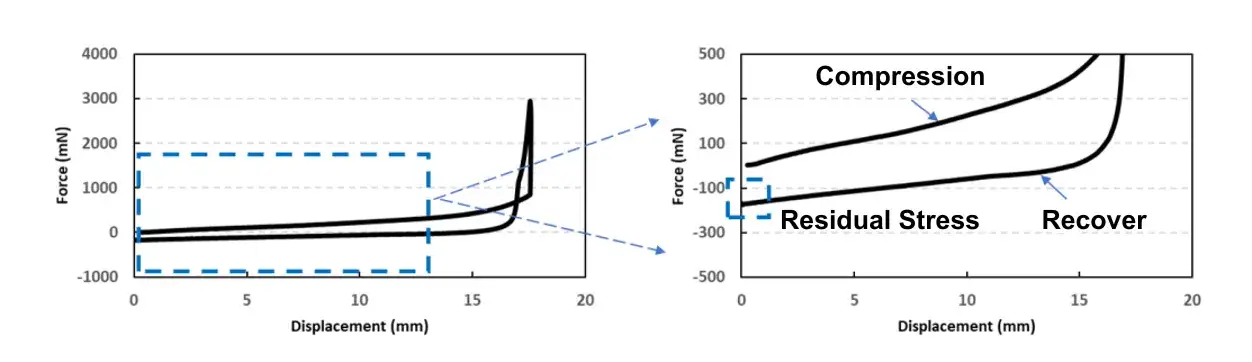

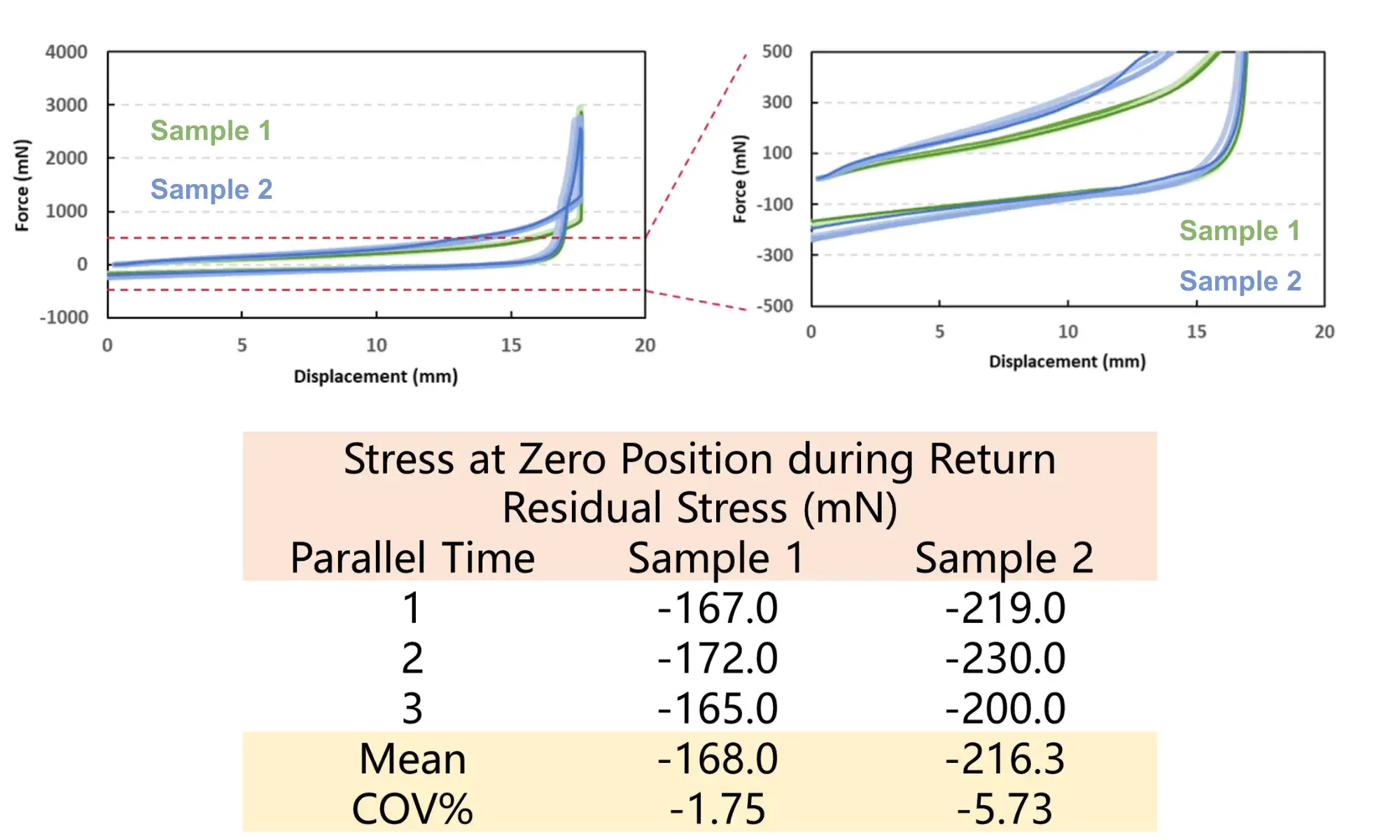

The BEF1000 device can perform cyclic (to-and-fro) bending tests. The “residual stress” measured upon returning to the starting point serves as a key metric for evaluating recoverability. The origin of this residual stress is as follows: the force sensor is zeroed before the test begins. During the cyclic bending, energy is dissipated due to irreversible deformation within the electrode structure. Consequently, when the probe returns to its initial position, the force measured deviates from zero. This non-zero force value is termed the “residual stress.” A larger absolute value of residual stress indicates greater energy loss (more irreversible damage) during cycling, signifying poorer recoverability and thus inferior flexibility.

Figure 4. Schematic of Residual Stress Analysis

Figure 5 shows data for two anode electrodes containing different binders. Reciprocating tests yielded their residual stresses. The results indicate that Sample 1 exhibited a residual stress closer to the initial value (zero) after one reciprocating cycle. This suggests less irreversible damage occurred during testing, indicating superior recoverability and, consequently, better flexibility for Sample 1. Furthermore, the IEST BEF1000 can perform multi-cycle reciprocating tests to observe electrode fatigue results, please check article: Electrode Fatigue Testing | Evaluation of Anode Electrode Recoverability

Figure 5. Reciprocating Test Results for Two Anode Electrodes

4. Summary

Based on the force-displacement curve characteristics and the physical state of the electrode during testing, the optimal testing mode and analysis method can be selected. Although electrode flexibility resides hidden within the battery, it constitutes a critical “invisible battlefield” determining product competitiveness. Through scientific testing methodologies and insightful data analysis, we empower each electrode with enhanced resilience – enabling batteries not only to “travel farther” but also to “endure longer”.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.