-

iestinstrument

Lithium Metal Batteries With Zero Volume Expansion Composite Anode For High Energy Density and Stability

1. Author information and article abstract

2022, Yonghong Deng’s group at SUSTech, in collaboration with Prof. Zijian Zheng’s team at the Hong Kong Polytechnic University (first author: Chao Luo, a PhD student at SUSTech), developed a roll-to-roll approach to prepare a lithium composite anode with zero volume expansion, which can significantly enhance the energy density and bendable mechanical properties of lithium metal batteries. The anode has a sandwich structure: it includes an electronically insulating layer at the top, a lithium-friendly layer at the bottom, and a volume-expansion-absorbing porous layer in the middle. The authors further verified the excellent flexibility, energy density, and cycle retention of this lithium metal batteries by pairing it with an NCM and LCO anode.

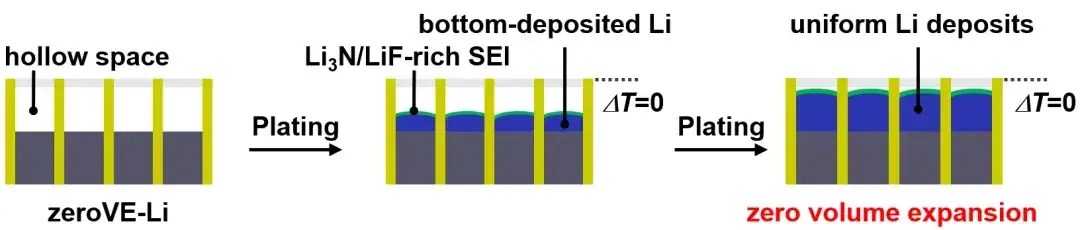

Figure 1. Schematic diagram of lithium intercalation of zero volume expansion anode

2. Test Plan

- Construct lithium composite anode and lithium metal batteries.

- Structural characterization: morphology characterization FE-SEM, surface chemical structure XPS, swelling behavior SWE2100 (IEST).

- Electrochemical performance characterization: cycle performance of deduction and soft pack.

- Mechanical performance characterization: bending performance of electrodes and pouch cells.

3. Result Analysis

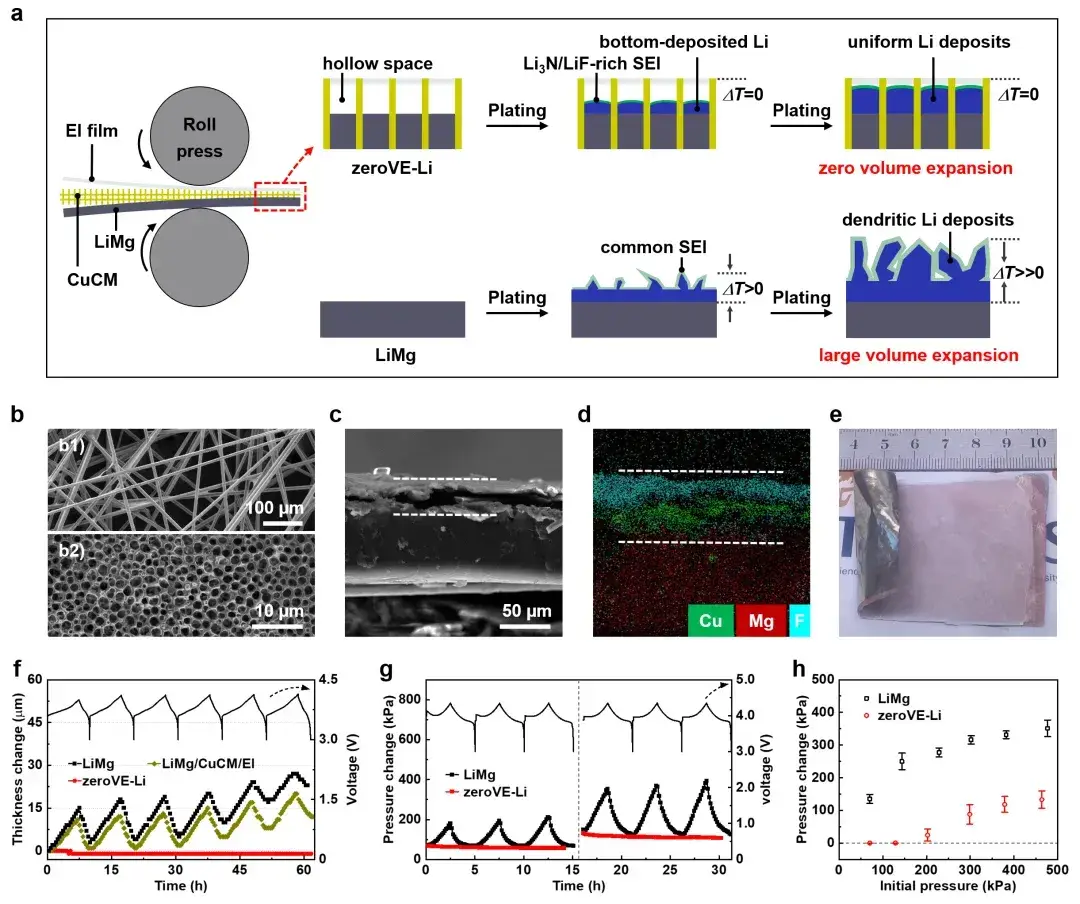

Figure 2. Design principle and volume expansion behavior of Li metal anode with zero volume expansion

The authors prepared a hollow composite lithium metal anode by using an electronically insulating porous film (EI film) combined with a Cu-coated carbon fiber matrix (CuCM) and an ultra-thin LiMg alloy sheet through a rolling process. The morphology of the composite material was observed by SEM and element mapping, which confirmed the successful preparation of the sandwich-structured lithium composite anode. In order to prove the zero volume expansion property of the composite, the authors assembled a Li-to-NCM811 single-layer battery, using the in-situ expansion thickness and expansion force test methods, it can be clearly compared that the zeroVE-Li anode has almost no thickness during the charge-discharge cycle. Or the expansion of stress, demonstrating the excellent resistance to expansion of the composite.

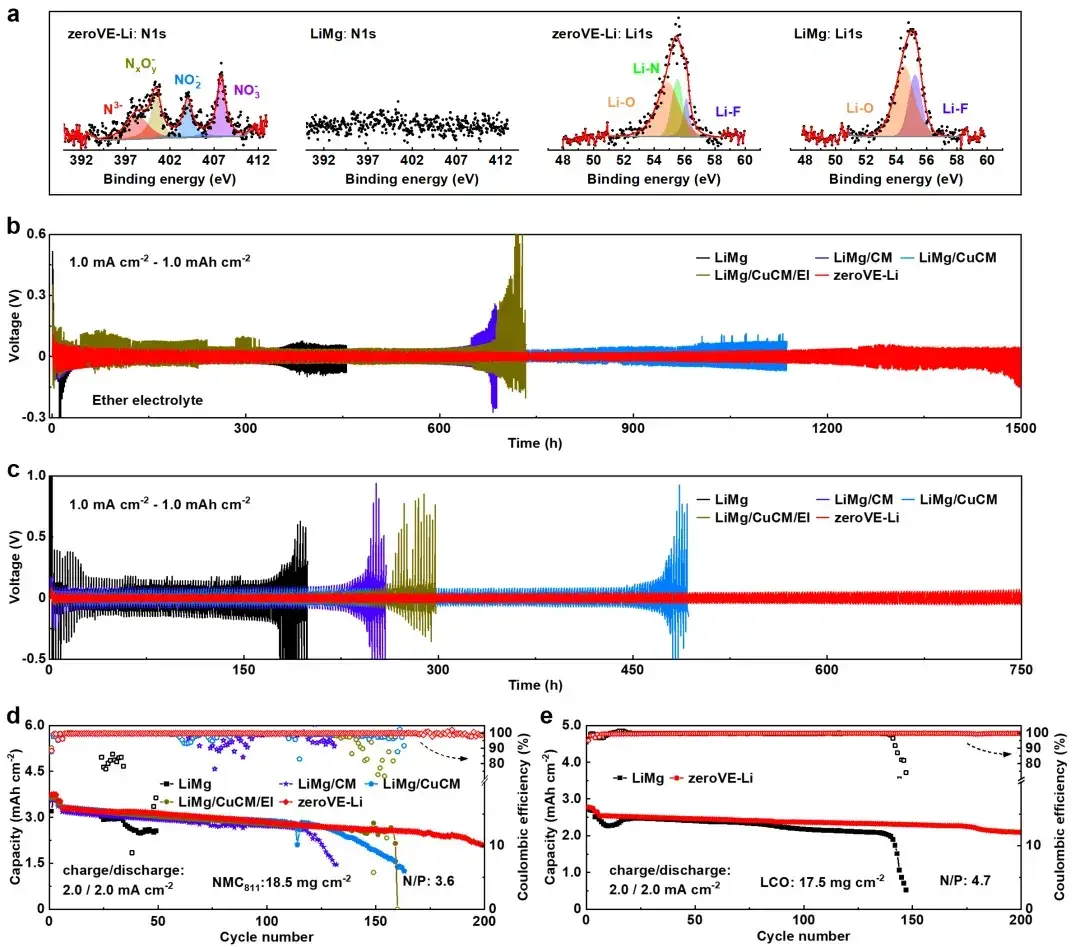

Figure 3. SEI and cycle stability analysis of the lithium metal anode with zero volume expansion

The change of the lithium metal interface brought by the upper insulating functional layer in the new lithium metal anode was characterized by XPS, which proved that the SEI contains the inorganic layers Li3N and LiF with the best inhibition effect on lithium dendrites. And by assembling two kinds of batteries whose positive electrodes are NCM811 and LCO respectively, it can be clearly compared that the cell has the highest cycle capacity retention rate when zeroVE-Li is used as the negative electrode.

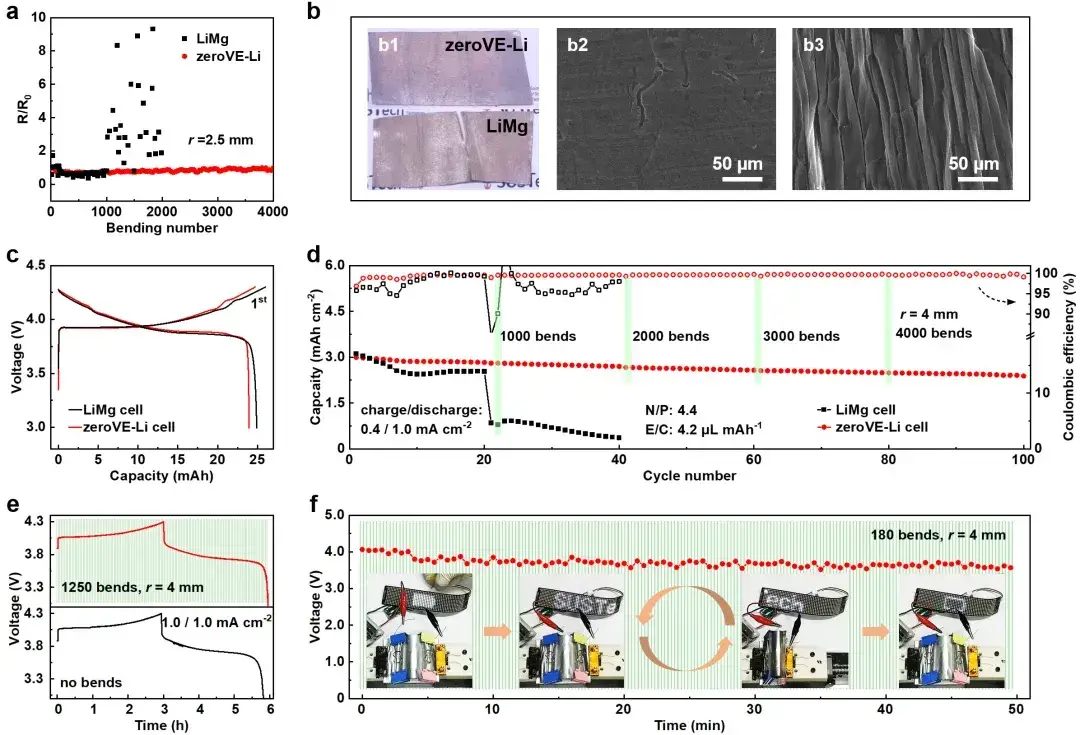

Figure 4. Electrochemical and mechanical stability of single-layer lithium metal batteries

Through dynamic bending and resistance test, the author found that after 4000 bending experiments, the resistance and morphology of zeroVE Li did not change significantly, showing excellent flexibility. The zeroVE Li electrode was matched with a high surface loaded flexible positive electrode to assemble a flexible battery. From the aspects of electrochemical cycle stability and mechanical stability, the zero volume expansion negative electrode showed high coulomb efficiency, high cycle capacity retention rate and good bendability.

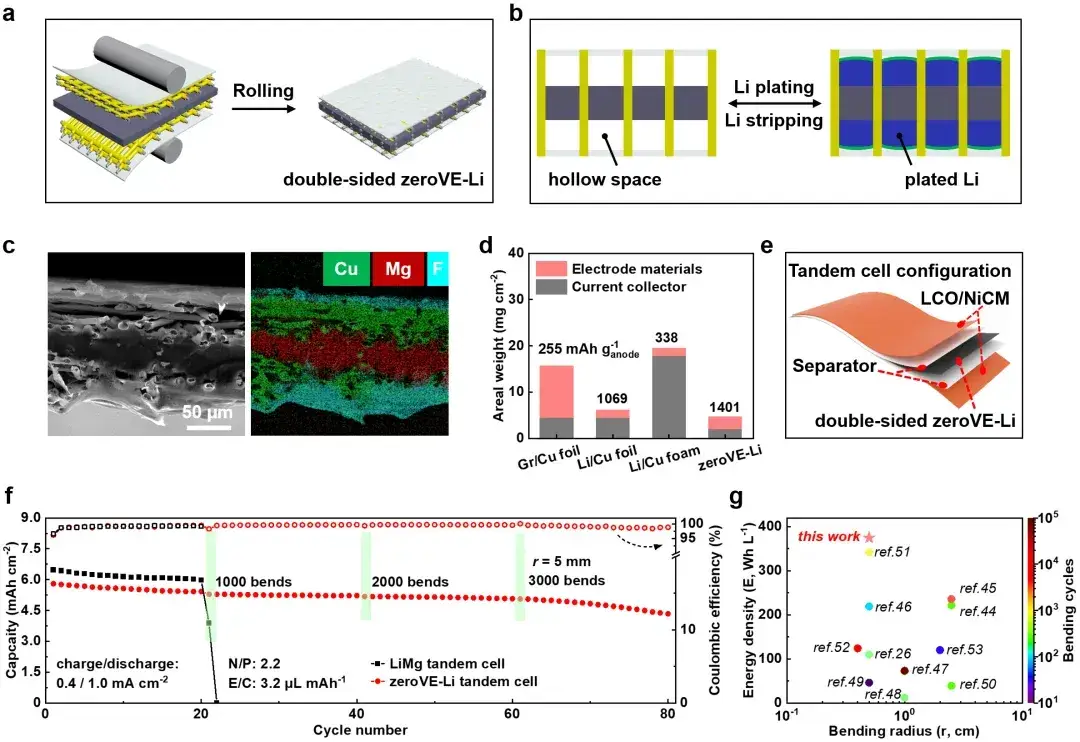

Figure 5. Electrochemical and mechanical stability of multilayer lithium metal batteries

The author continues to prepare double-sided zero volume expansion anode and finds that it has higher mass specific capacity than commercial anode materials. The assembled multilayer flexible lithium metal battery has high weight energy density and volume energy density, and can still maintain 75% capacity retention after 3000 cycles of bending test. By comparing the energy density values of flexible lithium based batteries in other relevant documents, the flexible lithium metal batteries developed in this work based on zero volume expansion lithium composite anode has a very high surface energy density (22.7 mWh cm-2), a practical volume energy density (375 Wh L-1, based on the volume of positive and negative electrodes, diaphragms and packaging materials) and a record flexible quality factor (FOM, 45.6).

4. Summary

In this paper, a roll-to-roll method was developed to synthesize a lithium composite anode with zero volume swelling, which has excellent electrochemical performance and mechanical flexibility, and can significantly improve the energy density of lithium metal batteries. The negative electrode has a sandwich structure: it includes an electronic insulating layer on the top, a lithiophilic layer on the bottom, and a porous layer in the middle that absorbs volume expansion. By matching NCM and LCO anode electrodes, the author further verified the excellent flexibility of the corresponding flexible lithium metal batteries, properties such as energy density and cycle retention. The zero volume expansion design provides a new idea for the practical application of lithium metal batteries. The roll-to-roll manufacturing process also shows its potential for large-scale production. In principle, this zero volume expansion design is also applicable to construct other metal battery anodes (such as sodium, potassium, and zinc metal batteries, etc.) to improve energy density, cycling, and structural stability.

5. Original Literature

Chao Luo, Hong Hu, Tian Zhang, Shujing Wen, Ruo Wang, Yanan An, Shang-Sen Chi, Jun Wang, Chaoyang Wang, Jian Chang*, Zijian Zheng*, and Yonghong Deng*. Roll-to-roll Fabrication of Zero-Volume-Expansion Lithium Composite Anodes to Realize High-Energy-Density Flexible and Stable Lithium Metal Batteries. [Advanced Materials]

6. Recommendation of Test Equipment Related to IEST

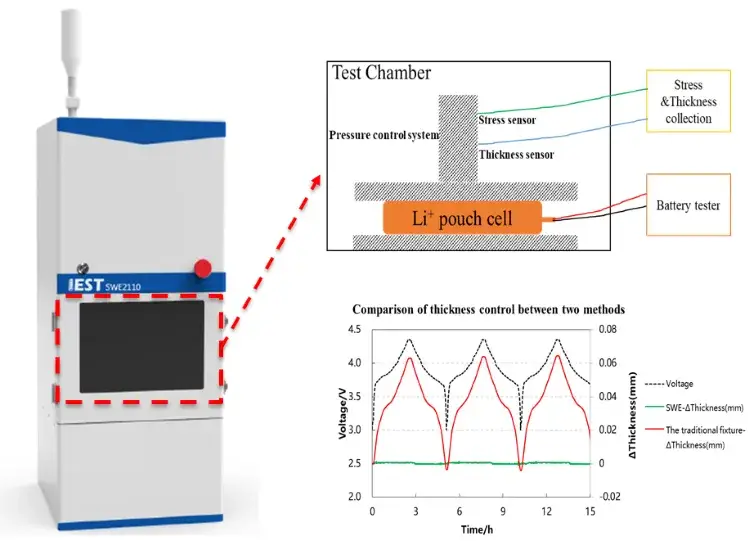

SWE series in-situ swelling system (IEST): using a highly stable and reliable automation platform, equipped with high-precision thickness measurement sensors, it can measure the thickness change and change rate of the entire charge discharge process of the electric core, and can achieve the following functions:

1.Test the battery expansion thickness curve under constant pressure.

2.Test the battery expansion force curve under the condition of constant gap.

3.Battery compression performance test: stress-strain curve compression modulus.d

4.Step by step test of battery expansion force.

5.Different temperature control: – 20~80 ℃.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.