-

iestinstrument

What Sulfide Solid-state Battery Expansion Looks Like?

1. Preface

In this paper, IEST has tested the expansion behavior of sulfide solid-state battery during charging and discharging by using a Solid Electrolyte Test System(SEMS) and a In-Situ Silicon-Based Anode Swelling Rapid Screening System(RSS).

Currently the performance of liquid batteries has met most of the needs of our daily use, but the development of liquid batteries in terms of material systems and process technology is also close to the limit. More and more researchers are turning their research efforts to the ultimate goal of lithium batteries: all-solid-state batteries. Solid-state electrolyte has good mechanical properties, the use of solid-state electrolyte to replace the original electrolyte and separator, which can effectively prevent the lithium dendrite caused by the cathode and anode short-circuit problem[1]. At the same time, the solid-state electrolyte is chemically and thermally stable, which can effectively avoid the safety problems at high temperatures[2]. Starting from 2023, the state began to strongly support solid-state battery research and development in policy[3], driven by policy and the unremitting efforts of researchers, the solid-state battery industry has been rapidly developed.

In the solid state battery system, there are currently three main technology routes: oxide, polymer and sulfide/halide. In the sulfide/halide system of solid-state batteries, the cathode electrode layer, anode electrode layer, electrolyte layer are all prepared using solid powder, and pressurized molding under high pressure conditions[4], the contact between particles and particles belongs to hard contact. The expansion and contraction of the particles during the charging and discharging process leads to a more serious volume change behavior in the actual charging and discharging process of solid-state batteries than that of liquid batteries. However, less research has been done in this area.

2. Experimental Sample

Sample: Sulfide full battery.

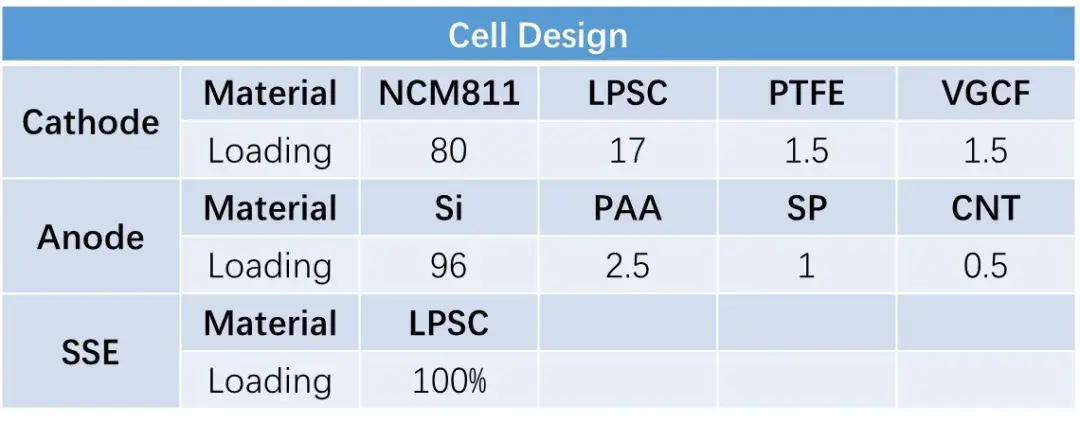

The specific formula ratio is shown in the table below. The cathode electrode is prepared into a electrode by a dry process, and the anode electrode is prepared into a electrode by a wet process. The solid electrolyte is directly pressed from powder into a sheet.

Table 1. Battery Formulation Ratios

3. Experimental Instruments

Figure 1. IEST Solid Electrolyte Test System(SEMS)

Figure 2. In-Situ Silicon-Based Anode Swelling Rapid Screening System(RSS)

3. Battery Assembly Process

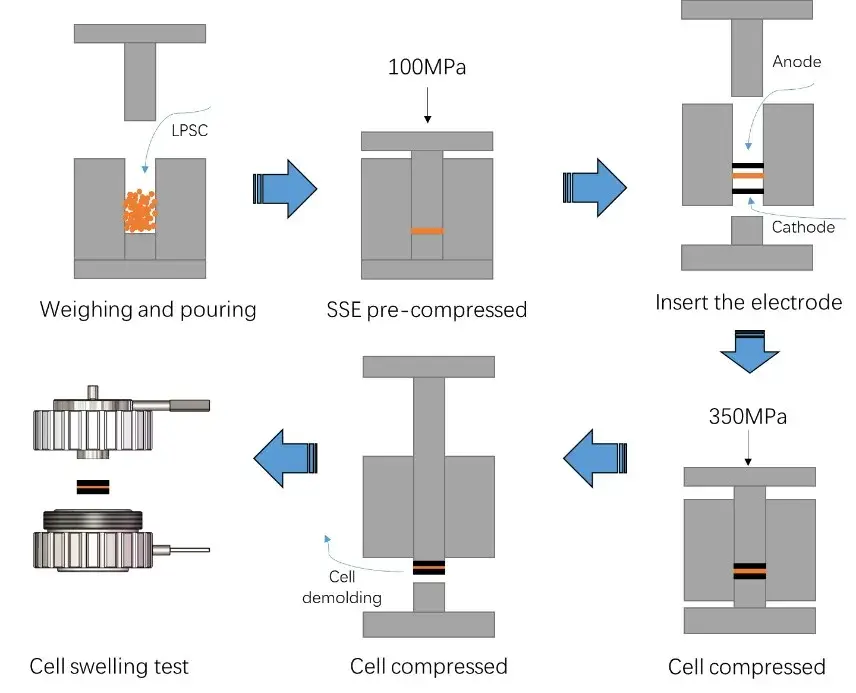

3.1 Electrolyte layer pre-compression

First, a certain mass of LPSC solid electrolyte was weighed inside the glove box and added into a mold with a diameter of 13mm. Then, after transferring the mold to the outside of the glove box, SEMS was used to pre-pressurize the powder at 100MPa (holding pressure for 60s) to make the LPSC powder into flakes. The mold was then moved back into the glove box. Inside the glove box, the solid electrolyte upper and lower indenters were withdrawn to check the state of the solid electrolyte flakes inside the mold to ensure that the solid electrolyte flakes were free of defects such as dents, dropped edges, and chips.

3.2 Putting in the cathode and anodee electrodes

Inside the glove box, the cathode electrode is punched and cut into small round pieces with a diameter of 12mm, and the anode electrode is punched and cut into small round pieces with a diameter of 13mm. Next, the cathode electrode is put into the mold cavity as a priority, and then put into the indenter to fix it initially. Then the anode electrode is also put into the mold testing cavity, put into the indenter to fix, and turn the mold out of the glove box.

3.3 Full-cell pressurization

Using SEMS, the mold cell is pressurized to 350MPa, holding pressure for 60s and then transferred to the glove box. Exit the pressurized sulfide solid-state battery from the mold cavity, and confirm that the whole cell is in a more complete state, with no shattering, edge dropping and other phenomena.

3.4 Full Battery Test

Place the pressed complete solid-state battery into the RSS buckling mold, using constant pressure mode, pressurized to 95kg (about 7MPa), with a charge/discharge rate of 0.1C multiplication rate. Start the software to begin the in-situ thickness expansion test of the sulfide solid-state battery.

Figure 3. All-solid-state battery expansion test assembly process

4. Experimental Results

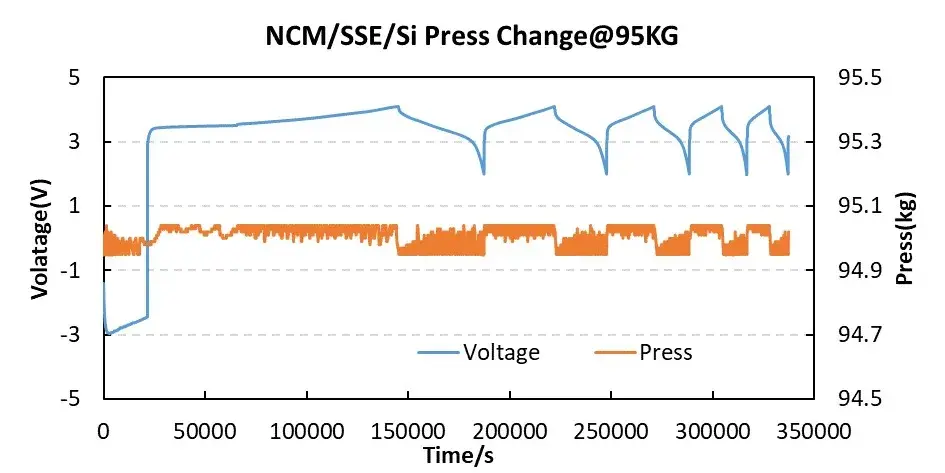

Figure 4. Stress stability test

Pressure stability control test results are shown in Figure 4, as can be seen from the figure, in a long time during the test, the RSS instrument pressure is basically maintained within the range of 95 ± 0.1 kg, the equipment pressure stability is good.

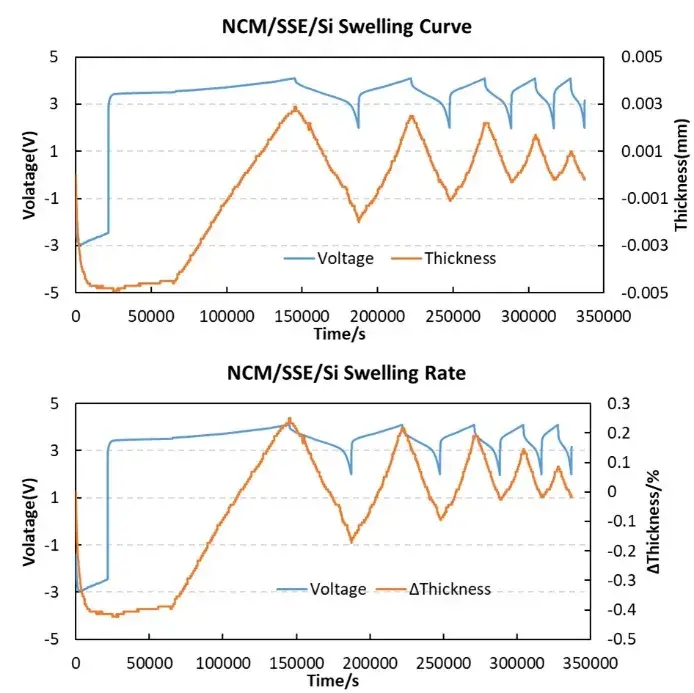

Figure 5. Variation of expansion curves of sulfide solid-state battery

The results of the battery expansion test are shown in Figure 5, which shows that the thickness of the battery gradually decreases during the 6-hour resting process. As the battery began to charge, the battery began to expand. When the battery was first charged to 100% SOC, the battery expanded by 8 μm as a whole, an expansion rate of nearly 7%. Subsequently, during the first lap of discharge, the battery thickness contracted, but the contracted thickness was only 4.5 μm, showing a large irreversible expansion. However, the structure gradually stabilized with the charge/discharge cycles, which was closely related to its significantly decayed capacity.

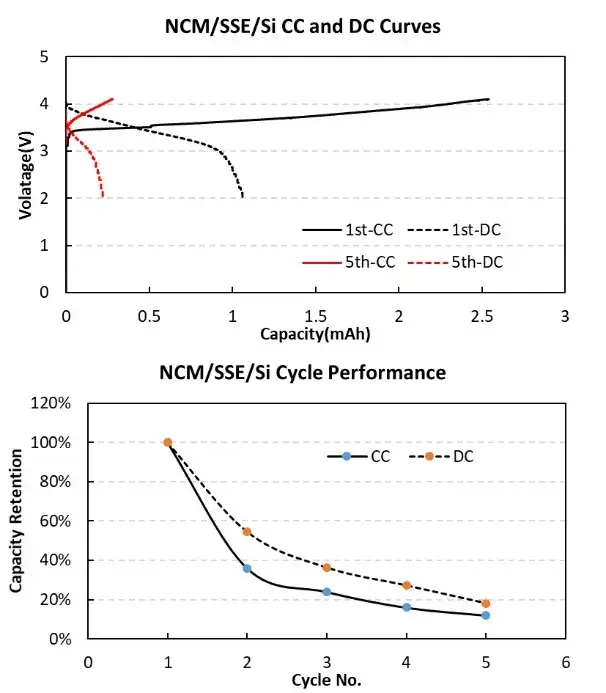

Figure 6. Sulfide solid-state battery capacity curve variation

As shown in Figure 6, it can be seen from the results of the battery charge/discharge test that the first efficiency of the battery is low during the first charge/discharge process, which is only 42%, and the capacity of the battery decreases sharply after 5 turns of cycling, with a capacity retention rate of only 18.2%. This shows that the high nickel with pure silicon system sulfide solid-state battery in the preparation process, despite the large pressure pressurization molding, but the test process using a small pressure pressurization, the battery charging and discharging process of the volume change is still large, although the volume change with the cycle continues to reduce, but the battery’s capacity degradation intensified, basically unable to meet the conventional use of the scene.

5. Summary

In this experiment, a sulfide solid-state battery with high nickel paired with a pure silicon system was used to subject it to in-situ swelling tests. The test results show that in all-solid-state batteries, there is a large expansion phenomenon in the battery as a whole due to the hard contact between the particles. Due to the fact that the test pressure used in this experiment was only 7 MPa during the swelling test, the cell performance was poor.

However, it can also be seen from the test results that In-Situ Silicon-Based Anode Swelling Rapid Screening System(RSS) has very good volumetric swelling test results for the swelling test of sulfide solid-state battery, and that it can be used to perform rapid screening of silicon anode electrode swelling at the mold (coin cell) stage, speeding up the progress of the evaluation of the material system and promoting the progress of the overall research and development project.

6. References

[1] Luo, S. T. et al. Growth of lithium-indium dendrites in all-solid-state lithium-based batteries with sulfide electrolytes. Figshare repository. Nature Communications (2021)

[2] Y. Nikodimos, C. Huang, B. W. Taklu, W. Su, B. J. Hwang. Chemical stability of sulfide solid-state electrolytes: stability toward humid air and compatibility with solvents and binders. Energy Environ. Sci., 2022, 15, 991-1033

[3] State Council department document: Guiding Opinions of the Ministry of Industry and Information Technology and other six departments on Promoting the Development of the Energy Electronics Industry, 2023

[4] Cui Yanming, Zhang Zhihua et al., Prototype all-solid-state battery electrodes preparation and assembly technology, Energy Storage Science and Technology, 2021, 10(3): 836-847.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.