Description

1. The significance of measuring the expansion behavior of silicon-based anode

Due to its unique advantages such as high specific capacity (4200mAh/g) and rich resources, silicon (Si) anode is expected to replace the graphite anode and become the main anode material for the next generation of lithium-ion batteries(LIBs). However, the rapid capacity degradation of silicon materials during the cycling process seriously hinderedits practical applications, This is due to the large volume expansion of silicon anode of more than three times during the intercalation process of lithium-ions, which will destroy the original solid electrolvte interphase (SEll fommed on the surfaceof the silicon anodes. During the cycling of the LIBs, the SEI will be destroyed and regenerated continually, which consumes a large amount of electrolyte and results in a rapid degradation of the capacity.Therefore, it is urgent to solve the problems caused by the volume expansion of silicon anode.

At present, researchers often use composite technology (e.g, “buffer skeleton”) to compensate the volume expansion of silicon materials. The common composite routes include silicon-carbon composites, silicon-polymer composites silicon-based alloy composites, and so on. Silicon-carbon composites are relatively easy and these two elements can also be tightly combined. Because it combines the high stability and conductivity of carbon materials, with the high specific capacity of silic on materials, the silicon-carbon anodes can not only efectively suppresses the volume expansion within a controllable range, but also increase the energy density and cycle life of the LIBs. Thus, it is regard as the most promising silicon-based anode for industrialization, and has received a lot of attentions.

It is worth noting that although the composite technology can alleviate the volume expansion of silicon-based anode, it still cannot fundamentally solve the expansion problem. With the increase of silicon content in silicon-based anode, the volume expansion also becomes more significant. Therefore, it has great significance for the research and manufacturing of silicon-based anodes if the volume expansion behavior of silicon-based anodes can be rapidly evaluated during the charging and discharging.

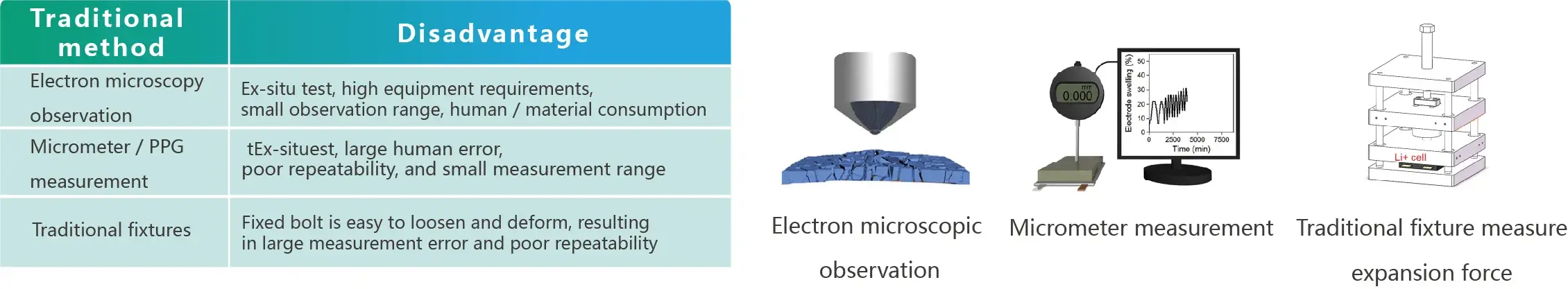

2. Traditional test methods

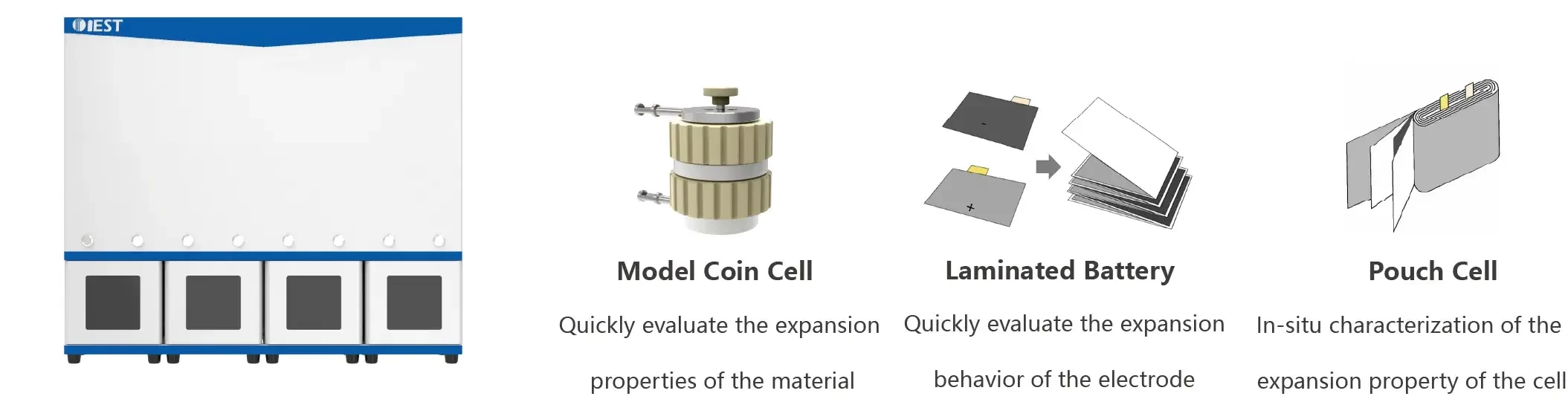

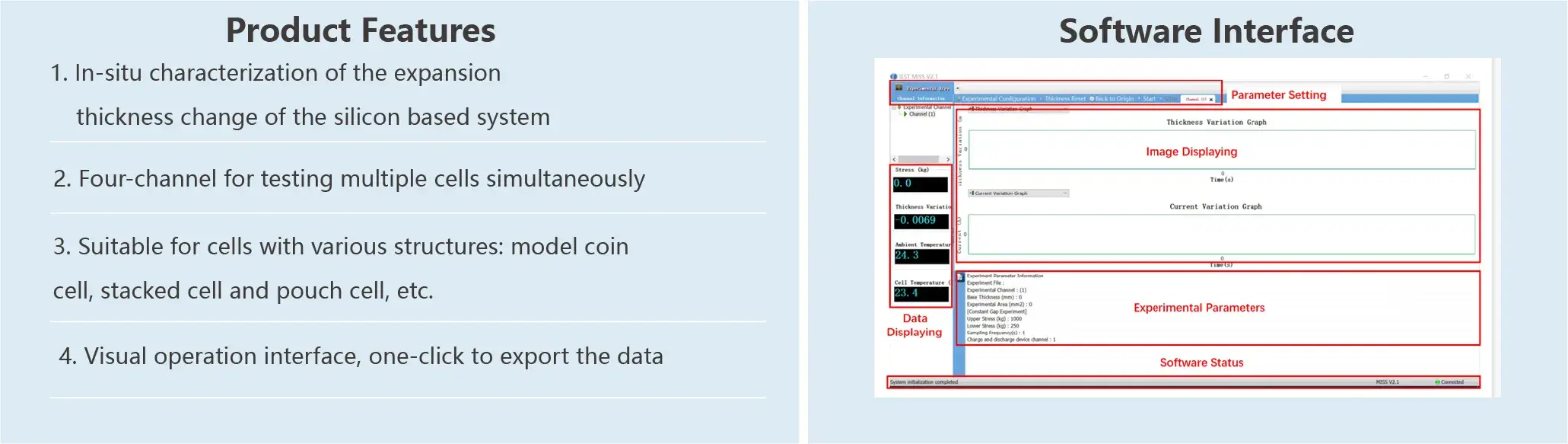

3. Introduction of in-situ rapid swelling screening for silicon-based anode

Applications

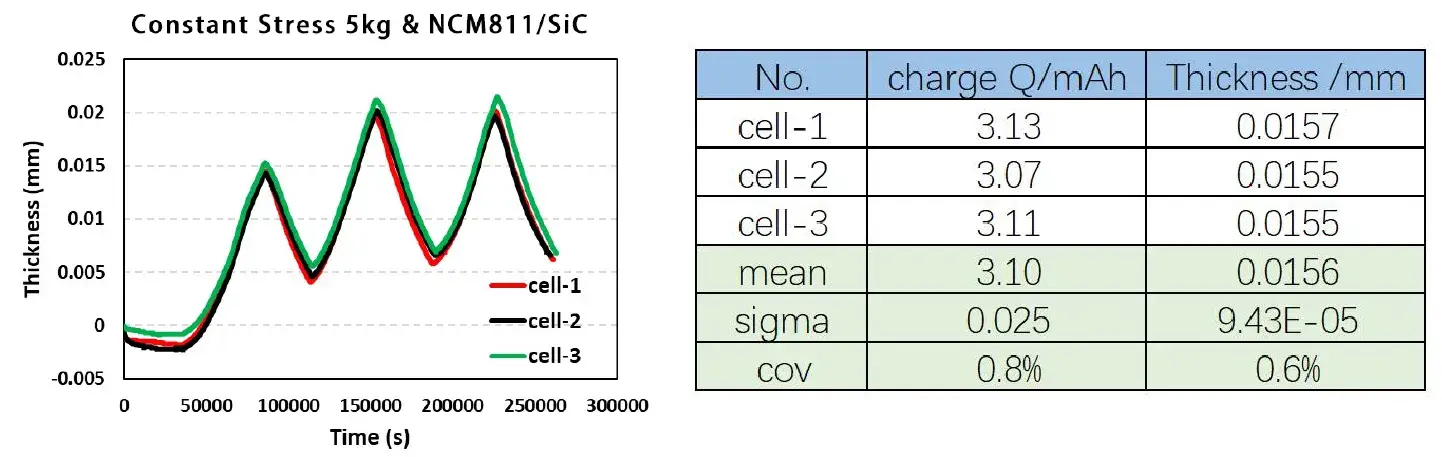

Case 1. In-situ swelling test of model coin cell:

- Cell parameters: Full coin cell(NCM811/SiC), with the capacity of about 3 mAh;

- Experimental parameters: Three parallel samples, charing and discharging for three cycles, and synchronously recordthe expansion thickness of these three full coin cells.

Experimental result:

- The full coin cellexpands/shrinks with the charge / discharge process, and the tuming point of the voltage curve in the three cycles is highly consistent with the tuming point of the thickness expansion curve, indicating that the expansion thickness curve can effectively reflect the volume change of the electrodes caused by the intercalation/deintercalation of lithium-ions, was only 0.6%, indicating the good cycle consistency of the model coin cell.

- Note: COV (Coefficient of Variation)= (standard deviation, sigma)/(mean )

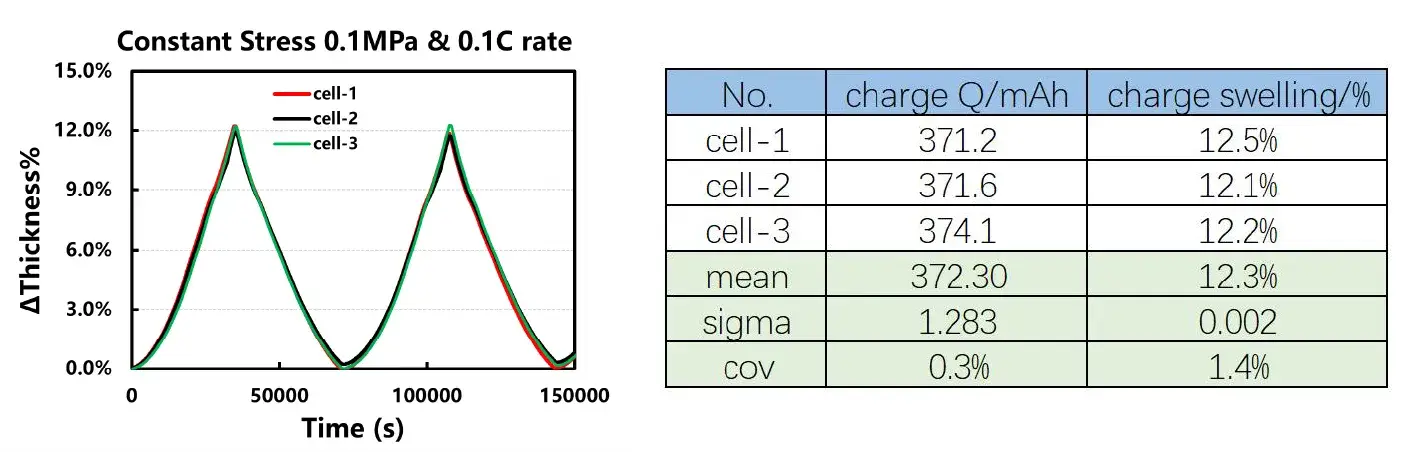

Case 2. In-situ swelling test of multi-layer laminated cells:

- Cell parameters: Multi-layer stacked cell (NCM811 /SiC), with a capacity of about 400 mAh.

- Experimental parameters: Three parallel samples, synchronously test the thickness expansion ratioat a constant pressure of 0.1MPa.

Experimental result:

- The multilayer stacked cell expands/contracts with the charge/discharge process, and the thickness expansion curves of three parallel samples maintain good repeatability for both two cycles. The maximum expansion ratio is about 12.5%, and the expansion thickness COV of three parallel samples is 1.4%, indicating a good agreement between the parallel samples.

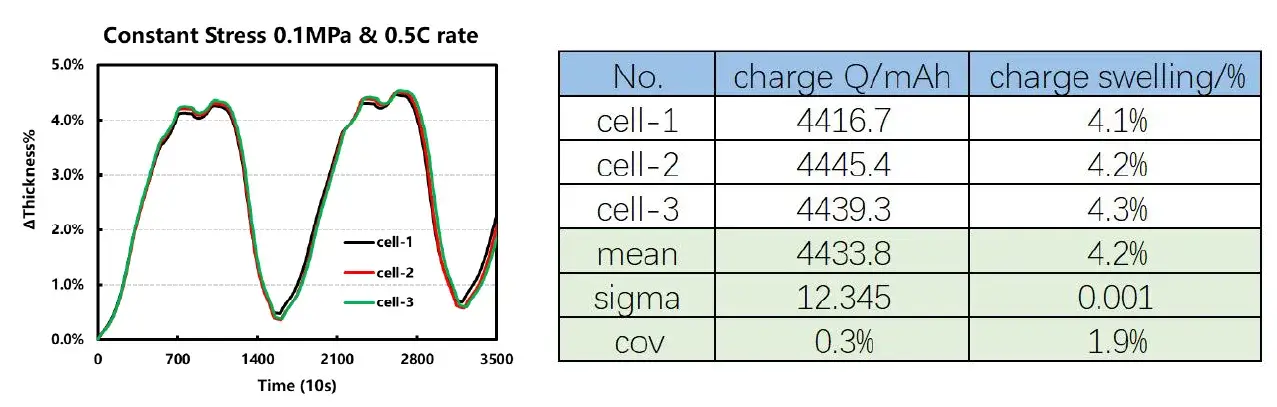

Case 3. In-situ swelling test of the pouch cell:

- Cell parameters: Multi-layer pouch cell with winding structure (NCM811/SiC), capacity of about 400 mAh;

- Experimental parameters: synchronously test thickness expansion ratio at a constant pressure of 0.1 MPa.

Experimental result:

- The multilayer pouch cell swelling/contracts with the charging/discharging process, and the thickness expansion curves of three parallel samples maintain good repeatability for both two cycles. When the pouch cell is fully charged, the corresponding maximum expansion ratio is about 4.3%, and the expansion thickness COV between the three groups of batteries is 1.9%, indicating that the consistency among these three parallel samples.

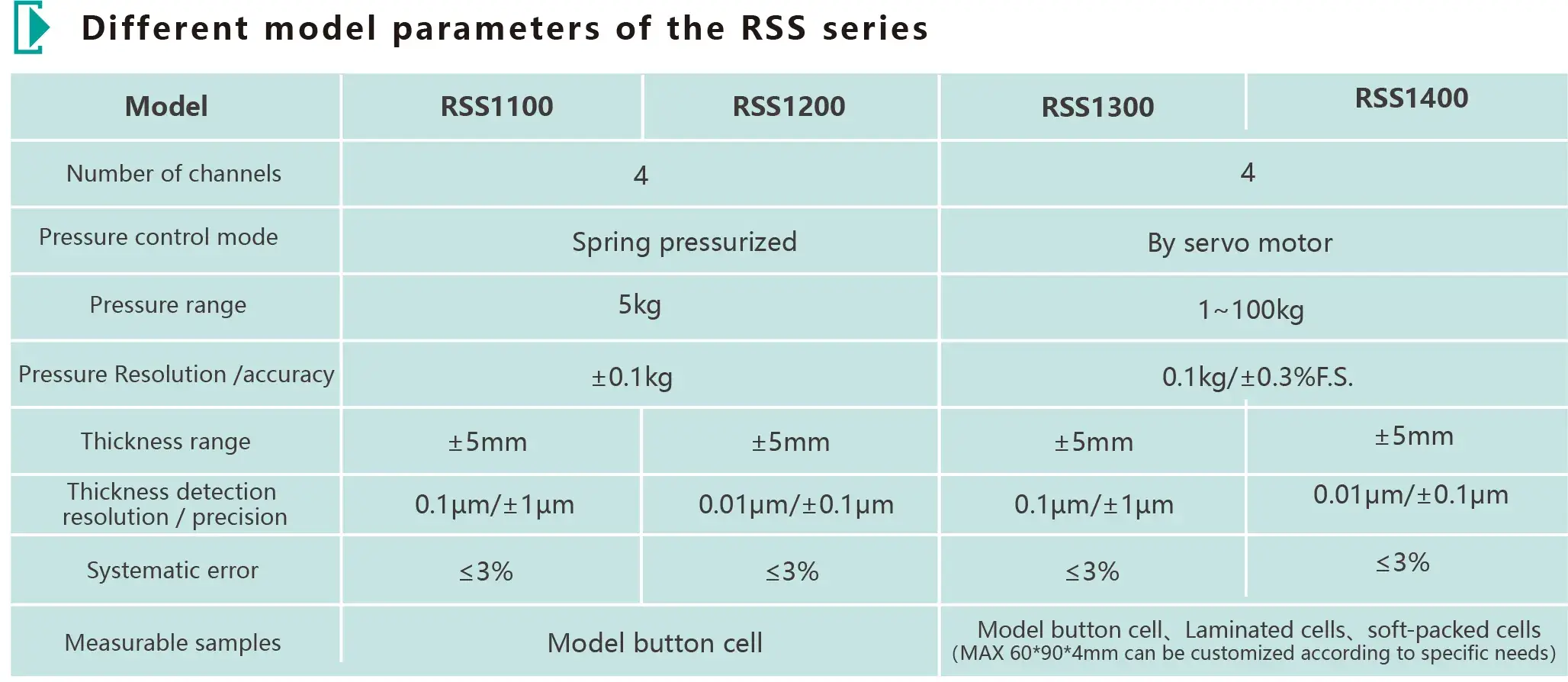

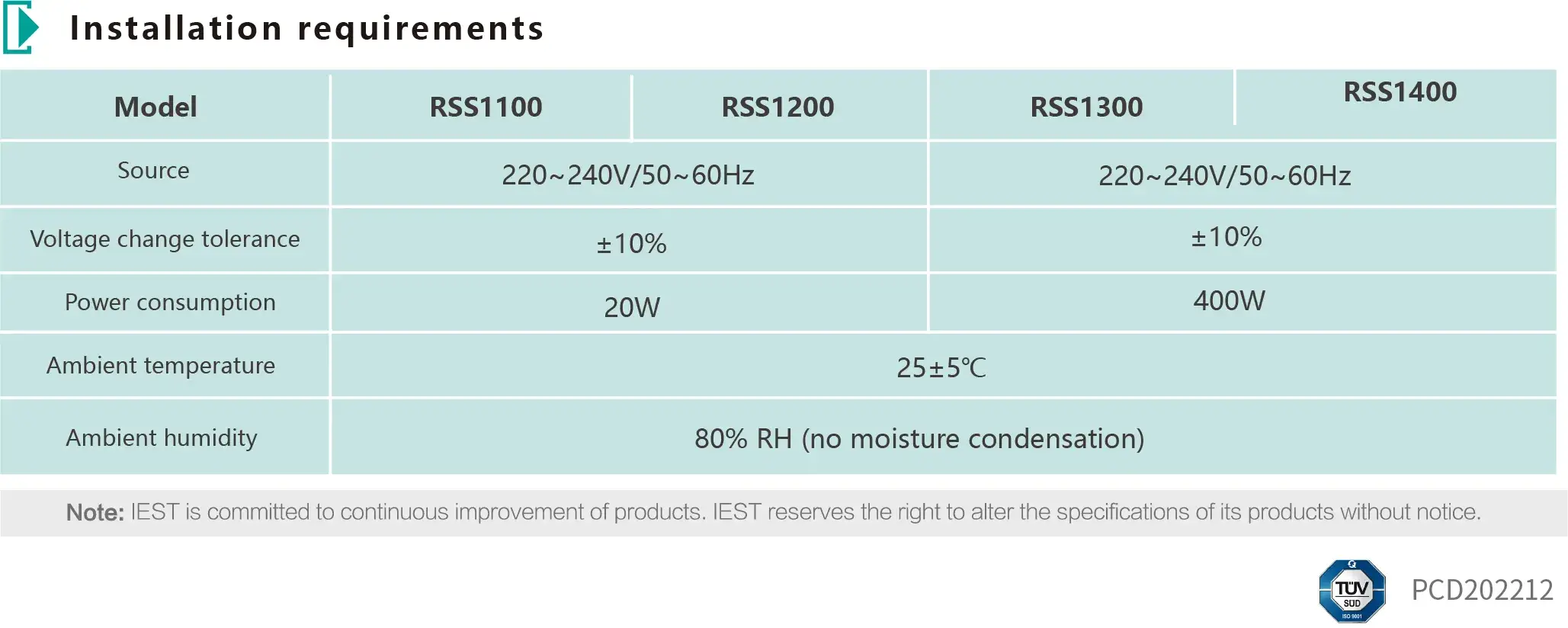

Specifications