-

iestinstrument

Entering Electrochemistry | Dynamic EIS Testing: Real-Time Impedance Diagnostics for Lithium Batteries

1. Introduction

Electrochemical Impedance Spectroscopy (EIS) is a fundamental technique for investigating electrochemical interfaces and is extensively used to analyze processes within lithium-ion batteries. The method treats the battery as a “black box,” applying a sinusoidal AC signal across a spectrum of frequencies and measuring the resulting electrical response. By interpreting the frequency-dependent feedback in the EIS spectrum, it becomes possible to diagnose irregularities in the battery’s internal electrochemical behavior.

Conventional static EIS testing must meet three key requirements: causality, linearity, and stability. As a result, measurements are typically performed after the cell has reached a steady state through prolonged rest. and therefore requires long equilibration times before measurement. That constraint, however, can miss fast, transient phenomena that occur during real operation. Dynamic EIS (DEIS) or continuous EIS testing overcomes that limitation by measuring impedance during charging or discharging, enabling actionable EIS diagnostic testing in non-steady-state conditions.

2. Significance of Dynamic EIS Testing

As the name suggests, Dynamic EIS involves performing EIS testing during battery charging or discharging. Its significance lies primarily in the following aspects:

2.1 Real-time Monitoring and Capturing Dynamic Processes

Dynamic EIS can reflect the instantaneous state information of a battery in real-time. For instance, it can capture the rapid growth process of lithium dendrites or fast electrochemical reactions during fast charging. If one waits for a long rest period before conducting EIS testing and monitoring, lithium plating behavior may gradually weaken or even disappear. Therefore, Dynamic EIS possesses a unique advantage in capturing rapid electrochemical reaction behaviors.

2.2 Analysis of Non-linear and Non-steady-state Processes

Actual battery systems often exhibit non-linear or non-steady-state characteristics. For example, batteries in practical use frequently operate under non-steady-state conditions, constantly subject to disturbances like temperature fluctuations and load variations. Dynamic EIS enables testing under these non-steady-state conditions, acquiring impedance information of the battery in different states. This provides more comprehensive data support for battery performance evaluation and fault diagnosis.

2.3 Early Fault Diagnosis and Advantages for Data Modeling

Since Dynamic EIS eliminates the need for lengthy rest periods, it enables earlier detection of potential battery faults. For instance, when lithium plating or abnormal thermal runaway occurs internally, the mid-frequency impedance measured by Dynamic EIS may decrease or increase abnormally, providing timely warning information to users. Furthermore, the volume of data acquired in Dynamic EIS mode is typically much larger than in static EIS. This data can be used to establish more accurate battery models, providing more reliable data support for battery performance prediction, lifetime assessment, and optimized design.

3. Innovative Solution: IEST Battery Impedance Tester (BIT6000)

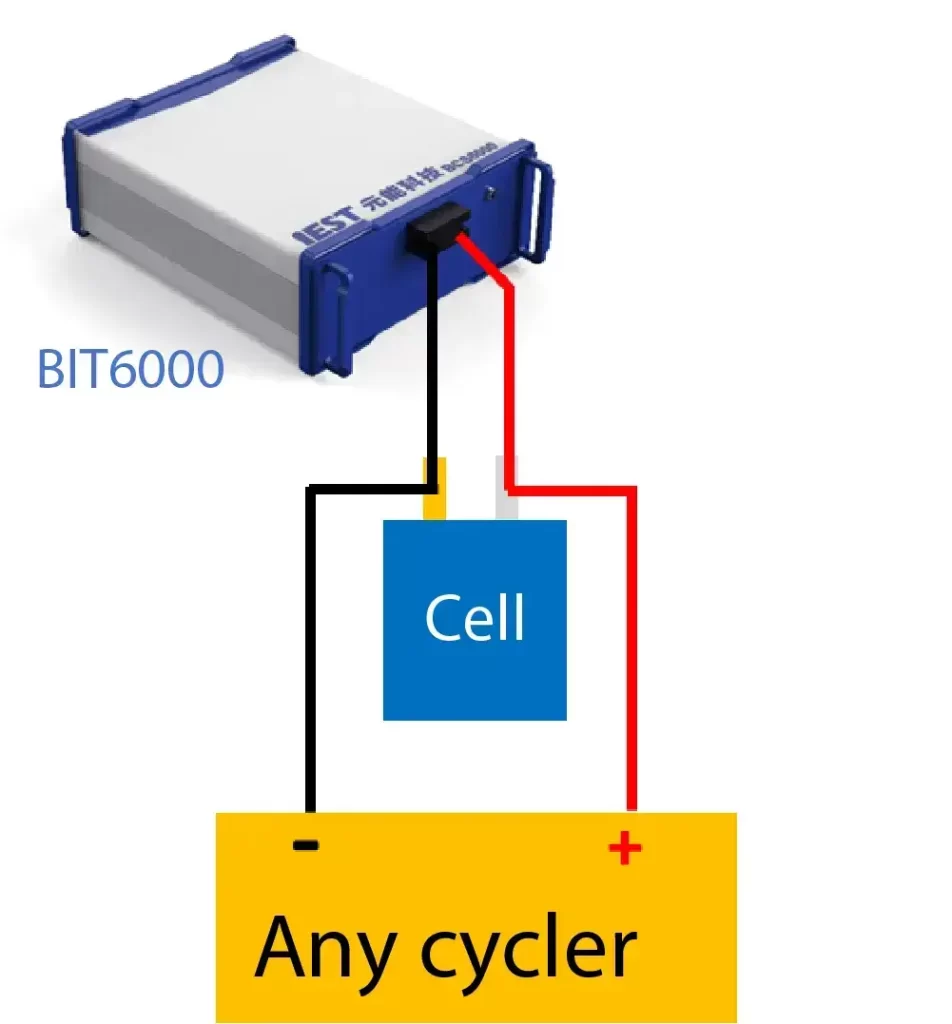

The IEST BIT6000 Battery Impedance Tester can be seamlessly integrated with third-party charging equipment to enable Dynamic EIS testing during battery operation. Its software supports continuous testing modes, allowing real-time impedance monitoring under non-steady-state conditions. A major advantage of the BIT6000 is its ability to perform EIS diagnostic testing on high-capacity, low-impedance cells (such as power or storage batteries) without an external amplifier—effectively overcoming a key industry challenge.

Figure 1. IEST BIT6000 Integrated with Third-Party Charger for DEIS Testing

4. Continuous Dynamic EIS Monitoring During Charging

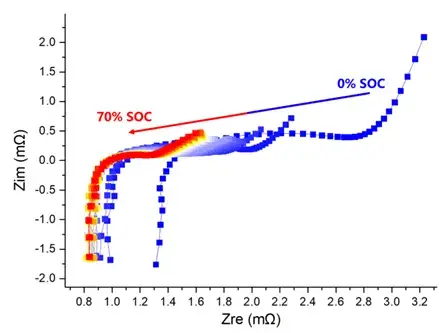

Next, taking a 40Ah power battery (LFP//C) as an example, the battery was first fully discharged. Subsequently, under a constant current (CC) charging condition of 0.3C, DEIS testing was performed continuously while charging, until the battery reached approximately 70% State of Charge (SOC). The results are shown in Figure 2. These test results can be further analyzed by leveraging established electrochemical models to obtain the evolution of dynamic parameters (including resistance and capacitive reactance corresponding to electrochemical processes with different time constants) as the cell charges to different SOC levels. This assists in understanding the instantaneous electrochemical behaviors occurring during the charging process.

Figure 2. Continuous Dynamic EIS monitoring of an LFP battery under 0.3C constant current charging

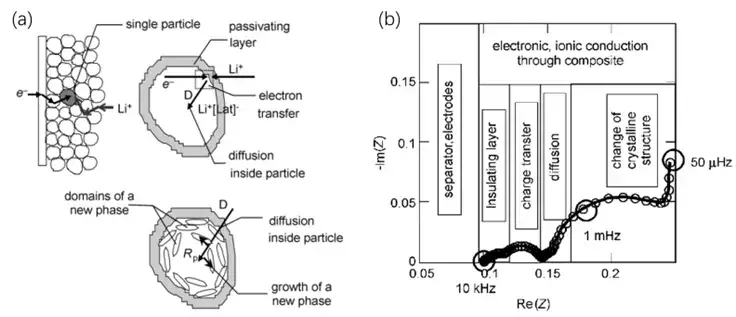

Figure 3(a) illustrates the micro-model proposed by Barsoukov et al. [1] for the intercalation and deintercalation processes of lithium ions within the electrode active material. Figure 3(b) shows the typical EIS spectrum for the deintercalation and intercalation of lithium ions in the electrode active material. It can be observed that conventional EIS test results generally encompass five electrochemical processes with distinct time constants [1, 2]:

4.1 Ultra-High Frequency Region:

The ohmic resistance associated with lithium-ion and electron transport through the electrolyte, porous separator, and current collectors. This appears as a single point intersecting the real axis (Z’) on the EIS plot, typically denoted as Rs.

4.2 High Frequency Region:

A semicircle related to lithium-ion diffusion through the Solid Electrolyte Interphase (SEI) film. This process can be represented in an equivalent circuit by a parallel combination of R~SEI~ and C~SEI~ (R~SEI~ // C~SEI~).

4.3 Mid-Frequency Region:

A semicircle corresponding to the charge transfer process. This process can be represented in an equivalent circuit by a parallel combination of charge transfer resistance (R~ct~) and double-layer capacitance (C~dl~) (R~ct~ // C~dl~).

4.4 Low Frequency Region:

Related to solid-state diffusion of lithium ions within the active material particles. This appears as a straight line with a 45° slope on the EIS plot. In the equivalent circuit, this process is represented by a Warburg impedance (Z~W~) describing diffusion.

4.5 Very Low Frequency Region (<0.01 Hz):

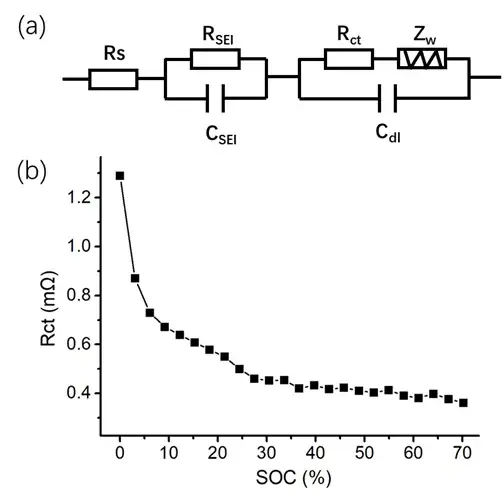

Comprises a semicircle potentially related to changes in the active material particle crystal structure or new phase formation, and a near-vertical line related to lithium-ion accumulation/depletion in the active material. Lithium batteries are typically not analyzed at such low frequencies. Therefore, the common equivalent circuit used for analyzing lithium battery EIS spectra is shown in Figure 4(a).

Figure 4(b) shows the variation of the dynamic R~ct~ with SOC, obtained by fitting the continuous DEIS test results (shown in Figure 2) using the equivalent circuit. It can be observed that within the 0% to 70% SOC range, the dynamic R~ct~ first decreases rapidly (0%-30% SOC) and then decreases more slowly (30%-70% SOC). It is known that for LFP batteries, due to their relatively flat charge/discharge voltage plateau, using the Open Circuit Voltage (OCV) curve to estimate SOC in practical applications results in significantly larger errors compared to other cell chemistries [3]. However, DEIS analysis reveals that the change in dynamic R~ct~ exhibits a strong correlation with SOC. Therefore, it can serve as an important parameter for estimating the SOC of LFP batteries.

Figure 3. (a) Micro-model for Li-ion intercalation/deintercalation in electrode active materials proposed by Barsoukov et al.; (b) Typical EIS spectrum for Li-ion deintercalation/intercalation in electrode active materials.

Figure 4. (a) Common equivalent circuit model for lithium batteries; (b) Variation curve of dynamic R~ct~ with SOC derived from continuous DEIS testing of a 40Ah LFP power battery.

5. Summary

The IEST BIT6000 Battery Impedance Tester enables continuous Dynamic EIS testing on large-format, low-impedance cells when integrated with standard charging equipment. It provides valuable insights into transient electrochemical behaviors, supporting advanced research into battery kinetics under realistic operating conditions. In a case study with an LFP cell, dynamic Rct showed a clear correlation with SOC, highlighting the potential of EIS diagnostic testing for improved state estimation and battery management.

Figure 5. Appearance of the Battery Impedance Tester (BIT6000)

6. References

[1] E. Barsokov, D.H. kim, H.-S. Lee, H. Lee, M. Yakovleva, Y. Gao and J.F. Engel, Comparison of kinetic properties of LiCoO2 and LiTi0.05Mg0.05Ni0.7Co0.2O2 by impedance spectroscopy. Solid State Ionics 161 (2003) 19-29.

[2] E. Barsoukov and J.R. Macdonald. Impedance spectroscopy theory, experiment, and applications. Second Edition. New Jersey: John Wiley & Sons, Inc., Hoboken, 2005.

[3] P.P. Xu, J.Q. Li, Q. Xue and F.C. Sun. A syncretic state-of-charge estimator for LiFePO4 batteries leveraging expansion force. J Energy Storage 50 (2022) 104559.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.