-

iestinstrument

Accurate LFP Compaction Density Testing: A Guide for Compliance and Performance Optimization

1. Preface

Recent adjustments to export control policies concerning lithium iron phosphate (LFP) have brought LFP compaction density testing into sharp focus for the battery industry and international trade. As a critical indicator impacting both export compliance and core battery performance, accurate and professional testing for this parameter has become essential for companies seeking a competitive edge.

IEST Instrument, leveraging its technical expertise and integrated resources, now offers comprehensive LFP compaction density testing capabilities for both LFP and lithium iron manganese phosphate (LMFP) powders, providing the industry with a reliable solution.

2. The Critical Role of Compaction Density Testing

The compaction density of LFP powder directly influences key battery performance metrics such as energy density and cycle life. Furthermore, it is a pivotal parameter in export control regulations.

-

From a Regulatory Perspective: Previous announcements from regulatory bodies explicitly restricted the export of LFP materials with a powder compaction density ≥ 2.58 g/cm³ at 220 MPa. While specific control measures may be adjusted, maintaining robustLFP compaction density testing capability remains a core competency for companies navigating policy fluctuations.

-

From a Market Perspective: Whether for R&D, quality control, or export clearance, authoritative LFP compaction density test reports serve as vital documentation for demonstrating product compliance and ensuring smooth international trade.

3. Core Testing Capabilities at IEST Instrument

Building on technical积淀 and strategic partnerships, IEST has established a full-spectrum testing service centered on its PRCD series instruments, with core competencies spanning three key dimensions:

-

Explicit Standard Adherence: Testing is conducted in strict accordance with the Chinese National Standard for compaction density (GB/T 44330-2024), ensuring data accuracy and regulatory compliance. This aligns directly with the requirements of authoritative certifications like CMA and CNAS.

-

Technical Resource Integration: We have established collaborative intentions with leading industry testing institutions and metrology bodies. This facilitates alignment on testing standards and technical synergy, creating a seamless “testing-to-certification” pathway.

-

Equipment and Metrological Assurance: Device configurations are optimized for specific testing needs. We are progressing with whole-instrument metrological calibration in coordination with metrology systems, guaranteeing the reliability and credibility of test results at the hardware level.

Figure 1. Schematic diagram of IEST PRCD series powder resistivity and compaction density tester

4. Demonstrating Accuracy and Long-Term Stability

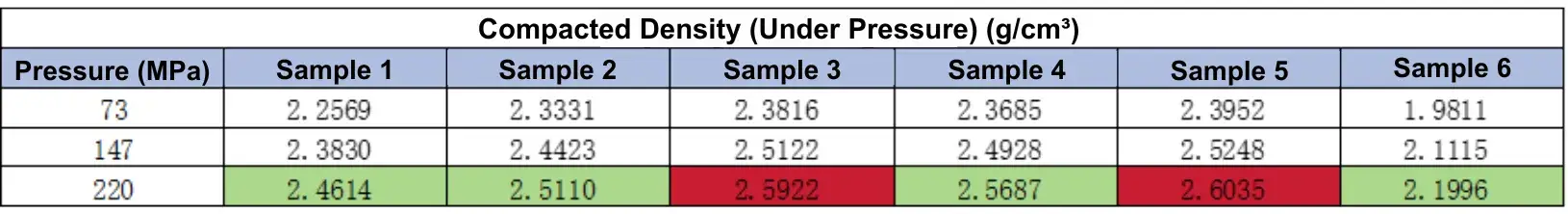

The table below presents LFP compaction density data for six different LFP cathode materials, tested using the IEST PCD2000 Powder Compaction Density Tester. The industry-standard “three-point method” was employed, with density at 220 MPa as the evaluation benchmark.

Table 1. Compaction Density of Six Different LFP Samples at 220 MPa

The data clearly differentiates the samples. At 220 MPa, Samples 3 and 5 exhibit compaction densities of 2.5922 g/cm³ and 2.6035 g/cm³, respectively, both exceeding the 2.58 g/cm³ control threshold. From a powder compaction performance standpoint, these would fall under regulatory control. Samples 1, 2, 4, and 6, with densities below the threshold, would not.

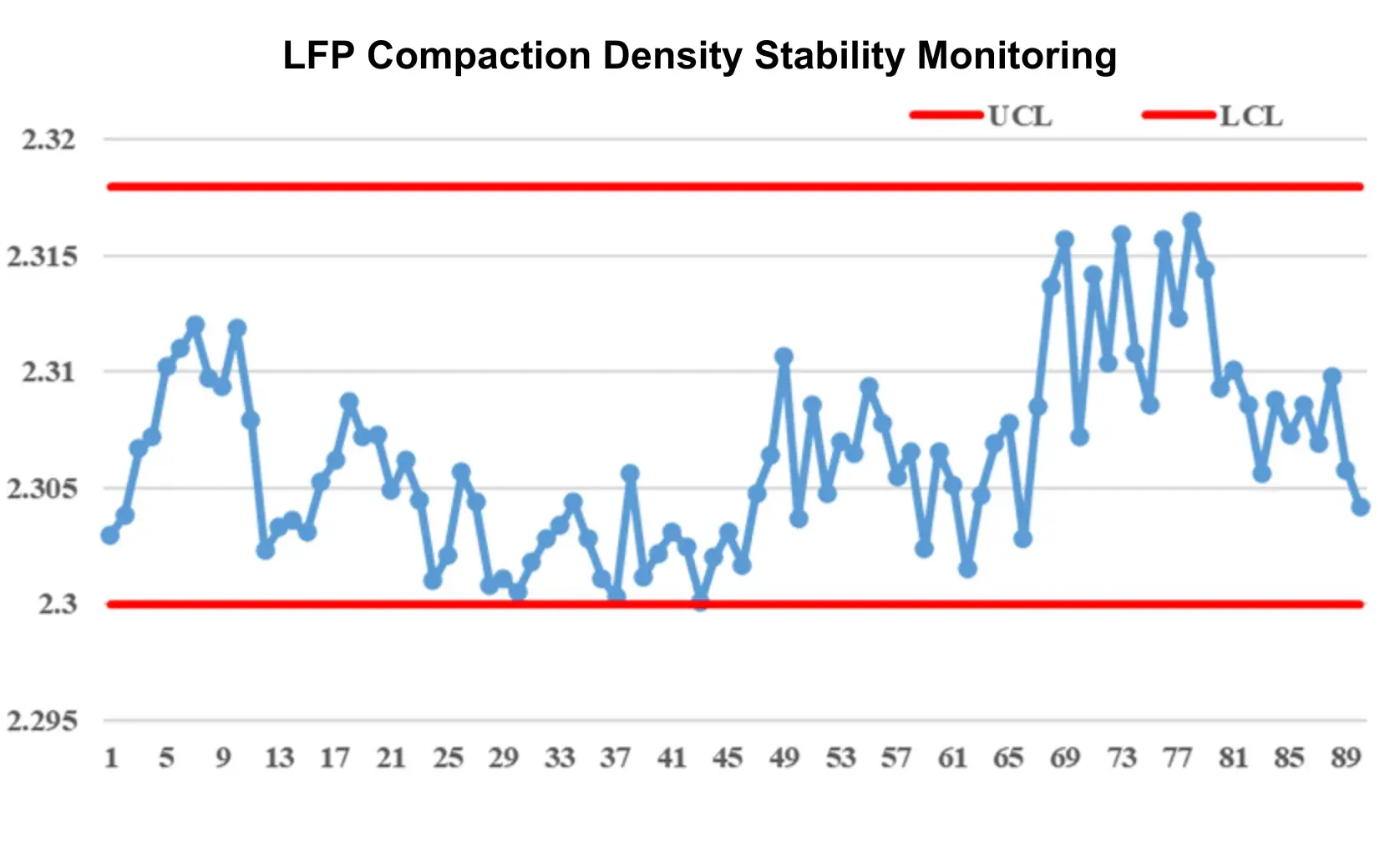

Figure 2. Control chart of LFP compaction density stability data

Long-term testing stability is another critical strength. A control chart monitoring LFP compaction density stability over 90 days of continuous testing demonstrates the exceptional reliability of IEST instruments. The data consistently fluctuates within the Upper Control Limit (UCL) and Lower Control Limit (LCL) bands, with no significant shifts or out-of-control points. This confirms that the PCD2000 tester provides not only precise results but also excellent long-term stability and repeatability—essential for material quality control, process consistency evaluation, and batch-to-batch monitoring.

5. Beyond Testing: Enabling Full-Industry-Chain Compliance

IEST’s LFP compaction density testing service extends beyond single-point measurement, offering comprehensive support tailored to real-world business needs:

-

For exporters, we provide compliant test data to navigate customs supervision and trade verification.

-

For R&D and manufacturing teams, we deliver precise feedback to support product optimization and quality management.

-

By collaborating with third-party certification systems, we enhance industry-wide recognition of test results, helping to reduce redundant testing costs.

While policies may evolve, a company’s foundational capability to test core performance and compliance parameters must remain robust. IEST Instrument is committed to advancing testing technologies for LFP and related materials. By leveraging our standards expertise, resource network, and equipment advantages, we provide efficient and accurate LFP compaction density testing services, empowering the industry’s compliant development and global expansion.

6. Recommended testing instruments: Powder Resistivity & Compaction Density Measurement System (PRCD Series)

Introduction: Powder Compaction Density & Powder Resistivity Measurement System combined with high-precision pressure control, thickness and resistance testing system, free choice of four-probe and two-probe method. Accurately powder resistivity tests and compaction density measurements for materials R&D and for monitoring batch-to-batch stability of battery powder materials.

Features:

- Ultra-wide pressurization range (maximum 350MPa) and ultra-wide resistance measurement range (200MΩ);

- When measuring resistance, two-probe and four-probe dual principles can be switched freely;

- Fully automatic test software, free parameter setting, one-click start;

- Real-time monitoring and output of pressure, pressure, ambient temperature, ambient humidity, thickness, resistance, resistivity, conductivity, compaction density and other parameter curves, and automatic saving of test data.

- Multiple powder test modes: pressurization, single-point pressure relief, steady-state pressure relief;

- Equipped with standard thickness blocks and resistance blocks calibrated by a third-party metrology institute.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.