-

iestinstrument

Unveiling the Inhomogeneous Degradation Mechanisms in LiFePO4/Graphite Pouch Cells Under Coupled Thermal and Electrical Stress

1. Article Information

-

Title: Inhomogeneous degradation mechanisms in LiFePO4 Graphite pouch cells under temperature and over-discharge coupled accelerated aging

-

First Author: Rui Tang

-

Corresponding Authors: Lai Chen, Xuebing Han, Yuefeng Su*

-

Affiliations: Beijing Institute of Technology, Beijing Institute of Technology Chongqing Innovation Center, Tsinghua University

-

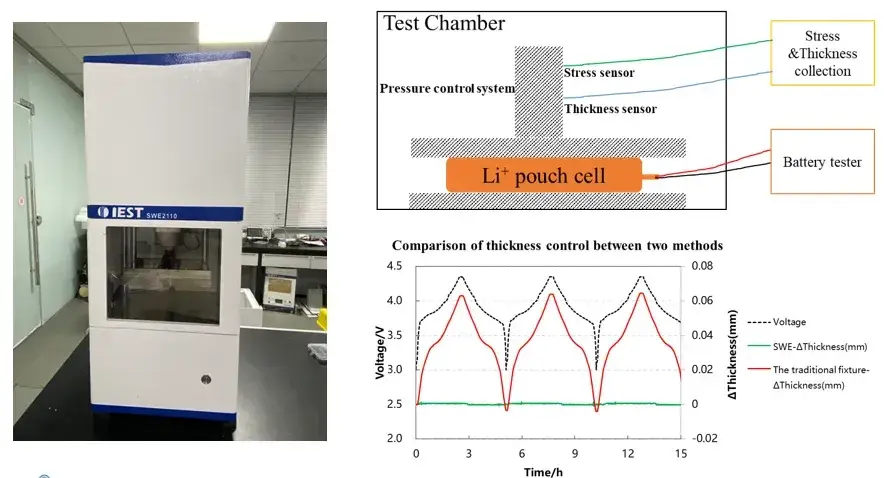

Used Instrument: IEST In-situ Battery Swelling Tester(SWE2100)

2. Understanding Battery Aging Under Real-World Complex Conditions

LiFePO4/Graphite (LFP/Gr) batteries are widely adopted in electric vehicles and energy storage systems due to their high safety and long cycle life. However, in real-world complex operating conditions, batteries often endure multiple external stresses simultaneously—such as high temperature and over-discharge—leading to accelerated performance decay and safety risks. Current research predominantly focuses on single stress factors, leaving a gap in systematic understanding of aging mechanisms under multi-stress coupling, particularly the spatiotemporal heterogeneity of the failure process. High temperature exacerbates side reactions and interface deterioration, while over-discharge can induce copper current collector dissolution and internal short circuits. Understanding whether their coupling creates synergistic or nonlinear acceleration effects, and whether the aging process is uniform within the electrode, is crucial for developing accurate life prediction models and safety management strategies. Therefore, this study aims to clarify the degradation mechanisms of LiFePO4 Graphite pouch cells under coupled high-temperature and over-discharge conditions, with a focus on the nonlinear characteristics and spatial heterogeneity of the aging pathways, providing theoretical support for developing accelerated test methods and accurate state-of-health evaluation.

3. Decoding Nonlinear Aging Trajectories and Spatial Heterogeneity

Recently, Professor Yuefeng Su, Researcher Lai Chen, and colleagues from Beijing Institute of Technology systematically revealed how coupled stresses induce nonlinear decay trajectories, spatially heterogeneous failure, and cross-electrode effects, using multi-scale electrochemical and material diagnostics. The study found that high temperature dominates early-stage interface deterioration and iron dissolution, while over-discharge later exacerbates copper dissolution, graphite structural disordering, and lithium plating. Their synergy leads to accelerated aging. This research provides systematic insights for understanding battery failure mechanisms under multi-stress coupling and lays an important foundation for developing reliable accelerated aging evaluation methods and battery health management strategies. The related work was published in eTransportation under the title “Inhomogeneous degradation mechanisms in LiFePO4 /Graphite pouch cells under temperature and over-discharge coupled accelerated aging.”

4. Key Electrochemical and Interfacial Evolution Findings

Electrochemical analysis revealed that the HO (High-temperature & Over-discharge) condition caused significantly accelerated aging. The equivalent full cycle number to reach 80% capacity retention was only 40% of that under NN (Normal-temperature & Normal-discharge) conditions, yielding an acceleration factor of 2.5. NN samples exhibited a nearly linear capacity fade, whereas HO samples showed a distinct nonlinear accelerated decay trajectory. Incremental capacity (IC) and differential voltage (DV) analysis further indicated that loss of active lithium (LLI) and loss of active negative material were more severe under HO conditions, accelerating with cycling. In-situ swelling tests showed greater expansion in HO cells at the end of charge, corresponding to increased gas evolution from electrolyte decomposition. Distribution of relaxation times (DRT) analysis revealed that the SEI-related impedance peak in HO cells emerged early and then decayed rapidly, indicating an unstable interface layer undergoing repeated rupture and reformation cycles.

Figure 1: (a) Capacity retention curves, (b) Comparison of equivalent full cycle numbers, (c, d) Charge/discharge voltage curves under NN and HO conditions, (e-h) DV and IC curves, (i, j) IC peak voltage shifts, (k) DC internal resistance change.

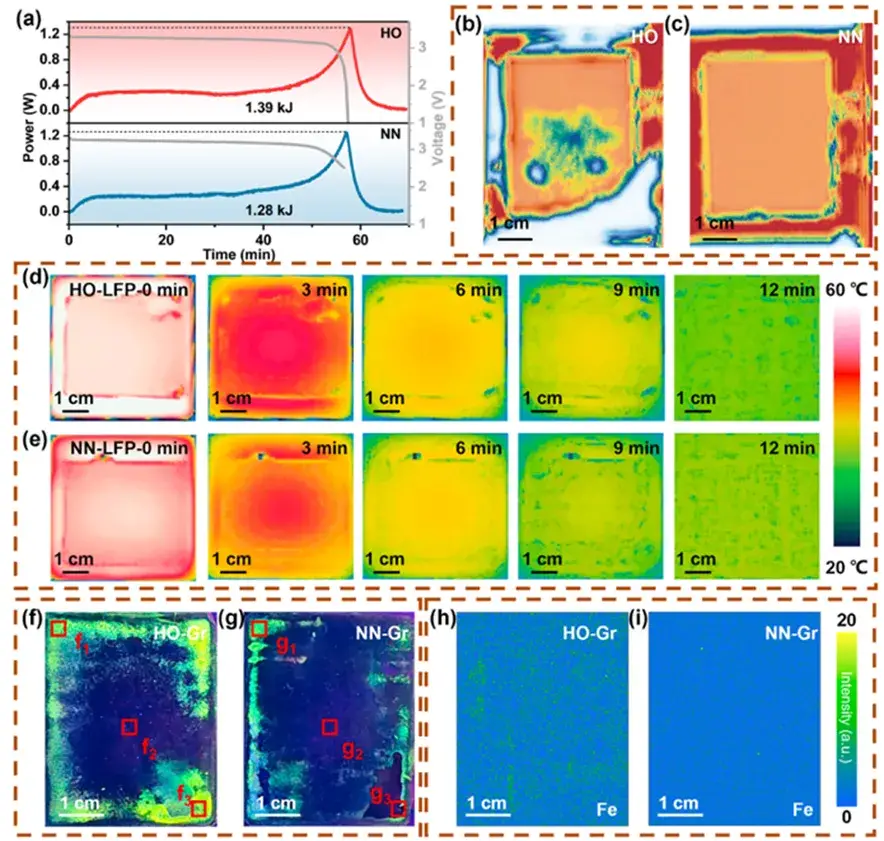

5. Revealing Spatial Heterogeneity Through Multi-Modal Imaging

Multi-modal imaging clearly revealed the spatial heterogeneity of degradation mechanisms under coupled stress. Ultrasonic scanning showed local areas with significantly reduced ultrasound transmittance inside HO cells, corresponding to non-uniform electrolyte consumption and gas generation. Infrared thermography indicated local temperature anomalies on the HO-aged LFP cathode during cooling, reflecting uneven surface thermal conductivity. Fluorescence imaging combined with micro X-ray fluorescence (μXRF) confirmed that signals for lithium plating and iron deposition were significantly stronger at the edge regions of HO-aged graphite anodes compared to the center, and far exceeded those in NN samples, demonstrating a pronounced edge-aggregation effect.

Figure 2: (a) Heat generation rate during adiabatic discharge, (b, c) Ultrasonic scan images after discharge for HO and NN cells, (d, e) IR thermography of HO and NN-aged LFP cathodes, (f, g) Fluorescence imaging of HO and NN-aged Gr anodes, (h, i) Iron element μXRF imaging of HO and NN-aged Gr anodes.

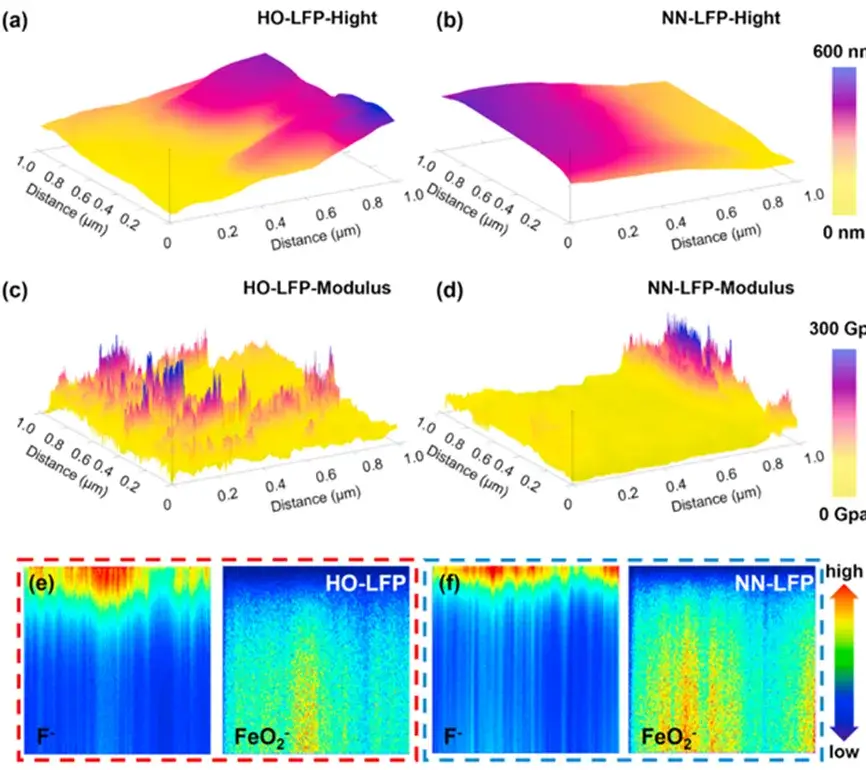

6. Multi-Scale Analysis of Cathode Degradation

Cathode multi-scale analysis demonstrated that HO conditions triggered more severe surface chemical and structural degradation. SEM and AFM showed increased surface deposits, higher roughness, and uneven distribution of Young’s modulus on HO-aged LFP. Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS) indicated enhanced and unevenly distributed F^- signal, and a gradient change in FeO2^- signal, revealing non-uniform deposition of side reaction products. HRTEM and elemental mapping further confirmed the formation of a thicker amorphous layer on the HO-aged LFP surface, along with a phase transition from bulk LiFePO4 to surface FePO4 and disordered structures. Surface enrichment of fluorine and copper was also detected, with the copper originating from cross-deposition after anode copper dissolution

Figure 3: (a, b) AFM surface morphology of HO and NN-aged LFP, (c, d) Corresponding Young’s modulus distribution, (e, f) ToF-SIMS results for HO and NN-aged LFP.

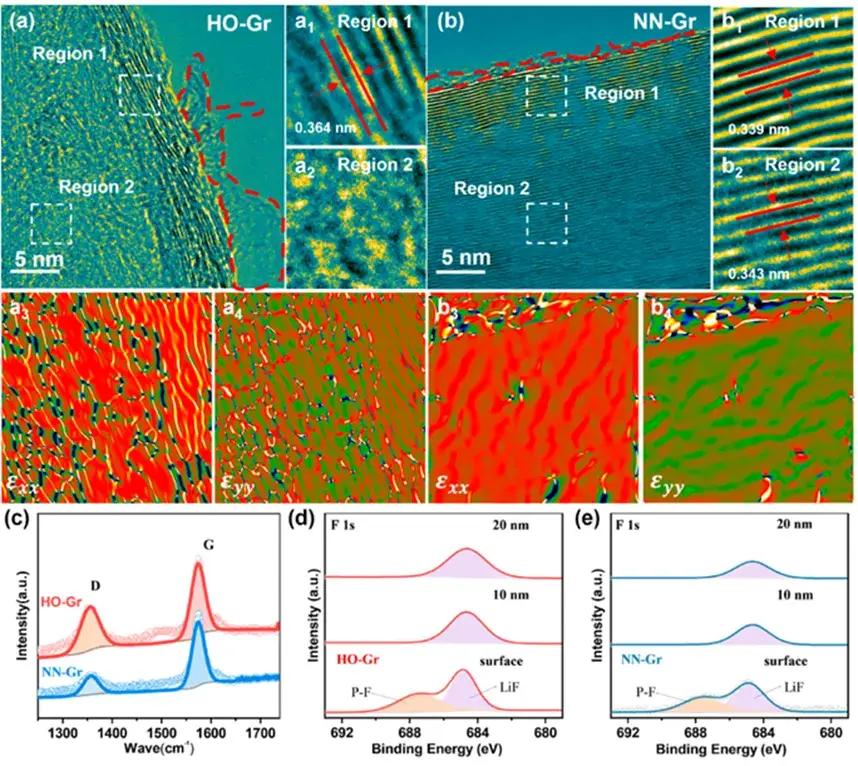

7. Multi-Scale Analysis of Anode Degradation

Anode analysis also revealed significant non-uniform degradation. Moss-like aggregates appeared on the HO-aged graphite surface, and AFM showed a rough structure with alternating “trench-peak” features. ToF-SIMS depth profiling indicated that the SEI layer on HO-aged graphite was thicker, with substantial increases in both organic (CH2–, CH3O–) and inorganic (F–) components. HRTEM showed abnormally expanded interlayer spacing and even loss of graphitic order in some regions of HO-aged graphite. XRD and Raman spectroscopy confirmed decreased crystallinity and a increase in defect density (ID/IG ratio). XPS depth profiling also found higher LiF content within the SEI of HO-aged graphite at all etching depths.

Figure 4: (a, b) HRTEM images and geometric phase analysis of HO and NN-aged Gr, (c) Raman spectroscopy results, (d, e) F 1s XPS depth profiling spectra of HO and NN-aged Gr.

8. Conclusions and Implications

This study, through a systematic approach combining multi-scale experimentation and analysis, provides an in-depth revelation of the non-uniform degradation mechanisms in LiFePO4 Graphite pouch cells under coupled high-temperature and over-discharge stress. The research finds that coupled stress induces nonlinear accelerated aging, with clear temporal and spatial heterogeneity in the failure process: high temperature drives early-stage interface decomposition and iron dissolution, while over-discharge later exacerbates copper dissolution, graphite structural disorder, and edge-localized lithium plating. Their synergy creates a positive feedback loop, leading to accelerated performance decline. Spatially, reactions and degradation were highly concentrated at electrode edge regions. The study clarifies that high-temperature over-discharge conditions can serve as an accelerated aging research method to some extent, but the nonlinear decay patterns and spatial heterogeneity they induce must be considered. The multi-scale analytical framework established and the aging mechanism insights obtained not only provide methodological references for multi-factor coupled accelerated testing but also lay a vital foundation for developing mechanism-based battery state-of-health prediction and intelligent lifetime management strategies.

9. IEST Recommended Testing Equipment: In-Situ Cell Swelling Testing System(SWE Series)

Utilizing a highly stable and reliable automated platform integrated with a high-precision thickness sensor, this system measures the total thickness changes and rate of change during the entire charge/discharge cycle of the battery. Its capabilities include:

- Measuring the battery’s expansion thickness curve under constant pressure conditions.

- Measuring the battery’s expansion force curve under constant gap conditions.

- Testing the battery’s compression performance: stress–strain curves and compression modulus.

- Stepwise testing of battery expansion force.

- Temperature control over a range of −20 to 80°C.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.