-

iestinstrument

Systematic Solution For Rapid Testing Separator Ion Conductivity

1. Abstract

Accurate measurement of separator ion conductivity is essential for predicting cell rate capability, internal resistance, and overall safety. This application note describes a high-throughput, multi-channel workflow for ion conductivity measurement using a purpose-built EIS test platform. The procedure—vacuum bake, standardized electrolyte fill (300 µL, 1 M LiPF₆ in EMC:EC:DMC = 1:1:1), and multi-layer EIS fitting—yields repeatable Rs values that convert directly to ionic conductivity. The method discriminates process differences between separators and highlights how cell aging at elevated temperature reduces effective ionic pathways.

2. Introduction

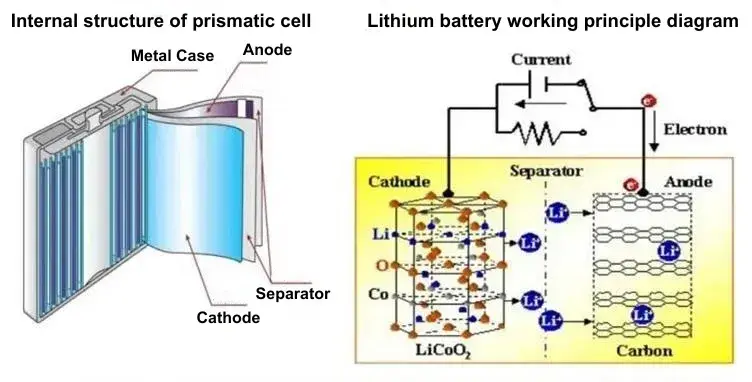

Cathode, anode, electrolyte and separators are the four main materials that make up lithium-ion batteries. During the charging process of a lithium-ion battery, lithium ions are detached from the cathode transported through the separator through the electrolyte, and then embedded in the anode, the discharge process is the opposite. Because the separator plays the role of isolating cathode and anode in the battery, the separator must meet the following points:

-

Electronically insulating.

-

Easily wettable by the electrolyte with sufficient electrolyte retention capability.

-

Possess good mechanical strength and structural stability.

-

Exhibit high chemical stability against the electrolyte, impurities, and electrode reaction products.

-

Effectively block the migration of particles, colloids, or soluble species between electrodes.

-

Feature appropriate porosity to enable fast ion transport.

In liquid lithium-ion batteries, the existing separator materials are usually PE material, PP material or a mixture of the two (PP, PE, PP/PE/PP). this type of material undergoes certain processes and is stretched to obtain a membrane base material of a certain thickness. This type of membrane must have a high porosity to ensure ion transmission performance. However, because the battery generates a lot of heat during charging and discharging, PP and PE separators will thermally shrink at high temperatures. To improve the heat shrinkage performance of the separator, the separator is usually coated with nano-alumina or boehmite powder [1].

Separator ion conductivity performance is mainly determined by the porosity and tortuosity of the separator. For the detection of separator ionic conductivity transport performance testing, the ion conductivity test method in 6.6.2 of《GB/T 36363-2018: Polyolefin Separators for Lithium-Ion Batteries》is currently commonly used in the industry [2].

Figure 1. Schematic diagram of the internal structure and working principle of the battery

3. Experimental Method: A High-Throughput System

3.1 Test Equipment

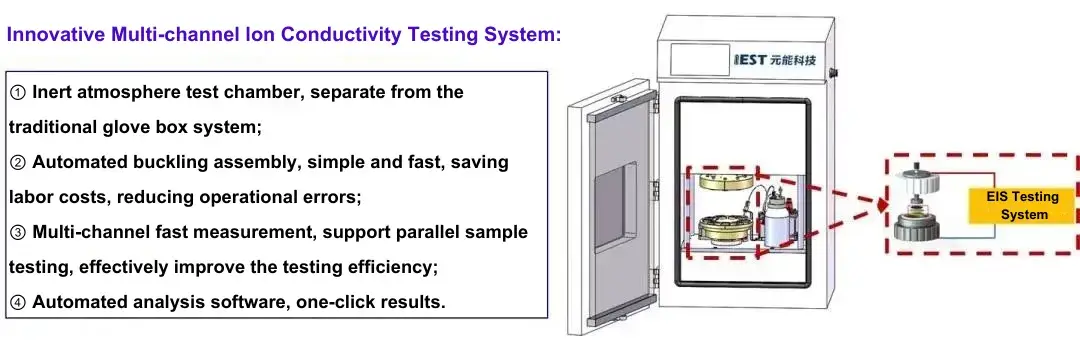

IEST independently developed multi-channel ion conductivity test system is used for testing. As shown in Figure 2. The instrument includes a four-channel symmetrical battery assembly jig, an electrochemical impedance test system, fitting software, etc. It can be combined with high-purity argon or nitrogen to control the inert atmosphere of the test environment to achieve electrochemical impedance spectroscopy testing of multi-channel symmetrical batteries or different separators.

Figure 2. Innovative IEST Electrode Tortuosity Tester & Separator Ion Conductivity Test System(EIC Series)

Figure 3. Appearance of IEST Electrode Tortuosity Tester & Separator Ion Conductivity Test System(EIC Series)

3.2 Test Steps

To verify the consistency of the equipment and the actual test conditions, we used separators treated with different processes and different aging temperatures to conduct ionic conductivity tests. The main experimental procedures are as follows:

-

Cut the diaphragm into small diaphragms of a certain area, and bake them in vacuum at 60°C for 12 hours.

-

The dried separators were assembled into a symmetric cell fixture and transferred into the test instrument.

-

Perform vacuuming-inflating and other steps to remove the relevant air and moisture in the sample.

-

Automatically and quantitatively inject liquid (300μL, 1M LiPF6, EMC:EC: DMC=1:1:1) into each channel, and let it sit for a certain period after completing the injection.

-

After the rest is completed, the EIS module of the IEST multi-channel separator ion conductivity testing system is used to conduct impedance testing.

-

Complete the assembly and testing of 1 to 4 layers of diaphragms respectively, use automatic fitting software, and use the obtained EIS as the baseline for fitting. The intersection point of the impedance and the X-axis is Rs, as shown in Figure 4. By fitting the EIS test results of the n-layer diaphragm, the resistance Rs(n) of the n-layer diaphragm can be obtained.

Figure 4. Diaphragm fitting diagram of separator ion conductivity Rs

3.4 Principle of Measurement

The diaphragm is a porous structure with pores filled with electrolyte, and the equivalent circuit of its AC impedance spectrum can be described by a series circuit of a CPE phase element and an ionic resistor, as shown in Figure 5. The impedance of its equivalent circuit is given by the following equation:

Among them, in the corresponding Nyquist plot (Fig. 3), we simply determine the ionic resistance R Ion within the porous separator by high-frequency extrapolation (ω → ∞), that is, the intersection of the impedance spectrum with the real axis Rs.

Figure 5. Equivalent circuit of the electronically insulating porous separator under blocking conditions

4. Result Analysis

4.1 Case Study 1: Evaluating Different Separator Processing Techniques

We compared two separators (SEPE-1 and SEPE-2) with identical total thickness (12µm) but produced using different manufacturing processes. Their EIS spectra, shown in Figure 6, revealed a clear difference, with SEPE-1 exhibiting higher impedance than SEPE-2.

Figure 6. Diaphragm EIS after different processes

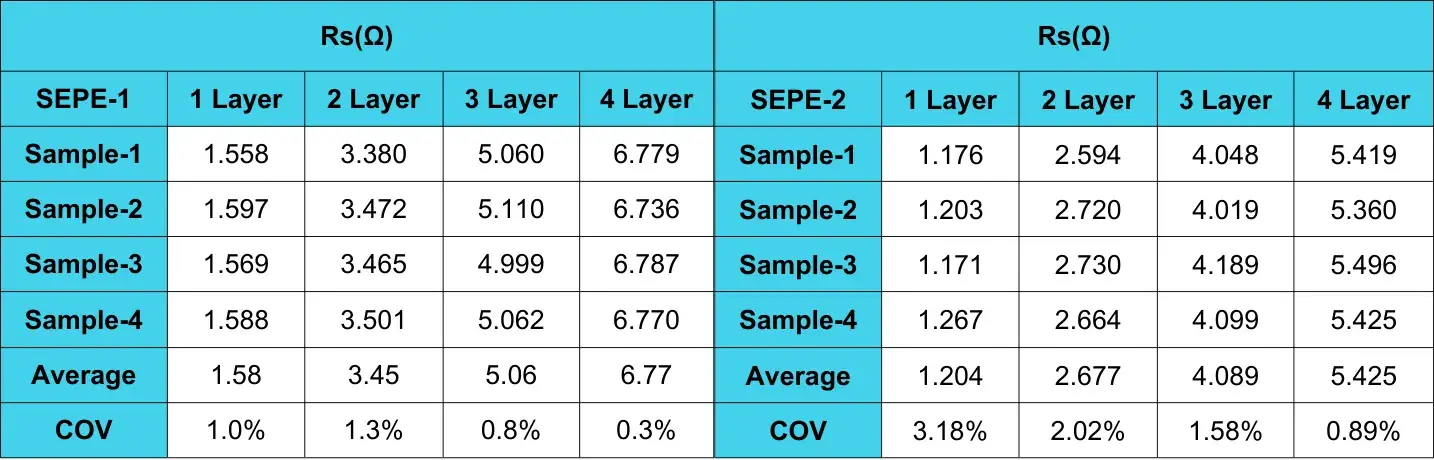

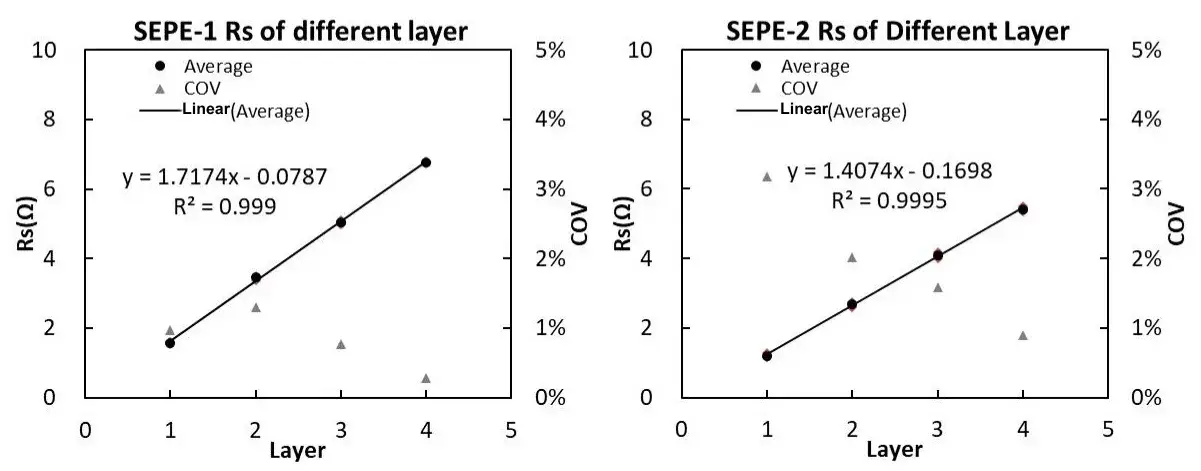

The Rs values for different layer stacks (1 to 4 layers) were obtained through fitting. The coefficient of variation (COV) for all parallel samples was below 5%(Table 1), confirming excellent measurement consistency (Table 1). Plotting Rs against the number of layers yielded a linear relationship (Figure 6).

Table 1. Resistance test fitting results for different layer numbers

Using the number of layers as the X-axis and Rs as the Y-axis, the relationship between the number of layers and resistance Rs can be obtained, as shown in Figure 7.

Figure 7. Separator Rs after treatment with different processes

According to the national standard formula, it can be calculated that SEPE-1 ionic conductivity is 0.454mS/cm, SEPE-2 ionic conductivity is 0.554mS/cm, the diaphragm SEPE-1 ionic conductivity is smaller than the diaphragm SEPE-2, which indicates that SEPE-2 treatment process is better. The size of the diaphragm ion conductivity depends on a variety of factors, including the material of the diaphragm, thickness, pore size, porosity and so on. The ceramic coating structure on the surface of the diaphragm will also have an important influence on the ion conductivity, whether it is the surface coating layer or the diaphragm body, the diaphragm with a larger pore size can increase the transmission rate of ions, and the diaphragm with higher porosity can increase the number of ions’ channels, which can increase the ion conductivity. Different treatment processes result in different diaphragm microstructures and therefore diaphragms with different ion conductivities.

4.2 Case Study 2: Assessing Impact of Cell Aging Temperature

After completing the chemical formation of lithium-ion batteries, they are usually left at a certain temperature for a period of time, so that the battery polarization is fully released at the same time, the cell side reactions are more complete, and the cell interface is more stable. This process is called aging in the cell process. During the aging process, different ambient temperatures and resting time have great influence on the performance of the battery cell. In order to explore the effect of aging temperature on the diaphragm, we will be formed into a battery cell at room temperature and high temperature 60 ℃ static 48h, and then disassembled the battery cell, take the diaphragm for ion conductivity measurement.

The diaphragm material is PP, and the thickness of the substrate is 9 μm. In the process, the double-sided ceramic coating process is used, and the thickness of the single-sided coating is 2 μm, i.e., 9+2+2 process. Its EIS test results are shown in Figure 8. We can find that the EIS of the diaphragm after aging at 60°C is larger than that of the diaphragm aging at 25°C.

Figure 8. EIS of separators after different aging temperatures

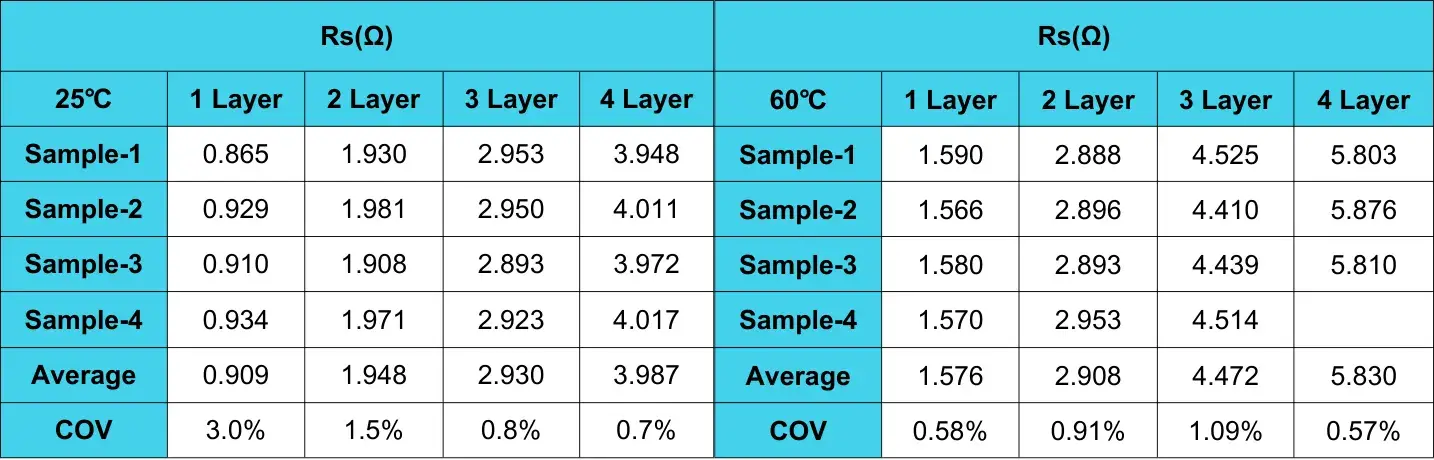

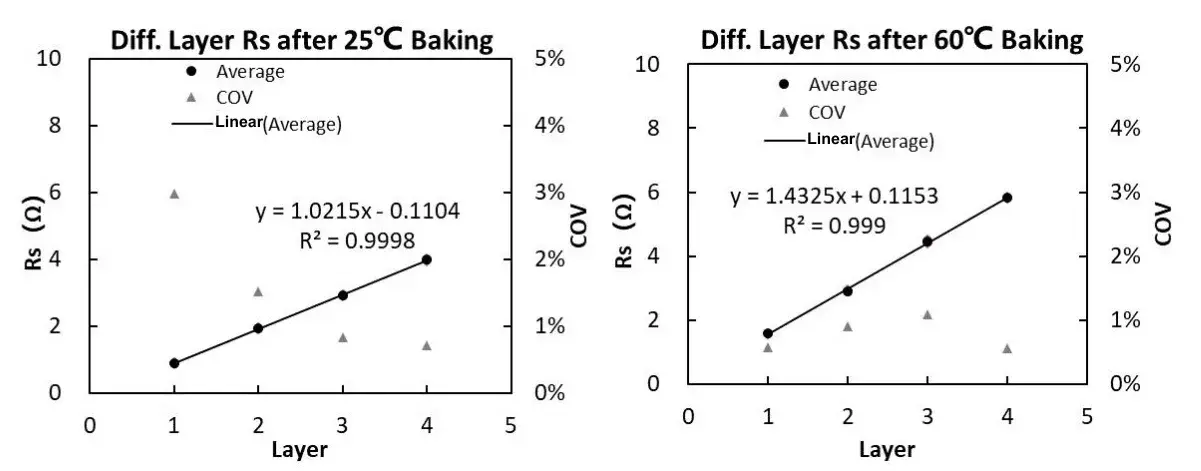

Rs values were fitted for different layer stacks (Table 2), again with a COV under 5%, ensuring reliability. The linear Rs vs. layer number plots are shown in Figure 8. Calculations based on the standard yielded an ionic conductivity of 0.803 mS/cm for the 25°C-aged separator and 0.509 mS/cm for the 60°C-aged separator. It shows that the ion conductivity of the separator after aging treatment at 25°C is higher than that of the separator aged at 60°C.

Table 2. Resistance test fitting results after different aging temperature treatments

Using the number of layers as the X-axis and Rs as the Y-axis, the relationship between the number of layers and resistance Rs can be obtained, as shown in Figure 9.

Figure 9. Separator Rs after different aging temperature treatments

The main reason is that aging caused by high-temperature storage will cause deposits to appear on the surface of the positive electrode material particles of the battery, which is mainly due to the oxidation of the electrolyte on the surface of the positive electrode particles during the high-temperature storage process. At the same time, sediments may also appear on the surface of the negative electrode, mainly due to the thickening reaction of the SEI film on the negative electrode surface and the decomposition reaction with the electrolyte. These deposits may cover the surface of the membrane and cause pore clogging. At room temperature, the degree of these side reactions is lower and the rate is slower. Therefore, high-temperature aging is more likely to cause the ionic conductivity of the separator to decrease. Therefore, we can determine that the aging process for 48 hours at 60°C may not be suitable for this type of battery.

5. Summary

This study demonstrates a systematic, high-throughput approach for separator ion conductivity measurement. Using a dedicated multi-channel separator ion conductivity measurement system, we efficiently assembled and tested multi-layer separator stacks, significantly improving testing throughput. The presented case studies clearly show how both separator manufacturing processes and downstream cell assembly conditions (like aging temperature) can profoundly impact this critical parameter. Accurate and efficient ion conductivity measurement is therefore essential for separator screening, process optimization, and root-cause analysis in battery development and failure diagnostics.

6. References

[1] Yang Baoquan, Ceramic Coated Diaphragm Modified Lithium Ion Battery Diaphragm, Aging and Application of Synthetic Materials, 2018, 47(1), 67-72.

[2] National standard: GB/T 36363-2018《Polyolefin separator for lithium-ion batterie》.

[3] Wall,Wolfgang,A,et al. Tortuosity Determination of Battery Electrodes and Separators by Impedance Spectroscopy (vol 163, pg A1373, 2016)[J].Journal of the Electrochemical Society, 2017, 164(4).

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.