-

iestinstrument

Crushing Strength Comparison Between Natural Graphite and Artificial Graphite

1. Introduction

The power of the microcosm determines the pinnacle of macroscopic performance. When we talk about lithium-ion batteries, terms like energy density, cycle life, and fast-charging capability often come up—these grand performance metrics might seem distant. But have you considered that all these properties originate from the most fundamental level: the “physical fitness” of each individual particle within the electrode material?

Today, we focus on one of the “hearts” of the lithium-ion battery—the graphite anode—and, through a revealing “Single Particle Crushing Test,” uncover the remarkable differences in strength between artificial graphite and natural graphite, and how this subtly shapes battery performance.

2. The Two Contenders: The Main Types of Graphite Anodes

In the field of lithium-ion battery anodes, graphite materials dominate due to their excellent conductivity and stable layered structure. They can be broadly classified into two types:

2.1 Natural Graphite: A Gift from Nature

-

Source: As the name suggests, it is derived from natural graphite mines, which undergo processes like purification, grinding, and spheronization.

-

Structural Characteristics: Being a product of nature, its structure is closer to a “perfect crystal.” The degree of graphitization is high, with a regular layered structure, facilitating lithium-ion intercalation and de-intercalation, thus resulting in higher capacity.

- Advantages and Disadvantages: The advantage is higher specific capacity and lower cost. However, its natural source means the particle surfaces often have many defects and edges, leading to poorer compatibility with the electrolyte and batch-to-batch instability.

2.2 Artificial Graphite: A Technological Masterpiece

-

Source: Artificially produced through high-temperature heat treatment (graphitization) using easily graphitizable carbon precursors like petroleum coke or needle coke.

-

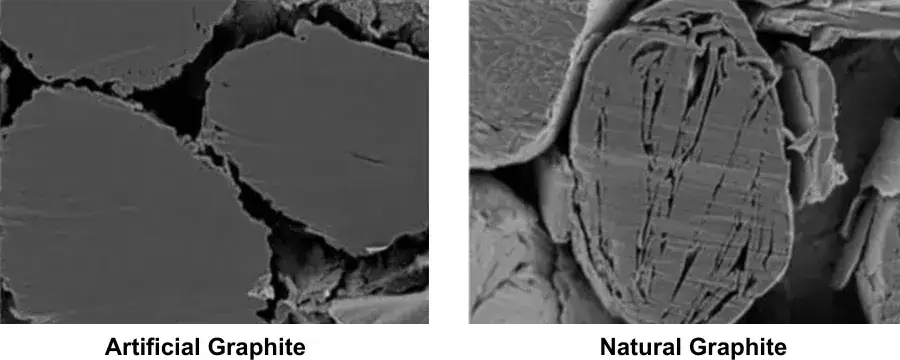

Structural Characteristics: This is the product of meticulous processing. During manufacturing, the tiny crystals in the precursor material re-arrange, grow, and fuse to form a complex polycrystalline structure. One can imagine natural graphite as a complete “marble block,” whereas artificial graphite is a “concrete” made of countless “pebbles” and “cement.”

- Advantages and Disadvantages: The advantages include a more stable structure, fewer side reactions with the electrolyte, and longer cycle life. However, the complex manufacturing process increases cost, and its capacity is slightly lower than natural graphite.

Figure 1. Artificial Graphite Vs. Natural Graphite

3. Microscopic Battle: Single Particle Compression Test

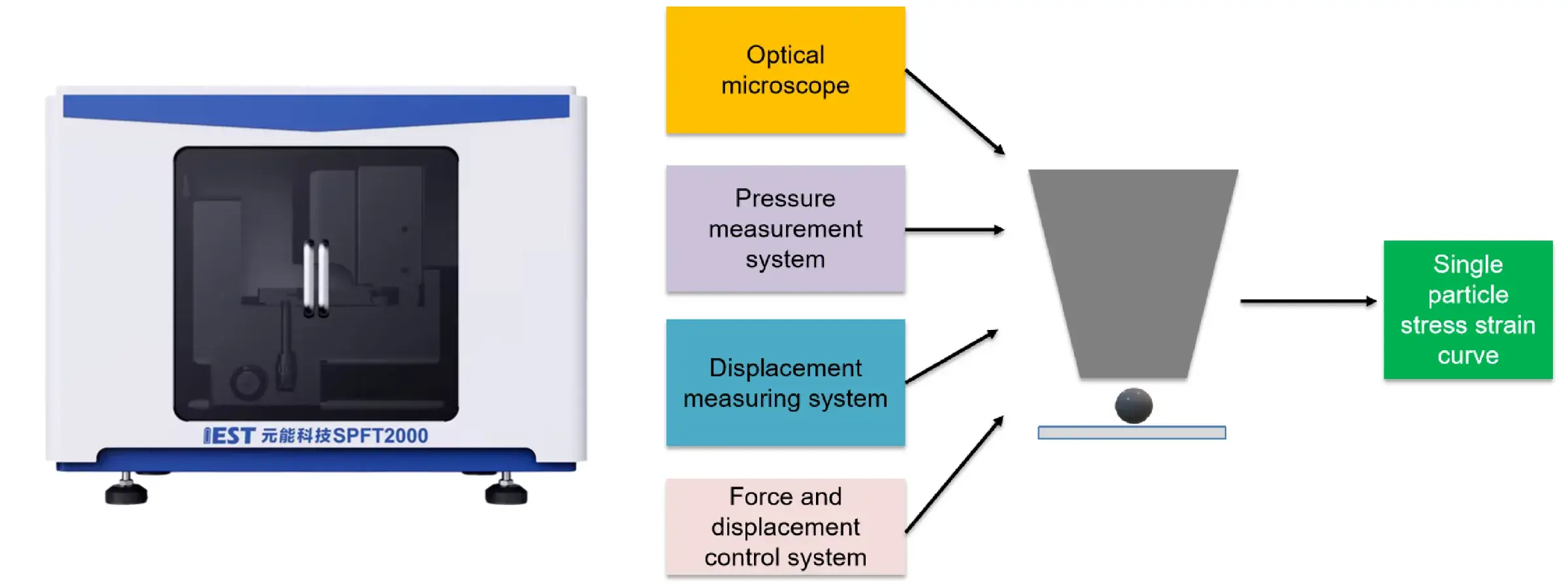

Using the IEST Single Particle Force Properties Test System, we can directly compare the “physical fitness” of the two material types. This test can be thought of as a “weightlifting competition” in the microcosm. Under a microscope, a complete, well-shaped particle of both natural and artificial graphite is selected and subjected to vertical pressure with a fine probe until the particle fractures. The “crushing force” value reflects the compressive strength of the individual particle. (For more detailed testing, refer to the Lithium-ion New Solutions | Single Particle Mechanical Testing System.)

Figure 2. Single Particle Force Properties Test System and Test Schematic

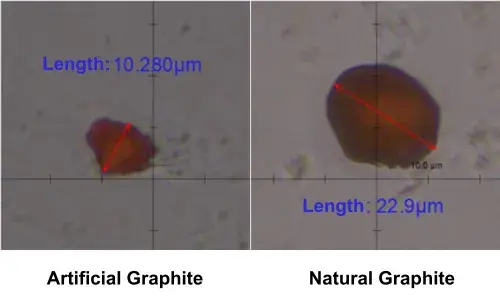

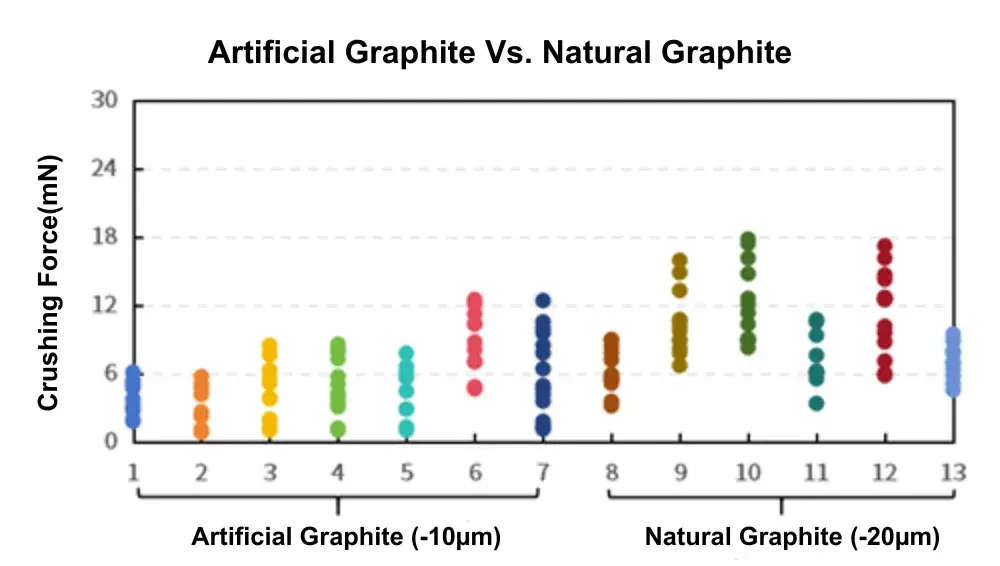

For this study, different types of artificial graphite (~10μm) and natural graphite (~20μm) were selected for single-particle crushing tests, following strict standardized procedures. First, samples were prepared by dispersing particles in ethanol to ensure uniform distribution. Next, optical microscopy was used to locate individual dispersed particles. After setting up experimental parameters, compression tests were performed, and the shape changes of the particles before and after compression were observed and recorded. Each sample typically underwent testing on more than 10 particles to ensure data reliability and statistical significance.

Figure 3. Individual dispersed particles of artificial graphite and natural graphite

4. Results Revealed: Artificial Graphite Demonstrates “Hard” Power

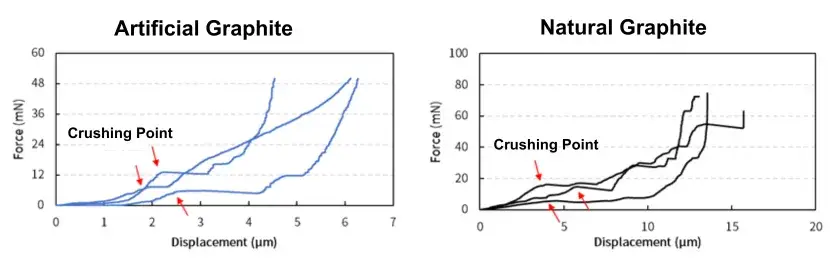

The crushing curves (force-displacement curves) for some particles are shown below. Particles undergo elastic-plastic deformation during the initial compression stage. When compressed to the point of fracture, this is termed the particle’s crushing point, and the corresponding force value is called the Crushing Force, indicating the pressure at which the particle fails. The crushing forces for each sample are aggregated, producing a comparative chart.

Figure 4. Crushing curves of Artificial and Natural Graphite particles

Figure 5. Comparative chart of Crushing Force for Artificial vs. Natural Graphite

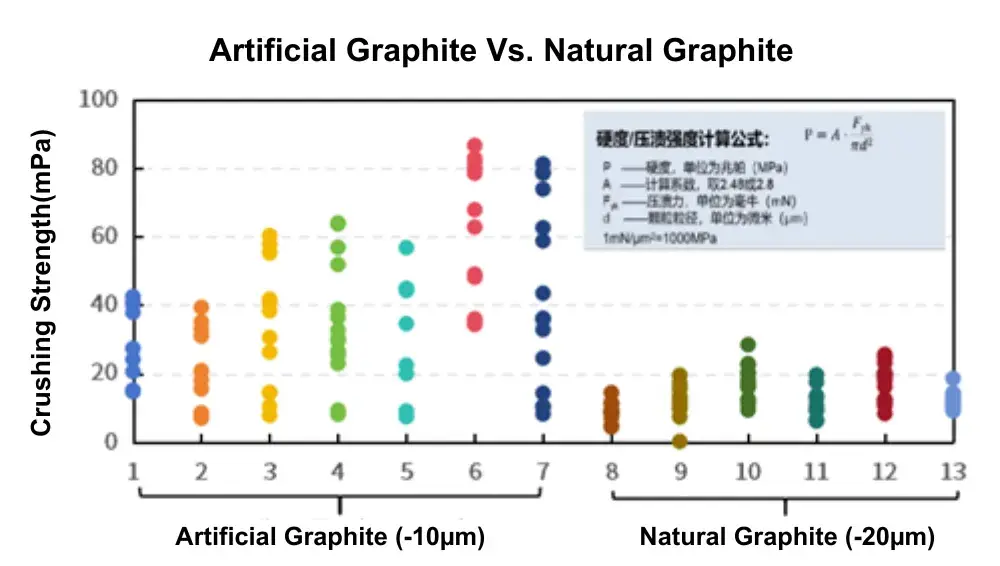

Based on the Chinese National Standard GB/T 43091-2023 method for testing powder compressive strength, the particle’s compressive strength is calculated from its crushing force. The test results clearly show that the average crushing strength of artificial graphite particles is significantly higher than that of natural graphite particles.

Figure 6. Comparative chart of Crushing Strength for Artificial vs. Natural Graphite

Natural graphite is like a well-structured book with weak adhesion, where its layers (bonded by van der Waals forces) are prone to slipping and cleavage under external force, leading to particle breakage from the weakest points.

On the other hand, artificial graphite resembles a book made up of numerous tightly bonded small pieces of paper. Its polycrystalline structure and grain boundaries effectively hinder crack propagation under external force, dispersing concentrated stress in all directions. Each time a crack expands, it encounters a new grain boundary, requiring more energy to break the particle. This makes artificial graphite more resilient.

5. How Does “Hardness” Enhance Battery Performance?

What does a harder anode particle mean for a lithium-ion battery? This is not just a display of “muscle” but translates into tangible performance improvements.

-

Higher Resistance to Pulverization Ensures Longer Cycle Life: During the charging and discharging process of the battery, graphite particles expand and contract repeatedly. Weak natural graphite particles are prone to breaking and pulverizing after hundreds or thousands of cycles due to mechanical fatigue.

-

More Stable Electrode Structure Supports High Energy Density: Stronger particles are less likely to break during electrode calendering, enabling manufacturers to create electrodes with higher packing densities. A higher packing density means more active material can be packed into the same volume, directly enhancing the battery’s volumetric energy density.

-

Potential for Fast-Charging Enhancement: In fast charging, the rapid influx of lithium ions generates significant internal stress. Particles with higher strength are better able to withstand the structural damage caused by this stress, providing a material foundation for the development of safer, more durable fast-charging batteries.

6. Future Trends: Integration and Innovation

Currently, the clear boundaries between purely natural or artificial graphite are blurring, with a shift towards hybridization:

-

Composite Graphite: Blending natural and artificial graphite in specific ratios, or incorporating natural graphite into artificial graphite particles, combines their strengths to find the optimal balance between cost, capacity, rate capability, and cycle life. This is a very mainstream technical direction currently.

-

Silicon-Carbon Anodes: Both natural and artificial graphite are approaching their theoretical capacity limits. The future direction involves incorporating silicon into graphite, forming silicon-carbon composite anodes, which can significantly boost energy density. In this context, artificial graphite, due to its more stable structure, is generally considered a better “host” material for silicon.

7. Conclusion: The Competitive Edge of Artificial Graphite

Through the microscopic window of the single-particle crushing test, we clearly see that artificial graphite, with its “concrete-like” dense structure, possesses superior mechanical strength compared to the structurally regular yet “brittle” natural graphite. This “hard” core strength ultimately translates into longer lifespan, higher energy density, and better reliability for lithium-ion batteries.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.