-

iestinstrument

In-situ Analysis of Overcharge Swelling Behavior of Different Cathode Material Systems

1. Introduction

This study utilizes in situ swelling analysis to directly compare the overcharge response of three commercial lithium-ion cell types, each featuring a different cathode material: LCO (LiCoO₂), LFP (LiFePO₄), and NCM (LiNiₓCoₓMnₓO₂), all paired with graphite anodes. By simultaneously monitoring thickness, temperature, and internal resistance, we capture the real-time sequence of failure events.

Safety remains a paramount concern for the lithium-ion battery industry. As reports of electric vehicle fires persist, material suppliers, cell manufacturers, and OEMs share the urgent challenge of enhancing safety performance. Standard safety evaluations subject cells to abuse conditions—overcharge, over-discharge, crush, nail penetration, and thermal extremes.

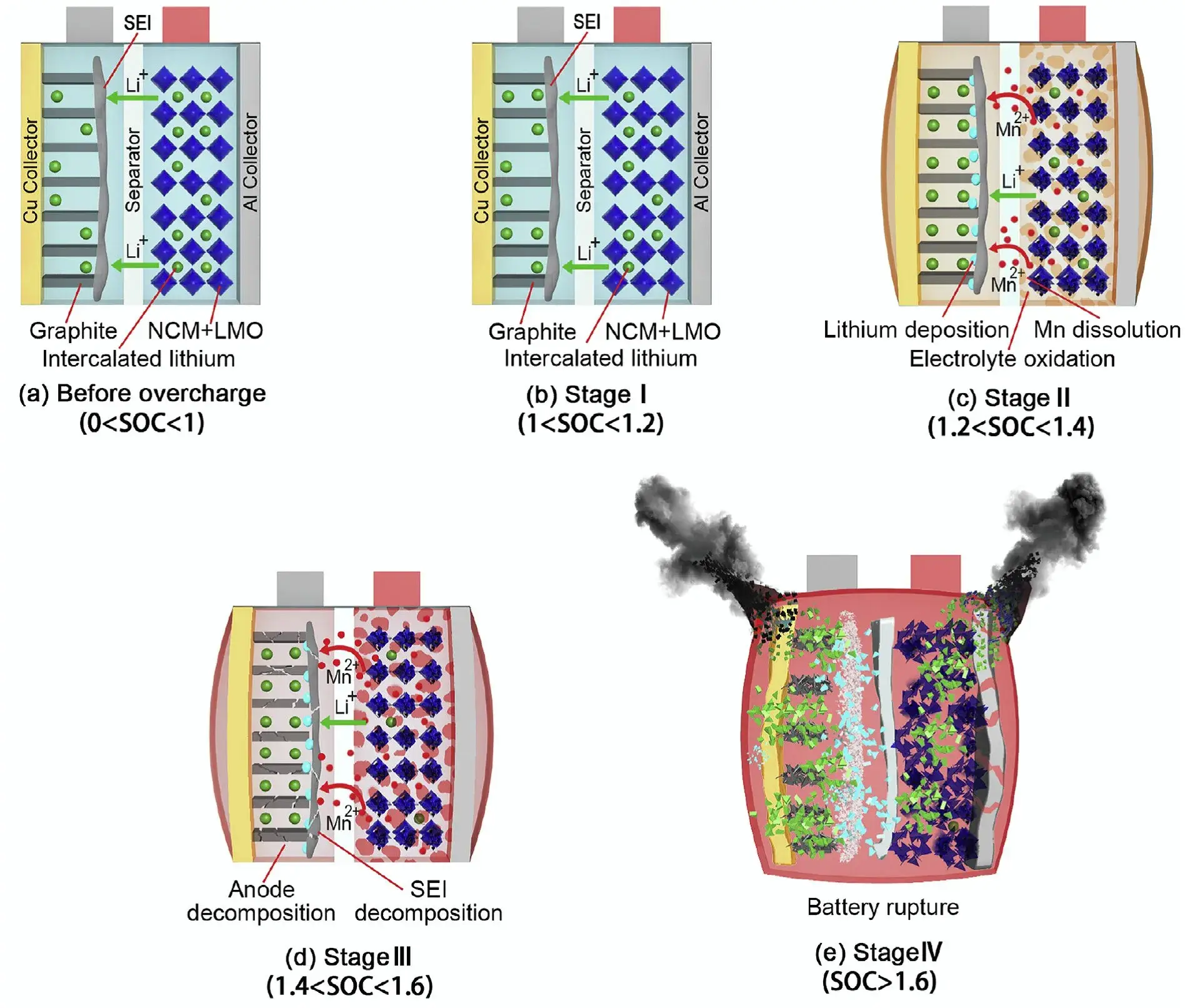

Overcharge is a particularly critical scenario. As depicted in Figure 1, this condition triggers a cascade of detrimental reactions: lithium plating, transition metal dissolution, electrolyte oxidation, and SEI decomposition. These exothermic processes lead to heat generation, gas production (swelling), and, ultimately, thermal runaway and fire. The safety performance indicators of lithium-ion batteries are detailed in the published national standards, GB 31241-2014 “Lithium-ion cells and batteries used in portable elec tronic equipments-Safety requirements” 1 and GB/T 31485-2015 ” Safety requirements and test methods for traction battery of electric vehicle” 2 stipulates that the battery must ensure no fire or swelling under certain overcharge conditions.

Figure 1. Schematic of failure mechanisms during lithium-ion battery overcharge 3

2. Experimental Equipment and Test Methods

2.1 Testing Equipment

The core instrument for this analysis is the IEST In-situ Swelling Analysis System (SWEI2110). This device applies a configurable pressure (50–10,000 N) to the cell and integrates sensors to measure thickness, surface temperature, and internal resistance concurrently during electrochemical cycling.

Figure 2. Appearance of SWE2110 Equipment

2.2 Test parameters:

All cells were tested at 25°C. The charge protocol was a 1C constant current (CC) charge, continued beyond the manufacturer’s specified cut-off voltage to induce overcharge. Put the cell to be tested into the corresponding channel of the equipment, open the MISS software, set the corresponding cell number of each channel, sampling frequency, test pressure and other parameters, and the software automatically reads the cell thickness, thickness change amount, test temperature, current, voltage, capacity and other data.

3. In-situ Monitoring of Lithium-ion Battery Cell Overcharging Behavior

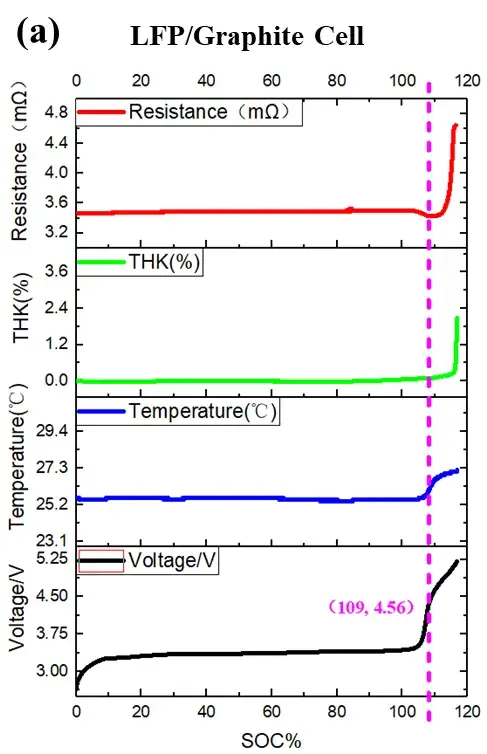

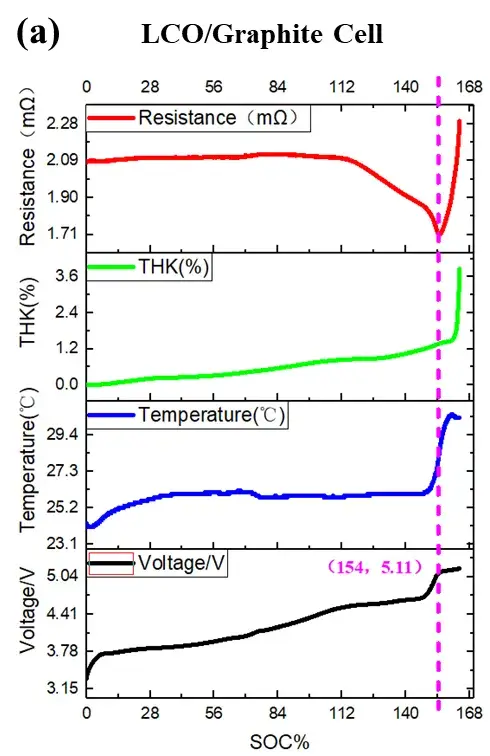

3.1 LCO/Graphite Cell Overcharge

The LCO/Graphite cell used in this study has a nominal capacity of 3 Ah and a normal operating voltage range of 3.0–4.35 V. During overcharge, the cell’s internal resistance, thickness, temperature, and voltage profiles are shown in Figure 3(a). When the voltage reached 5.11 V, corresponding to 154% SOC, the internal resistance, temperature, and thickness all increased sharply, indicating the onset of gas evolution. Examining the inflection points of each curve reveals that the internal resistance inflection coincides with that of the voltage curve, whereas the temperature inflection occurs slightly earlier, and the thickness inflection appears slightly later than the voltage inflection. This sequence suggests that upon reaching a critical overcharge voltage, the cell temperature rises first, causing an initial decrease in internal resistance. As heating continues, side reactions intensify, leading to an increase in internal resistance. The gas produced by these side reactions then drives a rapid swelling of the cell.

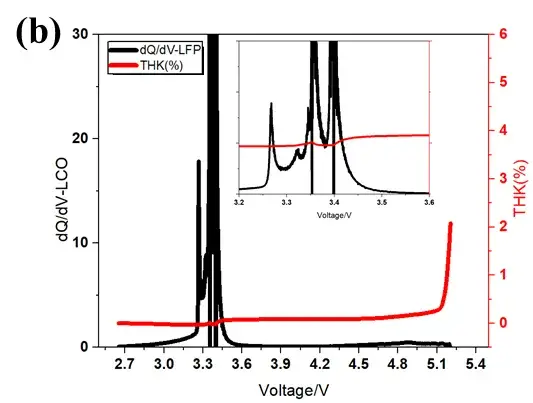

As illustrated in Figure 3(b), the correspondence between the differential capacity curve and the thickness‑change curve shows that every electrochemical reaction alters the slope of the thickness curve. Therefore, for effective cell safety management, close monitoring of internal resistance, temperature, and thickness is essential to provide early warning against the risk of fire or explosion.

Figure 3. (a) Internal resistance, thickness, temperature and voltage curves of LCO system cells under overcharge conditions

Figure 3. (b) Correlation between dQ/dV and thickness change.

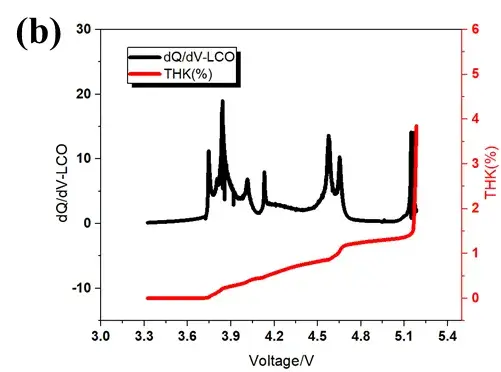

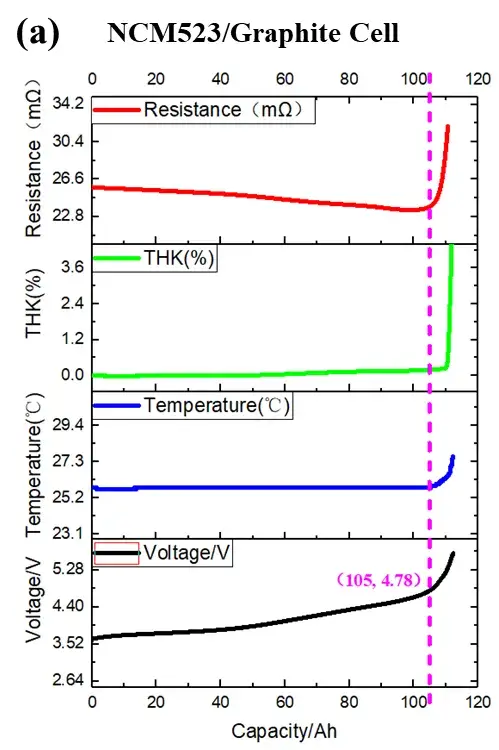

3.2 NCM/Graphite Cell Overcharge

The 3Ah LFP cell (normal range: 2.5–3.65V) entered a failure state at a lower overcharge voltage of 4.56V (109% SOC). Figure 4(a) shows a similar pattern: a temperature increase precedes significant jumps in resistance and thickness. The strong correlation between the dQ/dV features and swelling slope changes in Figure 4(b) confirms that gas generation is tightly coupled to specific electrochemical reactions, even for the typically stable LFP chemistry.

Figure 4. (a)Internal resistance, thickness, temperature and voltage curves of LFP system cells under overcharge conditions

Figure 3. (b) Correlation between dQ/dV and thickness change.

3.3 NCM/Graphite Cell Overcharge

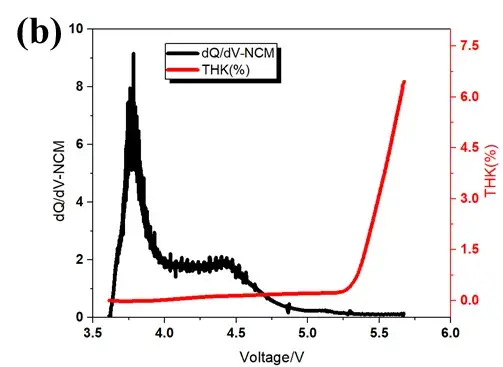

The 2.4Ah NCM cell (normal range: 2.8–4.35V) began showing signs of failure at 4.78V (105% SOC). In this case, as shown in Figure 5(a), the temperature and internal resistance inflections coincided closely with the voltage knee point, while thickness increase followed. Notably, Figure 5(b) reveals that lithium (de)intercalation within the normal voltage range causes minimal swelling. A sudden, violent thickness spike occurs near 5.25V, signaling massive gas generation, even without a distinct peak in the dQ/dV curve at this high 1C rate.

Figure 5.(a)Internal resistance, thickness, temperature and voltage curves of NCM system cells under overcharge conditions

Figure 5.(b) Correlation between dQ/dV and thickness change.

4. Comparative Interpretation: Commonalities and Material-specific Differences

Across all three chemistries the monitored sequence is broadly consistent: temperature rises first, parasitic chemistry accelerates, IR trends respond (initially dropping with gentle warming, then increasing as reactions progress), and thickness increases last as gas accumulates. Nevertheless, the precise overcharge voltages and SOC thresholds vary by cathode material:

-

LCO showed severe responses by ~5.11 V (154% SOC).

-

LFP began to produce gas and swell around 4.56 V (109% SOC) despite its lower nominal voltage window.

-

NCM exhibited catastrophic swelling near ~5.25 V, with earlier signs starting around 4.78 V (105% SOC).

These differences reflect material-dependent electrochemistry: oxygen release propensity, transition-metal dissolution tendencies, and electrolyte oxidation onset differ among LCO, NCM and LFP. Consequently, battery management and abuse-mitigation strategies should account for cathode material behavior under overcharge.

5. Practical Implications For Safety Monitoring and Cell Management

From an engineering perspective the combined monitoring of temperature, IR and thickness provides a layered early-warning system:

-

Temperature is the earliest and most sensitive indicator of incipient parasitic activity; implement rapid thermal detection and throttling logic.

-

IR trends add electrochemical context — a transient IR drop followed by a sustained increase signals progressing side reactions.

-

Thickness (expansion) confirms gas generation and mechanical distress; use it as a definitive trigger for hard cut-off or venting measures.

Integrating these signals into BMS diagnostics will allow earlier interventions than using voltage alone. Furthermore, because some high-rate conditions blur dQ/dV features, redundant monitoring channels (thermal + mechanical + electrical) reduce false negatives.

5. Summary

In this paper, an in-situ swelling analyzer (SWE) was used to monitor the internal resistance, thickness, temperature and voltage changes during the overcharging process of three different cathode material systems, and it was found that cathode material choice significantly influences the onset and progression of failure during overcharge. LCO cells tolerated higher overcharge energy (154% SOC) before failing, while NCM and LFP cells failed earlier at ~105-109% SOC. However, the fundamental failure sequence was consistent: an initial temperature rise, followed by increased internal resistance from side reactions, culminating in rapid gas generation and cell swelling.

For safety management systems, these findings highlight critical in situ metrics for early warning. Monitoring the real-time trajectory of cell surface temperature, internal resistance, and thickness—especially their inflection points—can provide valuable seconds of warning before thermal runaway becomes inevitable. This data-driven approach enables more proactive safety interventions, moving beyond simple voltage cut-offs to multi-parameter failure prediction.

6. References

[1] GB 31241-2014《Lithium-ion cells and batteries used in portable electronic equipments-Safety requirements》.

[2] GB/T 31485-2015《Safety requirements and test methods for traction battery of electric vehicle》.

[3] Dongsheng Ren, Xuning Feng, Languang Lu, Minggao Ouyang et al. An electrochemical-thermal coupled overcharge-to-thermal-runaway model for lithium ion battery. Journal of Power Sources, 364 (2017) 328-340.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.