-

iestinstrument

In-situ Swelling Analysis Of Ternary Batteries At Different Charge Rates

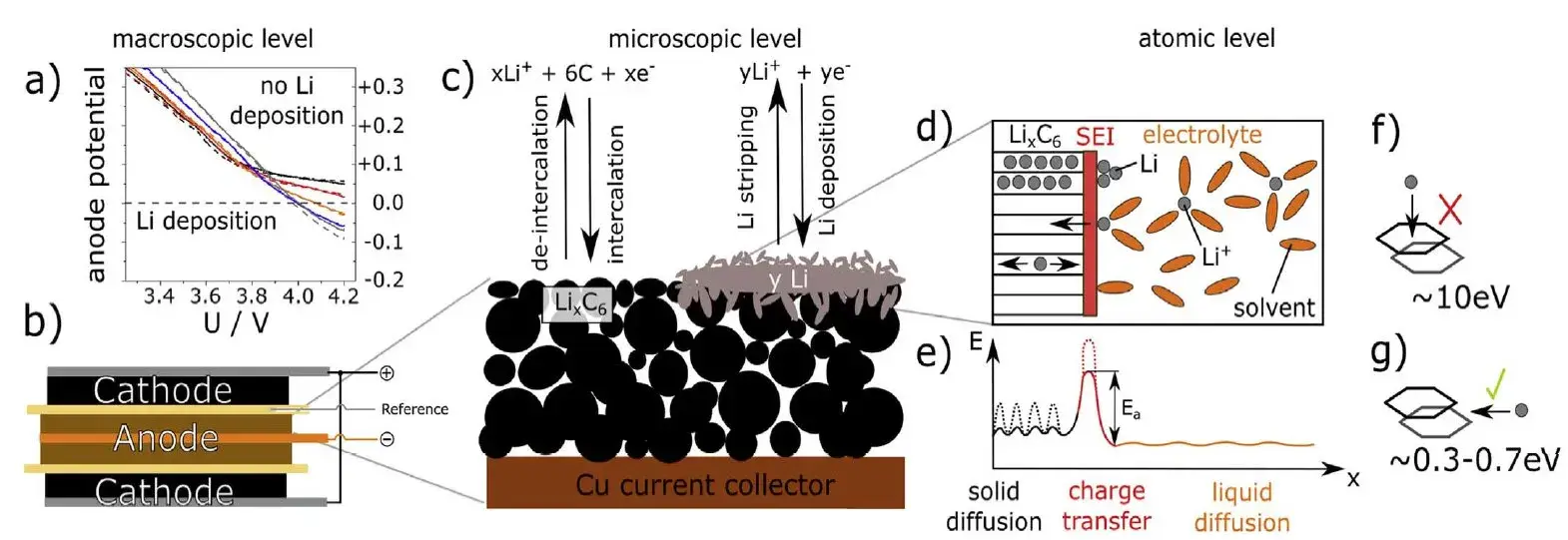

During the charging and discharging process of lithium-ion batteries, as lithium ions are continuously inserted and removed, the thickness of the battery will expand and shrink to a certain extent. Since the lithium insertion and removal process of the cathode and anode electrode materials is not completely reversible, the irreversible thickness of the battery will continue to increase with the increase of cycles 1-3. The higher the charge rate, the greater the current density and the greater the concentration of lithium ions that react. If the charge rate is too high, a large amount of lithium ions will accumulate on the surface of the anode electrode, which will easily cause lithium ions to precipitate on the surface of the negative electrode and increase the thickness of the battery. Figure 1 is a schematic diagram of the lithium deposition process from different dimensions4. This paper uses an in-situ swelling analyzer (SWE) to test the thickness of NCM523/graphite batteries (3446106, theoretical capacity 2400mAh) under different charge rates conditions (0.04C/0.2C/0.5C/1.0C/1.5C) to compare and analyze the expansion behavior of the battery.

Figure 1. Schematic diagram of lithium analysis4

1. Test Information

1.1 Test Equipment

In-situ swelling analyzer, model SWE2110 (IEST), can apply pressure range 50~10000N, the appearance of the equipment is shown in Figure 2.

Figure 2. Appearance of SWE2110 Equipment

2. Test Parameters

2.1 Charge and discharge test

25℃, voltage range 2.8~4.35V, theoretical capacity 2400mAh, charge rate is 0.04C/0.2C/0.5C/1.0C/1.5C respectively, discharging rate are 0.5C.

2.2 Cell Thickness Expansion Test

Put the cell to be tested into the corresponding channel of the equipment, open the MISS software, set the corresponding cell number of each channel, sampling frequency, test pressure and other parameters, and then the software automatically reads the cell thickness, thickness change amount, test temperature, current, voltage, capacity and other data.

3. Analysis Of Results

3.1 Charge-discharge curve analysis

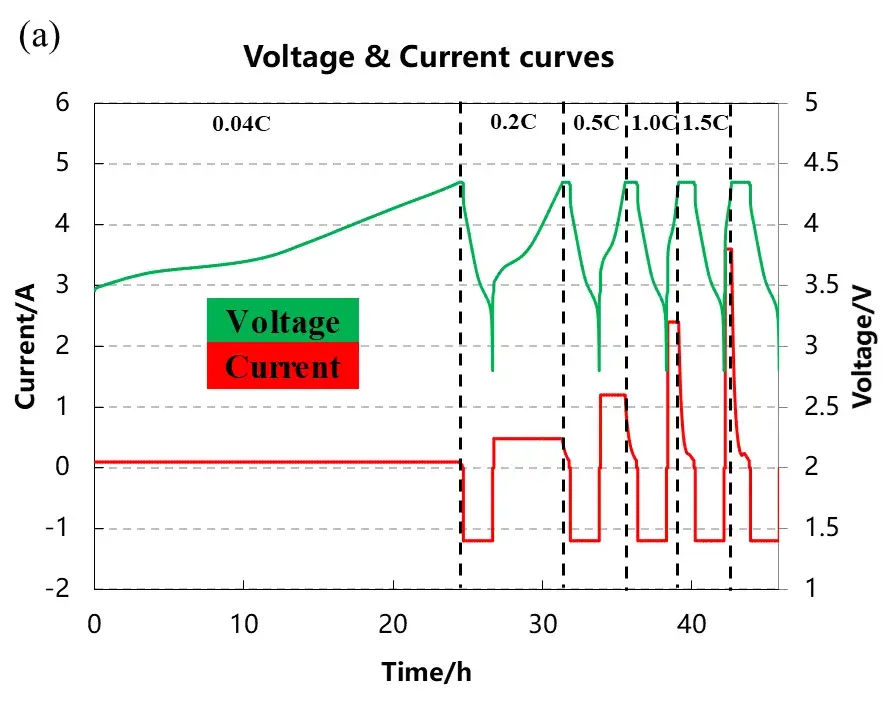

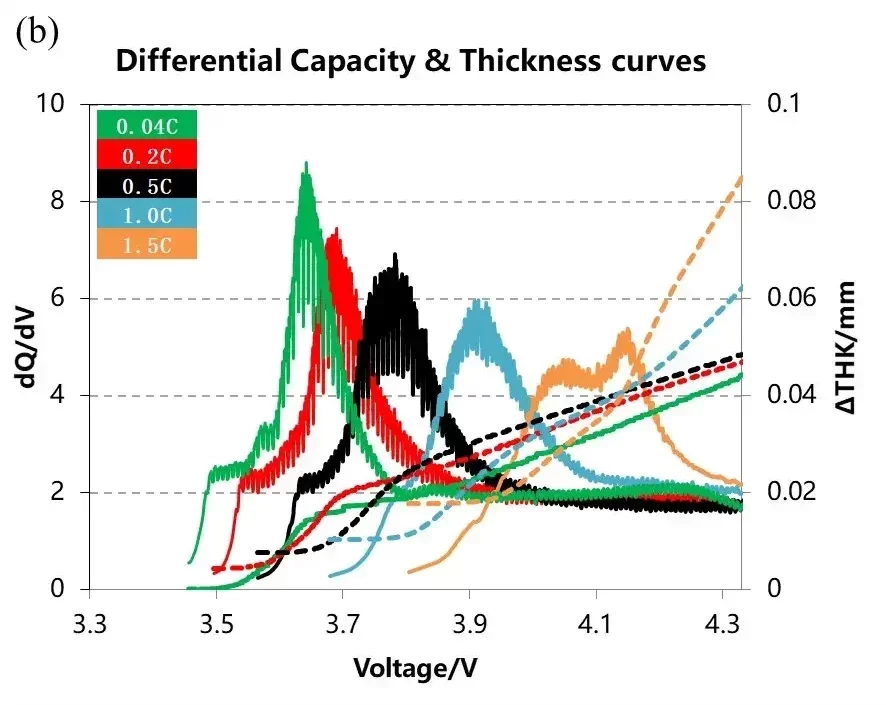

The charging and discharging curves and differential capacity curves of the cell are shown in Figsure 3(a) and 3(b). Using different charge rates to charge the battery, it can be seen that the peak of the differential capacity curve is shifted to the right with the increase of charging rate, which is mainly due to the fact that the large charge rate increases the polarization of the battery, making the electrochemical reaction potential higher. When the charge rate is increased to 1.5C, the differential capacity curve has a split peak, which may be due to the large charge rate leading to the emergence of lithium analyzed in the battery, and then with the increase in voltage, the precipitated lithium will be further embedded in the graphite. When discharged at 0.5C, the peak position and peak intensity of the differential capacity curve are almost the same, indicating that after charging at different charge rates, the initial capacity can be restored by discharging at small charge rates without the occurrence of dead lithium.

Figure 3. Charge-discharge curves (a) and differential capacity curves (b) of the cell at five charging rates

3.2 Swelling curve and differential capacity curve analysis

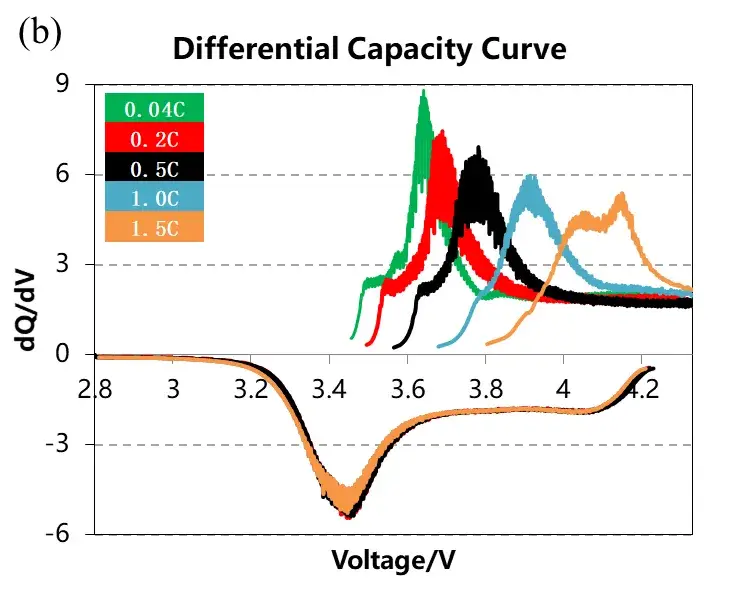

The thickness variation curves of the cells correspond to the voltage and differential capacity curves as shown in Figure 4(a) and 4 (b). Different charge rates were used to charge the cells, and it can be seen from Figure 4 (a) that the initial thickness of each lap increases with the increase of the number of cycling laps, which indicates that there exists a certain irreversible structural phase transition resulting in thickness expansion after charging and discharging at different charge rates. When the charge rate is less than 0.5C, the thickness of the battery is increased during constant voltage charging, but when the charge rate increases to 1.0C and 1.5C, the thickness decreases during the constant voltage charging stage, which may be attributed to the fact that as the current decreases during constant voltage, the internal polarization of the battery decreases gradually, and the distribution of lithium concentration in the negative electrode structure is gradually homogeneous, which exhibits a decrease in the thickness of the battery. As can be seen from the correspondence between the differential capacity curve and the curve of the amount of change in the thickness of the battery in Figure 4(b), the changes in the slope of the thickness curve all correspond one-to-one with the peak of the differential capacity curve, and the rate of growth of the thickness increases correspondingly with the increase in the charge rate.

Figure 4. Thickness & voltage curves (a) and differential capacity & thickness curves (b) of the cell at 5 charging rates

4. Summary

In this paper, an in-situ swelling analyzer (SWE) was used to analyze the thickness swelling of NCM523 cells during charging and discharging under different charge rate conditions. With the increase of the charge rate, the thickness change of the cell increases, and the slope of the thickness change curve also increases, and the relationship between the charge rate and lithium precipitation and the thickness expansion of the cell can be further explored.

5. References

[1] Yongkun Li, Chuang Wei, Yumao Sheng, Feipeng Jiao, and Kai Wu. Swelling Force in Lithium-Ion Power Batteries. Ind. Eng. Chem. Res, 2020, 59, 27, 12313–12318.

[2] Ximing Cheng and Michael Pecht. In Situ Stress Measurement Techniques on Li-ion Battery Electrodes: A Review. Energies, 2017, 10, 591.

[3] Amartya Mukhopadhyaya, Anton Tokranova, Xingcheng Xiaoc, Brian W. Sheldona. Stress development due to surface processes in graphite electrodes for Li-ion batteries: A first report. Electrochimica Acta, 2012,66, 28–37.

[4] Thomas Waldmann, Björn-Ingo Hogg, Margret Wohlfahrt-Mehrens. Li plating as unwanted side reaction in commercial Li-ion cells – A review. J. Power. Source. 2018, 384:107–124.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.