-

iestinstrument

In-Situ Analysis of Expansion Stiffness and Compression Stiffness in Lithium-ion Batteries

Abstract

Cell mechanical stiffness affects appearance, module integrity and abuse resistance of lithium-ion batteries. We used an in-situ swelling analyzer (IEST SWE2110) to quantify Expansion Stiffness (stiffness during electrochemical cycling) and compression stiffness (mechanical stiffness under static compression) across SOC states and applied preloads. Results show expansion stiffness depends strongly on SOC and applied preload and is measurably lower than compression stiffness; therefore, using compression tests alone to infer in-cycle behavior can produce large errors. Practical test and interpretation guidance are provided for battery R&D and module design.

1. Introduction

Mechanical stiffness of cells is commonly split into two concepts:

-

Compression stiffness — resistance to elastic deformation under externally applied static load (e.g., mechanical squeeze testing).

-

Expansion stiffness — resistance to dimensional change generated internally during lithium (de-)intercalation (i.e., during charge/discharge).

While compression testing is simple, it is often used as an approximate proxy for expansion stiffness. This study demonstrates that the two are not equivalent: electrochemical state (SOC/DOD) and preload markedly alter expansion stiffness, so direct measurement under cycling conditions is required for accurate module and safety design.

2. Test Information

2.1 Equipment

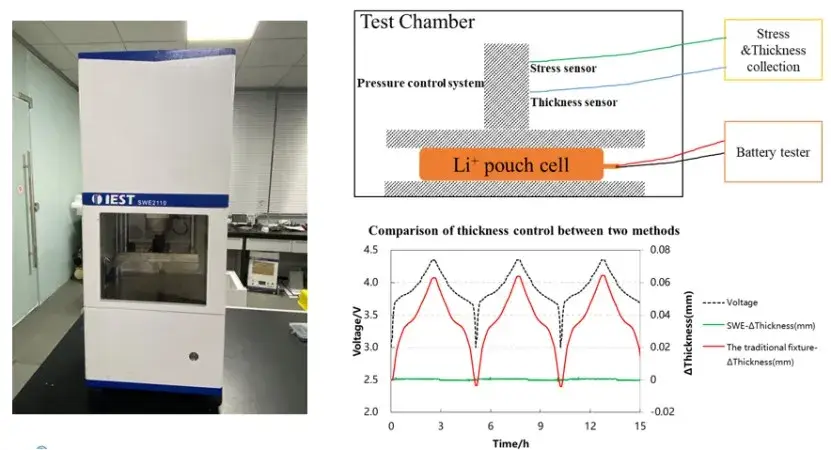

In-situ Swelling Analyzer — SWE2110 (IEST). High-precision displacement sensor and load cell enable real-time logging of thickness, force/pressure, temperature, voltage, current and capacity. The SWE2110 supports constant-pressure and constant-gap control. As shown below:

Figure 1. Schematic diagram of the in-situ swelling analysis system(SWE Series)

2.2 Cell Information

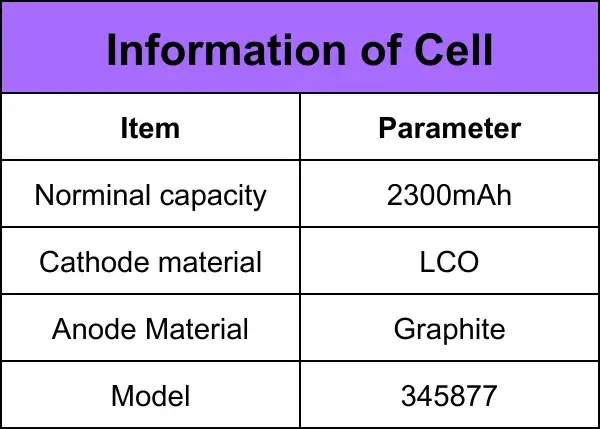

Details of the cell used in this study are summarized in Table 1.

Table 1. Cell Information

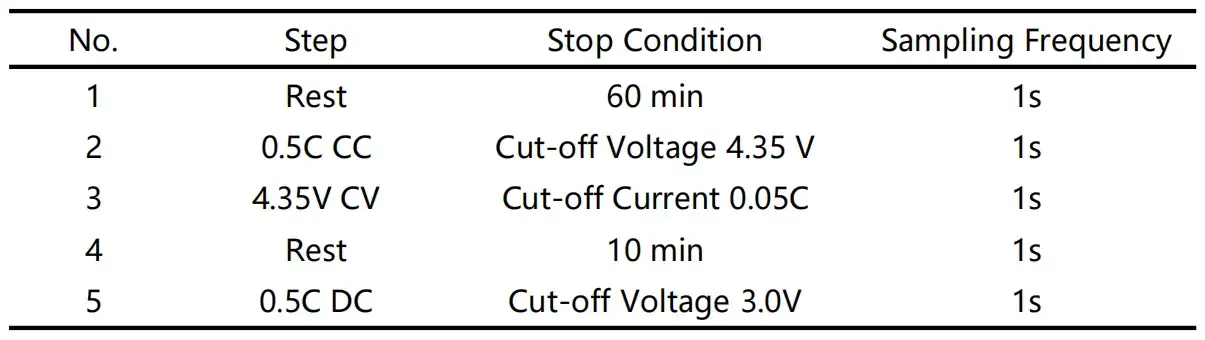

2.3 Charging and Discharging Process

Table 2. Charging and Discharging Process

3. Results and Analysis

3.1 Expansion Stiffness

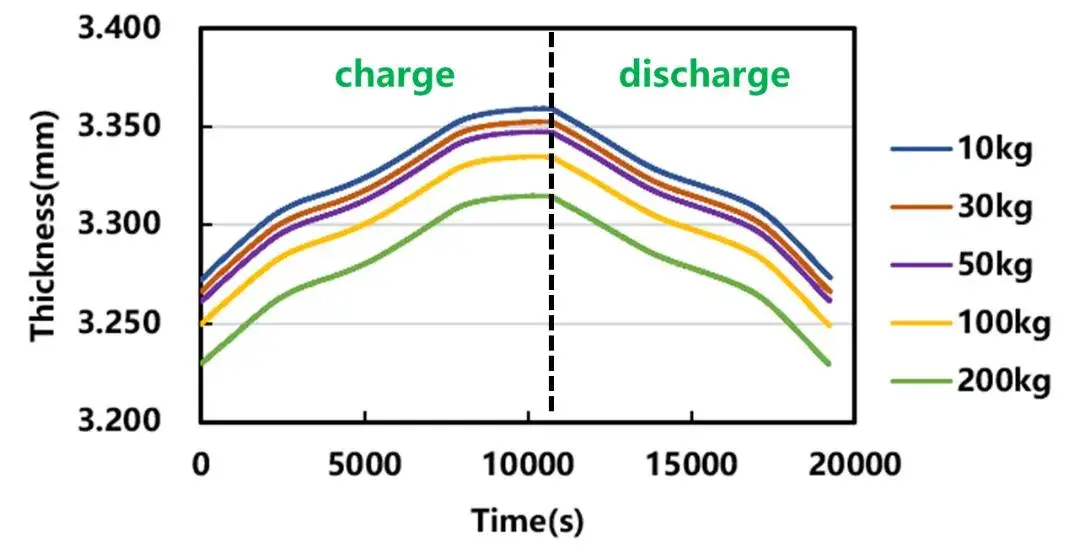

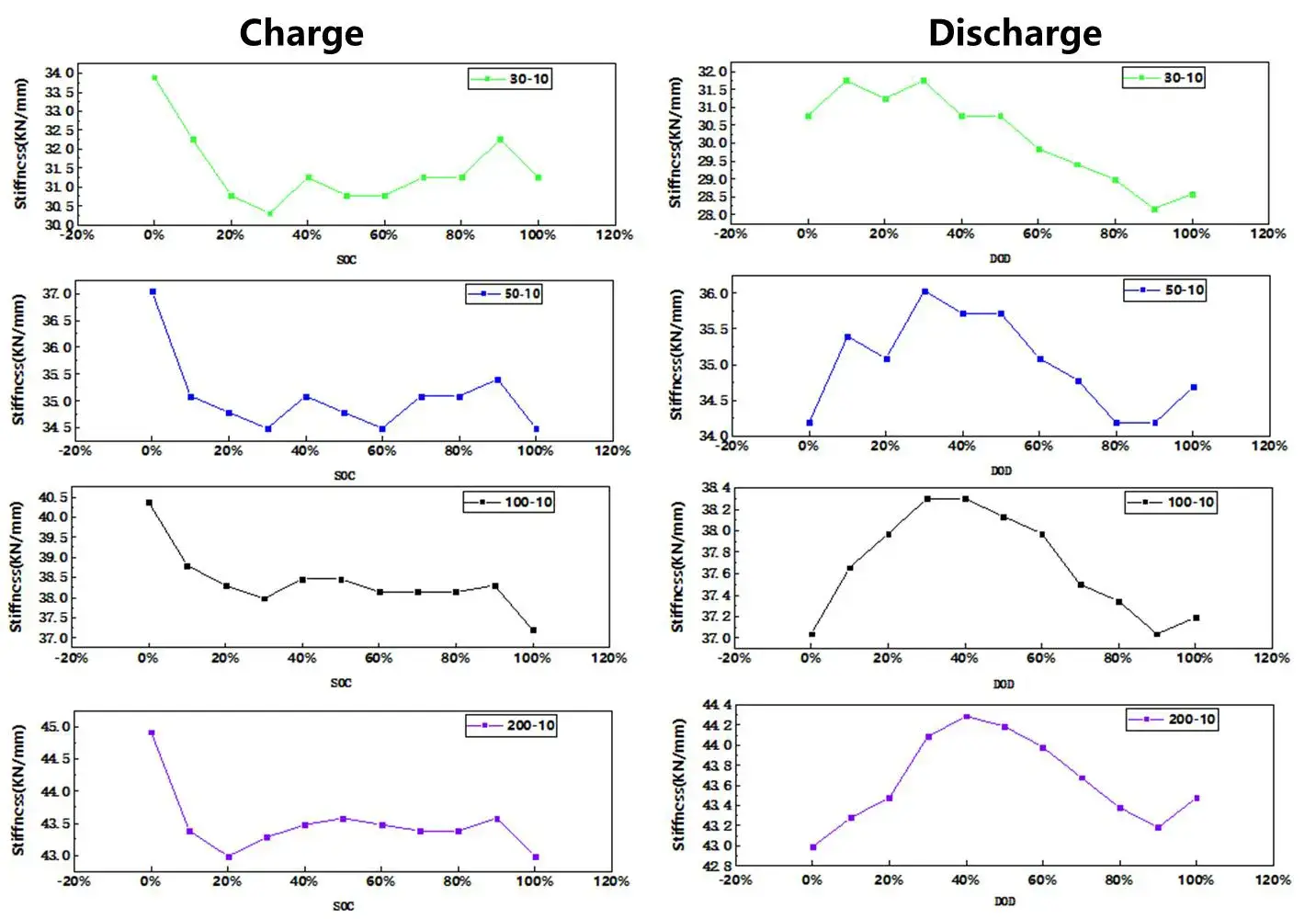

Using the constant-pressure mode of the SWE2110, tests were conducted under applied pressures of 10 kg (0.02 MPa), 30 kg (0.06 MPa), 50 kg (0.10 MPa), 100 kg (0.21 MPa), and 200 kg (0.42 MPa). As illustrated in Figure 2, cell thickness increased during charging—corresponding to lithium intercalation in the anode—while higher applied pressure reduced overall expansion.

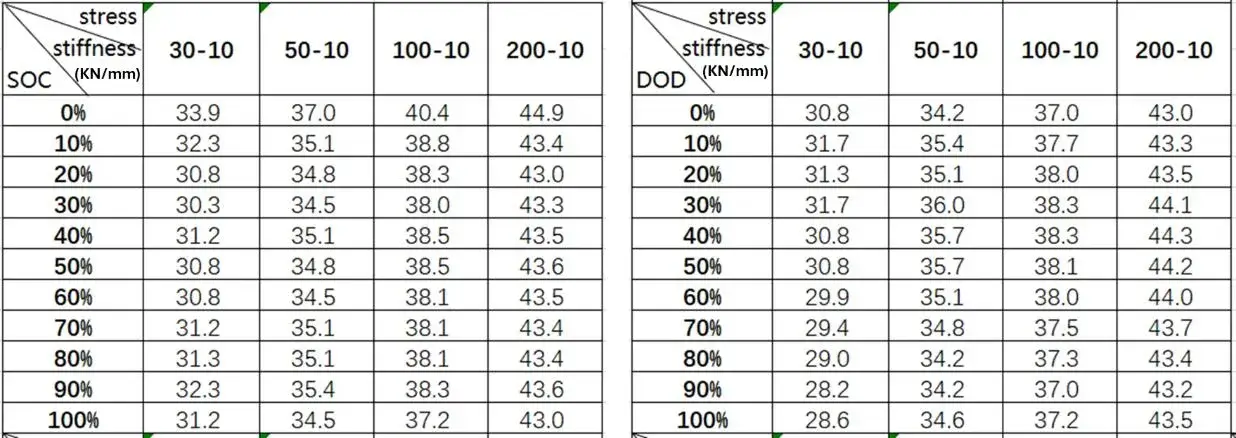

Expansion stiffness was calculated as K=ΔF/Δδ, where F is applied force and δ is thickness. Results in Table 3 and Figure 3 indicate that stiffness values rise with increasing pressure and vary with the state of charge (SOC) or depth of discharge (DOD). Specifically:

-

Expansion stiffness is highest at the beginning of charge, then decreases and stabilizes.

-

During discharge, stiffness initially increases, peaks around 30–50% DOD, and subsequently declines.

Figure 2. Thickness variation curve of charge/discharge of battery cell under different pressures

Table 3. Expansion stiffness of battery cells at different SOCs (charging process on the left, discharging process on the right)

Figure 3. Trend of cell expansion stiffness for different SOC/DOD states

3.2 Compression Stiffness

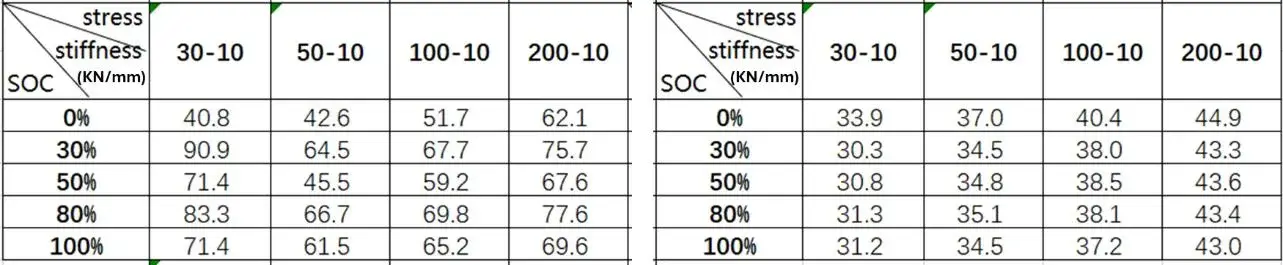

Cells at SOC levels of 0%, 30%, 50%, 80%, and 100% were subjected to the same pressure conditions. Measured compression stiffness values (Table 4, left) were significantly higher than expansion stiffness (Table 4, right), confirming that using compression stiffness to approximate expansion behavior may lead to substantial error.

Table 4. Comparison of cell stiffness (left table compression stiffness, right table expansion stiffness)

4. Discussion & Practical Recommendations

4.1 Why expansion stiffness differs from compression stiffness

-

Expansion stiffness reflects how electrochemically generated stresses are transmitted through electrode microstructure, SEI layers and current collectors; it is influenced by electrode porosity, binder elasticity, particle cracking and interfacial slip.

-

Compression stiffness measures response to externally applied, uniform mechanical load and is dominated by bulk collector and pouch mechanics rather than in-cycle microstructural rearrangements.

4.2 Test recommendations

-

Direct in-cycle measurement: Use SWE2110 constant-pressure mode to obtain true expansion stiffness across SOC windows relevant to your application.

-

Multi-pressure characterization: Test multiple preload levels to understand module preload sensitivity.

-

SOC mapping: Measure expansion stiffness at representative SOCs (e.g., 0%, 30%, 50%, 80%, 100%) because stiffness varies nonlinearly with SOC.

-

Statistical sampling: Test multiple cells to capture manufacturing scatter and irreversible changes over cycling.

-

Use both metrics wisely: Use compression stiffness for mechanical packaging studies where external compression dominates; use expansion stiffness for in-service deformation, stress accumulation and module clamp design.

4.3 Implications for design

-

Module clamps and springs must be specified considering lower expansion stiffness (i.e., cells exert less constraining force during swelling than predicted from compression tests), otherwise fasteners may be underspecified or overcompensated leading to unnecessary mass/complexity.

-

Safety analyses and drop/impact models should incorporate in-cycle stiffness to estimate realistic deformation and potential shorting risks.

5. Summary

This study demonstrates that the SWE2110 system effectively characterizes both expansion stiffness and compression stiffness in lithium-ion cells. Results confirm that cell stiffness is influenced not only by SOC/DOD but also by the magnitude of applied pressure. Crucially, compression stiffness cannot be directly used to estimate expansion stiffness due to measurable differences between the two. These findings underscore the need for dedicated expansion-stiffness testing to ensure accurate mechanical modeling and enhanced safety design in battery development.

5. References

[1] Hoeschele P , Heindl SF , Erker S ,et al. Influence of reversible swelling and preload force on the failure behavior of a lithium-ion pouch cell tested under realistic boundary conditions[J].Journal of Energy Storage, 2023.

[2] ZHU Maoyu,HE Jianchao,YU Ao,et al. Method for testing the expansion stiffness of an cell. Patent No. 202310112653[P][2024-01-15].

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.