-

iestinstrument

Analysis of Battery Cell Swelling and Swelling Force: Choosing Test Parameters for Reliable In-Situ Expansion Measurements

1. Preface

Understanding the lithium battery cell swelling behavior during charge and discharge cycles is critical for materials development and system design. This expansion stems from structural changes in the electrodes and gas generation from electrolyte decomposition. The measured swelling data—whether thickness change or force generation—is highly dependent on the applied boundary conditions during testing. This application note explains how to select test parameters for the two principal in-situ expansion measurement modes—constant pressure and constant gap—and it gives practical guidelines (including commonly used values) to obtain repeatable, industry-relevant cell swelling and swelling force data.

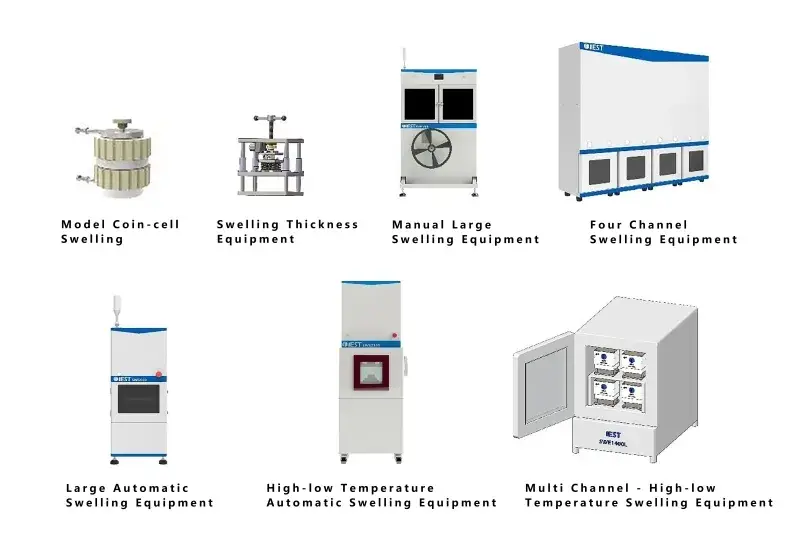

The in-situ swelling test system SWE series from IEST Instrument (Figure 1) enables precise characterization of these behaviors. Proper configuration of its measurement modes is essential for data accuracy. The recommendations below are based on the SWE series in-situ expansion test system and industry practice.

Figure 1. IEST in-situ swelling test system SWE series

2. Constant Pressure Mode: Measuring Thickness Change

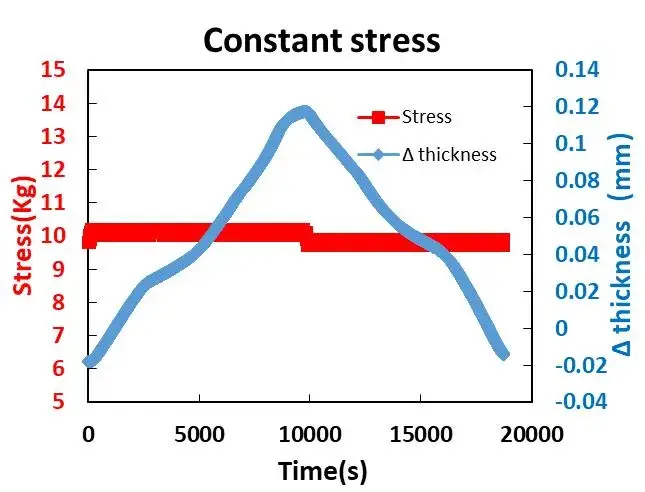

In this mode, the system maintains a constant pressure on the cell surface throughout the electrochemical cycle while recording the resulting thickness variation (Figure 2). This approach is ideal for comparing the intrinsic swelling characteristics of different materials, such as the expansion of various silicon-carbon composites.

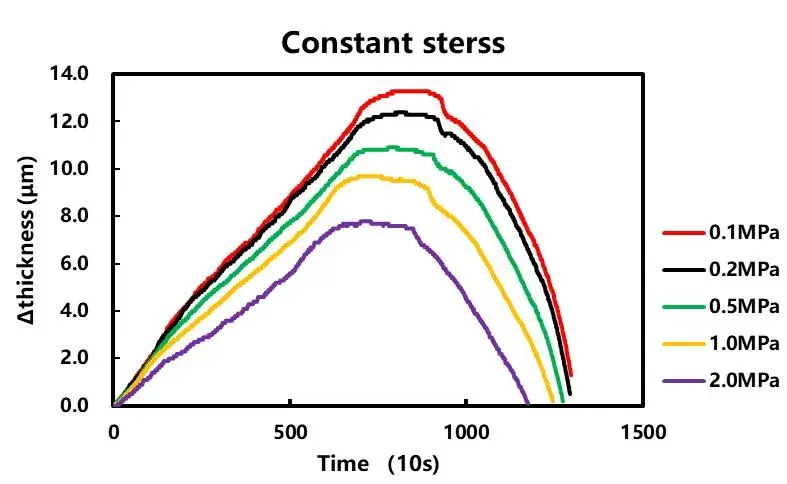

The choice of applied pressure significantly influences the results. Pressure is set based on the cell’s surface area (applied as MPa). Generally, higher pressures constrain the cell more, leading to smaller measured thickness changes during cycling, as shown in Figure 3. However, excessive pressure can increase cell polarization, adversely affecting performance and cycling data. Therefore, selecting a reasonable pressure is crucial. A common industry practice is to use 0.2 MPa for in-situ swelling thickness characterization.

This mode does not require a specific initial State of Charge (SOC). Data analysis typically focuses on comparing the thickness difference between fully charged and fully discharged states.

Figure 2. Schematic of Constant Pressure Mode and Thickness Variation

Figure3. In-situ swelling thickness curves under different pressure conditions

3. Constant Pressure Mode: Measuring Thickness Change

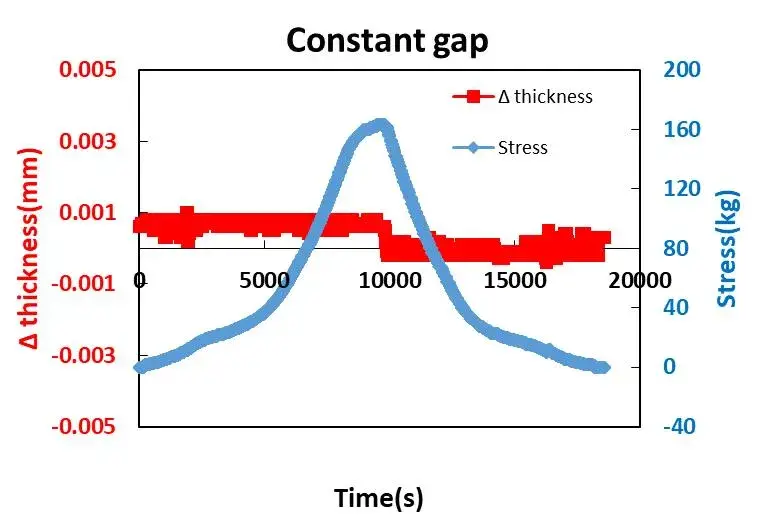

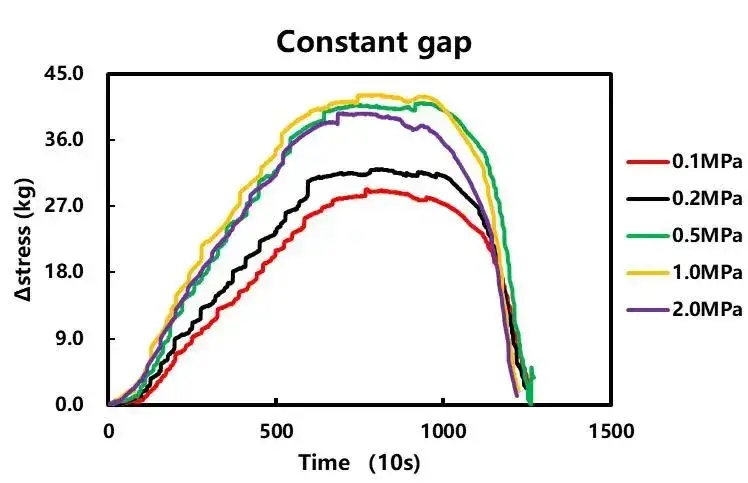

Constant Gap mode simulates a fixed mechanical boundary. The system first applies an initial preload force to the cell, then maintains the corresponding gap (distance between plates) constant. It continuously measures the swelling force generated by the cell during cycling (Figure 4). This mode is particularly valuable for cell, module, and pack design or simulation, helping analyze the stiffness of restraint system components like module housings or cushioning pads by testing under different initial preloads.

The preload force setting determines the initial gap. A higher preload results in a smaller gap, leading to a higher measured swelling force during subsequent cycles (Figure 5). Beyond a certain point, the swelling force change stabilizes. Further increasing the preload to minimize the gap can increase polarization and impact cell performance. A preload of 0.2 MPa is a standard industry choice for in-situ swelling force tests.

Notably, the cell’s initial SOC significantly affects this measurement. Under the same preload, a cell at 0% SOC will have a smaller gap than one at 100% SOC. The resulting swelling force difference over a full cycle will also differ. For consistent results, it is recommended to test cells at a uniform initial SOC, typically the fully discharged state.

Figure 4. Schematic diagram of constant gap swelling force variation

Figure 5. Swelling Force Changes in Constant Gap Mode with Different Preload Forces

4. Summary

When characterizing the cell swelling performance, the constant pressure and constant gap modes have different application scenarios and test parameters. Usually, when evaluating materials, the constant pressure mode is preferred to characterize the cell swelling thickness. At this time, there is no special requirement on the initial SOC of the cell, in cell design, the constant gap mode is more preferred to characterize the cell swelling force. At this time, the initial SOC of the cell will greatly affect the subsequent test results, and the cell in the fully discharged state can be selected for testing. In addition, for the setting of the initial pre-tightening force, the pressure of 0.2MPa is applied to the surface of the cell as the initial condition of constant pressure or constant gap in the industry.

5. References

[1] Li Linyang, He Fan, Lv Xixiang. Analysis method of lithium cell module swelling displacement [J]. Power Technology, 2023, 47(5): 632-634.

[2] Liang Haobin, Du Jianhua, Hao Xin, et al. A review of current research on the formation mechanism of lithium batteries [J]. Energy Storage Science and Technology, 2021, 10(2): 647-657.

[3] MARTIN W, JORG K, DIRK U S. Investigation of the influence of different bracing of automotive pouch cells on cyclic lifetime and impedance spectra[J]. Journal of Energy Storage, 2019, 21:149-155.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.