1. Introduction

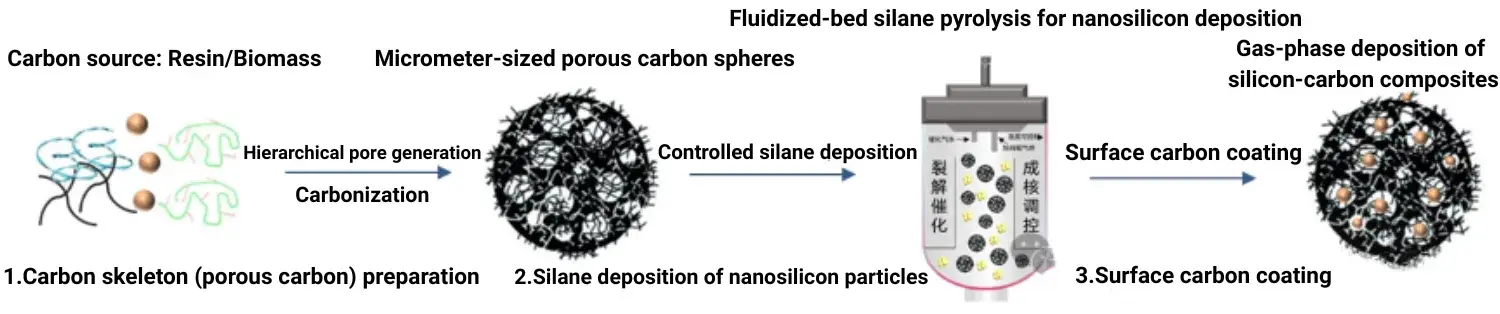

Chemical Vapor Deposition silicon(CVD/PECVD) has emerged as a key breakthrough in lithium-ion battery anode materials. Its development trajectory is closely tied to the choice of substrate, which not only influences deposition morphology and interfacial stability, but also directly determines cycle life, energy density, and manufacturing economics. Among the mainstream pathways, biomass-based and resin-based chemical vapor deposition silicon represent two dominant technical routes. These differ significantly in cost structure, performance ceiling, scalability, and sustainability, collectively shaping the strategic direction of the chemical vapor deposition silicon sector.

This article investigates the fundamental structural distinctions between biomass-based and resin-based chemical vapor deposition silicon. It explores the full mechanical response chain—from single-particle mechanics to calendering stress fields to electrode-level crack propagation—to identify a new direction for industry development.

Figure 1. Schematic of chemical vapor deposition silicon process routes.

2. Root Differences in Single Particle Mechanical Properties

Biomass-based carbon particles possess a natural porous framework (porosity: 60–80%) with non-uniform pore distributions (macro-, meso-, and micropores). Under mechanical stress, they exhibit elastic pore closure at low pressure and plastic wall collapse at high pressure. Fragmentation generates secondary debris (50–200 nm), which can partially fill pores but may also obstruct ion transport when excessive (>30%).

In contrast, resin-based carbon particles feature a rigid and highly cross-linked dense structure (porosity <10%) with smooth surfaces (roughness Ra < 0.1 μm). They exhibit minimal elastic deformation and undergo brittle intergranular fracture beyond the elastic limit, often producing sharp fragments (20–50 nm) that can puncture binders and separators, risking disconnection of the conductive network or even micro-short circuits.

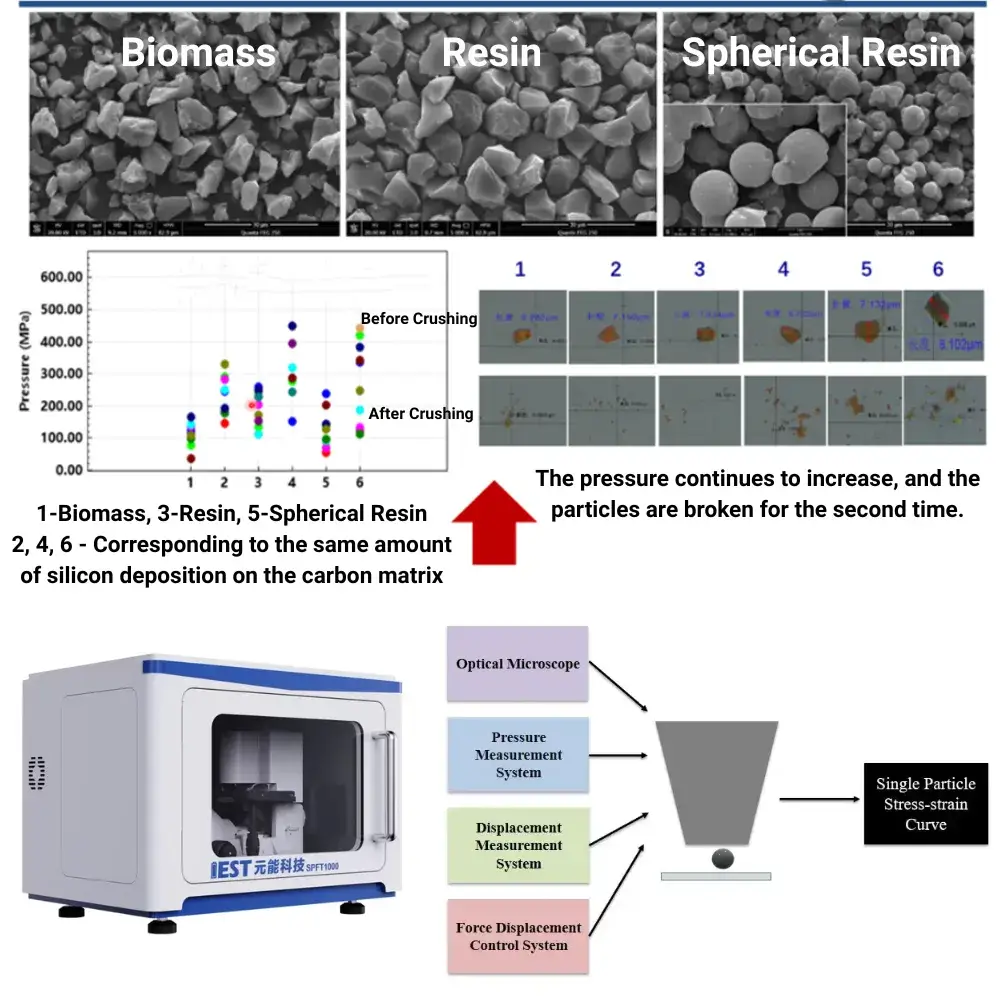

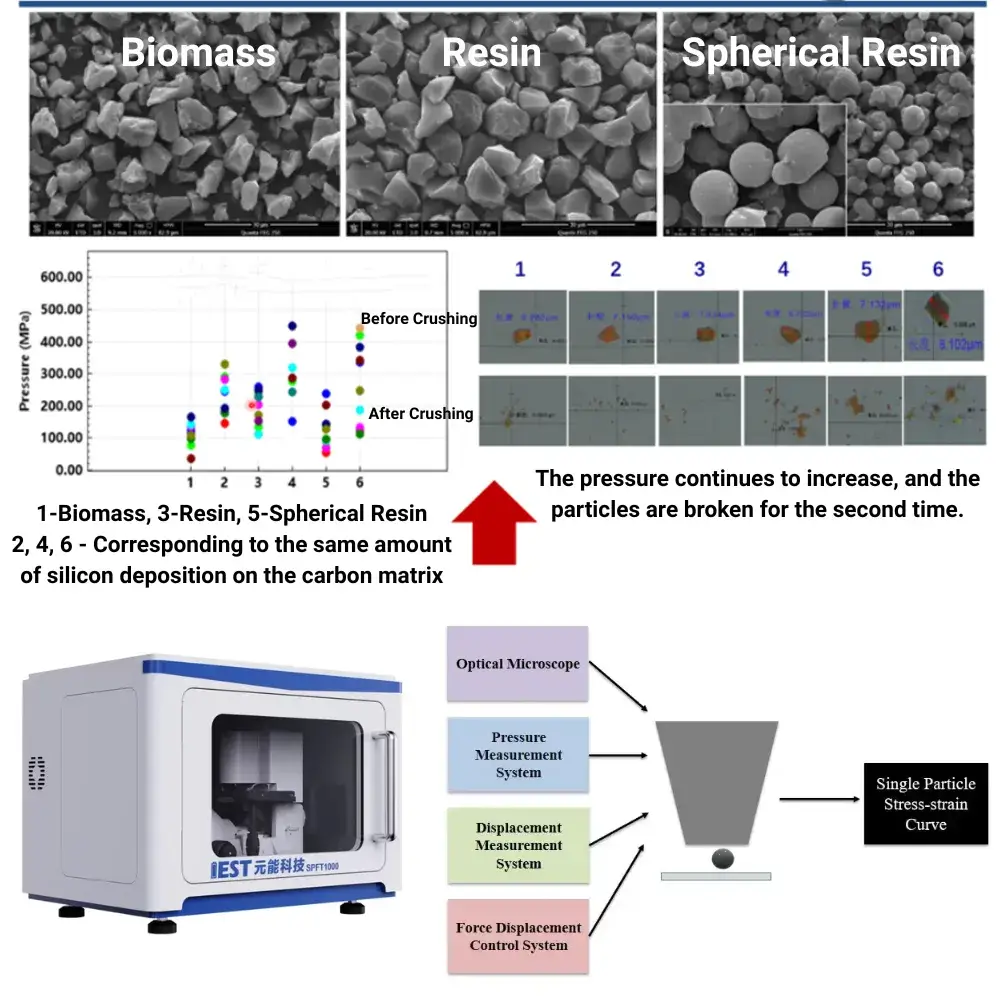

The mechanical performance evaluation of silicon-based single particles at the particle level is currently a focal point of widespread attention in the lithium-ion battery industry. As illustrated in Figure 2, researchers have conducted schematic single-particle mechanical evaluations on biomass-based particles, resin-based particles, and chemical vapor deposition silicon-based particles. The results indicate that resin-based particles exhibit higher compressive strength than biomass-based particles, a trend consistently observed in silicon-carbon (Si/C) particles with equivalent silicon deposition on carbon substrates. Single-particle mechanical assessments enable high-performance material screening at the initial material development stage, significantly accelerating R&D progress.

Figure 2. Comparison of mechanical properties evaluation of biomass-based and resin-based single particles and evaluation equipment

3. Cross-Scale Transmission Mechanisms of Calendering-Induced Fracture

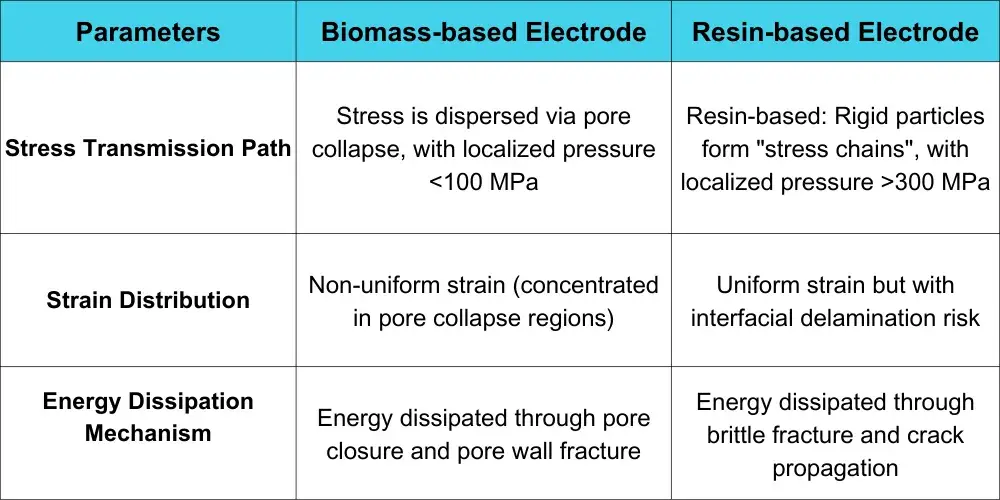

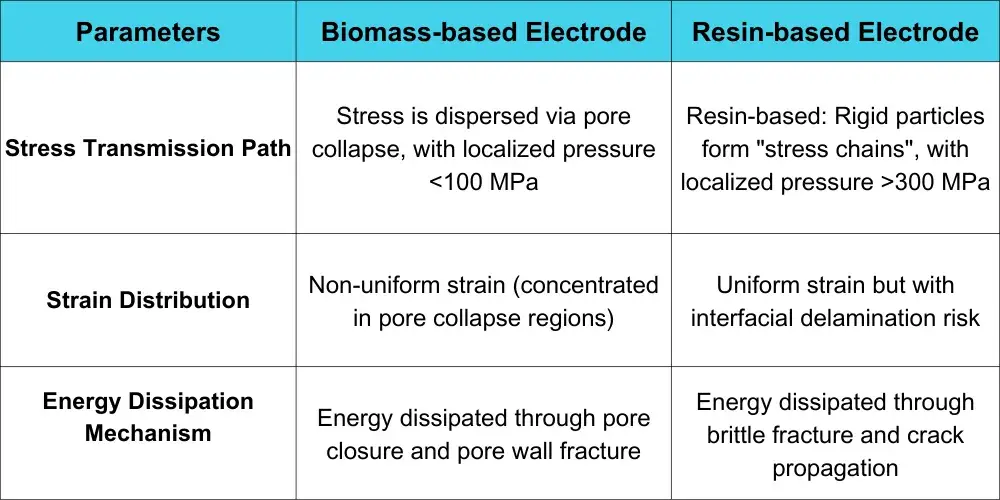

In calendering processes, fracture behavior directly influences stress distribution, and the variations in stress distribution critically determine the structural integrity and electrochemical performance of electrodes. Due to inherent structural differences, biomass-based and resin-based gas-phase deposited silicon exhibit distinct stress distribution patterns under calendering stress fields. This study conducts a comparative analysis of stress transmission paths, stress distribution profiles, and energy dissipation mechanisms (see Table 1) to evaluate the impact of calendering on electrode performance. The divergence in rolling stress distribution between biomass- and resin-based electrodes stems from their intrinsic material characteristics: “porous buffering” (biomass-based) versus “rigid constraints” (resin-based). Understanding these differences and implementing targeted optimizations can significantly enhance electrode yield rates and battery lifespan.

Table 1. Comparison of calendering stress field distributions

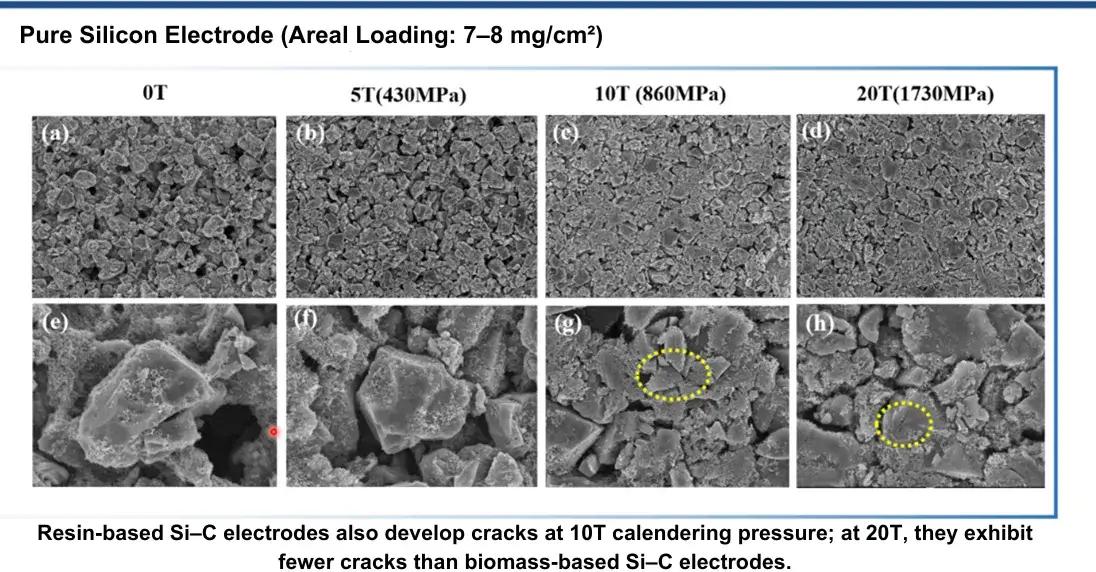

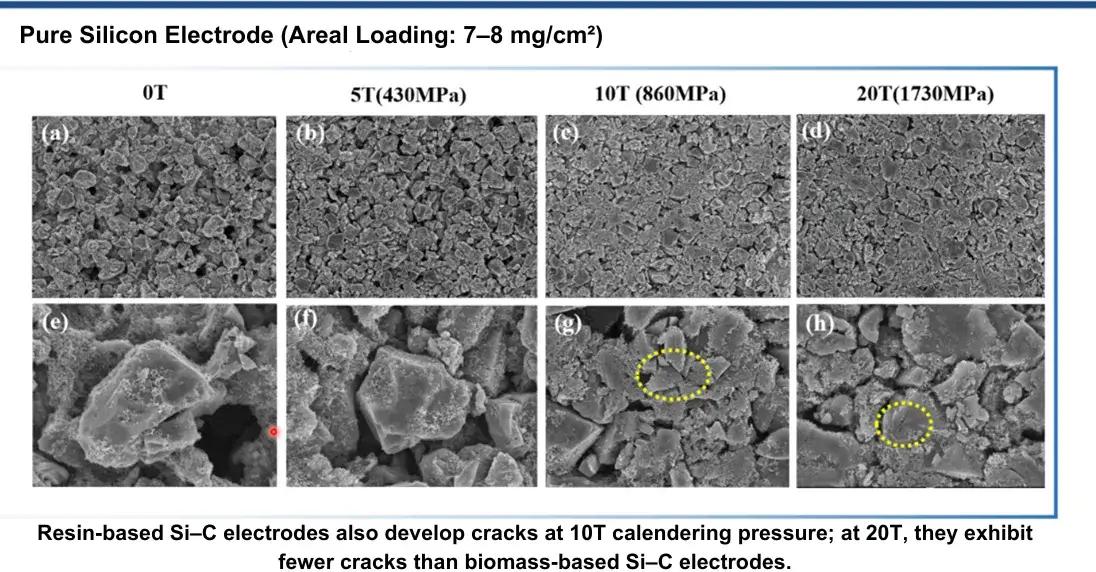

Fracture behavior during electrode calendering is directly linked to single particle mechanics. In biomass‐based electrodes, the predominant failure sequence is pore collapse → conductive network rupture → localized polarization intensification → capacity fade. By contrast, in resin‐based electrodes the primary failure pathway is brittle fragment penetration of the binder → conductive network disconnection → “island” silicon particle deactivation. Comparative studies of chemical vapor depositionsilicon electrodes on these two substrates—subjected to escalating calendering pressures—show that both biomass‐based and resin‐based Si–C electrodes develop cracks under high pressure; however, resin‐based electrodes exhibit significantly fewer cracks even at equivalent or higher pressures (Figure 3). This observation aligns with single‐particle mechanical test results, further confirming the direct correlation between calendering‐induced fracture modes and particle‐level mechanical properties.

Figure 3. Morphological evolution of resin-based Si/C electrodes under varying calendering pressures.

4. Summary and Outlook

The divergence in calendering‐induced fracture behavior between biomass‐based and resin‐based CVD silicon fundamentally mirrors their single‐particle mechanical characteristics at the macroscale manufacturing level. By precisely tuning the particle fracture threshold, optimizing stress‐dissipation pathways, and tailoring the calendering process, one can markedly improve electrode integrity and extend cell lifetime. Looking forward, the integration of smart materials with digital‐twin technology will usher silicon‐based anode production into a new era of defect predictability and process self‐optimization. Rather than being mutually exclusive, the biomass and resin routes act as complementary engines driving Si–C commercialization. Through technological innovation and market synergy, silicon anodes will transition from an optional upgrade to an industry‐standard solution. As material hybridization, green processing, and intelligent manufacturing converge, these two pathways will blur their boundaries and open the era of all‐scenario applications for silicon–carbon materials.

5. Reference

[1] GB/T 43091-2023, Test method for compressive strength of powder[S].