-

iestinstrument

Evaluating the Compression Behavior and Compaction Density of Powder Materials for Lithium-ion Batteries

1. Introduction — Why Powder Material Compaction Matters

The performance and safety of lithium-ion batteries are fundamentally governed by the properties of their constituent materials. Among these, the characteristics of the active powder materials—cathode and anode particulates—are paramount. A key metric linking material properties to cell performance is electrode compaction density. This parameter, which directly influences energy density, internal resistance, and cycle life, is determined by the particle size, distribution, and the compressibility of the powder itself.

Accurately assessing compaction density and understanding the underlying compression behavior of powders are therefore critical for material selection, process optimization, and quality control in battery manufacturing. This article provides a systematic analysis of powder compression fundamentals and offers practical methodologies for reliable evaluation.

2. Fundamental Properties of Battery Powders

In lithium-ion battery manufacturing, the calendering process densifies the coated electrode, essentially compacting a layer of powder mixed with binder and conductive additives. This makes the study of powder behavior directly relevant to process outcomes.

According to Mr. Yang Shaobin, “lithium-ion battery manufacturing process principles and applications, powder density is defined in three primary forms:

-

True Density (ρt): The mass per unit volume excluding all pores (both intra- and inter-particle).

-

Particle (or Apparent) Density: The mass per unit volume including intraparticle pores but excluding interparticle voids.

- Bulk (or Fill) Density: The mass per unit volume including all pores and voids. The relationship is: True Density > Particle Density > Bulk Density[1].

Filling density includes loose-fill density, vibration density and compaction density. Loose packing density is the density of free accumulation of particles under no pressure conditions; vibration density is mainly the filling density tested after vibration of the powder; compaction density is the overall filling density of particles after external pressure. Compaction density is the overall filling density of the particles after external pressure. The order of comparison of the size of the filling density is as follows: compaction density>vibration density>loose loading density. Electrode compacted density pool is one of the key indicators of concern in the design process of lithium-ion batteries, electrode compacted density = surface density / (thickness of the electrode rolled – the thickness of the collector), and the compacted density of the powder material = the mass of the powder after compression / the volume of the powder after compression; the determination of the compacted density of the powder can be used in the powder research on the differences in compacted density of powders under different conditions of the process modification to carry out an effective assessment, and at the same time In the powder production process stability and incoming material monitoring are of great significance[1].

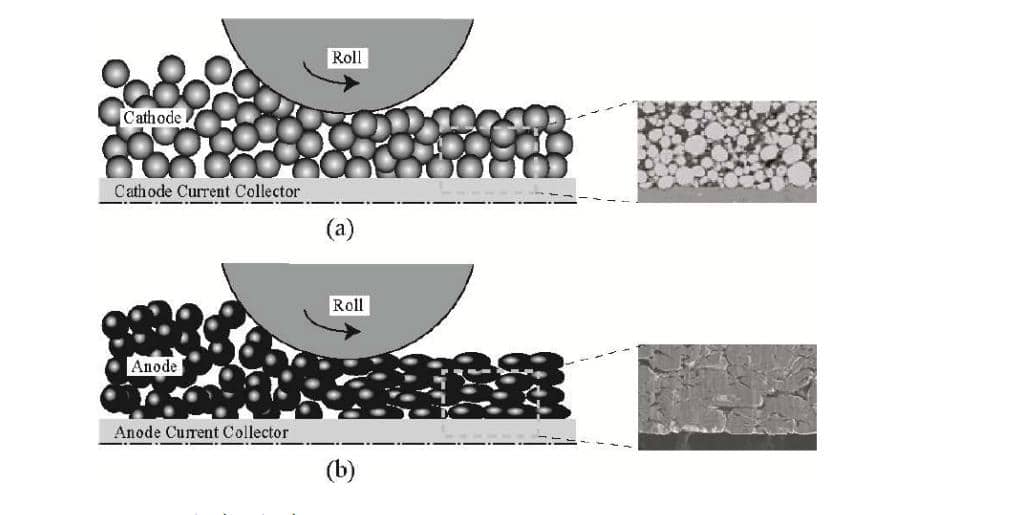

Powders have similar fluidity to liquids, similar compressibility to gases, and specifically the deformation resistance of solids. Powder study is mainly a science based on the properties of various shaped particle aggregates. Most of the particle size of powder research between 0.1 ~ 100μm, a small number of particles can also be as small as 1nm or as large as 1mm. powder compression process will be subject to the powder particle size and its distribution, morphology, density, specific surface area, void distribution, surface properties, mechanical properties and mobility properties, and ultimately show the filling properties and compression performance of different. Lithium-ion battery production and manufacturing process of the electrode roll pressing process process is actually the process of compaction of cathode and anode electrode materials, is the rearrangement of the powder and densification process (Figure 1 for the electrode coating roll pressing process of microstructure evolution schematic), so the powder performance research is also the focus of the current lithium-ion battery process modification research and development. In this paper, the actual determination process of lithium powder compaction density as the basis for systematic analysis, clear impact on the powder compaction density, compression performance measurement and parameter selection of correlation index, in order to ensure the effectiveness and rationality of the compaction density determination and assessment[1,2].

Figure 1. (a) Schematic diagram of the microstructure evolution of the coating material during the roll pressing process of the cathode (b) anode electrode sheet[2]

3. Understanding Powder Compression Behavior

After the powder is compressed by external force, under small pressure conditions, the filling between the powder particles is not tight, and the porosity between the powders is large; with the increase of the external force, the powder particles flow and rearrangement to form a tight stacking state, and the porosity between the particles is also reduced; as the pressure continues to increase, the powder particles undergo elastic deformation, and the change in the porosity between the particles is not significant, but the particle pore size will be reduced; along with the further increase of pressure With the further increase of pressure, some powder particles will be irrecoverable plastic deformation, particle pore size will be further reduced; at the same time will be accompanied by brittle particles system breakage, particle pore size will be significantly reduced. The actual compression process of powder is a complex composite process, elastic deformation will coexist with plastic deformation, elastic deformation can be recovered, plastic deformation is partially unrecoverable[1].

Powder compression performance is the focus of the study of powder materials mechanical properties, in the field of pharmacology has a relatively comprehensive study, and in the field of lithium-ion batteries we are more concerned about the compression performance of the finished battery tends to be, with the development of lithium-ion battery industry and the powder material compaction density indexes are valued, the compression performance of powder materials is also gradually being focused on by the researchers, and more and more researchers prefer to be from the powder, the electrode, More and more researchers prefer to evaluate the compression performance of powder, electrode, cell and other layers to determine the relevance of each stage of the process development process. IEST production of the PRCD series of powder resistance & compaction density tester currently has nearly 200 + customer groups in the lithium industry, currently used for powder materials process modification indicators to assess the difference between the evaluation and batch stability assessment of an effective means of the instrument in addition to the basic resistance and compaction density indicators in addition to the determination of the powder material compression properties can also be realized.

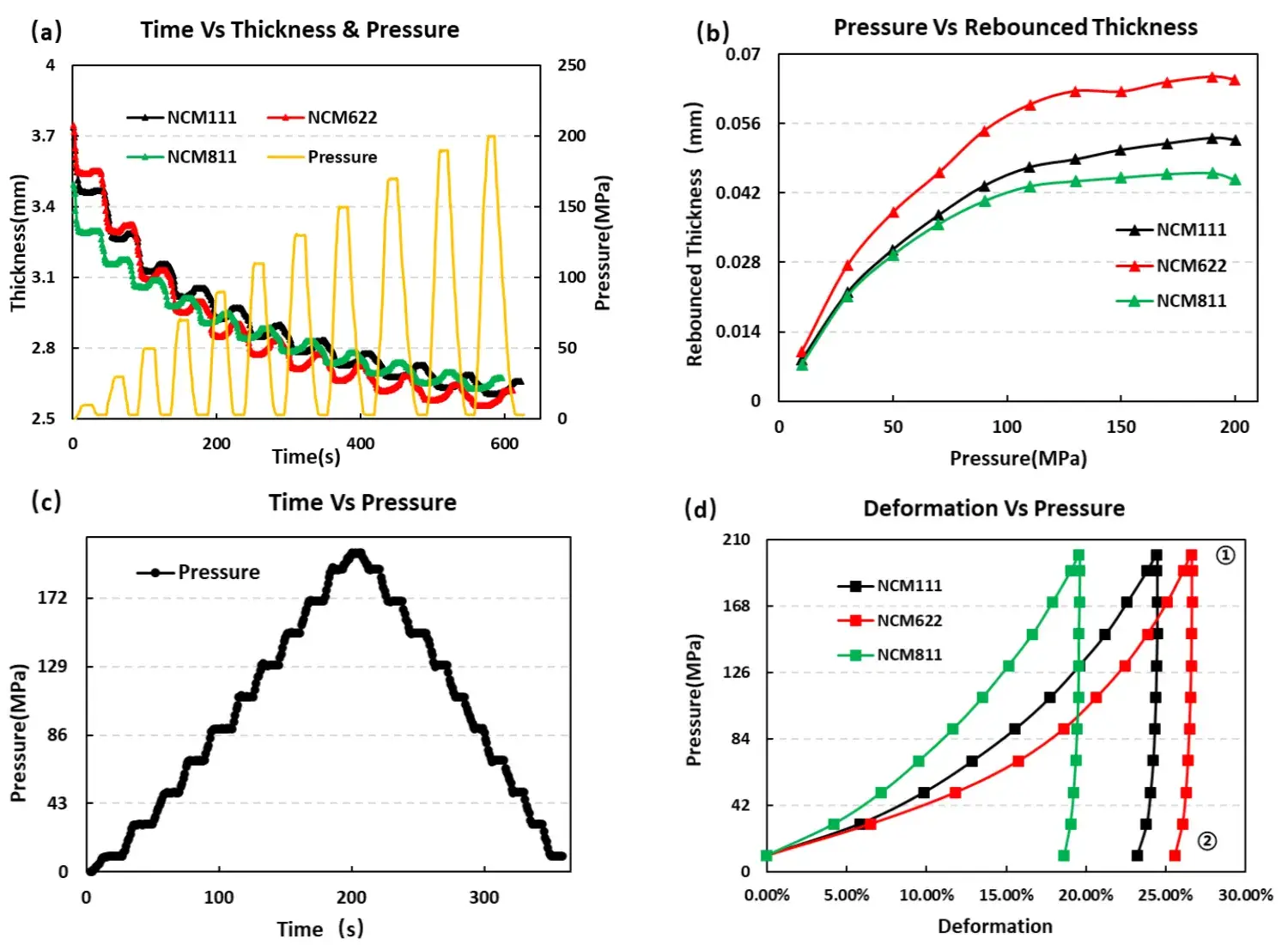

As shown in Figure 2 shows the PRCD series of powder resistance & compaction density test equipment, Figure 3 shows the compression performance test function schematic diagram, which (a) & (b) for the assessment of compression performance of the unpressurized test method, powder particles are subjected to pressure accompanied by elastic deformation and plastic deformation, when the pressure exerted on the powder particles to unloading, the elastic deformation part of the restoration, combined with the pressure setting mode in Figure 2 (a), the thickness of the powder after the pressure is unloaded. Deduction of the pressurized powder thickness is defined as the rebound thickness of the powder, Figure 2(b) shows the rebound thickness difference between different materials with the pressure change curve, with the increase of the pressurized pressure, the rebound thickness of the material gradually increases and tends to stabilize. Combined with the mechanism of the powder compression process, when the powder itself is broken, the irreversible plastic deformation accounts for a larger proportion, and the rebound thickness of the material will not be able to recover after unpressurization, which is the original intention of the development of unpressurized test method, hoping to realize the characterization of powder particle crushing through the unpressurized test mode. Figure 2 (c) and (d) show the steady state test pressure application mode and steady state test results, the method mainly characterizes the powder compression stress – compression thickness deformation percentage curve. In (d), ① is the maximum deformation point of the material after compression, with the unloading of the pressure, ② is the irreversible compression deformation part of the material, ① – ② is the reversible deformation part of the material after pressurization and unloading of the material, the results of the experiment for powder materials with different particle sizes or ratios of the particles will be significantly different, and this method can be combined with the method of assessing the stress-strain properties of the material in the actual development of the powder material.

Figure 2. IEST Powder Resistivity & Compaction Density Measurement System (PRCD3100)

Figure 3. (a-b) Unloading test method and results showing rebound thickness. (c-d) Steady-state compression test method and a representative stress-deformation curve showing reversible and irreversible components.

4. The Heckel Equation and Powder Compaction Density Analysis

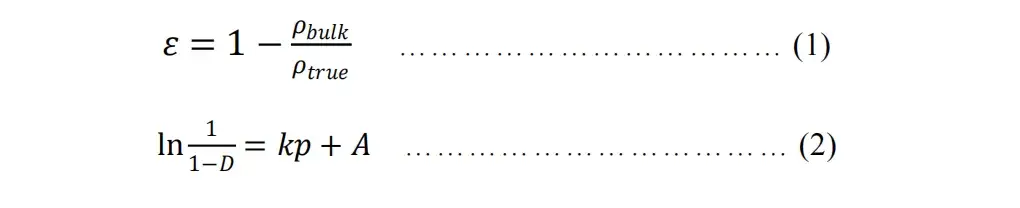

Powder materials compression process will be accompanied by changes in the voids between the powder as well as the particles themselves, which can be used in the Heckel equation to express the relationship between the void ratio and the compression pressure, it is more to summarize the compression force and density changes in the semi-empirical formulas, the void ratio (1) and the Heckel equation expression (2) is as follows[4]:

Figure 4. Void ratio (1) and Heckel equation expression (2)

Where ρb is the filling density, ρt is the true density, p is the pressure; D is the relative filling density of the powder when the pressure is p, and the void ratio = 1-D, k and A are constants, which can be obtained from the slope and intercept of the straight line part of the empirical formula. the significance of A can be clarified by combining with the formula A= ln[1/(1-DA)], where the relative density DA is the maximum density of the particles after rearrangement under the low pressure and before the deformation. The relative density DA is the maximum density before deformation after particle rearrangement under low pressure, and the value may be closely related to the compaction density of lithium-ion battery wafer level; k is a parameter to measure the size of powder plasticity, the larger the value of k is, the larger the density change caused by the same pressure is, and the larger the plasticity of the powder material is. Powder compression is a very complex process, Heckel’s equation is usually applied to high-pressure, low void ratio powder material.

5. Key Practical Factors that Influence Measured Powder Compaction Density

Lithium-ion battery design and manufacturing process in the current powder compaction density assessment has become the focus of many materials and host plant indicators, the stability of the powder compaction density determination is particularly important. Operationally, compaction density is calculated as the mass of the compact divided by its volume after pressing. Standard methods, such as China’s GB/T 24533-2019, describe manual techniques. However, modern automated systems like the PRCD series integrate pressing, thickness measurement, and calculation, significantly improving repeatability and throughput.With the increase of attention to the compaction density, there are more and more professional testing equipments for compaction density determination. Compared with the method of tablet press assisted testing, the current multi-autonomous pressurization and thickness measurement integrated equipment, equipped with a stable lower computer control system, sends the parameter commands through the software system of the upper computer, which can effectively improve the overall testing efficiency.

Compaction density measurements depend on multiple controllable variables:

-

Powder characteristics: particle size and distribution, morphology, specific surface area and inherent true density. Typical powder size ranges for battery materials are 0.1–100 µm (most industrial powders fall within this window).

-

Test fixture and sample mass: mold diameter, aspect ratio and sample mass affect side friction and pressure distribution.

-

Loading protocol: compression speed, dwell time and whether thickness is measured under load or after unloading (the latter yields rebound-affected values).

Note: when benchmarking between labs, confirm mold dimensions, measurement point (under load vs. unloaded), and sample mass to avoid misleading differences.

6. Testing Protocols of Powder Compaction Density

Testing protocols can vary based on the application:

-

Single-Point (Unloading) Test: Mimics standard methods, measuring density after pressure release.

-

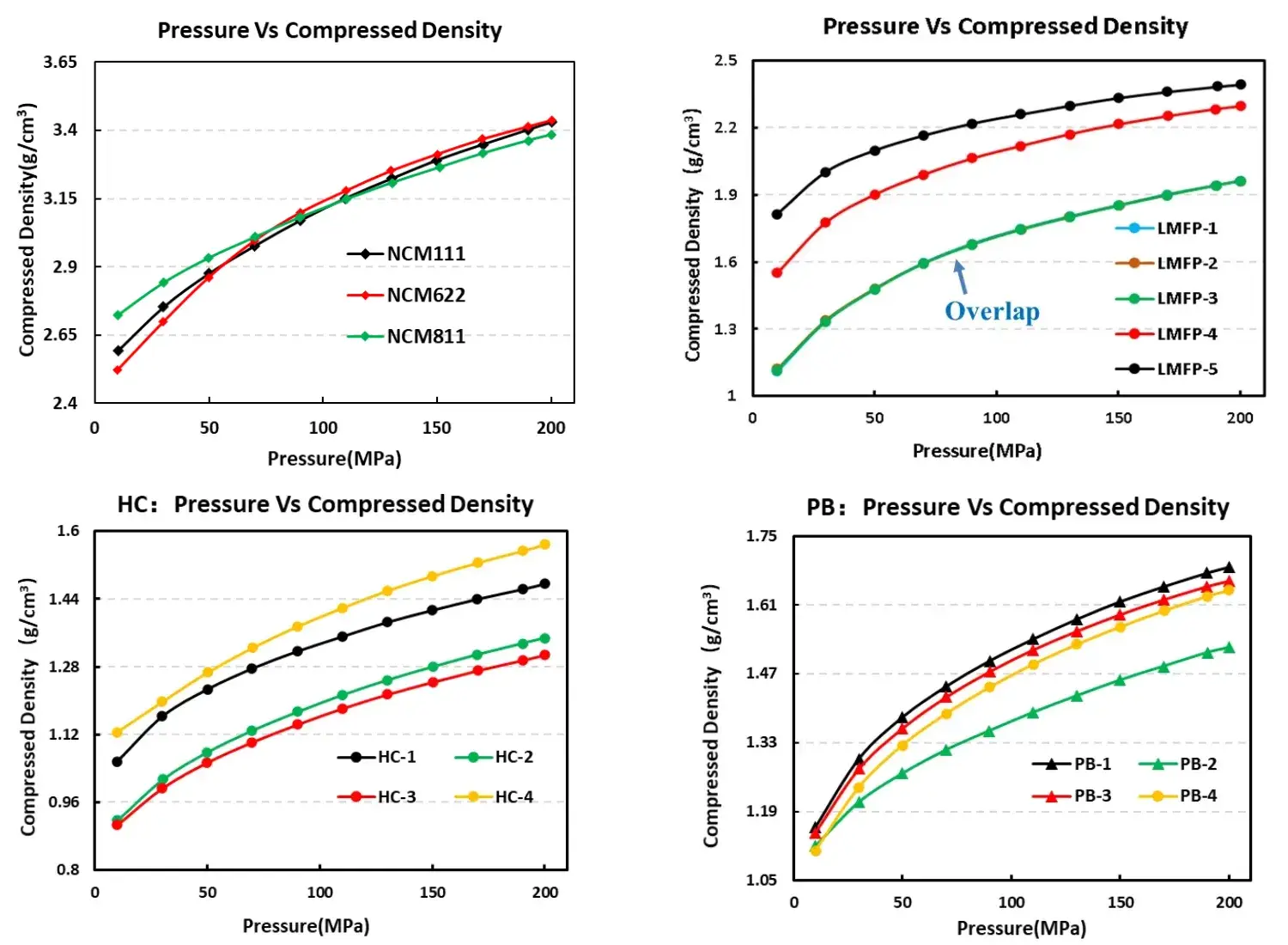

Multi-Point Pressure Test: Measures density across a range of pressures, generating a profile like the one shown in Figure 3.

-

Continuous Compression Test: Provides a complete curve for advanced analysis.

When comparing results from different laboratories or instruments, it is crucial to align test parameters such as pressure, hold time, die size, and measurement method (in-situ vs. ex-situ thickness). A clear understanding of these variables is necessary for effective benchmarking.

Figure 4. Compaction density measured under varying pressure for different powder materials.

7. Summary

The compaction density of electrode powder materials is more than a simple number; it is a synthesis of the material’s intrinsic compressibility, particle properties, and response to process forces. A deep understanding of powder compression behavior, supported by tools like the Heckel equation and advanced automated testers, enables battery engineers to make informed decisions. This approach is vital for optimizing electrode formulations, ensuring batch-to-battery consistency, and ultimately developing higher-performance, more reliable lithium-ion batteries.

8. References

[1] Yang Shaobin, Liang Zheng. Lithium-ion Battery Manufacturing Process Principles and Applications.

[2] mikoWoo@Ideal Life. Theory and Process Basis of Lithium-ion Battery Polar Cells.

[3] B K K A , A S A , A H N , et al. Internal resistance mapping preparation to optimize electrode thickness and density using symmetric cell for high performance lithium-ion batteries and capacitors[J]. Journal of Power Sources, 2018, 396:207-212.

[4] SI Guo-ning, HUANG Wan-ting, LI Gen-sheng, XU Fei, CHU Meng-qiu. Application Research of Different Compression Model on Four Powder Excipients Compression[J]. Chinese Pharmaceutical Journal, 2018, 53(23): 2021-2028 https://doi.org/10.11669/cpj.2018.23.009

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.