-

iestinstrument

Analysis of Calendering Pressure Effects on Electrode Compression and Conductivity

1. Abstract

Calendering pressure is a primary process lever for tuning electrode porosity, thickness and electronic pathways. In this study, we compare four graphite electrode batches produced at increasing calendering pressures (labeled 1 → 4) and quantify how calendering pressure alters compaction density, compressive stress–strain behavior, reversible/irreversible deformation and through-thickness electrical resistivity. Tests were run on a BER2500 electrode resistance/compaction workstation using a steady-state compression protocol from 5 MPa to 60 MPa (5 MPa steps, 15 s hold). Our results show that increasing calendering pressure raises compaction density and reduces maximum, reversible and irreversible deformation, while the impact on measured resistivity depends on thickness change and contact tightening between coating and current collector.

2. Preface

The calendering process is a critical step in LIB electrode manufacturing. By applying pressure between rollers (through predefined gaps or force control) at optimal speed and temperature, this step ensures electrodes achieve the required compaction density. Calendering aims to increase volumetric capacity, improve electronic conductivity, and enhance overall electrochemical performance. Consequently, investigating how process parameters like calendering pressure influence the electrode’s final microstructure and properties is essential for precise process control and superior cell design.

In 2022, Zhang et al.¹ conducted a systematic micro- and macro-scale study of electrode calendering by combining Discrete Element Method (DEM) simulation with experimental trials. Their work, supplemented by the Heckel equation for compression modeling, clarified that electrode deformation involves particle crushing, secondary particle fusion, binder network compression, and current collector surface deformation. The study also confirmed that improved electronic conductivity stems from both enhanced internal conductive pathways and tighter contact between the coating and the current collector.

Building on this foundational research, we employed a BER2500-series electrode resistance analyzer to test the conductive properties of graphite electrodes calendered at different pressures (and thus different compaction densities). Simultaneously, we utilized the instrument’s compression fixture to analyze the electrodes’ mechanical compression behavior. This combined approach offers a novel method for evaluating the calendering process in LIB electrode production.

Figure 1. Schematic diagram of the force-displacement curve of the electrode sheet

(Green areas represent experimental results, gray areas represent simulation results)

3. Experimental Equipment and Test Methods

3.1 Experimental Equipment

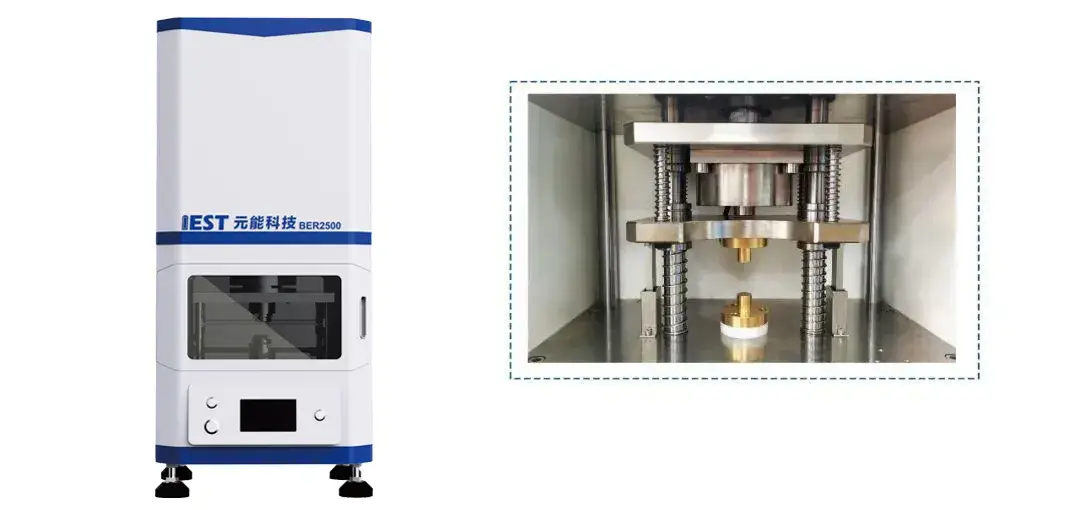

The tests were conducted using a IEST Electrode Resistance Analyzer (BER2500). This instrument, capable of applying pressures from 5 to 60 MPa on a 14-mm diameter electrode sample, is shown in Figure 2.

Figure 2. (a) BER2500 Appearance; (b) BER2500 structure diagram

3.2 Sample Preparation and Testing

3.2.1 Sample Fabrication

After uniformly coating the slurry under the same process formula conditions, we use different pressures such as small, medium and large to carry out roll pressing to obtain four kinds of compacted finished electrode sheets in 1/2/3/4 , wherein the electrode sheet calendering pPressure is 1<2<3<4. The compaction density of the four electrode sheets is calculated respectively by cutting-thickness-weighing method, and the compaction density also shows 1(1.35g/cm³)<2(1.5g/cm³)<3(1.6g/cm³)<3(1.6g/cm³) cm³)<4 (1.65g/cm³). As expected, higher calendering pressure yielded higher compaction density.

3.2.2 Testing Procedure

Combining with BER2500 equipment, using the steady-state test mode, with 5-60MPa, 5MPa interval, and holding pressure for 15s, the compression and resistance of electrode sheets with different compaction densities are compared and tested. The specific process of the test is: apply a certain pressure from 5MPa and keep it for 15s, the electrode sheet is compressed, and record the thickness and resistance of the electrode sheet at the same time; then increase the pressure at intervals of 5MPa, and then record the thickness and resistance of the electrode sheet, and so on until 60MPa; then gradually reduce the applied pressure to unload and record the thickness and resistance.

4. Data Analysis and Discussion

4.1 Compression Behavior Under Applied Pressure

After obtaining four electrodes with different compaction densities, use the steady-state mode to carry out loading compression-unloading rebound tests on the electrode sheet under different quantitative pressure conditions, record the thickness change, and use the initial pressure point of 5MPa as a benchmark to calculate the thickness deformation Perform normalized calculations to obtain the stress-strain curves of different electrode sheets (as shown in Figure 3), and summarize their deformations (as shown in Table 1).

It can be seen from the result chart that with the increase of the electrode sheet rolling pressure, the maximum deformation, reversible deformation and irreversible deformation of the four electrode sheets gradually decrease (1>2>3>4), but the decreasing trend Gradually slow down. This change trend is closely related to the filling and compaction effect of the powder in the electrode sheet coating, including the flow and rearrangement of powder particles, elastic and plastic deformation, and crushing. Usually, the electrode sheet calendering process needs to overcome friction, surface force, elastic deformation, plastic deformation and crushing to do work on the electrode coating to compact the electrode.

This trend is intrinsically linked to the powder compaction mechanisms within the electrode coating, including particle rearrangement, elastic/plastic deformation, and fracture. The calendering process must overcome friction, surface forces, and various deformation modes to densify the electrode. In our experiment, with a constant material formulation , higher calendering pressure first promotes particle rearrangement to fill voids. As pressure further increases, particles undergo elastic deformation, followed by plastic deformation once the yield stress is exceeded. This sequence is the fundamental reason compaction density rises with calendering pressure.

Figure 3. Stress-strain (compression performance) curves of four kinds of electrode sheets

Table 1. Summary of Four Kinds of Electrode deformation

4.2 Thickness and Resistivity Response

During the rolling process of lithium-ion battery electrode sheet, the deformation of the width and length of the electrode sheet is very small, and the electrode sheet rolling can reduce the thickness of the coating, increase the compaction density, and improve the adhesion of the coating, so as to stabilize the electrode structure and improve purpose of battery capacity. The rolling process of the electrode sheet is a process in which the mass per unit area is almost constant and the volume is reduced. Between the particles, between the particles and the current collector, they are combined by a binder. The compression in the thickness direction of the electrode sheet is the result of the simultaneous compression of the current collector and the coating, but the change in the thickness of the current collector is relatively small. There is also interaction between the powder particles and the current collector. During the rolling process, the particles will form pits on the current collector, thereby increasing the contact area and cohesion between the coating and the current collector.

Figures 4 and 5 illustrate the thickness change and resistivity curves for the four electrodes during the stepwise pressure test.

-

Thickness: Electrodes calendered at lower pressures (1 & 2) were initially thicker and exhibited more significant thickness reduction (strain) under the test pressure. They also showed greater elastic recovery (rebound) upon unloading. In contrast, highly calendered electrodes (3 & 4) were denser, changed less in thickness, and showed less rebound, indicating a more stable, pre-compacted structure.

-

Resistivity: The resistivity curves for Electrodes 1 and 2 varied more significantly with applied pressure compared to Electrodes 3 and 4. This is primarily because the particles and the particle-current collector contacts in Electrodes 3 & 4 are already highly consolidated from the high calendering pressure, leaving less room for improvement during the test. Notably, the absolute resistivity values for the low-pressure electrodes were sometimes lower under test pressure. This suggests that the applied pressure during measurement can further improve through-plane (vertical) conductivity, especially in less-dense electrodes. This finding highlights that optimal conductivity assessment must consider the intended operating conditions of the electrode.

Figure 4. Thickness variation curves of four electrode sheets

Figure 5. Electrical conductivity test curves of four electrode sheets

5. Practical Guidance for Process Engineers on Calendering Pressure

Based on the measured behavior, apply these process guidelines:

-

Set calendering pressure to achieve the target compaction density for your electrode recipe; higher compaction densities (e.g., ≥1.6 g·cm⁻³) reduce subsequent compressibility and stabilize thickness under load.

-

Consider the measurement context when evaluating resistivity: test geometry and transient thickness change during flat-plate compression can mask or reverse apparent trends in conductivity. Use consistent test fixtures and report both thickness and resistance together.

-

Balance capacity and rate requirements. Higher calendering Pressure increases volumetric energy density but may restrict ion-transport if pore connectivity is over-compressed; optimize calendering alongside slurry formulation and conductive-additive content.

6. Summary

This study demonstrates the effective use of a BER2500-series analyzer to differentiate the compression and conductive properties of graphite electrodes produced under varying calendering pressures. The methodology clearly reveals how initial calendering dictates an electrode’s mechanical resilience and its electronic conductivity response to subsequent pressure.

The choice of optimal calendering pressure in actual production must be carefully tailored to the specific electrode formulation and cell design goals. The right balance can maximize battery capacity while ensuring robust mechanical integrity and efficient electronic conduction, ultimately enhancing overall cell performance.

7. References

[1] Zhang J, Huang H, Sun J. Investigation on mechanical and microstructural evolution of lithium-ion battery electrode during the calendering process[J]. Powder Technology, 2022, 409: 117828.

[2] BG Westphal et al. Influence of high intensive dry mixing and calendering on relative electrode resistivity determined via an advanced two point approach. Journal of Energy Storage 2017, 11, 76–85

[3] Yang Shaobin, Liang Zheng. Principles and applications of lithium-ion battery manufacturing process[M]. Chemical Industry Press, 2020.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.