-

iestinstrument

Electrochemical Dilatometry of Different Proportions of Silicon Carbon Composite Anode Electrodes

1. Author Information and Article Abstract

In 2020, DanielP. Abraham’s team used an electrochemical dilatometry to characterize the thickness expansion of silicon carbon composite anode electrodes, quantified the difference in electrode expansion when mixing different ratios of silicon-carbon, and analyzed several factors affecting the in-situ expansion test for subsequent researchers.

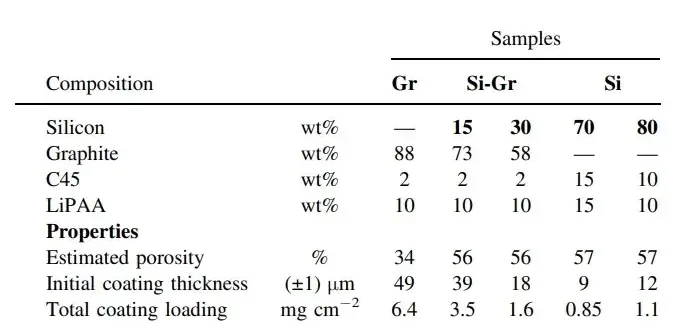

2. Sample Preparation and Testing Device

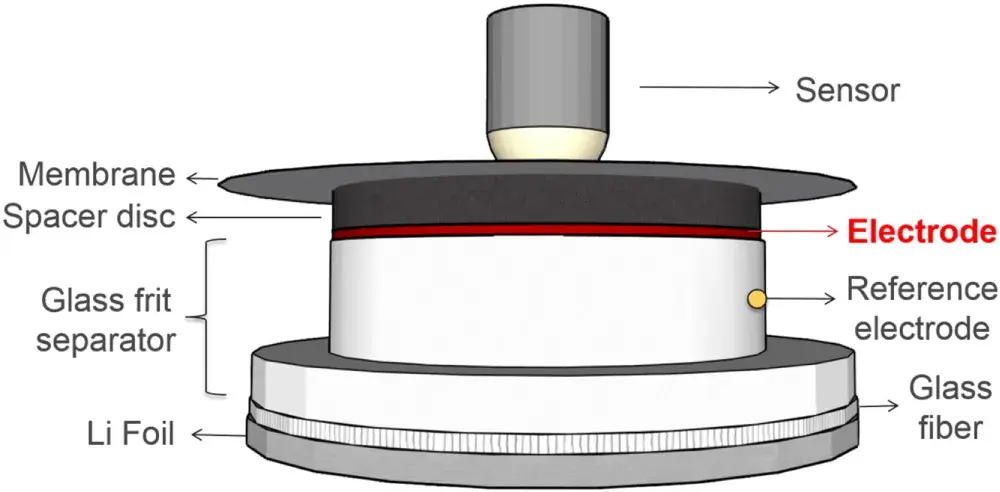

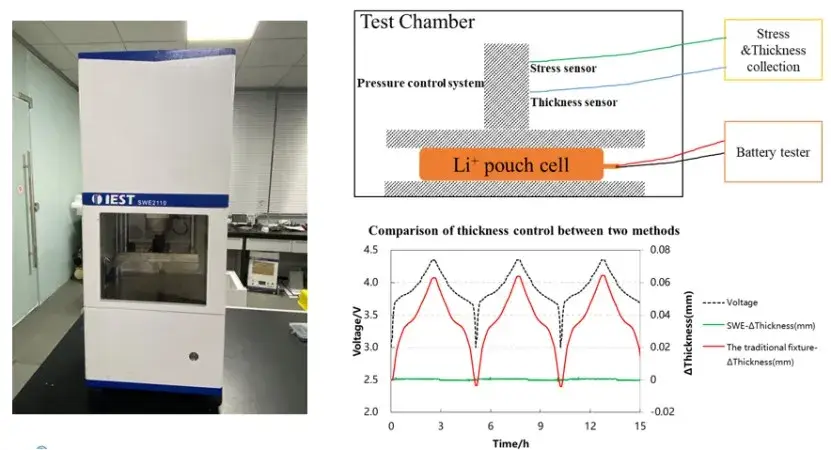

Different test si-bearing electrodes were prepared for the assembly of the buckle and in-situ electrolytic pools following the proportions in Table 1. Different si-bearing electrodes swelling thickness determination was performed using the apparatus shown in Figure. 1.

Table 1. Composition and performance parameters of the test electrodes.

Figure 1. Schematic illustration of the electrochemical dilatometer cell.

3. Analysis of Results

The swelling test curve of the negative electrode sheet with 15% mass percentage of silicon in Figure 2 shows that the maximum swelling thickness of the cycle increases significantly, and the irreversible swelling thickness of the complete lithium stripping state of each lap is also gradually increasing, which may come from the SEI membrane and the degree of negative electrode lithium embedding.

![]()

Figure 2. Swelling curve of the silicon carbon composite anode

As can be seen from the swelling and voltage rewiring of different proportions of silicon carbon composite anode electrodes in Figure 3, the thickness swelling for the pure graphite negative electrodes mainly occurs in the first and third platforms, whereas the expansion ratio of the second platform is only 1%, and there will be a certain degree of thickness shrinkage at high capacity lithium reduction. For the pure silicon negative electrode, the maximum swelling thickness reaches almost 300%, the irreversible swelling thickness is also close to 50%, and after a circle of charge and discharge, the battery capacity decay degree is also the largest.

![]()

Figure 3. Potentials and swelling curves of different proportions of silicon carbon composite anode

From the differential capacity curve of Figure 4, it can be seen that the pure graphite electrodes have three obvious reaction peaks when embedded in lithium, while the two lithium silicon alloys of the pure silicon electrodes are higher than the graphite. When the silicon carbon is mixed, it shows a mixture of the two materials, but the reaction summit of the lithium silicon alloy is weaker.

![]()

Figure 4. Differential capacity curves of silicon carbon composite anode with different ratios

Figure 5 shows that when different proportions of silicon carbon are combined, the specific capacity of the electrode is gradually increased, and the maximum swelling thickness corresponding to the electrode is full, but not linearly. Usually, when the content of silicon is less than 30%, the swelling thickness of the electrode is smaller, but after more than 30%, the slope of the thickness swelling increases significantly.

![]()

Figure 5. Specific capacity and maximum expansion ratio of silicon carbon composite anode with different ratios

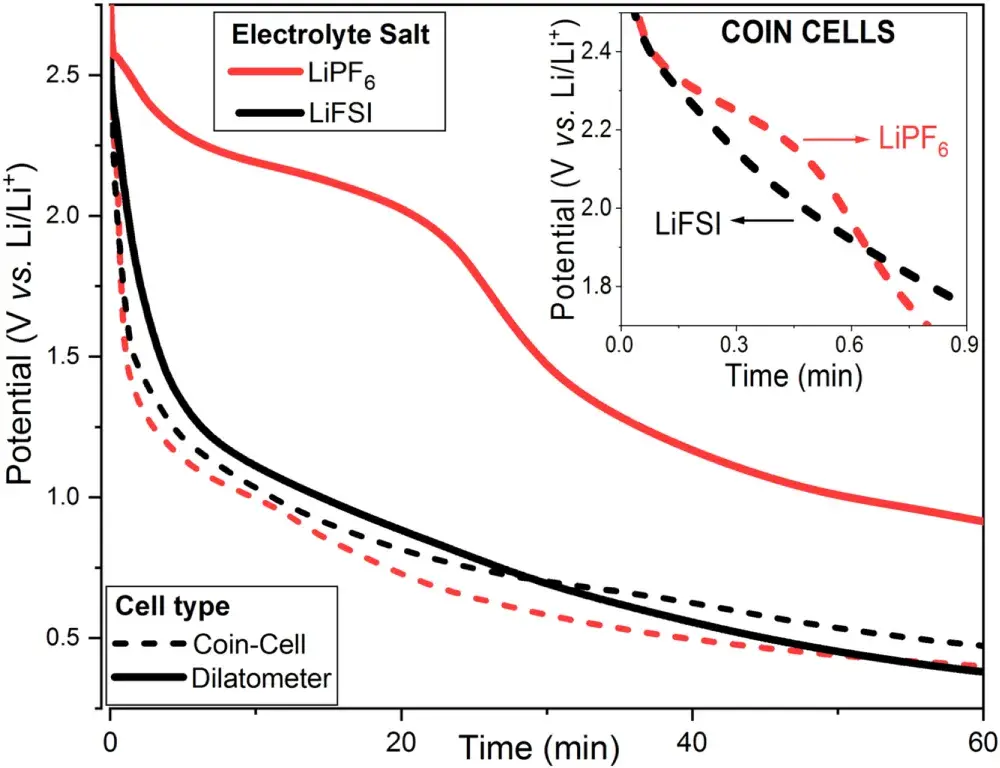

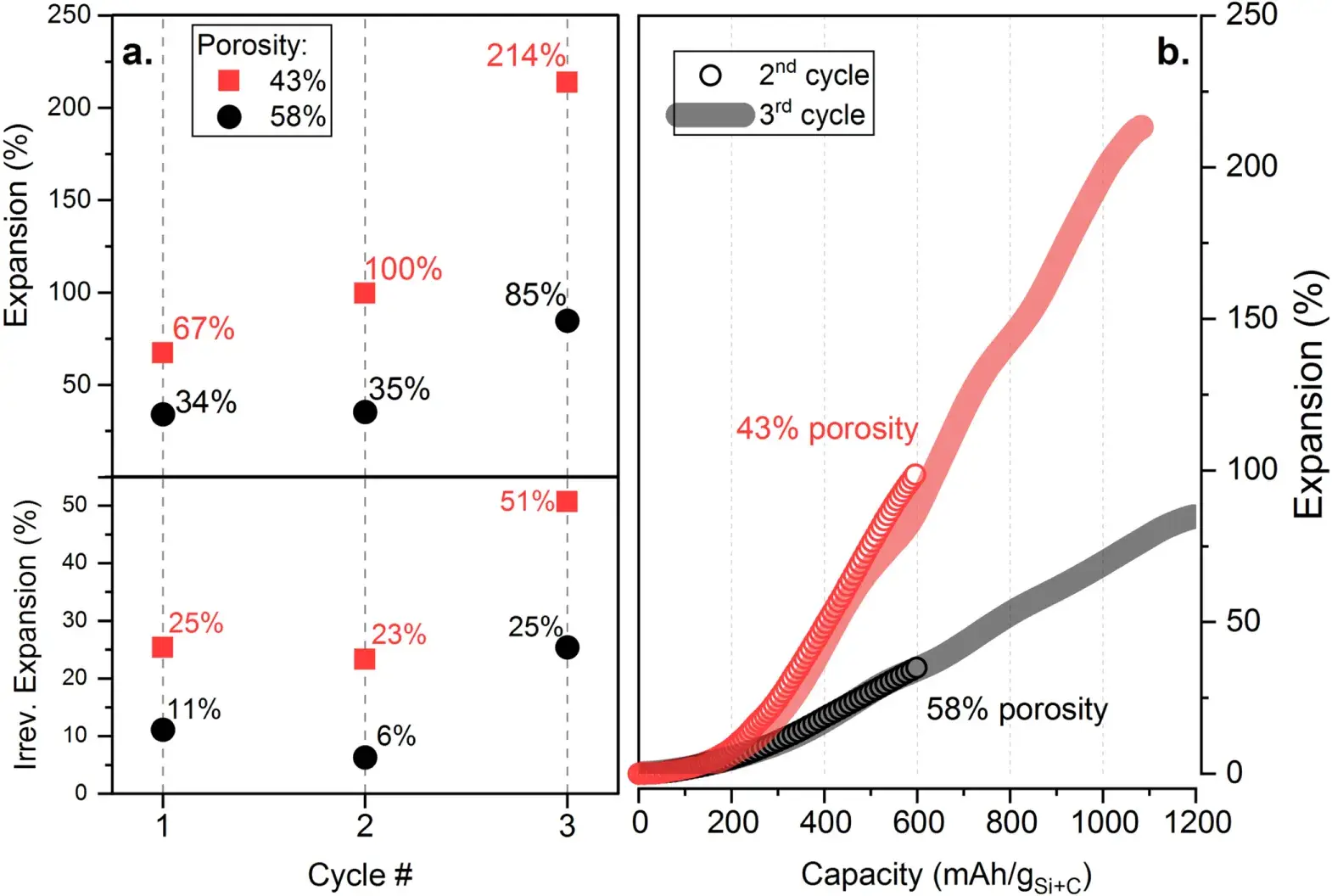

Figure 6 shows the three factors affecting the electrochemical swelling test device: electrolyte, test pressure, electrode porosity, the author found that because the sealing of the electrochemical in-situ pool is not good, so the potential capacity curve of the two structures will differ, but can be weakened by selecting LiFSi electrolyte and reducing the test ratio, and the porosity of the electrode will also affect the trend of electrode swelling thickness in the process of lithium removal. In addition to the above three, the authors considered the displacement sensor drift, test pressure applied, and the effect of gas production on swelling thickness measurements.

Figure 6. Factors that affect the outcome of electrochemical dilatometry experiments: Electrolyte

Figure 7. Factors that affect the outcome of electrochemical dilatometry experiments: Polarization

Figure 8. Factors that affect the outcome of electrochemical dilatometry experiments: Electrode porosity

4. Summary

In this paper, the thickness swelling of graphite and silicon anode is characterized by the electrochemical dilatometry to quantitatively analyze the difference in electrode swelling in different proportions of silicon carbon mixing, mainly with the following conclusions:

- Pure graphite electrodes swelling by ~19%, while pure silicon electrodes swelling by ~300%.

- Electrode-level expansion for Si-containing electrodes can be much larger than anticipated, as the electrode porosity may not be able to accommodate the additional swelling caused by morphological changes in the silicon particles.

- For different ratios of the silicon carbon anode, the swelling is nonlinear.

- Limiting the capacity of the silicon carbon anode can adjust the maximum swelling ratio.

- Limiting the depth of delithiation would not be as effective in restraining the dimensional variation as restricting the depth of lithiation.

- The proportion of electrode swelling with lower-porosity should be larger than electrode with higher porosity.

- Researchers should note the effects of several factors mentioned when using the electrochemical dilatometry method

5. Original Article

Andressa Y.R.Prado, Marco-Tulio F.Rodrigues, Stephen E.Trask, Leon Shaw and Daniel P.Abraham, Electrochemical Dilatometry of Si-Bearing Electrodes: Dimensional Changes and Experiment Design, Journal of The Electrochemical Society, 167(2020) 160551.

6. IEST Related Test Equipment Recommended:

SWE Series In-situ Swelling Analysis System

6.1 A Variety of Cell in-situ Characterization Methods (stress&swelling thickness)

The swelling thickness and swelling force of the cell charging and discharge process are measured at the same time, so as to quantify the changes of cell swelling thickness and swelling force.

6.2 More Refined and Stable Test System

Using a highly stable and reliable automatic adjustment platform, equipped with a high precision thickness measurement sensor and a pressure regulation system, the relative thickness measurement resolution is 0 m, to realize the long cycle monitoring of the long-term charging and discharge process of cells.

6.3 Diversity of Environmental Control and Test Functions

SWE series equipment can adjust the temperature of the charge and discharge environment to help study the swelling behavior of cell cells under high and low temperature; In addition to conventional thickness and pressure test, cell swelling force, compression modulus and compression rate can be tested.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.