-

iestinstrument

Visualizing the Electrolyte Filling Process in Li-ion Batteries Using X-ray Imaging

1. Abstract

Electrolyte filling is a critical step in lithium-ion cell manufacturing. Poor wetting increases internal resistance, reduces capacity, and can create localized current hotspots that promote lithium plating and separator penetration. This application note summarizes an X-ray-based, in-situ visualization method—originally developed by Schilling et al.—for directly observing and quantifying electrolyte filling and wetting dynamics in pouch cells. We describe the test rig, the imaging protocol (120 kV, 160 ms exposure), three quantitative image metrics used to describe wetting behavior, and how these metrics guide process optimization for industrial filling operations.

2. Why Electrolyte Filling Matters

Electrolyte filling is more than pouring liquid into a cell. Uniform wetting of electrode pores and separator through the entire stack determines ionic pathways and cell impedance. Incomplete or uneven filling leaves trapped gas and dry zones that elevate internal resistance and reduce usable capacity. Furthermore, nonuniform wetting promotes current inhomogeneity during charge/discharge, which can locally drive lithium plating, dendrite formation and, in the worst case, separator puncture and internal shorting. These failure modes make robust, well-controlled filling an essential quality target for both R&D and production.

3. X-ray imaging: A Direct Window into the Filling Process

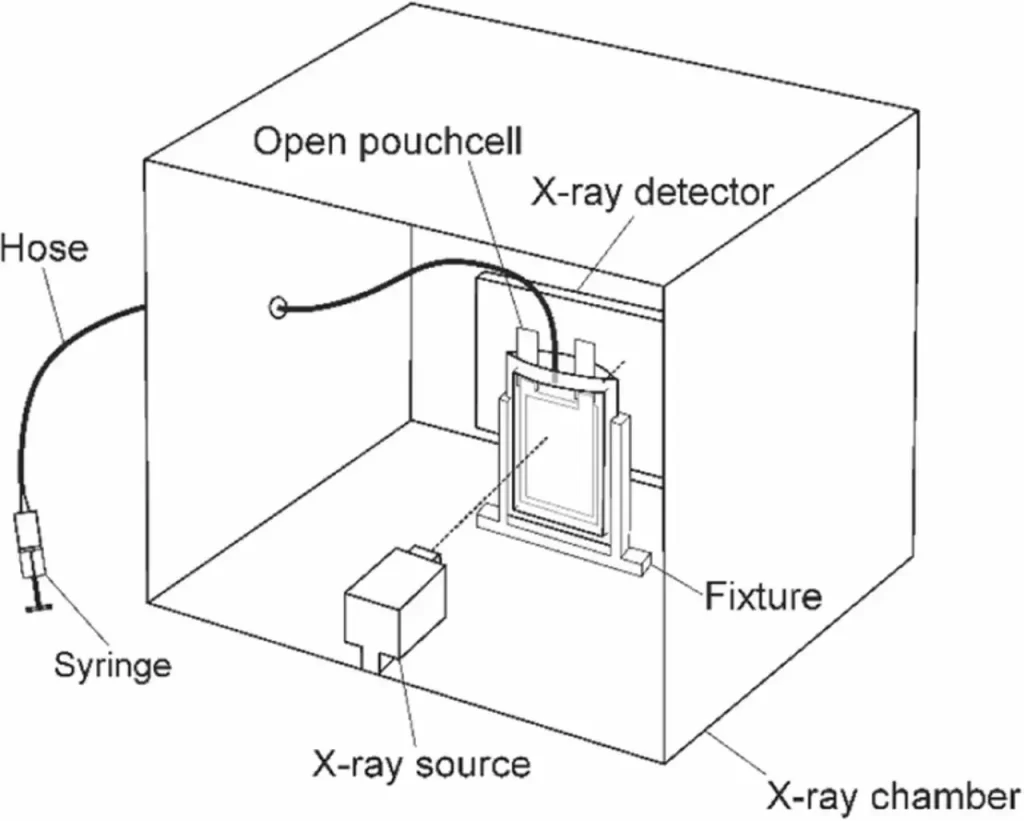

Unlike electrical or acoustic proxies, X-ray radiography visualizes the actual liquid front and trapped gas in real time. The test setup used in the referenced study integrates a syringe pump and filling tubing, a sealed imaging chamber, a fixed cell fixture and an X-ray source (see Fig.1 in the original work). In the reported protocol a dry, three-side-sealed LiNi₀.₃₃Co₀.₃₃Mn₀.₃₃O₂/graphite pouch cell was placed in the chamber and 60 mL of electrolyte was introduced while the system recorded radiographic images at 120 kV with 160 ms exposure. These settings provided good contrast between electrolyte, gas and electrode stack features for subsequent image analysis.

4. Quantitative image metrics for electrolyte filling

To convert images into engineering metrics, the method extracts three complementary parameters from each frame:

-

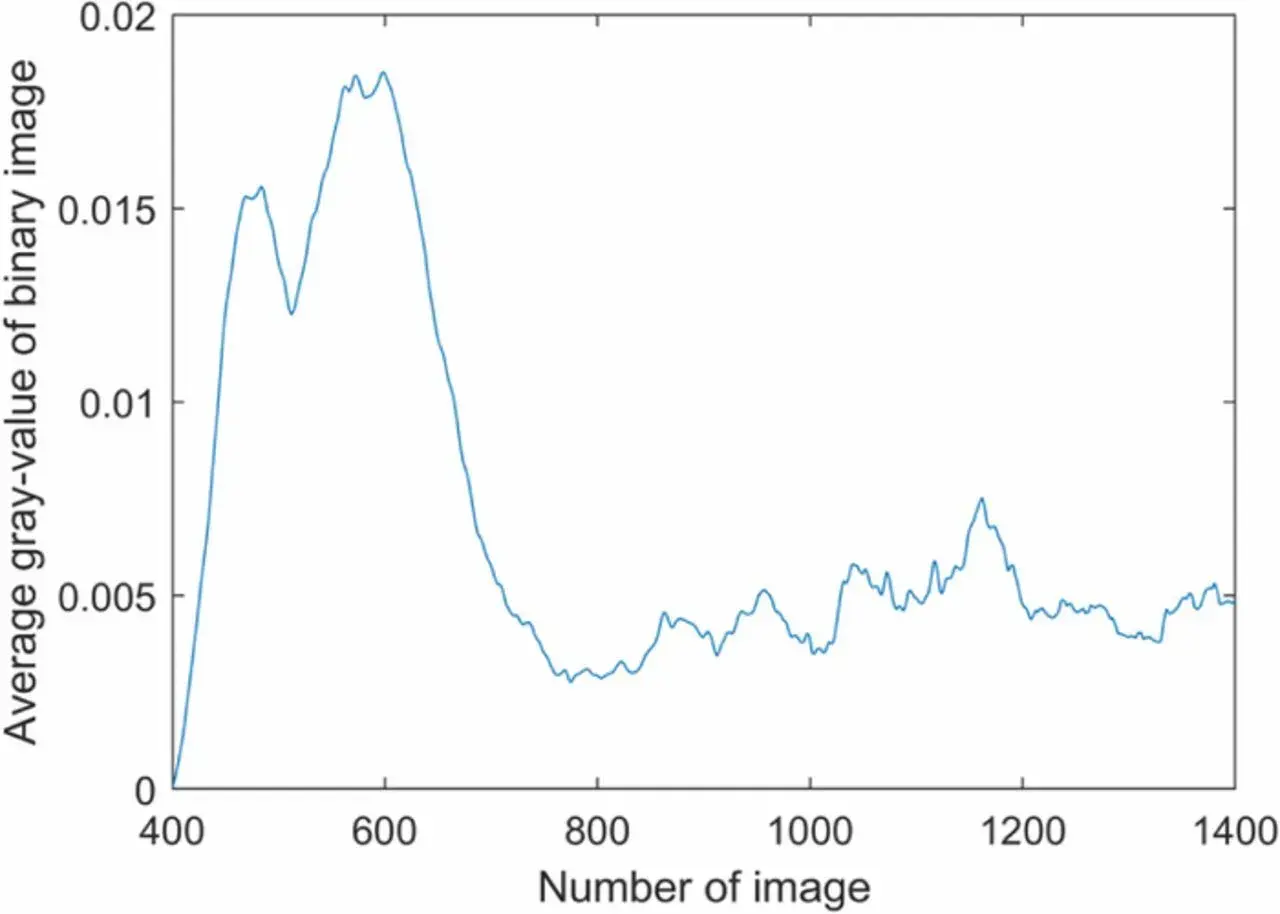

Trapped-bubble pixel count (bubble index). Image processing detects high-contrast regions indicative of gas pockets; the aggregated pixel count serves as a proxy for the number and area of retained bubbles.

-

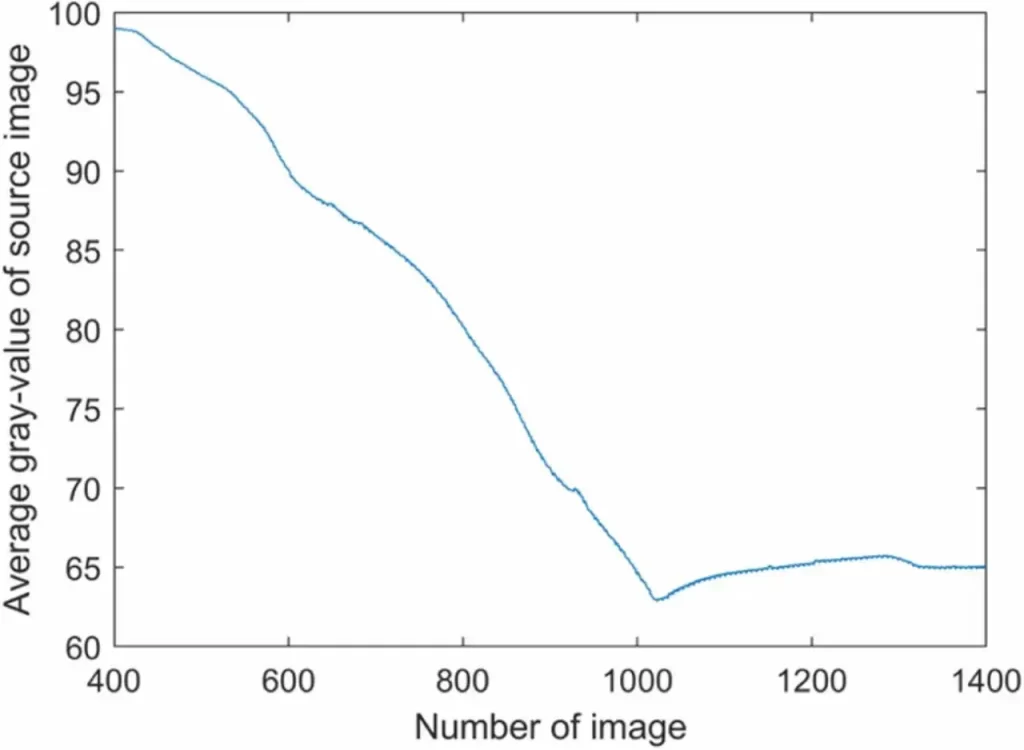

Grayscale fill fraction (filling degree). The local grayscale intensity correlates with X-ray attenuation: darker (higher attenuation) regions represent liquid-filled zones. Averaging grayscale across the active area yields a scalar measure of how completely the stack is wetted.

-

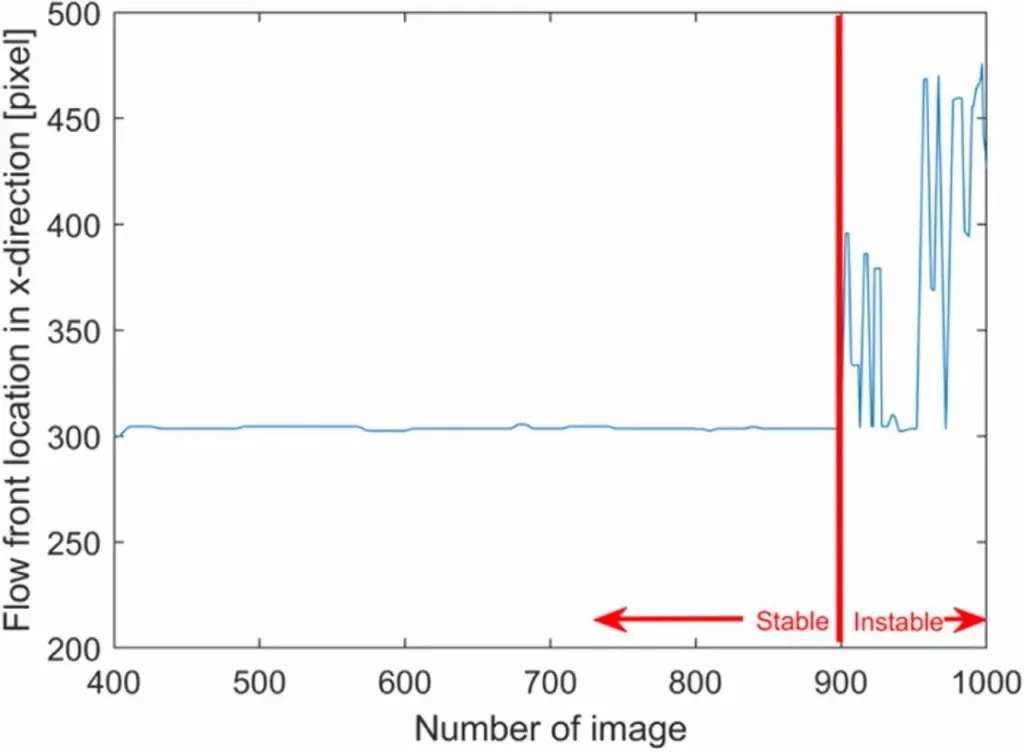

Fluid-front position (wetting front). Edge detection tracks the leading edge of the liquid as it advances through the electrode/separator stack, yielding a time-resolved front location and velocity.

Together, these metrics quantify both the rate and quality of wetting: the front position and velocity describe dynamics, while bubble count and grayscale fraction describe the final state and retained defects.

5. Typical Filling Behavior and How to Read The Curves

Representative image sequences show three phases:

-

Rapid advance: The initial injection drives a clear, advancing fluid front; grayscale fraction rises quickly and bubble counts may briefly increase as air is entrained.

-

Redistribution: Capillary forces and pressure gradients redistribute liquid into porous regions; bubble count typically decreases while grayscale stabilizes.

-

Equilibration: The front stalls and the remaining bubbles either dissolve, migrate to vents, or remain trapped. The final grayscale and bubble index quantify the residual wetting quality.

Plotting the three metrics versus time produces diagnostic curves: a fast rise in grayscale with minimal bubble residue indicates efficient filling. Conversely, a late plateau of grayscale with a persistent bubble index signals poor penetration or trapped air—conditions that require process change.

Figure 1. Electrolyte wetting visualization setup

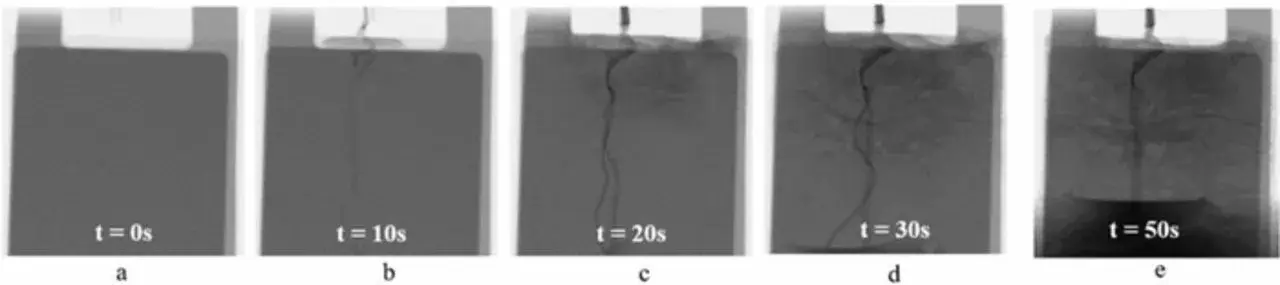

Figure 2. Electrolyte filling process of a flexible pouch cell using X-ray imaging.

Figure 3. Bubble detection images of the electrolyte infiltration process

Figure 4. Curcurves of the parameters representing the polarity with the process

Figure 5. Progression of the fill level of the cell during the electrolyte filling procedure

Figure 6. Progression of the flow front’s width during the electrolyte filling procedure

6. Practical Process Levers Informed by X-ray Data

X-ray visualization converts qualitative observations into prescriptive adjustments. Typical interventions include:

-

Adjust fill volume and rate. Slower rates can reduce bubble entrainment but extend cycle time; imaging helps pick the sweet spot where front advance and bubble removal are balanced.

-

Modify venting strategy. Relocating vents or increasing vent area often eliminates trapped bubbles in hard-to-reach pockets identified by imaging.

-

Change cell pre-conditioning. Pre-compression, pre-heating or partial vacuum can open pore networks and accelerate wetting—X-ray sequences quantify the benefit.

-

Reformulate electrolyte or use wetting agents. If the grayscale metric remains low despite mechanical fixes, a low-surface-tension additive can improve penetration; imaging confirms improved pore filling.

-

Optimize fixture and port geometry. Imaging may reveal flow paths that bypass sections of the stack; adjusting inlet/outlet geometry makes filling more uniform.

Each adjustment can be validated quickly with repeat imaging runs, enabling data-driven process optimization without destructive teardown.

7. Example Results and Interpretation

In the cited experiments (60 mL fill; 120 kV; 160 ms), processed image frames and derived curves showed clear, time-resolved filling dynamics. The study demonstrates that:

-

The grayscale fill fraction correlates closely with measured cell impedance: higher final grayscale → lower post-fill resistance.

-

Bubble index maps identify persistent retention zones that match later-observed capacity deficits or higher local impedance.

-

Fluid-front velocity correlates with the risk of entrainment: very high velocities produce more initial bubble counts, which may remain trapped unless venting or pressure relief is adequate.

These correlations allow engineers to translate imaging metrics into acceptance criteria for production.

8. Summary

X-ray radiography offers a direct, quantitative route to understand electrolyte filling and wetting in Li-ion pouch cells. By extracting three compact metrics—bubble index, grayscale fill fraction and fluid-front position—engineers can diagnose electrolyte filling failures, quantify process improvements and convert visual insight into production specifications. When paired with electrical validation, this method accelerates the development of robust filling procedures that minimize internal resistance, maximize capacity and reduce the risk of localized failures.

9. Original Article

Antje Schilling, Philip G¨umbel, Markus M¨oller, Fatih Kalkan, Franz Dietrich, and Klaus Dr¨oder. X-ray Based Visualization of the Electrolyte Filling Process of Lithium Ion Batteries. Journal of the electrochemical society, 166 (3) A5163-A5167 (2019).

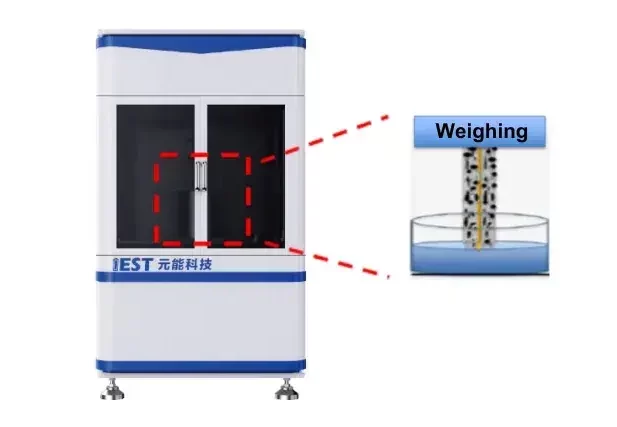

10. IEST Related Test Equipment Recommended:

Electrode Electrolyte wettability Testing: IEST’s self-developed electrolyte wettability test system (ETS1000, IEST) which is equipped with a high-precision weighing system to characterize the electrolyte wettability rate of the electrode in-situ, and to explore the wettability effect of different electrodes. At the same time, it can also carry out bare cell wetting effect test, liquid retention amount test, and so on.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.