-

iestinstrument

Effect of External Pressure Modulation On All Solid-state Battery Performance

1. Preface

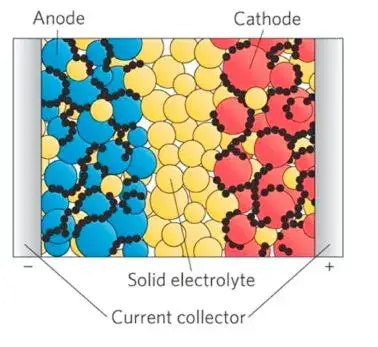

All solid-state Battery (ASSB) are the most promising next-generation energy storage systems due to their high theoretical energy density and intrinsic safety. However, the limitation of the “solid-solid” contact between the electrodes and the solid electrolyte severely hinders the interfacial charge transfer. It has been shown that the introduction of external pressure can effectively reduce the “solid-solid” contact resistance and extend the cycle life of the battery. The performance of all solid-state battery can be optimized by appropriately adjusting the external pressure. However, the effects of external pressure on all solid-state battery is multifaceted, mainly involving the solid-state electrolyte (SSE), the electrodes, and the interface between them (Figure 1). The following is a detailed analysis of these effects:

2. Interfacial Contact Performance

2.1 Improvement of interfacial contact performance

External pressure can deform the solid components, thus improving the contact state between the components inside the solid state battery. When the external pressure is applied uniformly, it can ensure that the contact between the various interfaces inside the battery (e.g., the electrode-electrolyte interface) is closer, reducing poor contact and porosity, and improving the transfer efficiency of ions and electrons.

2.2 Reduced interfacial resistance

Uniform external pressure helps to reduce interfacial resistance because tight contact reduces the obstruction of electrons and ions in the transmission process, thus improving the overall performance of the battery. Uneven stresses are shown in Figure 2.

Figure 1. All solid-state battery Composition[1,3]

Figure 2. Uneven force distribution

3. Cycle stability and safety

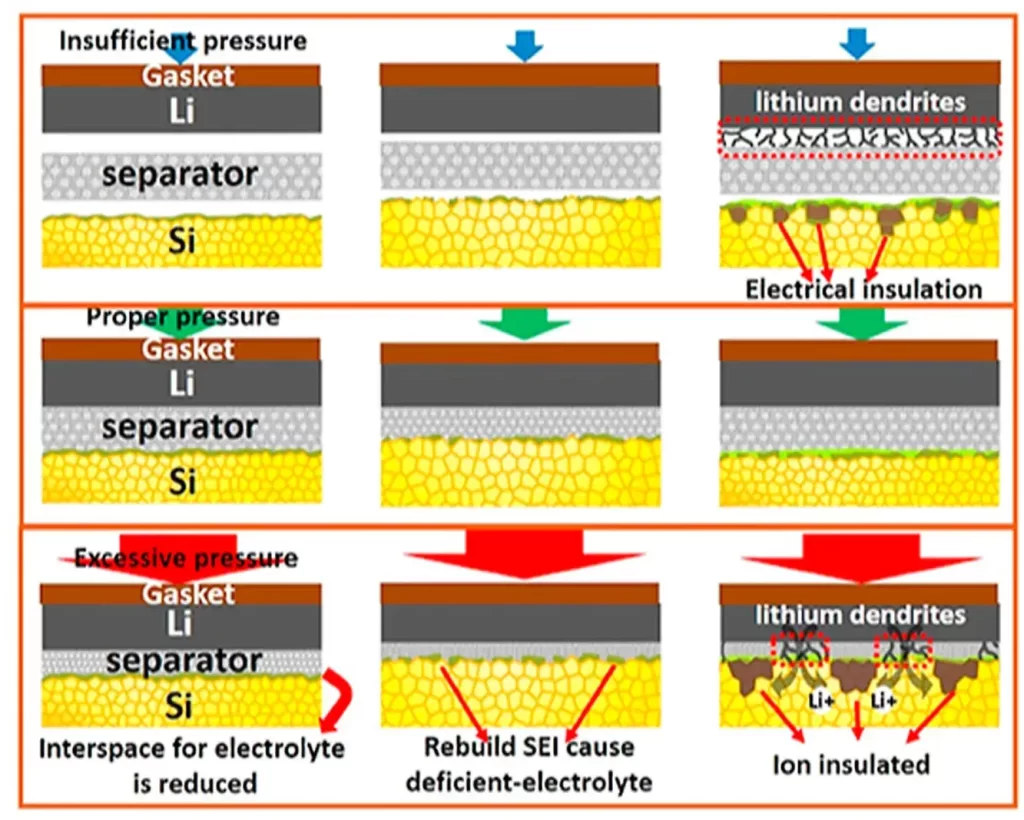

3.1 Preventing lithium dendrite growth

Lithium dendrites are one of the common problems in all solid-state battery, where they can penetrate the electrolyte and cause short circuits. Uniform external pressure can inhibit the growth of lithium dendrites because the pressure can be evenly distributed throughout the cell, preventing localized stress concentrations and preferential growth of lithium dendrites (Figure 3).

3.2 Improved cycle life

Uniform external pressure helps maintain the stability of the cell during cycling, reducing performance degradation due to poor contact and stress concentrations. This significantly improves the cycle life of the cell, making it more suitable for applications that require long periods of operation. Enhanced

3.3 Safety

The safety of all solid-state battery is a major advantage over liquid batteries. Uniform external pressure can further enhance this safety, reducing the probability of safety incidents such as thermal runaway and explosions by minimizing potential risks such as short circuits and leakage.

Figure 3. States at different pressures[2,4]

4. Energy Density and Power Density

4.1 Increased Energy Density

Uniform external pressure helps optimize the internal structure of the battery, reducing ineffective spaces and pores, thus increasing the energy density of the battery. This means that all solid-state battery can store more energy for the same volume or weight.

4.2 Improved Power Density

The power density of all solid-state battery may also be improved due to the uniform external pressure improving the efficiency of ion and electron transport. This allows the battery to charge and discharge faster for high power applications.

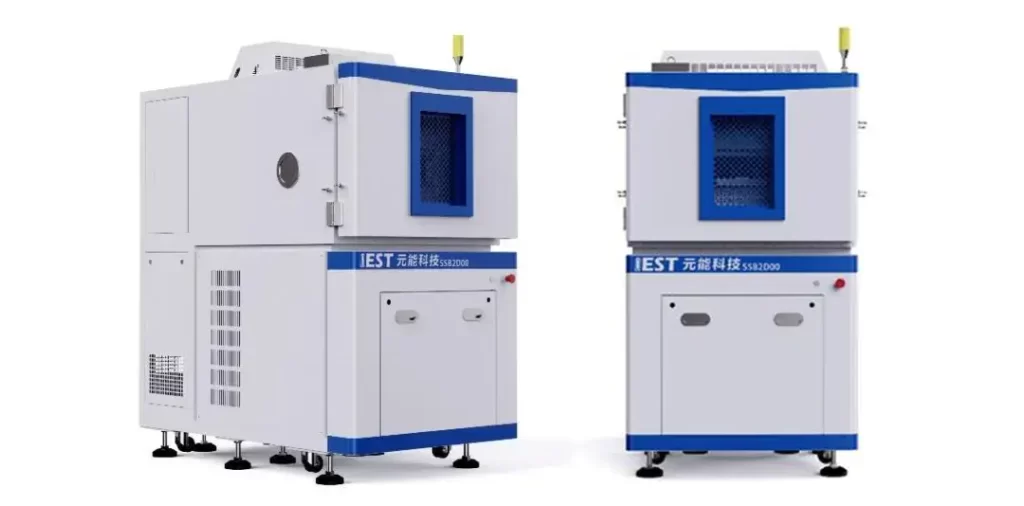

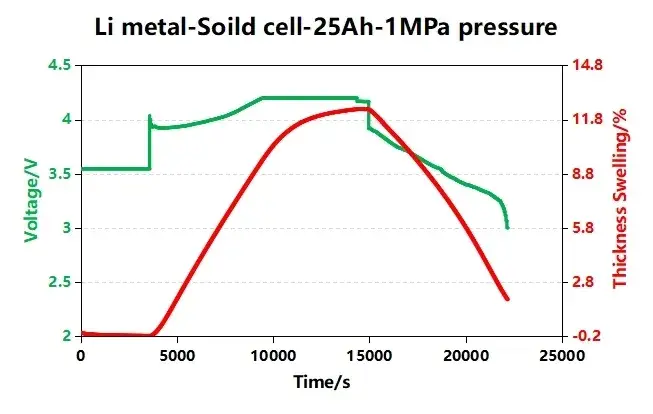

4.3 IEST Solid State Battery Condition Analyzer

Can apply uniform external pressure to solid state batteries, and can perform tests at different temperatures (-20℃~80℃) with different pressures and different conditions, with an upper pressure limit of up to 10T, and a thickness testing accuracy of 1μm, which can help in the pre-production mapping of external pressure for solid state batteries.

Figure 4. IEST Solid State Battery Condition Analyzer SSB2D00

Figure 5. Application case test data

5. Summary

In summary, the influence of external pressure on all solid-state battery are multifaceted, including both the direct effect on SSE, electrodes and the interface between them, and the indirect effect on the overall performance of the battery. When designing and manufacturing all solid-state battery, the role of external pressure needs to be fully considered to optimize the performance of the battery by reasonably designing the pressure parameters. At the same time, attention also needs to be paid to controlling the uniformity and stability of the pressure to avoid performance degradation or safety problems caused by uneven pressure.

6. Reference

[3] Yue J, Yan M, Yin Y-X, Guo Y-G. Progress of the interface design in all-solid-state Li-S batteries. Adv Funct Mater 2018;28:1707533.

[4] T. Liebmann, C. Heubner, M. Schneider and A. Michaelis, Understanding kinetic and thermodynamic properties of blended cathode materials for lithium-ion batteries, Materials Today Energy, 22 (2021) 100845.

[5] Jia M, Zhao N, Huo H, Guo X. Comprehensive investigation into garnet electrolytes toward application-oriented solid lithium batteries. Electrochemical Energy Reviews 2020;3:656–89.

[6] Sun C, Liu J, Gong Y, Wilkinson DP, Zhang J. Recent advances in all-solid-state rechargeable lithium batteries. Nano Energy 2017;33:363–86.

[7] Xia S, Wu X, Zhang Z, Cui Y, Liu W. Practical challenges and future perspectives of all-solid-state lithium-metal batteries. Chem 2019;5:753–85.

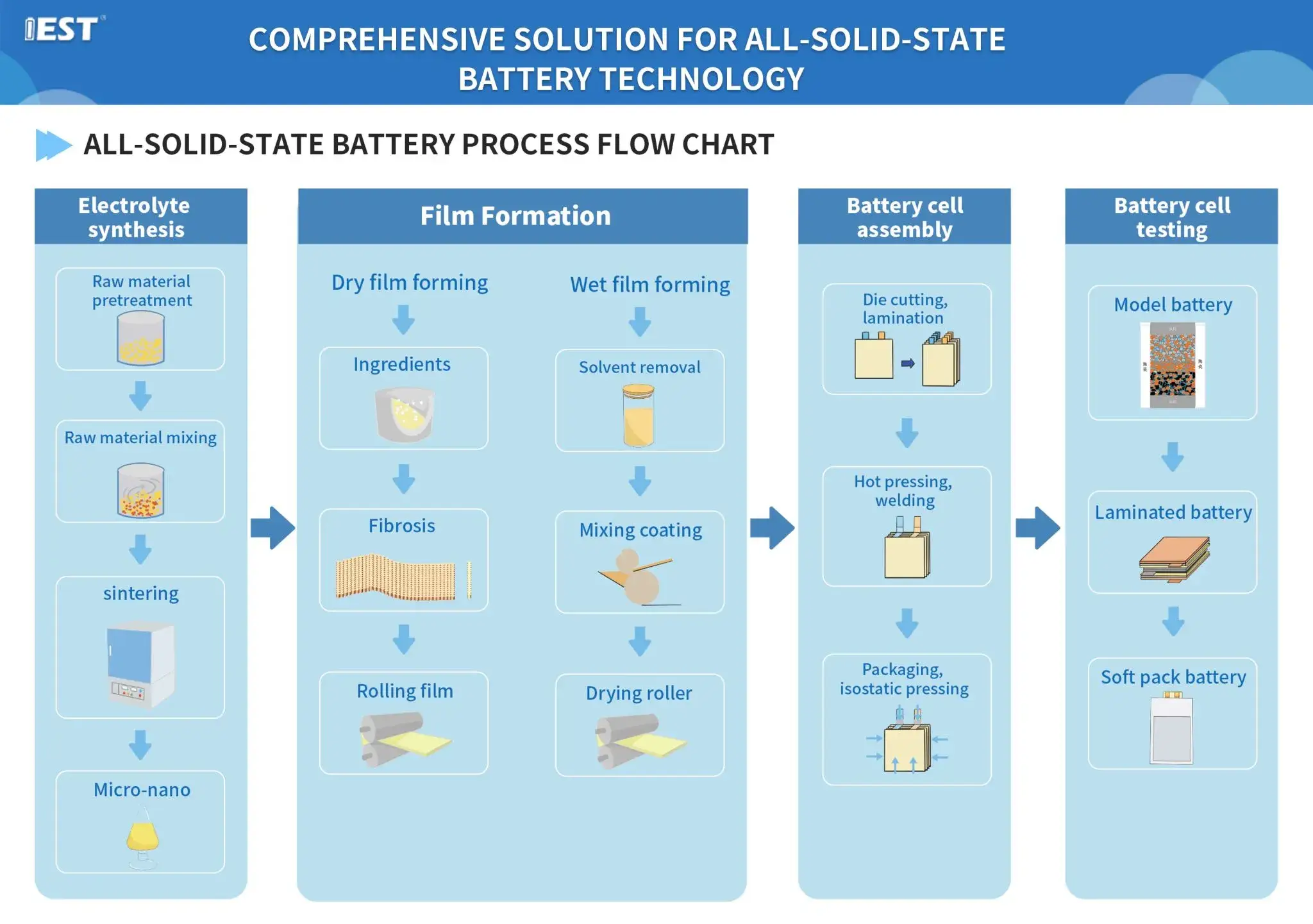

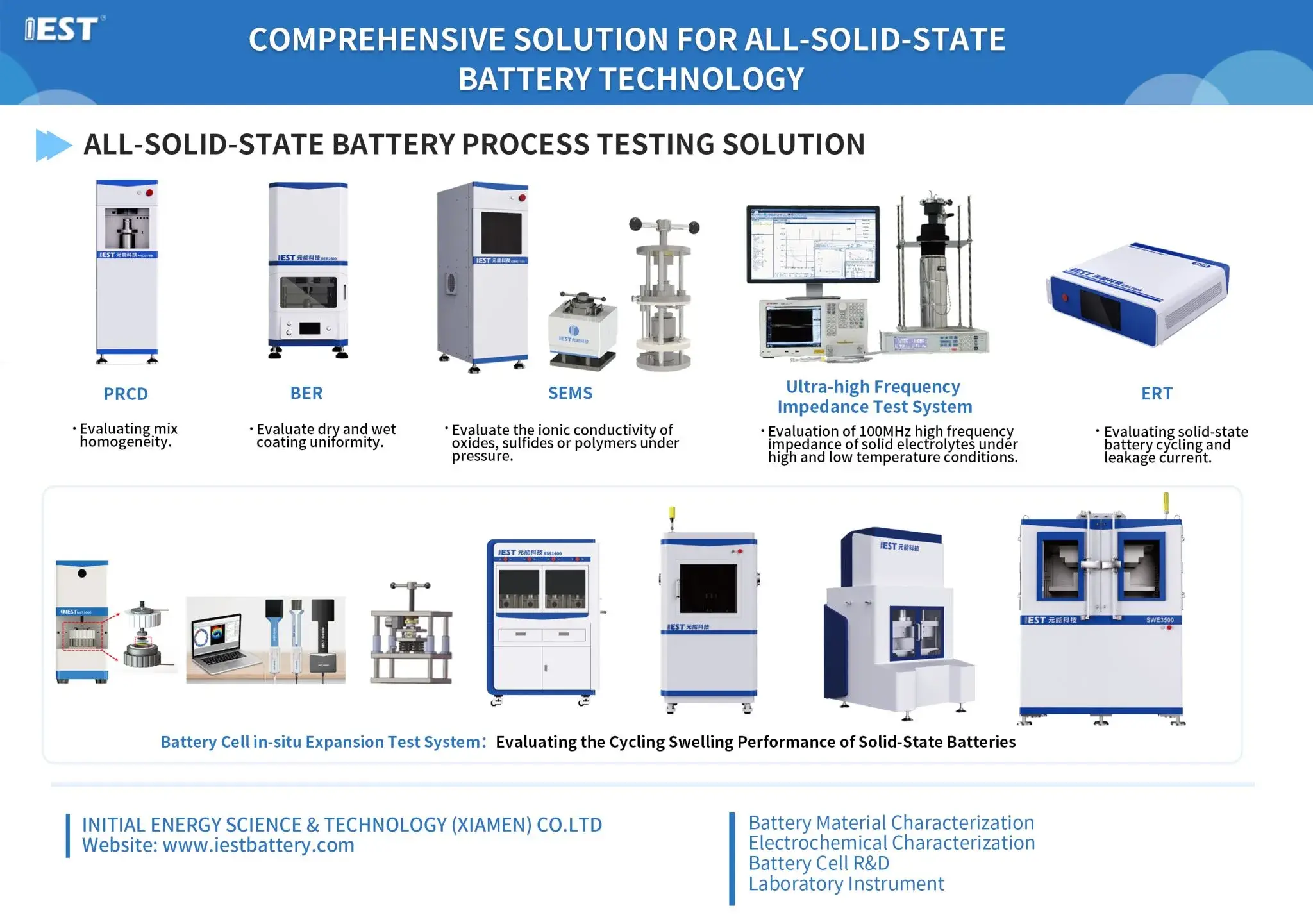

7. IEST Comprehensive Solutions For All-Solid-State Battery Technology

IEST provides relevant quality control equipment and application scenarios for the pre-assembly process of battery, and provides all solid-state battery testing solutions to help the all-solid-state industry develop rapidly and stably!

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.