1. Author Information and Article Abstract

In 2018, the Antje Schilling team proposed a new in situ X-ray device for observing the electrolyte filling and infiltration process in the injection stage. On the one hand, it can provide reference for the control of process parameters and on the other hand, the process picture of electrolyte infiltration.

2. Effect of Poor Electrolyte Infiltration on the Battery

2.1 Increase in internal battery resistance and reduced capacity.

2.2 Inuniform current distribution leads to lithium analysis, puncture diaphragm and internal short circuit.

3. Analysis of the Results of the Visual Test Device

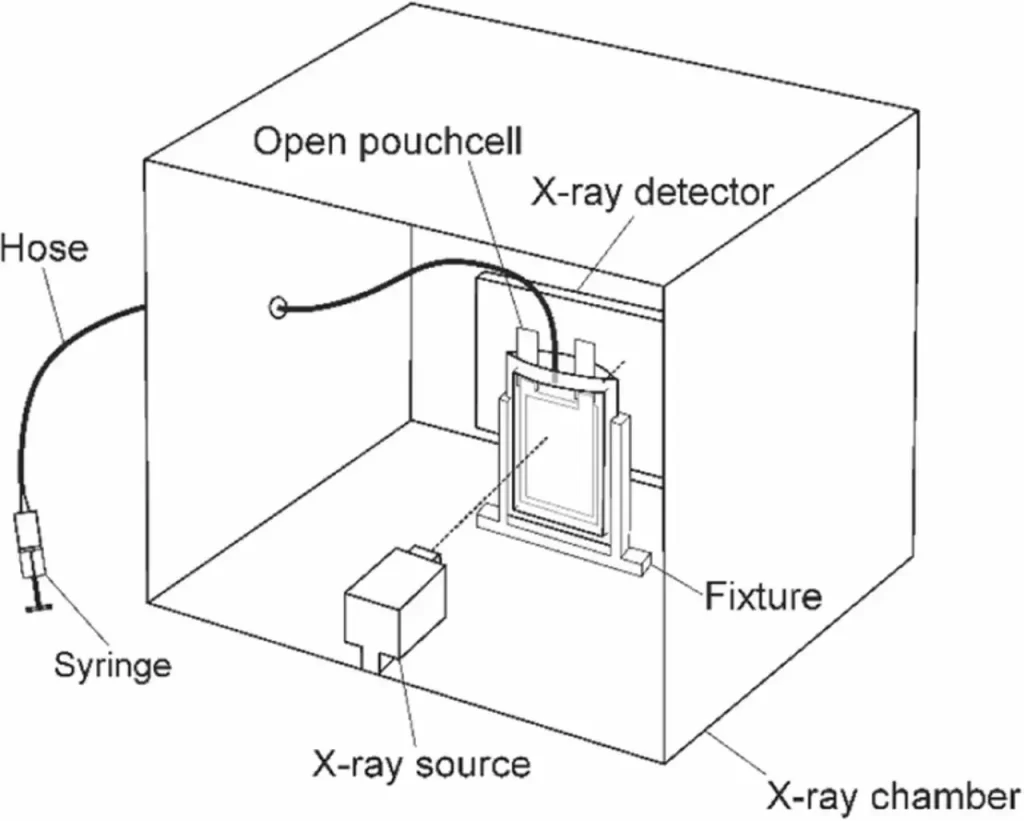

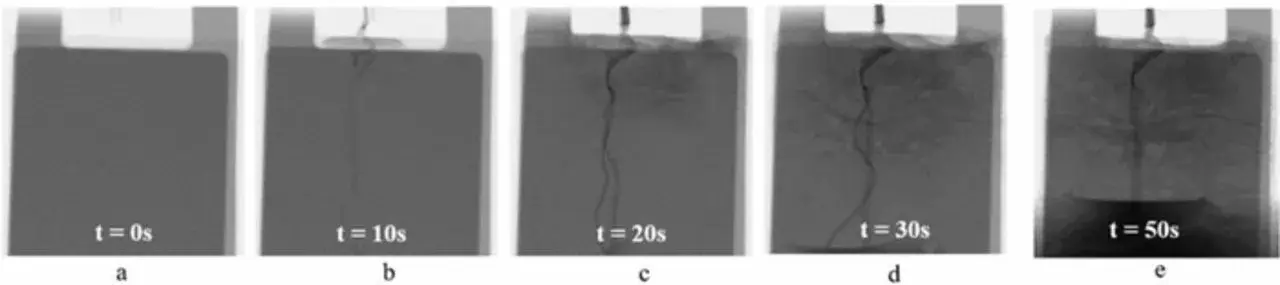

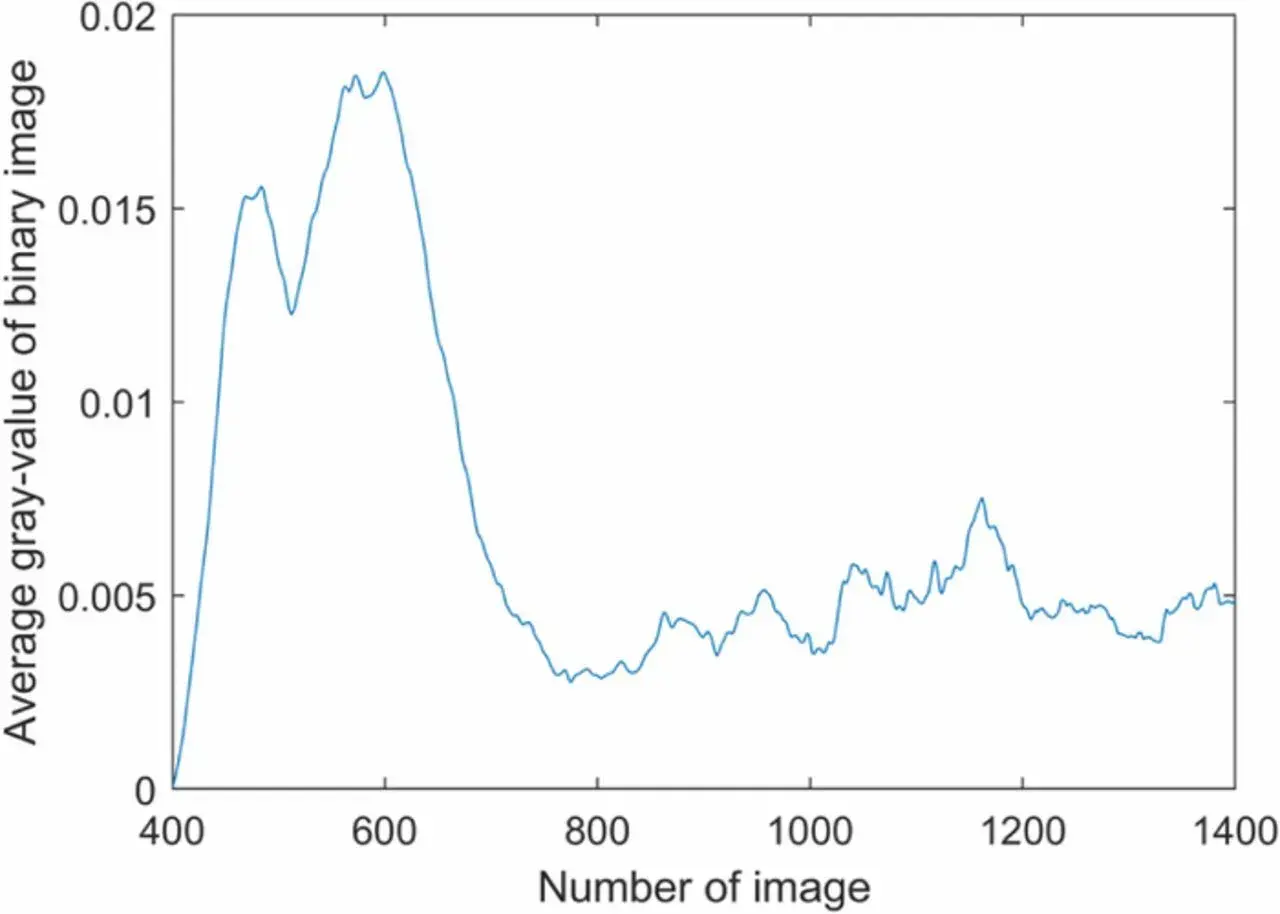

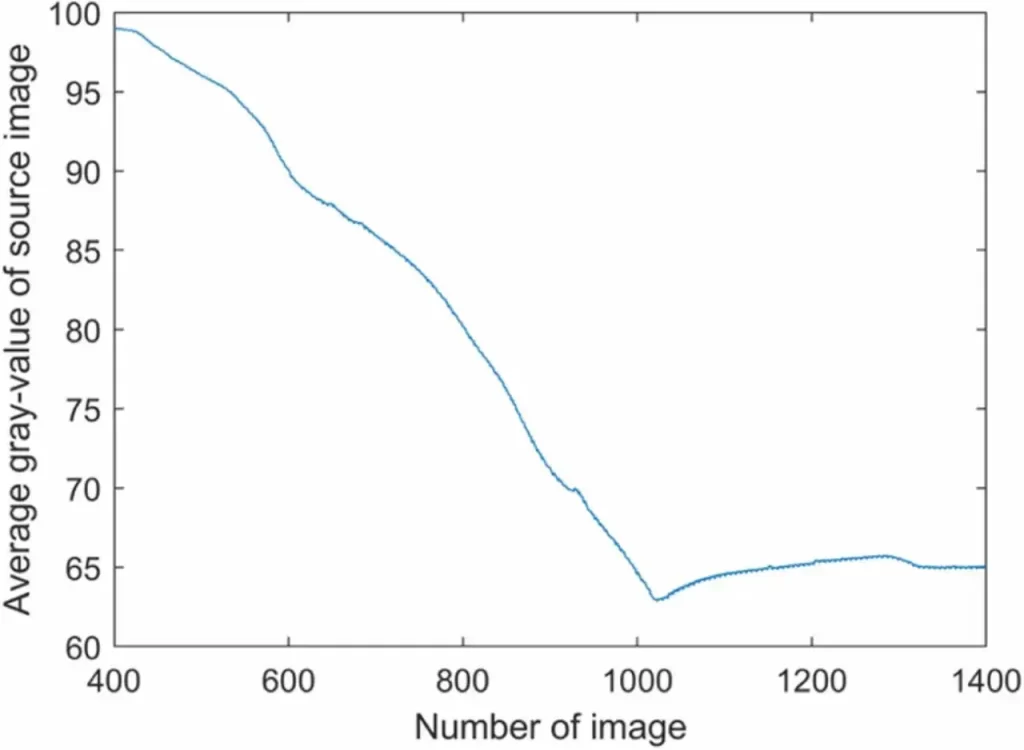

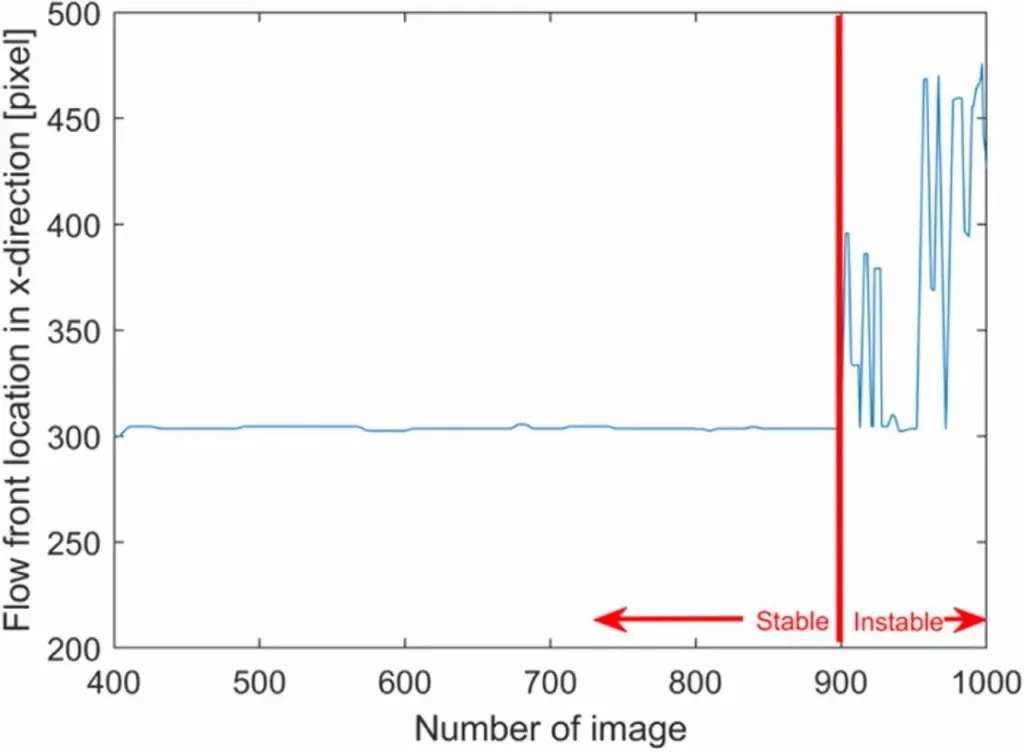

The device includes injection pump and injection pipe, battery fixture, X-Ray source, sealing cavity, schematic structure as shown in Figure 1.The battery system is LiNi0.33Co0.33Mn0.33O2/ graphite. After sealing the dry cell of the three sides into the injection chamber, 60mL electrolyte is added, the test parameters of X-ray are 120kV voltage, and the exposure is 160ms. Three quantitative parameters to visualize the invasive representation: reunited pixel representation of stranded bubbles, grayscale representation of image degree of filling, and fluid front values. Figures 2 and 3 intuitively show the filling process of the electrolyte infiltration and the change process of air bubbles. Quantitative change curves of the three parameters in Figure 4 can be obtained by the data processing of the image, from which the degree of electrolyte infiltration can be determined.

Figure 1. Schematic overview of the experimental setup

Figure 2. Electrolyte filling process of a flexible pouch cell using X-ray imaging.

Figure 3. Bubble detection images of the electrolyte infiltration process

Figure 4. Curcurves of the parameters representing the polarity with the process

Figure 5. Progression of the fill level of the cell during the electrolyte filling procedure

Figure 6. Progression of the flow front’s width during the electrolyte filling procedure

4. Summary

In this paper contributes a first analysis of the X-ray based visualization of the electrolyte filling process of lithium ion batteries. The visibility and quantifiability of effects characteristic for the filling process were assessed. The quantification gives three parameters that characterize the degree of infiltration, by which it can help to optimize the conditions of the electrolyte filling process during battery production.

5. Original Article

Antje Schilling, Philip G¨umbel, Markus M¨oller, Fatih Kalkan, Franz Dietrich, and Klaus Dr¨oder. X-ray Based Visualization of the Electrolyte Filling Process of Lithium Ion Batteries. Journal of the electrochemical society, 166 (3) A5163-A5167 (2019).

6. IEST Related Test Equipment Recommended:

Electrode Electrolyte wettability Testing: IEST’s self-developed electrolyte wettability test system (ETS1000, IEST) which is equipped with a high-precision weighing system to characterize the electrolyte wettability rate of the electrode in-situ, and to explore the wettability effect of different electrodes. At the same time, it can also carry out bare cell wetting effect test, liquid retention amount test, and so on.