-

iestinstrument

Optimizing Battery Cycle Life: How External Stress Impacts Capacity Fading in LCO / Silicon-Carbon Anode Cells

1. Introduction

The charge-discharge cycling of lithium-ion batteries involves complex physicochemical reactions, with battery cycle life influenced by numerous factors. These include intrinsic cell properties—such as material characteristics, electrode design, and manufacturing processes—as well as external conditions during use. Our goal is to identify a practical external-pressure window that minimizes capacity fading while preserving mechanical and electrochemical stability for longer battery cycle life. The findings offer practical guidance for both cell usage and module/pack design, particularly for systems utilizing high-expansion electrodes.

2. Experimental equipment and test methods

2.1 Experimental equipment

The study employed the SWE2110 In-situ Expansion Analyzer from IEST Instrument (Figure 1). This instrument enables precise monitoring of cell dimensional changes while applying controlled external pressure.

Figure 1. Appearance of SWE2110 device

2.2 Test Information and Procedure.

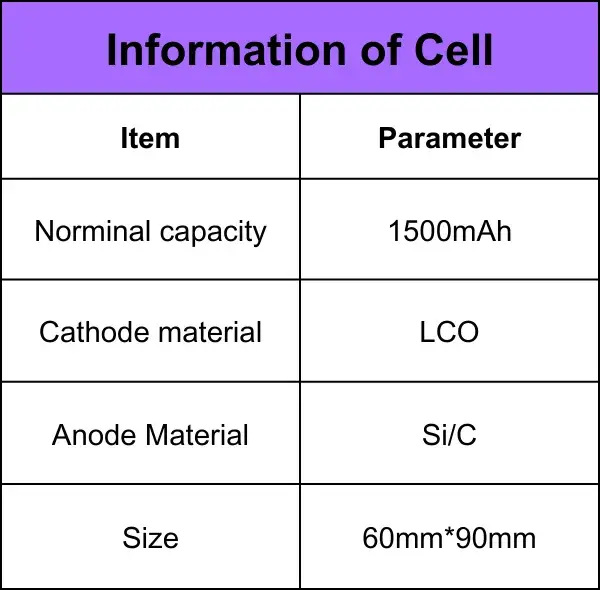

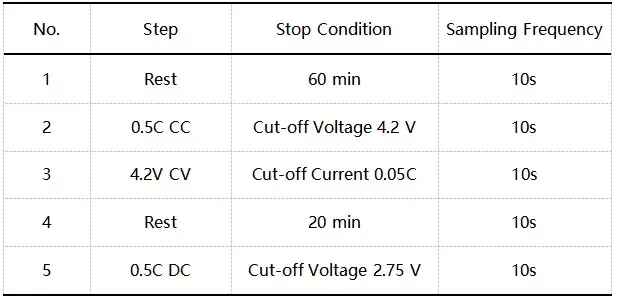

A commercial LCO/silicon-carbon anode pouch cell was used for testing (specifications detailed in Table 1). The cell was placed in the SWE2110, and the MISS software was configured to apply a series of constant pressures: 5.0 kg, 10 kg, 25 kg, 50 kg, 100 kg, and 200 kg. Each pressure was held for one hour before initiating a standard 0.5C charge-discharge cycle. Throughout the test, the system automatically recorded thickness variation, temperature, current, voltage, and capacity data.

Table 1. Test cell information

Table 2. Charging and discharging process

3. Results & Discussion

3.1 Pressure-Dependent Thickness Evolution and Irreversible Expansion

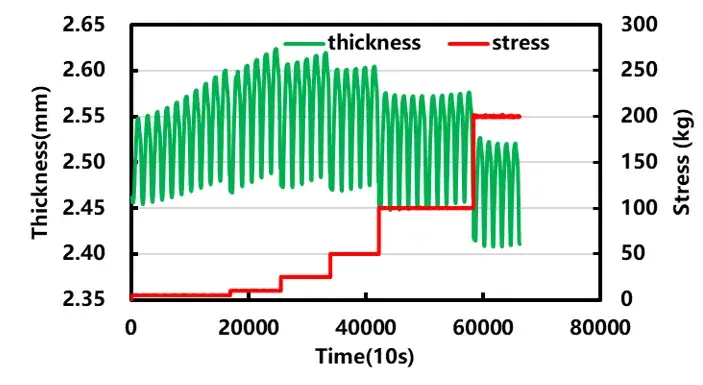

Under constant pressure mode, the SWE2110 tracked real-time thickness changes. As shown in Figure 2, the cell exhibited the characteristic pattern of charge-induced expansion and discharge-induced contraction, primarily driven by the reversible volume changes in the silicon-carbon anode during lithiation and delithiation. Notably, the maximum cell thickness during cycling decreased progressively as the applied external pressure increased. Higher pressure compresses the cell stack, increasing the interfacial contact and density between components.

A key observation was the continuous increase in maximum expansion per cycle under a fixed pressure, indicating cumulative irreversible expansion. This permanent thickness gain, calculated from the difference between initial charge and final discharge thickness each cycle, arises from mechanical and electrochemical degradation. For this silicon-carbon anode cell cycled at 0.5C, the dominant contributors are likely anode particle cracking and continuous SEI layer reorganization/growth.

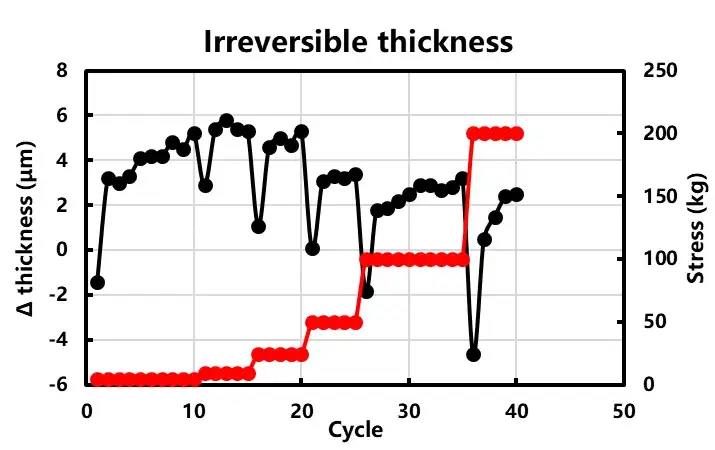

Figure 3 illustrates how irreversible expansion varies with applied pressure. The data suggests an optimal pressure range exists for minimizing this detrimental growth, implying that controlled stress can mechanically suppress fracture and degradation processes.

Figure 2. Thickness variation curve of different pressure cycles of the cell

Figure 3. Irreversible thickness variation curve of the cell

3.2 Identifying the Optimal Pressure for Minimizing Capacity Fading

Appropriate external stress can increase interfacial contact, reduce the loss of active lithium during cycling, and slow down the decay of battery capacity. At the same time, the positive and negative electrodes and the diaphragm of lithium-ion batteries are porous structures, and with the increase of pressure, the porosity of the electrodes and the diaphragm, as well as the tortuosity and other parameters will be changed to affect the diffusion of Li+, from causing the capacity fading[1].

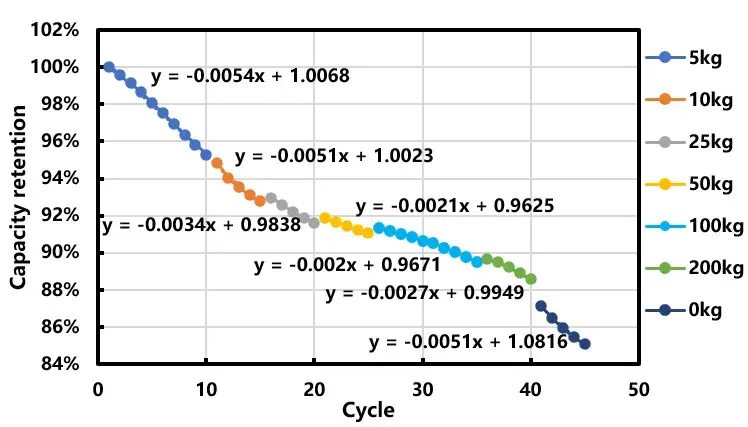

To quantify the impact on battery cycle life, the discharge capacity at each pressure was plotted against cycle number and fitted linearly (Figure 4). The slope of this fit represents the rate of capacity fading. The results reveal a non-monotonic relationship: the fade rate first decreased and then increased with rising pressure. The minimum capacity fading occurred within the external stress range of 50 kg to 100 kg, defining this as the optimal pressure window for this specific cell construction. Outside this range, either insufficient contact (low pressure) or restricted ion transport (high pressure) accelerates degradation.

Figure 4. Capacity decay curves of battery cells at different pressures

4. Mechanistic interpretation

The measured trends align with established degradation pathways in silicon-containing anodes:

-

Improved interfacial contact under moderate pressure reduces local current hotspots and contact resistance, which helps limit mechanical delamination and uneven SEI growth.

-

Excessive compression reduces electrode and separator porosity and increases tortuosity, which can slow Li⁺ diffusion and exacerbate concentration polarization; this, in turn, may accelerate capacity fading.

-

Irreversible swelling arises from cumulative plastic deformation, particle fracture in the Si-C composite, SEI thickening and gas evolution; these phenomena accumulate with cycling and are sensitive to the mechanical boundary conditions the cell experiences.

Where the report references a sudden “jump” or inflection in irreversible-swelling when switching pressures, that behavior likely reflects transient structural relaxation and the time required for the electrode/separator stack to reach a new mechanical equilibrium after the pressure change. The source notes that the magnitude of the jump increases with larger pressure changes.

5. Practical Implications For silicon-carbon anode Design and Pack Engineering

For engineers and scientists working on silicon-carbon anode formulations and pack designs, the data imply the following actionable points:

-

Implement moderate, controlled external stress in module and pack fixtures to improve electrode contact and reduce early capacity loss. In this dataset, 50–100 kg per cell produced the best trade-off between reduced irreversible swelling and minimal capacity fading.

-

Avoid over-constraining cells during assembly or in fixtures; excessive compression may degrade Li⁺ transport pathways and accelerate capacity fading, hurting long-term battery cycle life.

-

For silicon-carbon anode, combine mechanical optimization with materials strategies that mitigate particle fracture and SEI growth (for example, engineered binders, graded porosity, or compliant current-collector interfaces). These combined approaches address both mechanical and chemical contributors to irreversible swelling and capacity loss.

6. Summary

Using an in-situ expansion analyzer (SWE2110), this study demonstrates that external static compressive stress exerts a significant, non-linear influence on irreversible thickness growth and capacity fading in LCO / silicon-carbon anode pouch cells. A moderate external-pressure window (50–100 kg) produced the lowest measured capacity-decay rates and the smallest irreversible swelling for the tested cells.This approach provides a tangible strategy for improving the cycling performance of silicon-based battery systems, offering valuable insights for engineers designing battery modules and packs where controlled stack pressure is a critical design parameter.

7. References

[1] A.S. Mussa,M. Klett,G. Lindbergh, and R.W. Lindstrom, Effects of external pressure on the performance and ageing of single-layer lithium-ion pouch cells. J. Power Sources 385 (2018) 18-26.

[2] D.J. Li, D.L. Danilov, J. Xie, L. Raijmakers, L. Gao, Y. Yang and P.H.L. Notten, Degradation Mechanisms of C6/LiFePO4 Batteries: Experimental Analyses of Calendar Aging. Electrochim. Acta 190 (2016) 1124-1133.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.