-

iestinstrument

Analysis of Factors Affecting the Determination of Powder Compaction Density – Pressurization Method

1. Abstract

This technical article summarizes a comparative experimental study that evaluates how three common compression modes—single-point (static), stepped/variable, and unload—affect measured powder compaction density for battery electrode materials (NCM, LFP, Graphite). The work uses a PRCD3100 instrument to generate high-precision compaction data and demonstrates how differences in loading history change particle rearrangement, elastic and plastic deformation, and the measured density outcome. The findings are intended for materials scientists and process engineers optimizing electrode formulation and calendering.

2. Introduction: The Critical Role of Powder Compaction Density

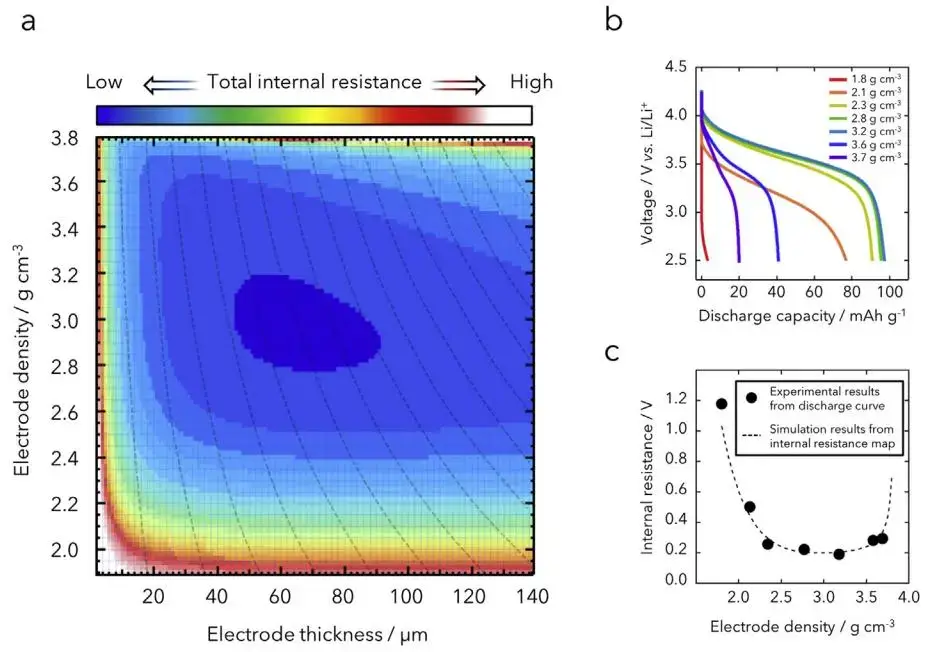

Powder compaction density is a pivotal metric in lithium-ion battery design, directly linked to critical performance parameters like capacity, internal resistance, and cycle life. The study of materials compaction density includes two directions: electrode density and powder density. For the evaluation of powder materials compaction density, the traditional way is to evaluate the electrode density, which needs to be tested through the steps of batching and stirring, coating and roller pressing, baking, weighing and thickness measurement, and calculating, and is further related to the electrical performance of the battery, and Figure 1 shows the relationship between the electrode density and the internal resistance and capacity of the battery. This electrode density evaluation method has a long testing cycle, low testing efficiency, and the production process of the electrode sheet will also cause certain hazards to personnel and the environment.

A more efficient and direct approach is gaining traction: measuring the powder compaction density of raw cathode and anode materials. This method uses a fixed-diameter mold and a precision press to form a pellet, with high-accuracy thickness measurement enabling rapid calculation. As this metric becomes a standard for material suppliers and battery manufacturers, ensuring consistent and comparable test results is paramount. This study investigates a key variable: how the pressure application method during testing influences the measured powder compaction density.

Figure 1. Schematic diagram of the relationship between electrode density and battery internal resistance and capacity

3. Test Methods and Parameters

3.1 Test Materials and Modes

Three key battery materials were selected: a Lithium Nickel Cobalt Manganese Oxide (NCM) cathode, a Lithium Iron Phosphate (LFP) cathode, and a Graphite anode. Each was tested using three distinct pressure application methods:

-

Single-Point Test: Direct compression to target pressures of 50, 100, 150, and 200 MPa, with a 10-second hold.

-

Stepwise Pressure Test: Gradual compression from 10 to 200 MPa in 10 MPa increments, with a 10-second hold at each step.

-

Unloading Pressure Test: Similar stepwise loading, but unloading to 3 MPa after each pressure step, followed by a 10-second hold.

3.2 Instrumentation: The PRCD3100 Powder Compaction Density Tester

All tests were conducted using the PRCD3100 Powder Compaction Density & Resistivity Tester from IEST Instrument(Figure 2). This system provides controlled pressure application and high-precision thickness measurement, essential for accurate powder compaction density calculation.

Figure 2. (a)The Appearance of PRCD3100; (b)The Structure of PRCD3100

4. Analysis of Results

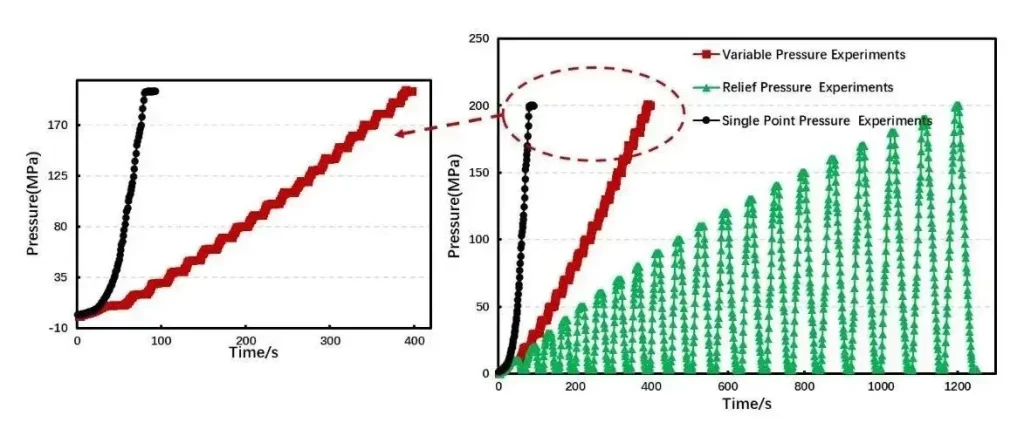

4.1 Visualizing the Pressure-Time Profile

The fundamental difference between the three methods is their pressure-time history. As shown in Figure 3, the pressure changes when pressurized to 200MPa under different pressing modes are shown in the schematic diagram. The Single-Point test applies pressure abruptly, the Stepwise test applies it incrementally, and the Unloading test adds a controlled release phase. These distinct mechanical histories directly affect how particles rearrange, deform, and pack.

Figure 3. Schematic diagram of pressure change when pressurized to 200MPa under different pressing methods

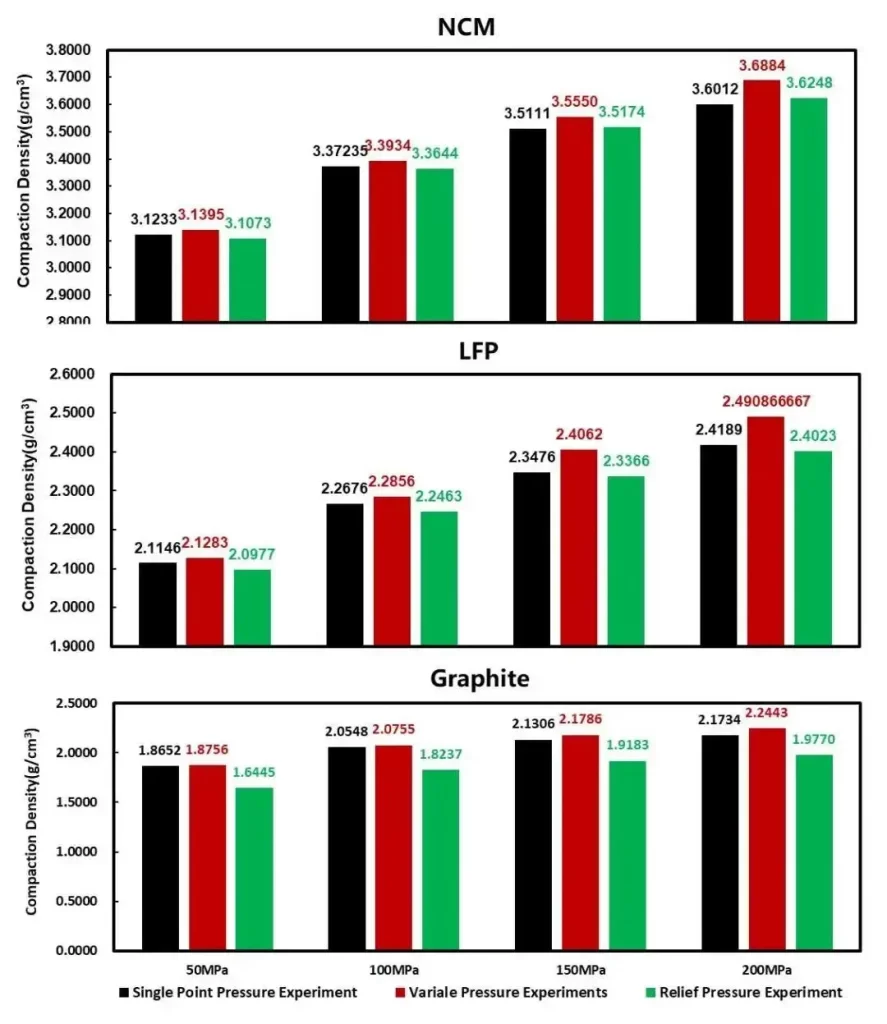

4.2 Comparative Density Results Across Materials

The measured powder compaction density for NCM, LFP, and Graphite at four key pressures (50, 100, 150, 200 MPa) is shown in Figure 4. Significant differences emerged based on the pressure application method. From the comparison results, it is seen that there are differences in the single-point compaction density, variable-pressure compaction density and unloaded-pressure compaction density under each pressure point, which is mainly due to the results of different pressing methods. From Figure 3, it can be seen that under different pressing methods, there are obvious differences in the way and time of the powder material under pressure during the measurement process, and the powder compression process is extremely complex. At the beginning of the pressing, the porosity between the powder is relatively high, with the pressing, the powder particles will be rearranged and slip, and ultimately form a relatively dense stacking state, and the porosity between the particles decreases; as the pressure continues to increase, the powder particles themselves will undergo elastic deformation, and the porosity between the particles will not change much, but the pore diameter will be reduced; with the further increase in pressure, some of the powder will undergo an irreversible plastic deformation, and the pore diameter will be reduced; with the further increase in pressure, some of the powder will undergo an irreversible plastic deformation, and the pore diameter will be reduced. With the further increase of pressure, some powders will undergo irrecoverable plastic deformation, and the pore size will be further reduced, and at the same time, for some brittle systems, the phenomenon of crushing may also occur, and the pore size reduction will be more obvious【2】.

Comparing the results of single-point pressing and variable pressure test, there is not much difference under small pressure, and as the pressure increases, the difference gradually appears, which is mainly due to the difference in the force changes of the powder under the two pressing methods. Samsung once studied the use of two-step pressing process in the electrode roller pressing. The first soft roll pressing smoothly reoriented the graphite perpendicular to the pressing force, thereby reducing stress and mechanical damage within the graphite and promoting uniform hole distribution throughout the electrode. The target density of the electrode is adjusted by a subsequent second roll pressing. Electrodes prepared by the two-step roll pressing process exhibited significantly reduced springback and swelling behavior. Therefore, the variable pressure test is equivalent to multiple compaction processes, which are able to reduce the rebound of the particles with higher powder compaction density【3】.

Comparison of the unpressurized compaction density results are significantly smaller than the other two pressing methods, which is mainly due to the powder pressing process is subject to elastic deformation and plastic deformation of the dual-factor constraints, when loaded on the powder end of the large pressure into a small pressure, the powder itself will overcome the elastic deformation of the small pressure to rebound, the thickness of the powder compacts will be obvious changes, which will result in the results of the difference.

These findings underscore a crucial point for laboratory benchmarking: comparing powder compaction density data is only valid if the pressure application method is identical. Ignoring this variable can lead to incorrect material comparisons and wasted R&D effort.

Figure 4. Comparison of the compaction density test results of NCM, LFP, and Graphite under different pressurization methods

5. Linking Powder Tests to Calendering Models and Process Parameters

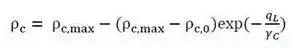

The data from powder compaction density tests can be used to build predictive models for the electrode calendering process. Researchers at the Technical University of Braunschweig, Germany, modeled the roll pressing process and revealed the relationship between the coating density ρc and the compaction load qL【5】.

Among them, ρc,max and γc can be obtained by fitting experimental data, which represent the maximum compaction density that the coating can achieve and the coating compaction impedance, respectively. These fitting parameters can be obtained by powder compaction experiments, for example, the maximum compaction density ρc,max that can be achieved by the coating is the limit value of the powder materials compaction density that basically no longer increases in the variable pressure test experiment. The compaction impedance γc can also be obtained by fitting the formula to the results of powder compaction density under a series of different pressures. In this way, for a specific powder, the compaction density process model can be obtained to know the electrode roll pressure experiment.

6. Conclusion: Standardizing Measurement for Accurate Material Evaluation

As powder compaction density becomes a universal benchmark, standardizing the test protocol is essential. This study clearly demonstrates that thepressure application method is a major source of variation, significantly affecting results through mechanisms of particle rearrangement, elastic and plastic deformation, and rebound. Laboratories must align on a single, defined method—considering the Stepwise Pressure Test for its closer simulation of industrial calendering—to ensure data is comparable, reliable, and truly useful for guiding material selection and manufacturing process optimization.

7. References

【1】B K K A , A S A , A H N , et al. Internal resistance mapping preparation to optimize electrode thickness and density using symmetric cell for high-performance lithium-ion batteries and capacitors[J]. Journal of Power Sources, 2018, 396:207-212.

【2】Yang Shaobin, Liang Zheng. Lithium-ion Battery Manufacturing Process Principles and Applications.

【3】 Improved swelling behavior of Li ion batteries by microstructural engineering of anode. Journal of Industrial and Engineering Chemistry 71 (2019) 270-276.

【4】LIANG Huamei, ZENG Yong, HUANG Shijian, et al. Study on the Conditions of Compaction Density Test for Positive Electrode Material of Lithium Battery[J]. Guangdong Chemical Industry, 2021, 48(19):3.

【5】Meyer C, Bockholt H, Haselrieder W, et al. Characterization of the Calendering Process for Compaction of Electrodes for Lithium-Ion Batteries[J]. Journal of Materials Processing Technology.2017

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.