-

iestinstrument

Entering Electrochemistry | High-precision Battery Cycle Tester

1. Preface

In the field of electrochemistry, battery testing equipment is a key tool for researching and developing new battery technologies, especially for emerging battery technologies. As new energy technologies advance rapidly, the importance of high-precision testing equipment becomes increasingly evident. Especially high-precision charge/discharge battery cycle tester. This equipment is indispensable across all stages of lithium battery production, research, and application, particularly for testing consistency, safety, functionality, and reliability.

2. Why is High Precision Necessary for Battery Cycle Tester?

In battery development and optimization, the accuracy of test data directly influences the reliability of research outcomes. High-precision battery cycle tester provides precise electrochemical parameters, enabling researchers to deeply understand the minute physical and chemical changes within batteries, which are often so subtle that only high-precision equipment can accurately capture them.

2.1 Precise Current and Voltage Measurement

During the charge-discharge process, changes in current and voltage are fundamental parameters for characterizing battery performance. High-precision current and voltage measurements not only ensure data authenticity but also help researchers identify potential performance issues, such as small voltage fluctuations that might indicate battery life degradation.

Most mass-produced equipment on the market has an accuracy of either 0.01% or 0.05%, primarily used for cell cycle testing and validation. For battery cycle tester, voltage and current accuracy generally involves two aspects: control accuracy and measurement accuracy. Although related, these aspects have different implications and improvement methods.

In simple terms, the equipment consists of stacked components, with specific logic control to achieve desired functionality. Choosing quality components not only enhances equipment accuracy but also ensures long-term stability. High-accuracy, stable battery cycle testerlikely results from substantial investment in the component selection stage, explaining why ultra-high precision battery cycle tester are tens of times more expensive than regular equipment.

2.2 Control Accuracy

Control accuracy refers to the equipment’s ability to precisely regulate and maintain the target voltage or current. This determines whether the equipment can operate according to set values during the charge-discharge process without deviating from the target. Key to this is the equipment’s hardware control capability, achieved through high-precision digital signal processors (DSPs) or microcontrollers for precise voltage and current control. Hardware design involves multiple aspects, such as the design of precision power supplies and control circuits, which can effectively reduce noise and interference, ensuring that the equipment responds quickly and remains stable at the set value. Additionally, using high-quality components such as low-temperature drift and low-time drift resistors and precision capacitors can effectively reduce errors caused by factors like temperature changes and aging—issues often referred to as “temperature drift and time drift” by R&D professionals.

2.3 Measurement Accuracy

Measurement accuracy indicates the equipment’s ability to approach the true value when measuring actual voltage or current. This reflects the accuracy and stability of the equipment’s measurement system, which includes the data the user sees in the control software. The process involves hardware first converting analog signals to digital signals via high-precision analog-to-digital converters (ADCs), which are then uploaded for users to read and utilize. Achieving high testing accuracy requires optimizing the measurement circuit to reduce noise and error introduced during measurement. For example, four-wire measurement methods can eliminate the influence of wire resistance. Additionally, users should regularly calibrate the equipment’s channels, a process that adjusts for control errors caused by hardware temperature drift and time drift, thereby ensuring measurement accuracy.

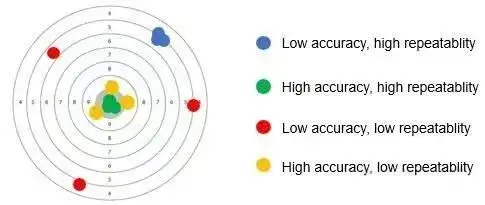

Figure 1. Accuracy and Repeatability Target Chart

In practical applications, both control accuracy and measurement accuracy are critical. Control accuracy ensures that the equipment executes operations precisely, while measurement accuracy ensures accurate feedback, providing reliable data for further equipment control.

When reviewing battery cycle tester specifications, you may notice that each manufacturer defines accuracy differently, often listing only one accuracy parameter. In such cases, accuracy usually refers to measurement accuracy, as this is the parameter directly observable and verifiable by the user.

As a professional supplier of lithium battery testing equipment, IEST has been deeply involved in equipment development for many years, accumulating extensive experience with customer needs and pain points. The development of battery cycle tester products aims to meet customers’ increasingly stringent standards and provide customized services. Our currently developed equipment is equipped with 8 test channels with 1 in 10,000 accuracy, integrating electrochemical modules such as CV (cyclic voltammetry) and EIS (electrochemical impedance spectroscopy). These modules can be synchronized with CV or EIS testing steps within long-cycle testing, making it convenient for customers to conduct extended CV or EIS monitoring.

Figure 3. IEST Electrochemical testing system

Figure 4. IEST Battery Cycle Tester Electrochemical Tester-ECT Series(8 Channels)

3. How Can High-Precision Testing Assist Battery Research?

The application scenarios for high-precision charge-discharge equipment are diverse. It’s not an exaggeration to say that “a thousand users have a thousand Hamlets” in mind. Ultimately, the goal is to address three key issues:

3.1 Enhancing Energy Density

By accurately testing the capacity, voltage platform, and cycle life of new materials, researchers can identify optimal solutions for improving battery energy density, leading to the development of more efficient and longer-lasting batteries.

3.2 Improving Safety

High-precision testing equipment can detect potential safety hazards within the battery, such as overcharging, over-discharging, or thermal runaway. By precisely analyzing these data, battery design can be improved, enhancing safety and preventing accidents.

3.3 Extending Lifespan

Battery degradation mechanisms are complex and varied. Through high-precision long-cycle testing and impedance analysis, researchers can deeply understand the battery’s aging process, finding effective ways to extend battery life.

4. Related article:

Application scenarios explained: Entering Electrochemistry | The Significance of High-Precision Charge/Discharge Testing for Predicting the Lithium ion Battery Lifespan

5. Conclusion

As a leader in innovative testing solutions for lithium batteries, IEST understands the importance of technological innovation for data accuracy. Seeing more and more precision equipment replaced by domestic equipment, I feel the progress of the industry. However, how to ensure the long-term stability of the equipment precision testing is still a systematic issue. Although the domestic equipment technology has improved significantly, some customers still turn to foreign brands due to the problem of “made in China” equipment, even if they have to pay a higher price.

The new energy industry, the volume of serious, from a positive point of view, the volume of technology to help China’s new energy industry to realize a lot of “curved road overtaking”, so that enterprises stand on the world stage. However, the key to maintain the leading position is technological innovation. Overtaking others is not the end of the road, the key is to do better. We are honored to contribute to the progress of the new energy industry.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.