-

iestinstrument

How Environmental Humidity Affects Electrode Sheet Resistance in Lithium-ion Batteries

1. Abstract

Electrode sheet resistance is a critical parameter that determines a cell’s internal resistance, rate capability and performance uniformity. In large-scale manufacturing, ambient humidity becomes a key process variable. Differences in humidity control between production sites can induce batch-to-batch variation in electrode electrical properties, which in turn affects cell performance and yield. This case study reports controlled experiments on LFP electrodes that quantify how short-term humidity exposure changes electrode sheet resistance and the underlying mechanisms that alter electronic conductivity.

2. Introduction: The Critical Role of Humidity in Electrode Manufacturing

In lithium-ion battery manufacturing, the electrode sheet is the fundamental platform for electrochemical energy conversion. Its electronic conductivity is a primary determinant of critical cell characteristics, including internal resistance, rate capability, and overall performance uniformity. During large-scale production, ambient humidity emerges as a key, yet often variable, process parameter.

This challenge intensifies for companies with global production footprints across diverse climatic zones. Inconsistent humidity control can directly impact electrode quality, leading to undesirable batch-to-beryformance variations. Consequently, a systematic investigation into how environmental humidity influences electrode sheet resistance is not only a significant scientific inquiry but also a pressing industrial need for achieving high-standard, precise quality control.

3. Experimental Validation: Measuring Humidity Impact on LFP Electrodes

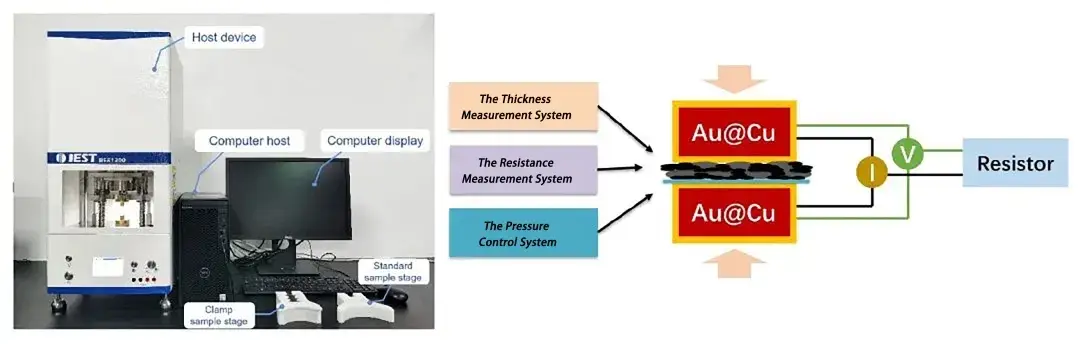

To quantitatively assess the effect of storage humidity on electrode resistance, we conducted a controlled study using an IEST Electrode Resistance Analyzer.

Figure 1. IEST Electrode Resistance Analyzer(BER Series) used for the study.

Test Sample & Protocol:

We used lithium iron phosphate (LFP) cathode sheets from the same production batch. After obtaining baseline resistance measurements on Day 1 (control group), the electrode samples were stored for 24 hours in four distinct humidity environments:

-

Glovebox: ~0% RH

-

Dry Room: ~2% RH

-

Laboratory: ~50% RH

-

Air Vent Area: >70% RH

After 24 hours, electrode sheet resistance was measured using IEST Electrode Resistance Tester under a compaction pressure of 25 MPa with a 15 s hold time. The protocol isolates the influence of ambient moisture on the electrode electrical response by keeping all electrochemical and mechanical test parameters constant across samples.

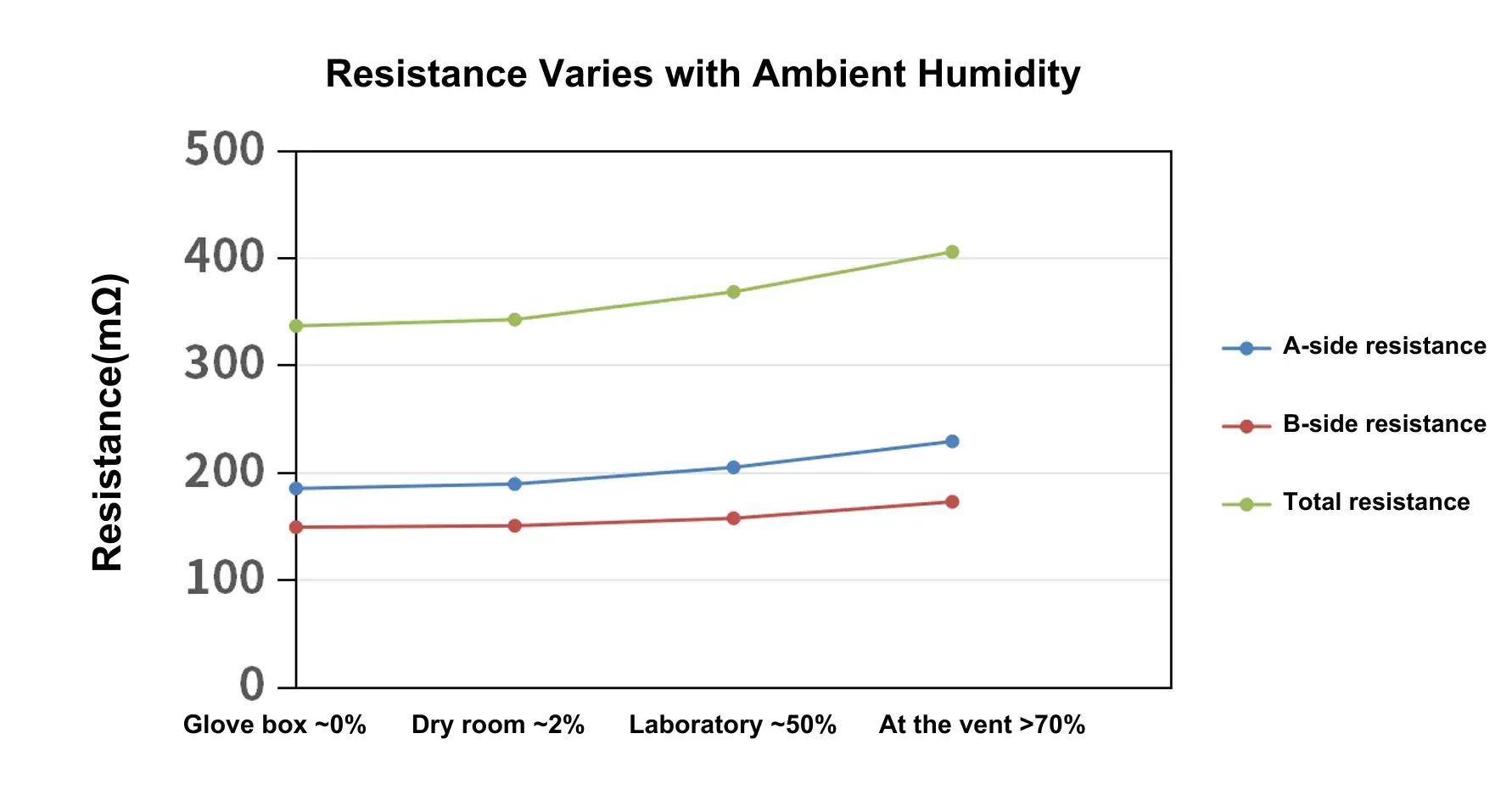

Figure 2. Electrode sheet resistance measurements after 24-hour storage at different humidity levels.

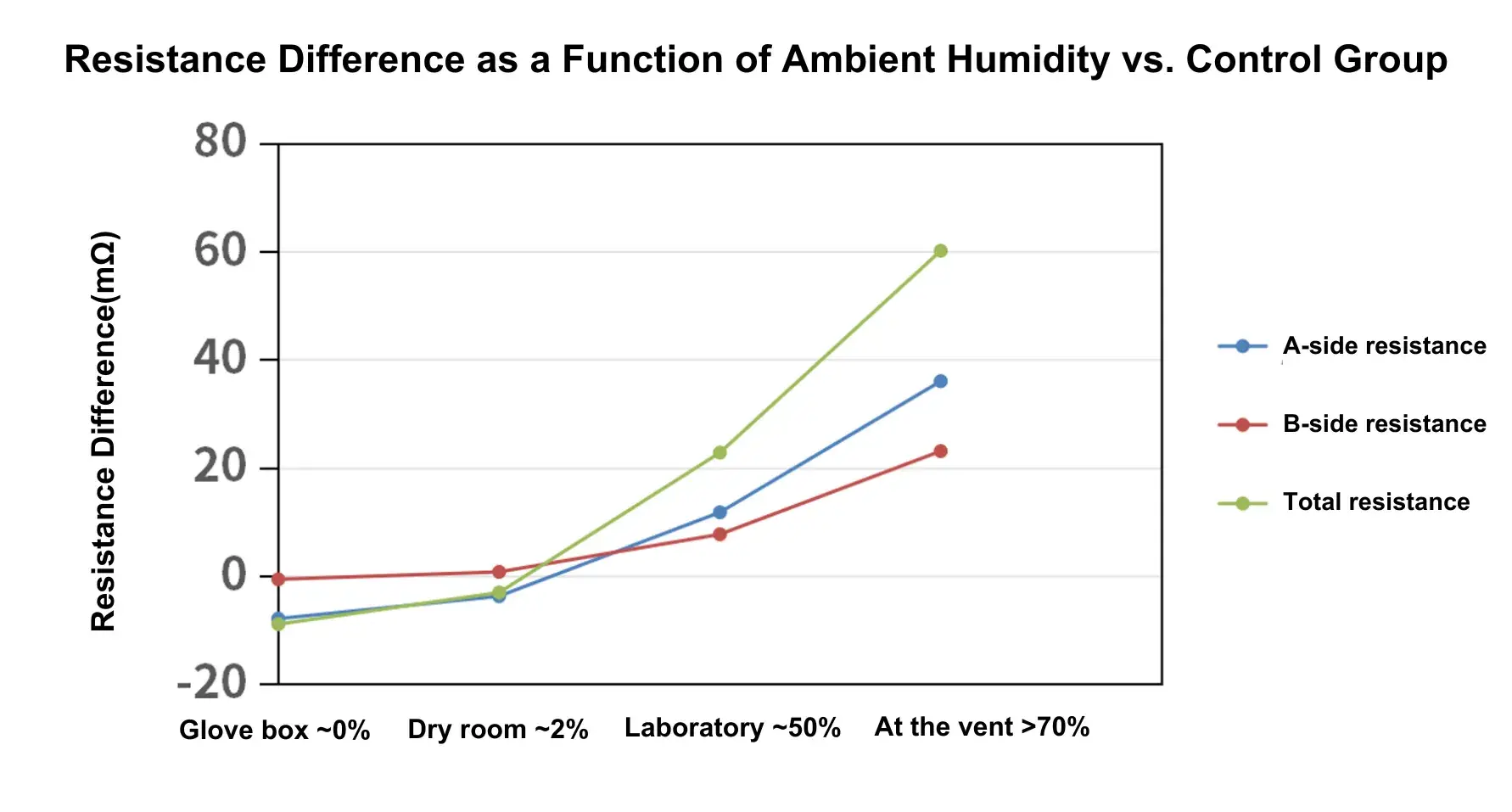

Figure 3. Changes in resistance difference with ambient humidity after 24 hours of storage at different humidity levels VS Control group

Table 1. Summary of measured electrode sheet resistance after storage at various humidity levels.

4. Results & Analysis: A Clear Correlation Emerges

The experimental data reveals a direct and significant correlation between storage humidity and measured resistance:

-

Low-Humidity Benefit: Storage in extremely dry environments (0-2% RH) resulted in a decrease in electrode sheet resistance compared to the Day 1 baseline. The lower the humidity, the lower the resistance.

-

High-Humidity Detriment: As storage humidity increased, electrode sheet resistance exhibited a clear upward trend. Notably, exposure to high-humidity conditions (>70% RH) caused a substantial increase in resistance.

5. Mechanistic Interpretation: Disrupting the Conductive Network

The electronic conductivity of an electrode relies on a stable, three-dimensional network formed by active material particles, conductive additives (e.g., carbon black, CNTs), and binder. This network is highly sensitive to moisture ingress. Humidity impacts performance through several interconnected microscopic mechanisms:

-

Degradation of the Conductive Network: Nano-scale conductive agents possess high surface areas, making them prone to water adsorption. The presence of water molecules can alter inter-particle interfacial energy, disrupting the uniform and efficient pathways for electron transport, thereby increasing bulk resistance.

-

Alteration of Active Material Interfaces: The surfaces of cathode and anode active materials (e.g., NCM, LFP, LCO) can interact with moisture physically and chemically. This may lead to slight surface hydrolysis or the formation of insulating/semi-conducting by-product layers (e.g., lithium carbonate), increasing the interfacial resistance for electron transfer from the active material to the conductive network.

-

Changes in Micro-Mechanics and Porosity: Binders (e.g., PVDF, SBR/CMC) can swell upon water absorption. This swelling can physically compress the conductive network, increasing electron tunneling distances. Furthermore, it can alter the electrode’s porosity and mechanical integrity, compromising the intimate contact with the current collector and raising interfacial contact resistance.

6. Recommendations for R&D and Production Teams

To mitigate humidity effects on electrode sheet resistance and electronic conductivity, implement the following:

-

Control and standardize ambient RH across critical process steps (coating, drying, calendaring, slitting and stacking). Maintain documented target ranges and alarm thresholds.

-

Integrate rapid resistance checks (online or offline) as a production QA metric. Use the same compaction pressure and dwell time for all checks (e.g., 25 MPa, 15 s) to ensure comparability.

-

Build a reference database correlating storage RH, time, and measured sheet resistance for each electrode formulation. This database enables trend detection and permits quantitative alarm limits.

-

Run targeted root-cause assays when resistance excursions occur: measure binder uptake (water uptake tests), perform surface analyses (XPS or FTIR) for carbonate or hydrolysis products, and image microstructure (SEM) to detect network disruption.

-

Design formulations and processing to reduce moisture sensitivity where possible (e.g., selection of less hydrophilic conductive additives, optimized binder chemistry, improved drying procedures).

7. Conclusion & Practical Implications

Exposure to humidity does more than immediately increase electrode sheet resistance; it can induce potentially irreversible microstructural changes, inflicting lasting “hidden” damage to the battery’s electrochemical performance. Therefore, stringent humidity control throughout the manufacturing process is a non-negotiable requirement for ensuring electrode quality and final cell consistency.

Implementing electrode sheet resistance as a key parameter for inline or offline rapid quality control provides a powerful tool. Establishing a quantified database of this metric enables manufacturers to promptly detect process deviations and material anomalies, ensuring robust batch-to-batch consistency and supporting the production of high-performance, reliable lithium-ion batteries.

8. Reference

[1] Zhen Tong, Chao Lv, Guo-Dong Bai, Zu-Wei Yin, Yao Zhou, Jun-Tao Li. A review on applications and challenges of carbon nanotubes in lithium‐ion battery. 2025, 7, 2

[2] Gongrui Wang, Zhihong Bi, Anping Zhang, Pratteek Das, Hu Lin, Zhong-Shuai Wu. High-Voltage and Fast-Charging Lithium Cobalt Oxide Cathodes: From Key Challenges and Strategies to Future Perspectives. Engineering, 2024, 37(6): 115–139.

[3] Malte Kosfeld, Bastian Westphal, Arno Kwade, Moisture behavior of lithium-ion battery components along the production process, Journal of Energy Storage, Volume 57, 2023, 106174.

[4] Niu Aimin, Li Xianhong, Lü Haoran, Zang Haoting, Song Ran, Gao Mingjuan, Ma Wenqing. Research Progress of Anode Binder for Lithium Ion Battery [J]. Journal of Liaocheng University (Natural Science Edition), 2025, 38(1):51-586

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.