-

iestinstrument

Parameters Selection Basis for Battery Swelling Performance Test

1. Preface

During the charge and discharge process of lithium-ion batteries, the swelling of the battery cells will occur due to the structural swelling of the positive and negative electrodes and the decomposition and gas production of the electrolyte. When the restraining boundaries of the battery are different, the battery swelling will manifest differently. When the stress applied to the surface of the cell is certain, the cell exhibits a change in thickness, while when the initial thickness of the cell is controlled constant, the cell exhibits a change in stress. Usually, when testing the battery swelling behavior, we need to control different boundary conditions to get the changes of the battery swelling thickness or swelling force, but different control parameters will significantly affect the measured swelling data, IEST has launched the in-situ battery swelling test system SWE series, as shown in Figure 1, which can in-situ characterize the battery swelling behavior, and how to carry out the parameter settings in different measurement modes is very important to get accurate and reliable swelling data. How to set the parameters in different measurement modes is very important to get accurate and reliable swelling data.

Figure 1. IEST in-situ swelling test system SWE series

The SWE series has two measurement modes for characterizing the battery swelling behavior: constant pressure and constant gap. The following describes the parameter settings for each of these two modes.

2. Constant pressure mode

In the constant pressure mode, the pressure applied to the surface of the cell is constant, and the pressure during the charging and discharging process of the cell is maintained in real time by a high-precision pressure regulation system, while the thickness change curve is collected, as shown in Figure 2. This model is usually applied to compare the difference in battery swelling behavior of different materials, such as the comparison of the swelling thickness of different silicon-carbon materials. The setting of the pressure parameter is related to the length and width area of the cell, in general, with the increase of the applied pressure, the longitudinal pressure on the battery cell is increasing, and the measured battery swelling thickness of the charging and discharging process is getting smaller and smaller, as shown in Fig. 3, but when the pressure is too large, it will lead to excessive polarization of the battery cell’s charging and discharging, which will affect the performance of the battery cell, so it is necessary to choose a reasonable applied pressure. Usually, industry personnel choose a pressure of 0.2 MPa to characterize the in-situ swelling thickness of the battery cell. There is no requirement for the SOC state of the cell before testing in this mode, and the analysis focuses on comparing the thickness difference with full charge and discharge.

Figure 2. Schematic diagram of constant pressure and thickness variation

Figure 3. In-situ swelling thickness curves under different pressure conditions

3. Constant Gap Mode

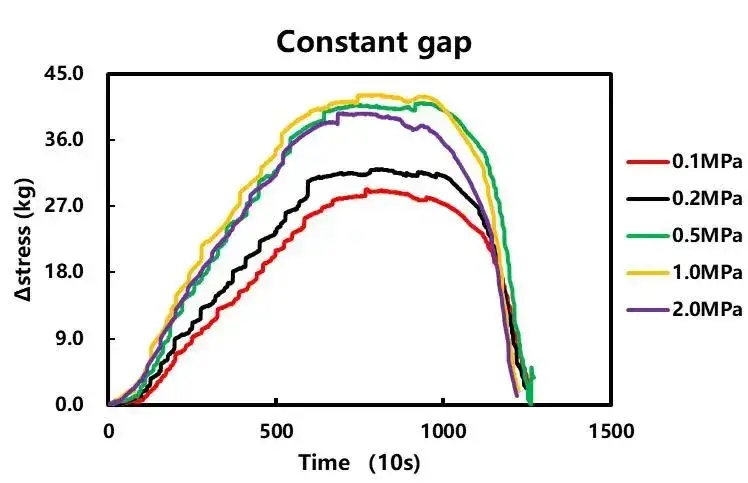

In constant gap mode, an initial preload force is applied to the battery cell, and the battery cell gap corresponding to this preload condition is kept constant by a high-precision displacement control system, which real-time collects the pressure change curve during the charging and discharging process of the cell, as shown in Fig. 4. This mode is usually applied in the cell/module/Pack design or simulation department, which controls the different gaps of the cell by comparing different initial preload conditions, and then analyzes the stiffness of the bounding boundary materials, for example, comparing the differences between different module shells or different buffer cottons. The setting of the preload force parameter affects the initial gap of the cell, the larger the preload force, the smaller the corresponding gap of the cell, the larger the swelling force measured in the subsequent charging and discharging process, but when the preload force reaches a certain level, the change of the swelling force of the battery cell will be relatively smooth, and if you continue to increase the preload force, the corresponding gap of the battery cell is smaller, which will increase the polarization of the battery cell charging and discharging, affecting the performance of the battery cell, and therefore you need to choose a reasonable preload force to ensure a proper cell gap, usually, industry personnel will choose a pressure of 0.2 MPa as the preload force to characterize the in-situ swelling force of the battery cell. In addition, the initial SOC state of the cell is different, which will affect the gap control amount of the battery cell, for example, under the same preload condition, the gap of the cell with 0% SOC is smaller than that of the cell with 100% SOC, and the difference of the swelling force of the full discharge of the battery cell measured under these two states will be different, therefore, we try to keep the same initial SOC state of the cell in the characterization of the swelling force, and usually choose the battery cell with the full discharge state for testing. We usually choose the fully discharged state of the cell for testing.

Figure 4. Schematic diagram of constant gap swelling force variation

Figure 5. Schematic diagram of the swelling force change at the constant gap corresponding to different preloading forces

4. Summary

Constant pressure and constant gap modes have different application scenarios and test parameters when characterizing the battery swelling performance of the cell. Usually, when evaluating materials, constant pressure mode is preferred to characterize the battery swelling thickness of the battery cell, at this time, there is no special requirement for the initial SOC of the cell, while in the design of the battery cell, it is more preferred to choose the constant gap mode to characterize the swelling force of the cell, at this time, the initial SOC of the cell will have a greater impact on the subsequent test results, and the fully discharged state of the battery cell can be chosen to conduct the test. In addition, for the initial preload force setting, the industry will use more 0.2MPa pressure applied to the surface of the cell as the initial conditions of constant pressure or constant gap.

5. References

[1] Li Linyang, He Fan, Lv Xixiang. Analysis method of lithium cell module swelling displacement [J]. Power Technology, 2023, 47(5): 632-634.

[2] Liang Haobin, Du Jianhua, Hao Xin, et al.A review of current research on the formation mechanism of lithium batteries [J]. Energy Storage Science and Technology, 2021, 10(2): 647-657.

[3] MARTIN W, JORG K, DIRK U S. Investigation of the influence of different bracing of automotive pouch cells on cyclic lifetime and impedance spectra[J]. Journal of Energy Storage, 2019, 21:149-155.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.