-

iestinstrument

Pouch Cells In-situ Characterization of Expansion Force Distribution

1. Introduction

Pouch cells are widely used in electric vehicles, portable electronics, and energy storage systems due to their high energy density and flexible packaging. However, during electrochemical cycling, electrode volume changes, gas evolution and heat generation cause macroscopic deformation—most noticeably pouch cell swelling in the thickness direction. Uneven lithium distribution and internal structural features lead to spatially non-uniform stresses across the pouch surface. Accurately monitoring these local changes is essential to understand failure modes, improve safety, and optimize cell and pack designs.

This study uses a Battery Pressure Distribution Measurement System(BPD Series) together with an in-situ swelling analyzer to measure pressure in pouch cell surfaces during charge–discharge, producing a high-resolution map of expansion force that reveals where the pouch expands most and why.

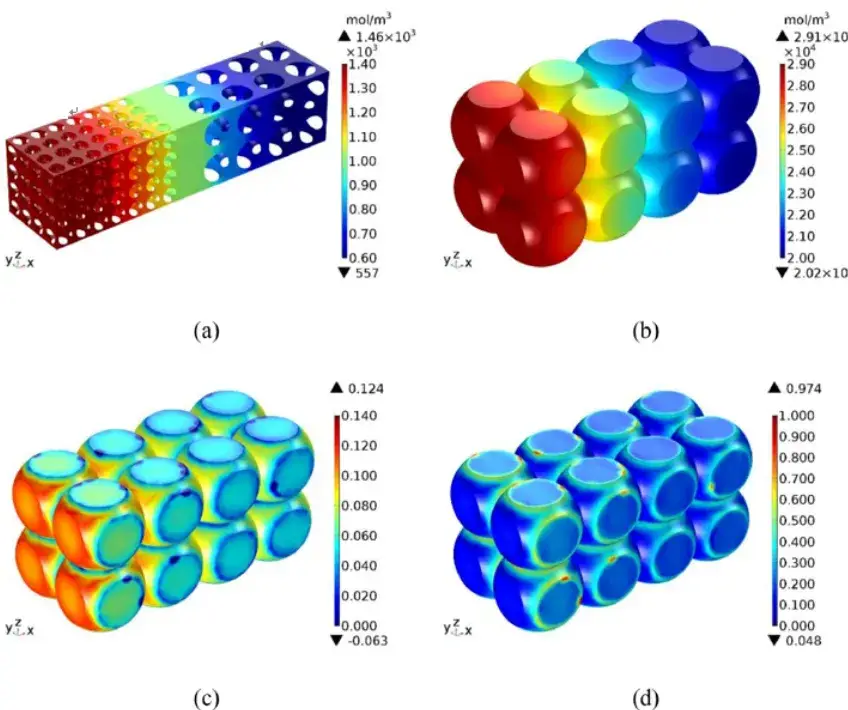

Figure 1. Simulation of lithium concentration and stress strain distribution corresponding to lithium-ion pouch cells when they are fully charged.

2. Test Information

2.1 Test Equipment

In-situ swelling analyzer, model SWE2110 (IEST), which can apply a pressure range of 50~10000N.

Sensor approach: A grid of thin-film pressure sensors (a “pouch cell swelling pad”) is placed beneath the pouch cell to record local normal forces during cycling. The pouch is divided into multiple measurement zones so each sensor logs a synchronous force trace.

Figure 2.Schematic diagram of the in-situ swelling analyzer (SWE series)

2.2 Test Parameters

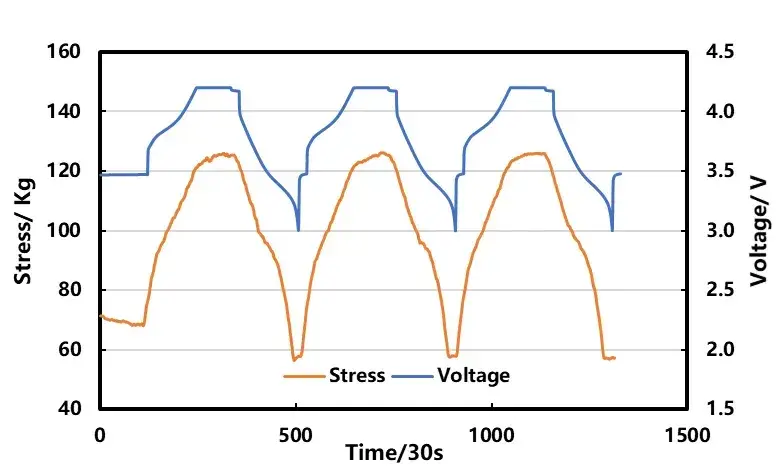

The Pouch Cells Information is Shown in Table 1

Table 1. Cell Information

2.3 Test Process

place the pouch cells in the test chamber of the in-situ swelling analyzer, set the charge and discharge parameters: leave for 60 minutes, charge 0.75C, cut-off current 0.05C, leave for 10 minutes, discharge 0.75C, cut-off voltage 3.0V, Simultaneously turn on the in-situ swelling analyzer to monitor the change curve of the cell expansion force in real time.

3. Result Analysis

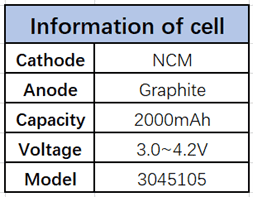

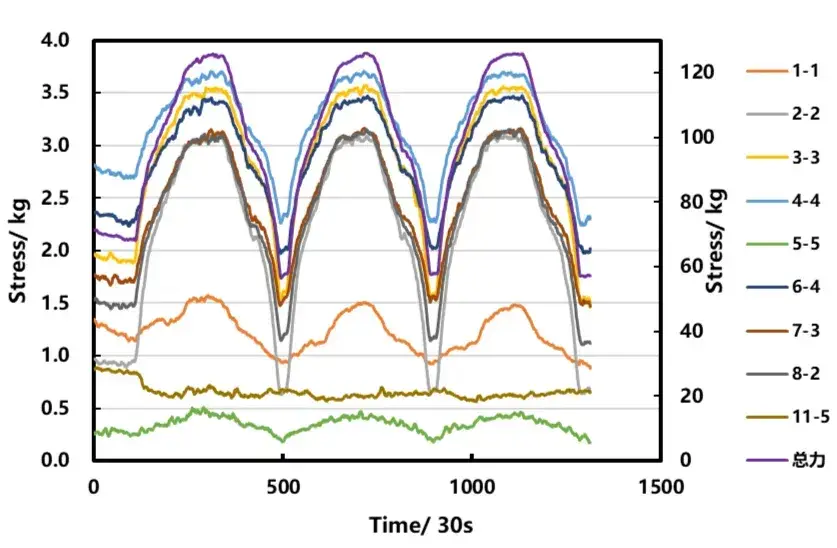

Charge and discharge the cell for three cycles in constant gap mode and collect the maximum expansion force curve of the cell synchronously, as shown in Figure 3. As lithium ions are continuously extracted from the positive electrode and inserted into the negative electrode, the structure of the negative electrode expands, and the pressure continues to rise. The peak pressure of the charging result is 125.3kg. During discharge, lithium ions escape from the negative electrode and return to the positive electrode. The structure of the negative electrode shrinks continuously, and the pressure continues to decrease. At the end of the discharge, the pressure is 56.9kg. As shown in Figure 3 below.

Figure 3. Cell charging and discharging voltage and pressure variation curve

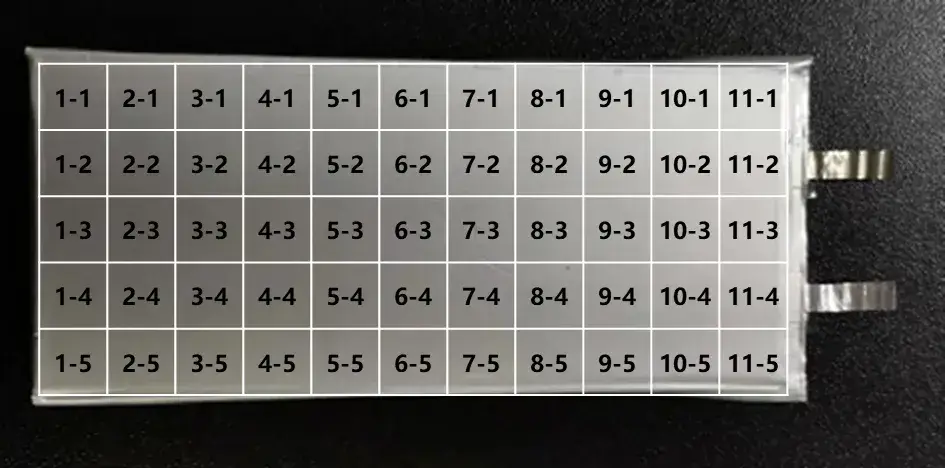

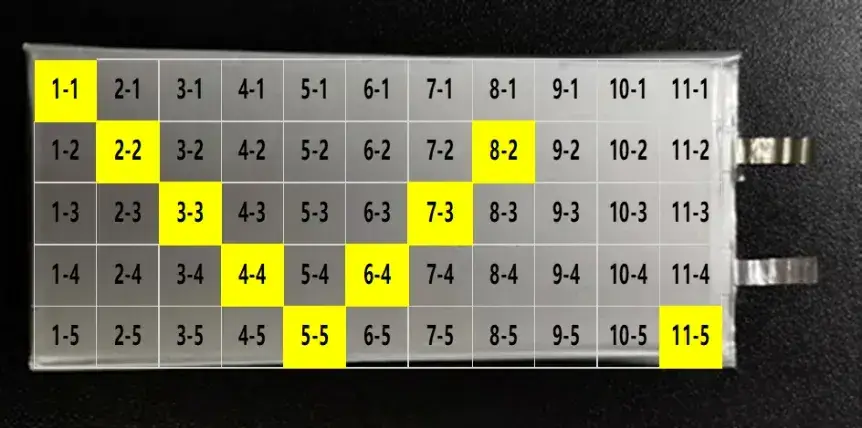

To further analyze the expansion force changes at different positions on the surface of the cell, we divide the cell into small units as shown in Figure 4, Each small unit corresponds to a pressure sensor, and the expansion force change curve of each position during the charging and discharging process of the pouch cells are collected synchronously.

Figure 4. Area division of small cells of the battery cell

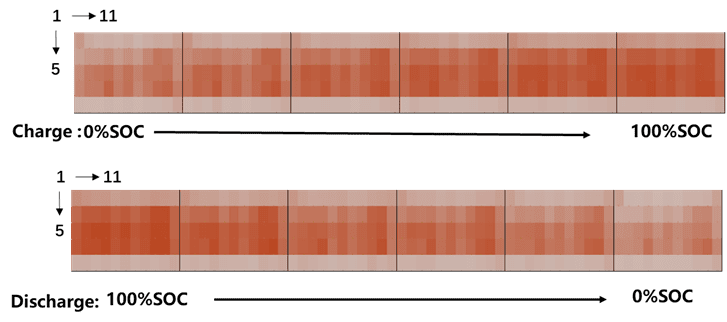

The thermal diagram of the force changes of each area unit during the entire charging and discharging process is shown in Figure 5. The darker the color, the greater the expansion force. As the SOC increases, the expansion force in the middle area of the cell can be seen to increase significantly. When discharging, the SOC gradually decreases, and the expansion force corresponding to each area gradually decreases. The overall change trend is consistent with Figure 3. The stress of the cell is strong in the middle and weak at the periphery. This may be since the heat-sealed edge of the aluminum-plastic film itself has a certain limiting effect on the battery. The thickness of the edge of the battery expands relatively little during charging and discharging. In addition, it is also related to the structural design of the wound cell. At the same time, the change of expansion force will also be affected by the glue at the end of the pouch cells and the thickness of the tab.

Figure 5. The thermal diagram of different regions of the cell changing with SOC.

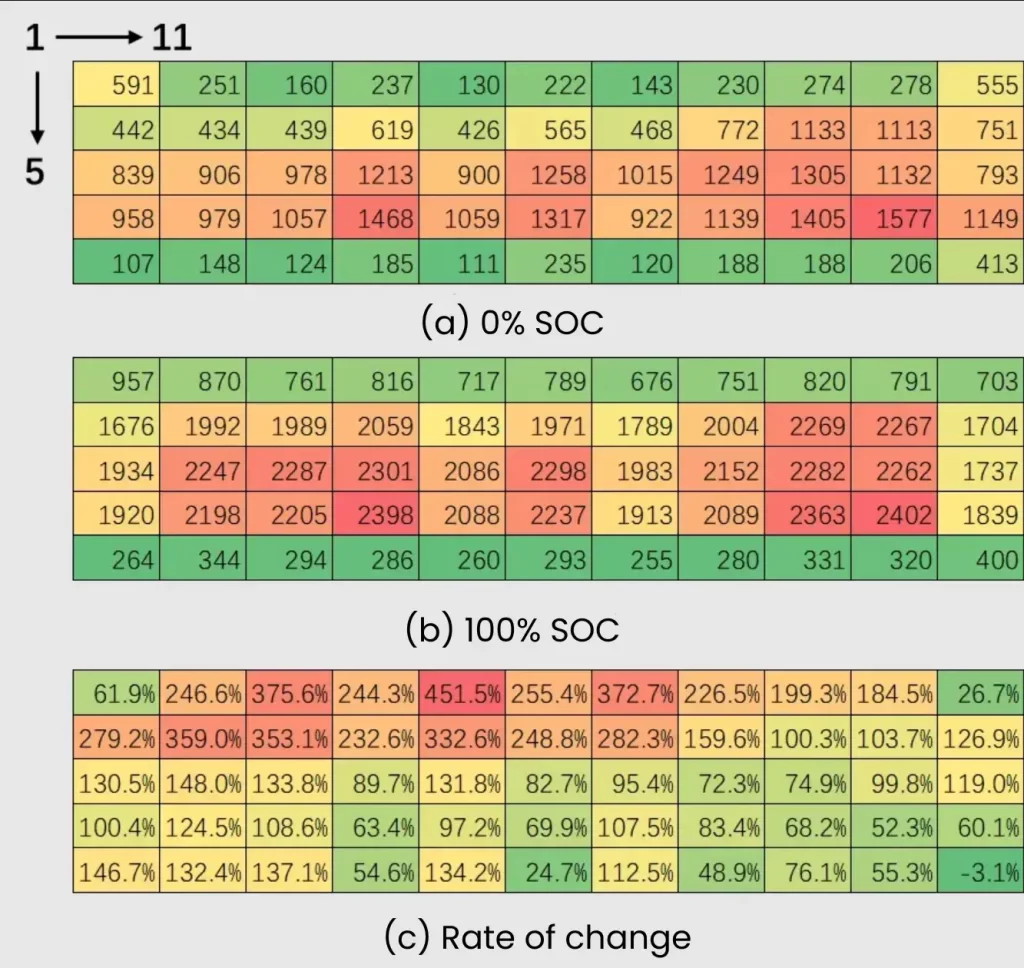

Further detailed analysis of the expansion force distribution corresponding to the zero-charge state and full-charge state of the second cycle charging, as shown in Figure 6, although the initial expansion force at the edge is smaller than the middle area, However, the rate of expansion change after full charge is the largest at the edge, which may be related to the fact that the corners of the wound cells are more prone to stress accumulation or lithium precipitation.

Figure 6. The force distribution (relative value) of small units in each area in the zero-charge state and the full-charge state

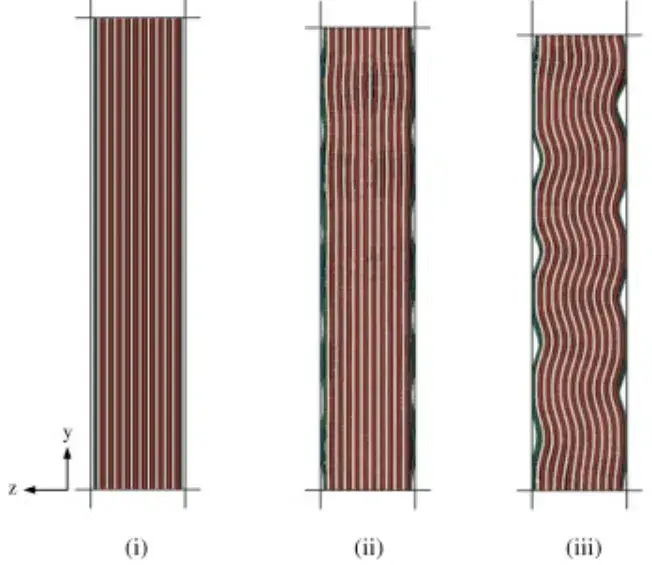

Figure 7 shows the expansion force curve of some selected small area units. Judging from the absolute value of the expansion force curves at different positions, the absolute value of the expansion force is the smallest at edge positions 1, 5, and 11,This may not be flat with the initial surface of the cell, so the initial force is less at the edge, Especially at the position 11 close to the tab, there is basically no obvious change in expansion force detected during the charging and discharging process, indicating that this position is basically not in contact with the pressure sensor. The uneven stress distribution in each area of the battery may also be related to the deformation process inside the winding cell. In the constant gap mode, the thickness of the battery expands during charging, and the expansion of the thickness forms a force on the clamp. Maintaining a constant gap between the clamps is equivalent to exerting a certain pressure on the battery. Under the pressure, wrinkles and curls may occur inside the cell. As shown in Figure 8, the stress on each area is not uniform.

Figure 7. Variation curve of expansion force of small elements in some areas

Figure 8. Schematic diagram of the deformation process inside the battery

4. Practical Considerations & Best Practices

-

Use a conformal pouch cell swelling pad (thin-film sensor array) sized and positioned to ensure full cell contact; account for tab height and edge thickness.

-

Calibrate pad sensors under known loads and repeatability tests to remove baseline offsets caused by initial gaps or creases.

-

Combine swelling maps with thermal data to correlate heat generation with mechanical responses.

-

For production screening, integrate a fast pad measurement stage to flag units with abnormal local stress before final assembly.

5. Summary

Measuring local expansion with in-situ swelling analyzer (SWE) and battery pressure distribution measurement system(BPD) provides precise, spatially resolved insight into pouch cell swelling behavior and enables teams to measure pressure in pouch cell surfaces non-destructively. It can quantitatively characterize the stress distribution difference on the surface of the cell, and provide a deeper perspective for the stress analysis of the cell. It can help technicians to analyze the internal stress distribution of the cell, explore the cause of the failed cell, and develop safer and more reliable cells.

6. References

[1] Yanan Wang, Hua Li, Zheng Kun Wang, Chen Lian, Zongfa Xie. Factors affecting stress in anode particles during charging process of lithium-ion battery, Journal of Energy Storage, 43(2021)103214.

[2] Anna Tomaszewska, Zhengyu Chu, Xuning Feng, et al. Lithium-ion battery fast charging: A review, eTransportation, 1 (2019) 100011.

[3] Yong Kun Li, Chuang Wei, Yumao Sheng, Fei Peng Jiao, and Kai Wu. Swelling Force in Lithium-Ion Power Batteries,Ind. Eng. CHem. Res,2020, 59, 27, 12313–12318.

[4] Ali M Y, Lai W J, Pan J. Computational models for simulations of lithium-ion battery cells under constrained compression tests, Journal of Power Sources, 2013, 242:325-340.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.