-

iestinstrument

Differences in Powder Compaction Density and Powder Conductivity in Pressurized and Unloading Modes

This paper tests the powder compaction density and conductivity of graphite and LFP materials, and analyzes the differences between the two test methods.

Measurement methods of compaction density and resistivity of lithium electric materials, detailed test methods are described in national standard GB/T 24533-2019《 Lithium-ion Battery Graphite Negative Materials and Carbon Composite Lithium Iron Phosphate Positive Materials for GBT 30835-2014》 《 Li-ion Battery.In the compaction density test of graphite materials》, the powder thickness with the cursor caliper to calculate the compaction density, which is a measure of pressure discharge.

The powder will have a certain degree of thickness rebound after pressure discharge, and the powder compaction density will change, so we should pay attention to what state value when comparing the powder compaction density of different materials. Two test methods are specified for measuring the conductivity of lithium iron phosphate materials: electrochemical impedance spectrum and four-probe method, The electrochemical impedance spectrum test is the impedance of the pressure sheet removed after pressure, The conductivity is then calculated by measuring the thickness of the removed pressure sheet, This is a method to measure the conductivity after pressure discharge, When the four-probe method measures the conductivity by applying a certain pressure on the powder for a period of time, After the resistance is stabilized, Read out the resistance value and calculate the conductivity, This is a pressurized method to test the conductivity, The conductivity at this time will be affected by the pressure thickness and pressure pressure, Therefore, the same test parameters must be used when comparing the material conductivity.

Figure 1. National standards for graphite class and lithium iron phosphate materials

1. Powder Compaction Density & Conductivity Test

1.1 Test Equipment

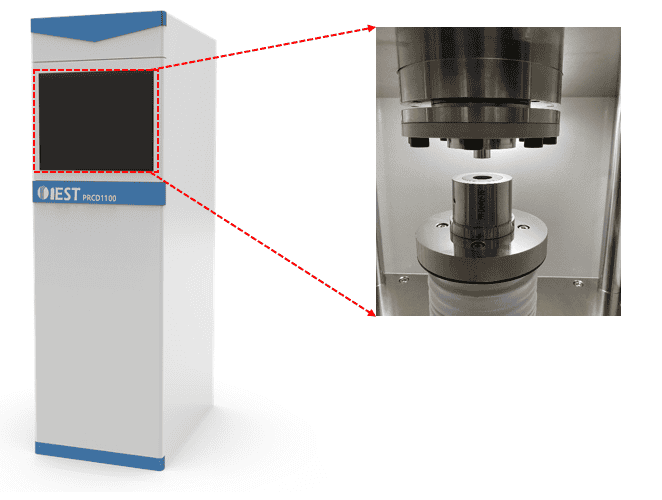

Test the powder compaction density and conductivity of graphite and lithium iron phosphate powder for compression and unloading using PRCD1100 (IEST-lithium iron phosphate technology), as shown in Figure 2.

Figure 2. (a) Appearance diagram of PRCD1100; (b) Structure diagram of PRCD1100

1.2 Test Parameters

Four probe testing principle, apply pressure range 10-200MPa, pressure interval 10MPa, 10s, discharge to 3MPa, 10s.

1.3 Sampling Quality

Graphite/LFP powder 1.0000±0.0010g.

1.4 Test Results

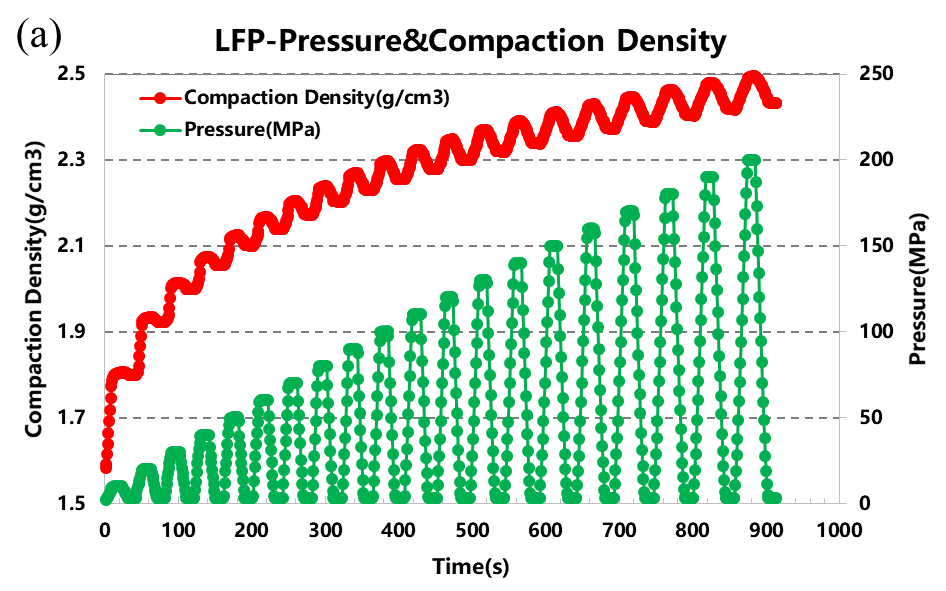

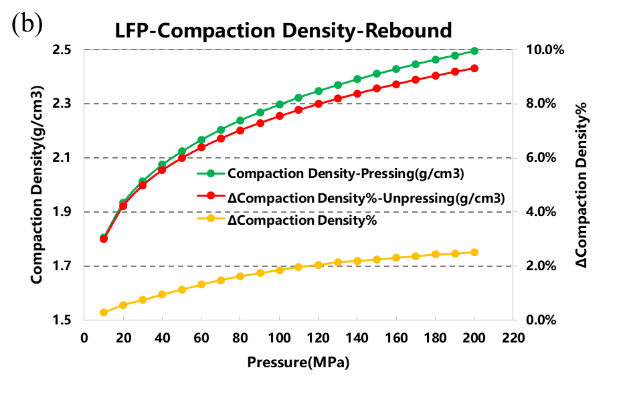

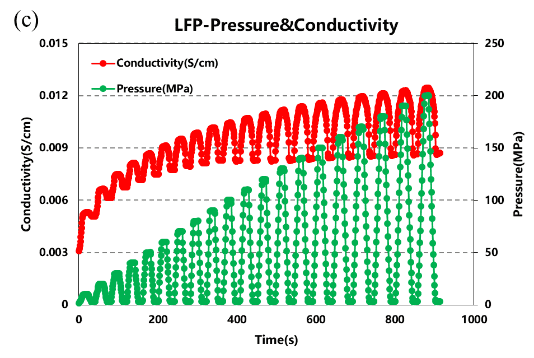

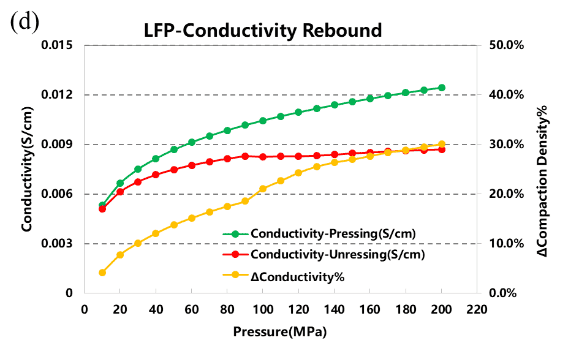

As shown in Figure 3, the LFP powder fluctuates during pressure and unloading with the powder compaction density and the powder conductivity curve, varying about 3% near 200MPa and about 3% while the conductivity changes about 30%.

|

|

|

|

Figure 3. LFP powder compaction density and conductivity variation curves of powder compression and unloading

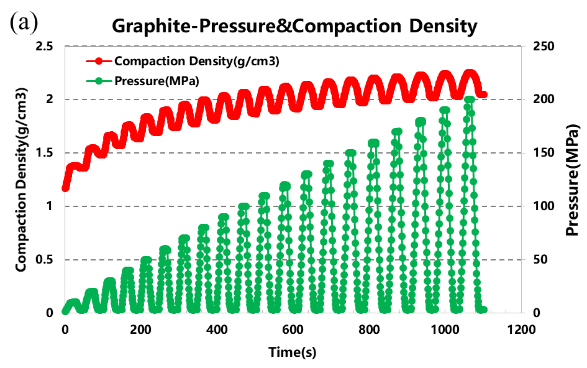

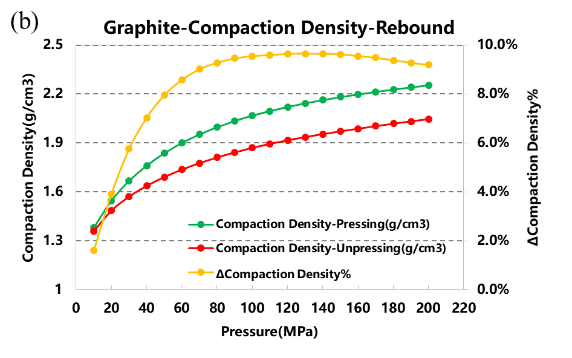

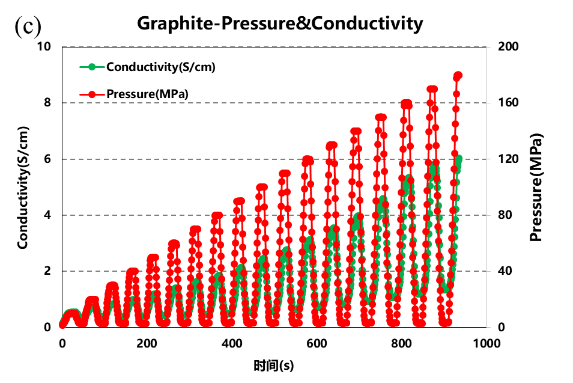

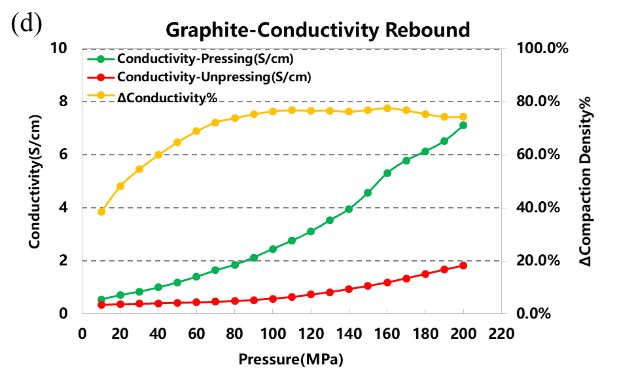

As shown in Figure 4, the graphite powder is pressurized and discharged with the powder compaction density and powder conductivity curve, near 200MPa, while the conductivity changes by about 80%.

|

|

|

|

Figure 4. Powder compaction density and conductivity change curves of graphite powder compression and unloading

2. Summary

When testing the powder compaction density and powder conductivity, attention must be paid to the impact of test conditions on the results, and pressure discharge will greatly affect the test results. When the pressure is approaching 200MPa, the compaction density between pressure and discharge changes about 3%, about 30%, while for graphite materials, the powder compaction density changes about 10% and about 80%.

3. References

[2] GB/T 24533-2019《 Lithium-Ion Battery Graphite Negative Pole Material”》

4. IEST Related Test Instrument Recommended

PRCD Series Powder Compaction Densities & Resistance Tester (IEST): Compaction density and resistance synchronous tests for all lithium powder pressure / discharge state, supporting two probe and four probe test methods, mainly with the following three test modes.

a.Single-point pressure synchronization test.

b .Multi-point pressure synchronization test.

c .Backash test of pressure and discharge state.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.