-

iestinstrument

Application Issues Analysis of Si Anode in High Energy Density Lithium-ion Batteries

1. Author Information and Article Abstract

In 2017, the Jaephil Cho team summarized several problems faced by the application of Si anode in the high-energy lithium-ion battery. In order to improve the volume and energy density of the battery, the impact on electrochemical performance from the cell system design, and focused on the reasons of electrode swelling and capacity loss, pointing out that the impact of performance should pay more attention to the battery cell process in the development and application of Si anode.

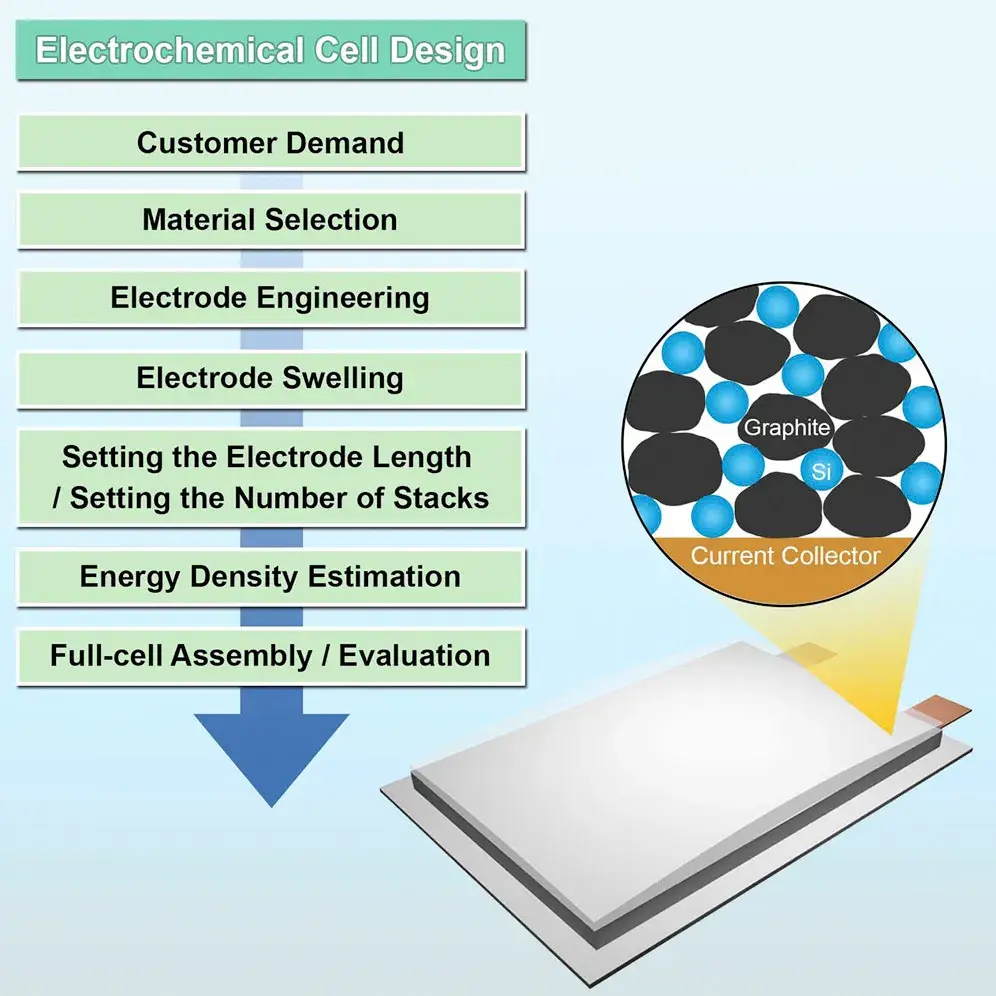

Figure 1. Electrochemical Cell Design

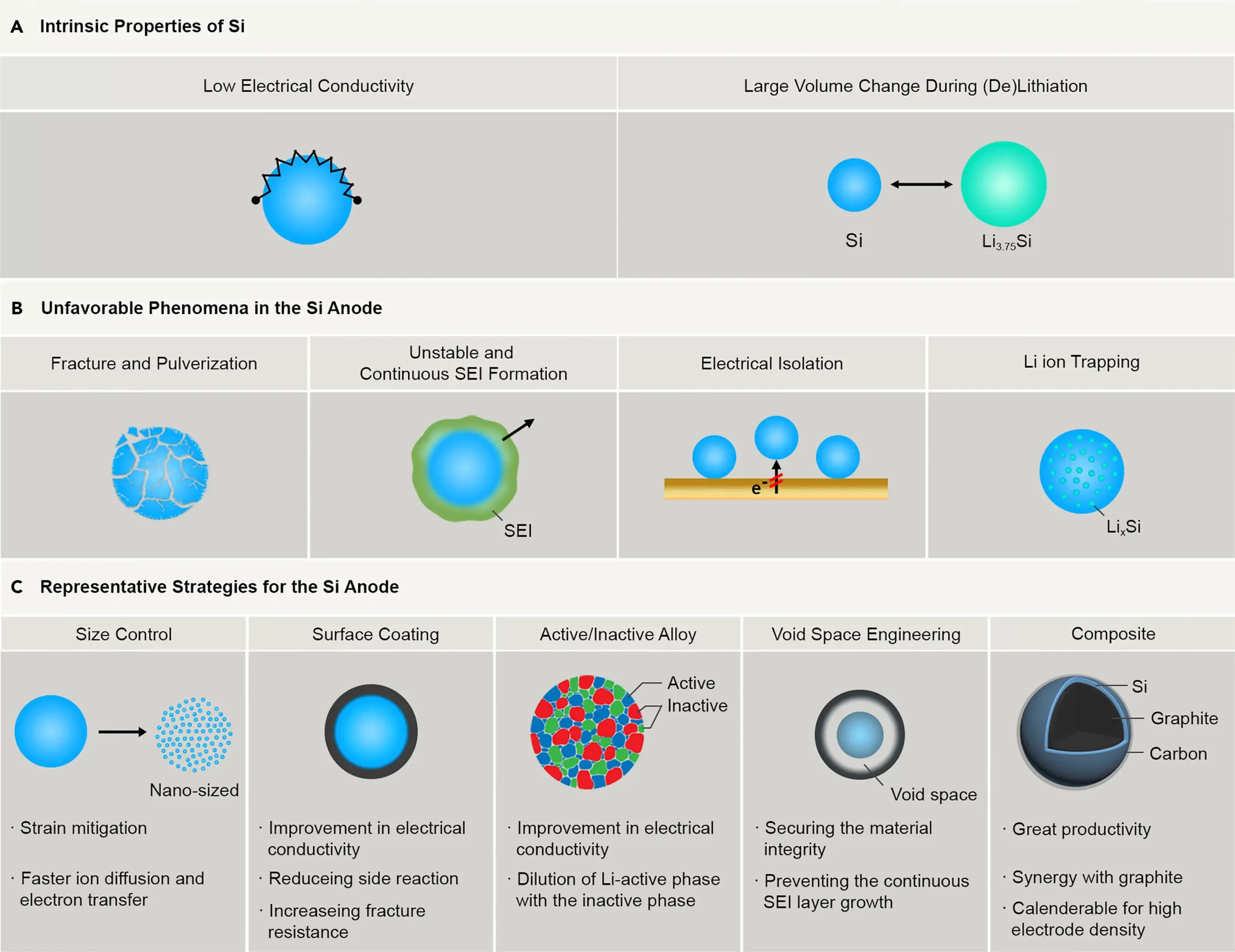

2. Problems and Current Situation of Si Anode

2.1 Natural Property of the Si Anode

The electrical conductivity is low at ~10-3S /cm, forms Li during cell charge and discharge Si alloy volume swelling is large ~400%.

2.2 Several Failure Phenomena of Si Anode

Particle fragmentation and pulverization, SEI membrane instability, loss of electrical contact, Li-ions trapped at failure sites, etc.

2.3 Several Common Si Anode Electrode Improvement Strategies

Silicon nanotechnology, silicon surface coating, doped alloy phase, nuclear shell structure, graphite or carbon coated silicon.

Figure 2. Overview of the Challenges and Representative Strategies Associated with the Si Anode

3. Full-battery Design Process

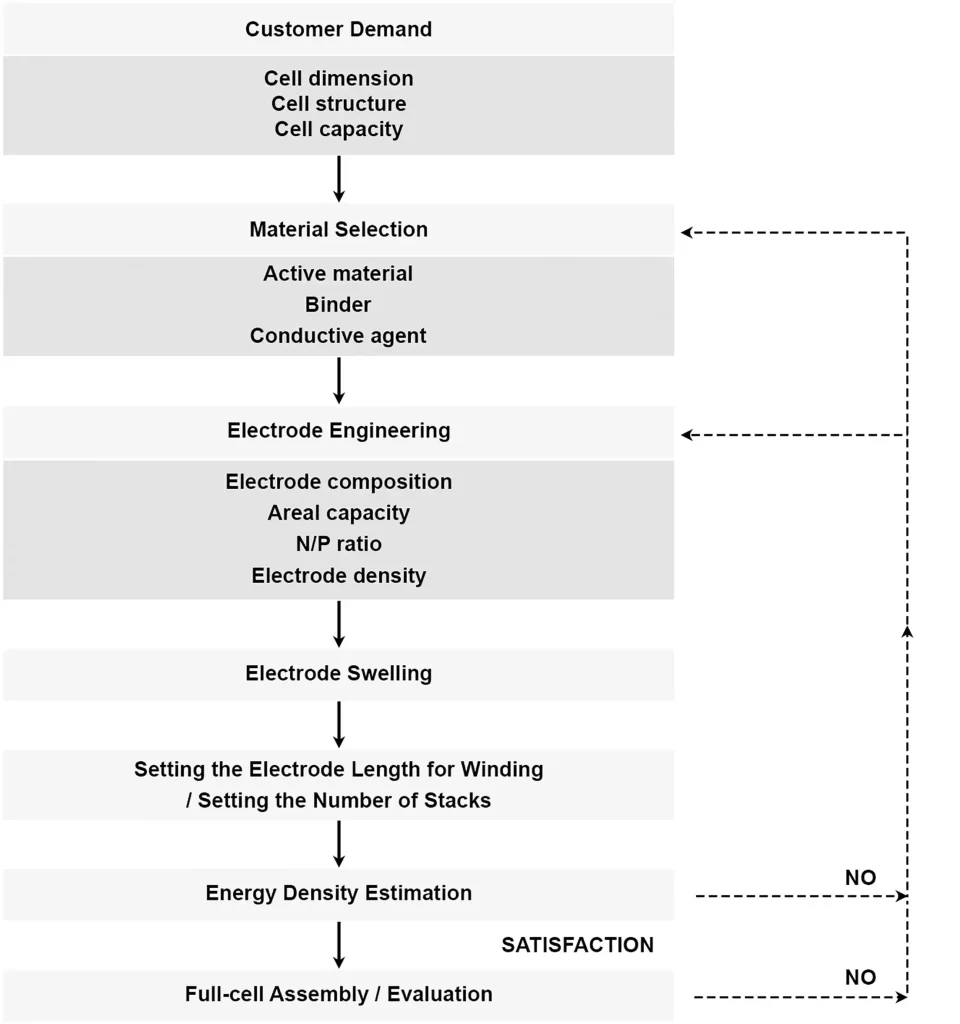

When silicon is used as a full battery anode material, it is necessary to confirm the material formula and process parameters according to the customer’s requirements for the cell performance. The general process is shown in FIG. 2, and the complete battery is finally assembled and the electrochemical performance is verified while ensuring that the customer needs are met.

Figure 3. Flow Chart of the Electrochemical Cell Design

4. Two Important Performance Analyses of the in Si Anode Electrodes

4.1 Electrode Expands

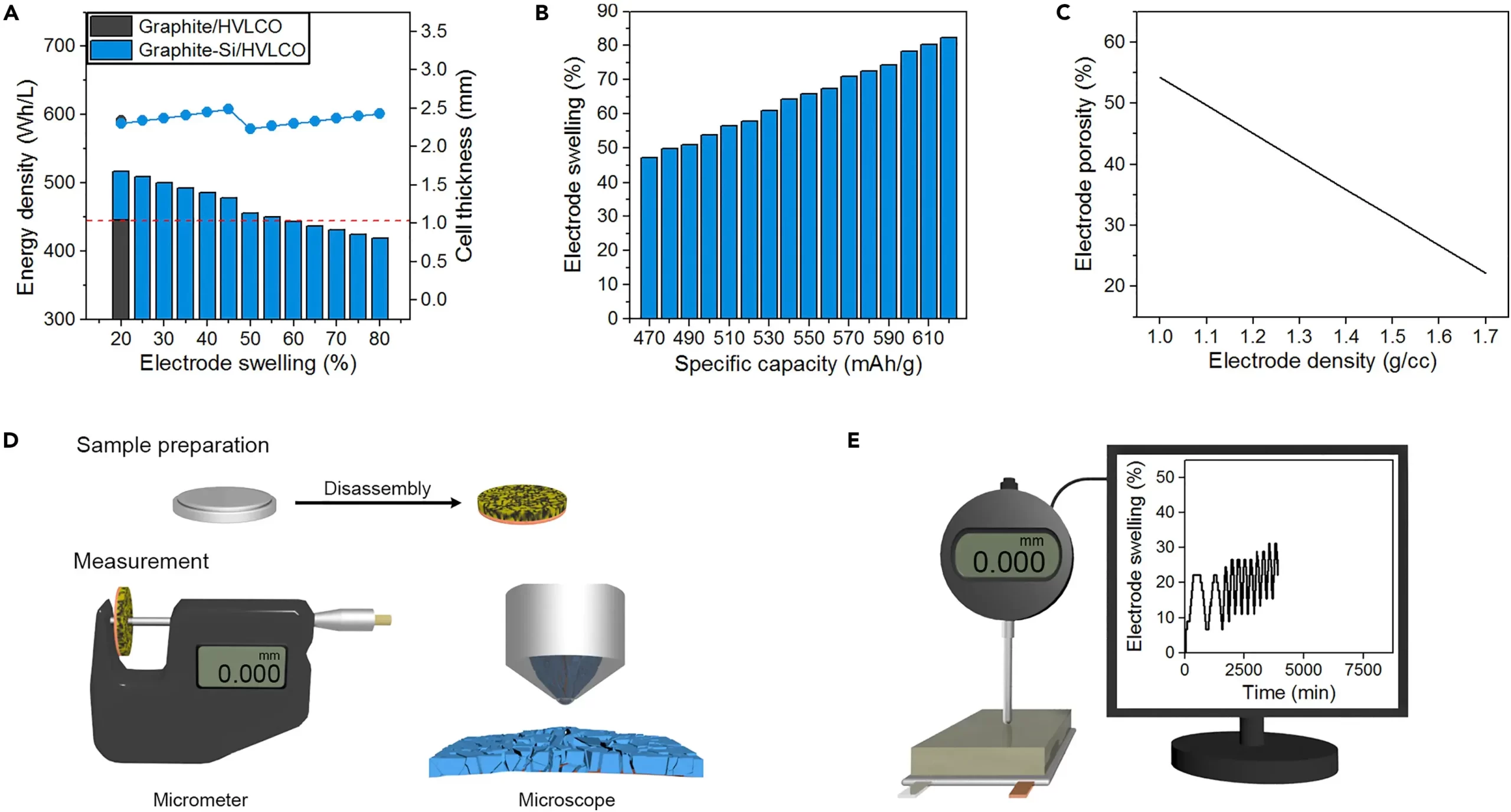

The thickness swelling of the negative electrode can cause the cell thickness swelling, thus affecting the volume energy density of the cell, which is severely reduced when the swelling ratio of the electrode exceeds 60%. The greater the gram capacity of the negative material of the silicon carbon composite and the greater the swelling thickness of the electrode, the thickness swelling of the battery can be quantified by in situ or in-situ methods.

Figure 4. Relationship between Energy Density and Electrode Swelling and the Measurement of Electrode Swelling

4.2 Si Anode Full Battery Capacity Decay

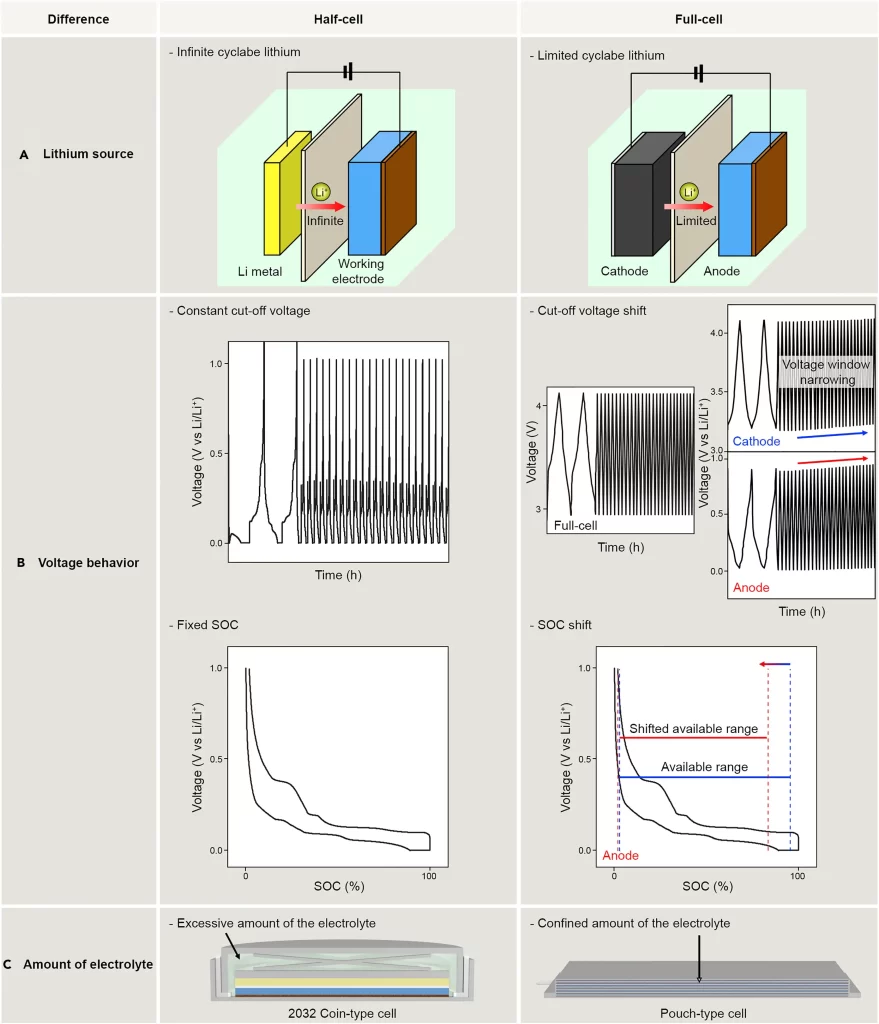

The mechanism of capacity decay is different when the si anode is assembled into half and full batteries. For half-batteries, because the use of lithium tablets as a side electrode, the lithium source is sufficient, and the whole battery in charging and discharge, and the lithium content is limited, when the battery is formed in the initial charging SEI, consume part of the lithium-ion, the whole battery is constantly decreasing, and the whole battery potential is increasing, which will lead to the available SOC interval offset of positive and negative electrodes, which leads to the reduction of usable capacity. Since the assembly structure of the half battery and the whole battery is different, the amount of electrolyte added will be different. And the gap structure in the half battery gives it sufficient electrolyte for recycling, but the full battery space limitation makes its capacity decay acceleration due to the late cycle due to the lack of electrolyte.

Figure 5. Causes of the Difference in Capacity Fading between the Half Cell and the Full Cell

5. Summary

This paper summarizes the problems of si anode application in high energy lithium-ion battery. In order to improve the volumetric energy density of the battery, it is necessary to consider the impact on the electrochemical performance in terms of the design of the cell system, and it focuses on the analysis of the reasons for the electrode expansion and capacity loss, pointing out that more attention should be paid to the impact of the battery cell process on the performance in the process of development and application of si anode.

6. Original Article

SujongChae, Minseong Ko,Kyungho Kim,Kihong Ahn and Jaephil Cho. Confronting Issues ofthe Practical Implementation of Si Anode in High-Energy Lithium-Ion Batteries.Joule 1, 47–60, September 6, 2017.

7. IEST Related Test Equipment Recommended:

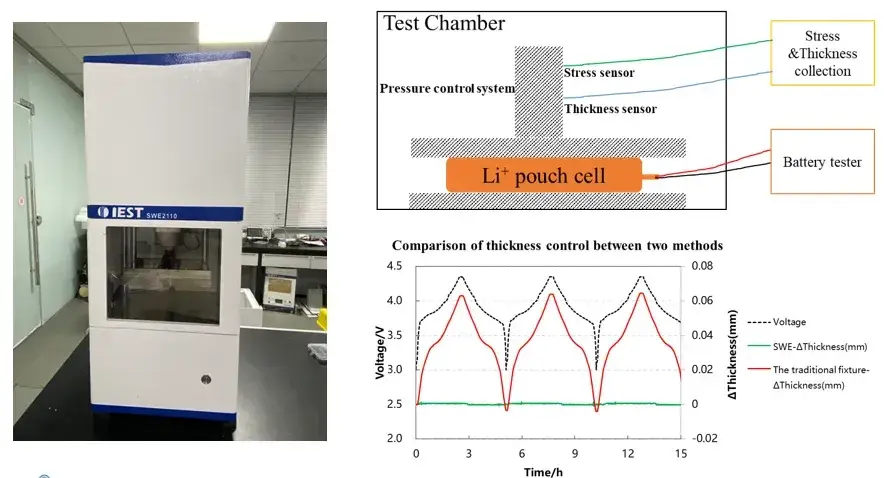

SWE Series In-situ Swelling Analysis System

- A Variety of Cell in-situ Characterization Methods (stress & swelling thickness): the swelling thickness and swelling force of the cell charging and discharge process are measured at the same time, so as to quantify the changes of cell swelling thickness and swelling force.

- More Refined and Stable Test System: Using a highly stable and reliable automatic adjustment platform, equipped with a high precision thickness measurement sensor and a pressure regulation system, the relative thickness measurement resolution is 0 m, to realize the long cycle monitoring of the long-term charging and discharge process of cells.

- Diversity of Environmental Control and Test Functions: SWE series equipment can adjust the temperature of the charge and discharge environment to help study the swelling behavior of cell cells under high and low temperature; In addition to conventional thickness and pressure test, cell swelling force, compression modulus and compression rate can be tested.

Updated on Jan. 14, 2025

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.