-

iestinstrument

Single Battery Cells and Module Cells’ Swelling Performance Correlation Analysis

1. Preface

With the rapid development of the new energy industry, lithium-ion powered vehicles have been widely used, and the safety performance of lithium-ion batteries has become increasingly important. During the long-term charge and discharge cycle of a module composed of individual battery cells connected in series or parallel, the cells will experience a certain degree of swelling due to lithium extraction and gas generation, which will affect the structural strength of the module casing. In a battery pack or vehicle system, if the swelling force of a single battery is too large, it may burst the outer casing and cause a safety risk. Therefore, monitoring of the swelling performance is required in long-term cycling tests of batteries. Since battery cells are combined into module cell in different quantities and different series-parallel configurations, and the pre-tightening force of different designed modules will also vary, it is necessary to conduct experiments on several factors that affect swelling performance to preliminarily explore the swelling variation law of battery cells-modules, combined with simulation and modeling, which can help design the modules better. This experiment provides basic data for the prediction and simulation of module cell swelling force by comparing the swelling thickness and swelling force correlation of single cell and multi-cell during charge and discharge.

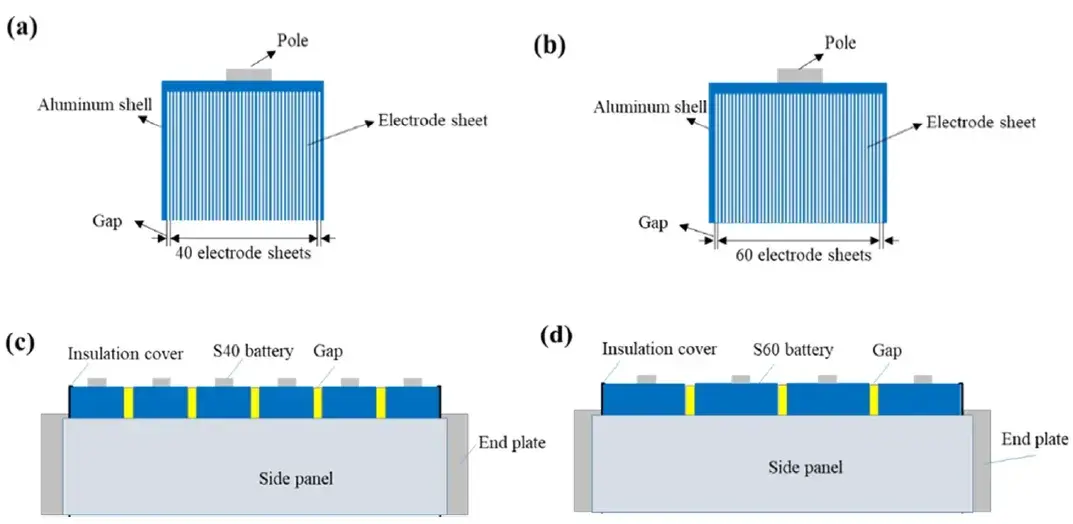

Figure 1. Schematic diagram of single cell and module cell

2. Experimental Equipment and Test Methods

2.1 Experimental Equipment

In-situ swelling analyzer, model SWE2110 (IEST), the equipment appearance is shown in Figure 2.

Figure 2. Appearance of SWE2110 Equipment

2.2 Test Procedure

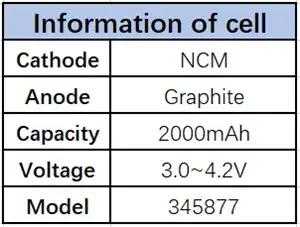

2.2.1 The Cell Information is Shown in Table 1

Table 1. Test cell information

2.2.2 Charge-discharge Process: 25°C Rest 60min; 0.5C CC to 4.35V, CV to 0.05C; rest 30min; 1.0C DC to 3.0V.

2.3 Cell Thickness Swelling Test

Put the cell to be tested into the corresponding channel of the device, open the MISS software, set the cell number and sampling frequency parameters corresponding to each channel, and the software will automatically read the cell thickness, thickness variation, test temperature, current, voltage, capacity, and other data.

3. Experimental Process and Data Analysis

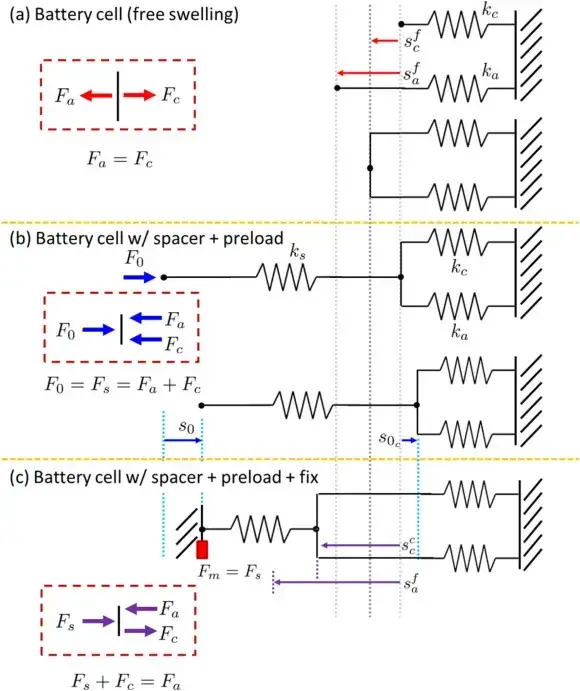

As shown in Figure 3, there are generally three modes for cell and module cell swelling tests: (a) measurement of free swelling without any constraints: (b) measurement of battery cell swelling with constant preload; (c) constant gap The battery cell swelling measurement.

The force analysis of the three situations under balanced conditions is shown in Figure 3. In the first case, the outer shell restricts the swelling of the inner core, the force on the outer shell and the core are balanced, and the external force is zero; In both cases, an external preload load (F0) is applied to the cell, which causes an initial displacement of the cell case (s0 and s0,c in Figure 3b), and the phase-side binding plates increase the direction perpendicular to the electrodes The equivalent stiffness KS above, the pre-tightening force F0 under equilibrium conditions (the same as the force Fs of the bound version on both sides) is equal to the sum of the forces on the winding core and the battery case; in the third case, when measuring the gap constantly, because the gap Under fixed conditions, the swellingof the winding core and the battery case when the battery expands is also different from that under free conditions.

In short, since the module cell is a combination of multiple batteries, the plastic gasket between the battery casing and the battery will shrink and expand during the stress process. The thickness and force tested are the swelling and contraction of lithium intercalation and desorption of electrodes and the swelling and contraction of other components are the combined result. In this paper, the constant pressure and constant gap test modes are used to study the correlation between the monomer and the module cell.

Figure 3. Three modes of cell and module cell unit swelling test.

3.1 Exploration on the Correlation Between the Swelling Thickness of the Single cell and the Module Cell

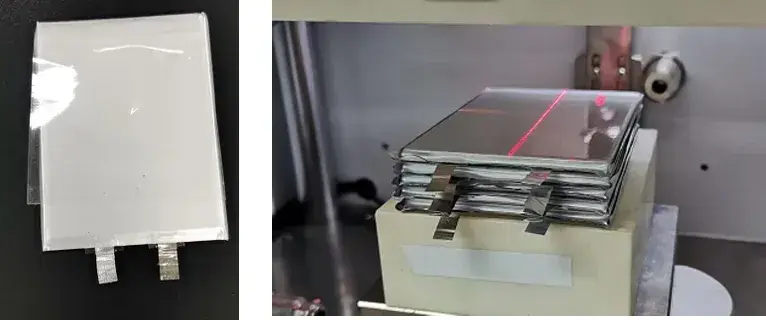

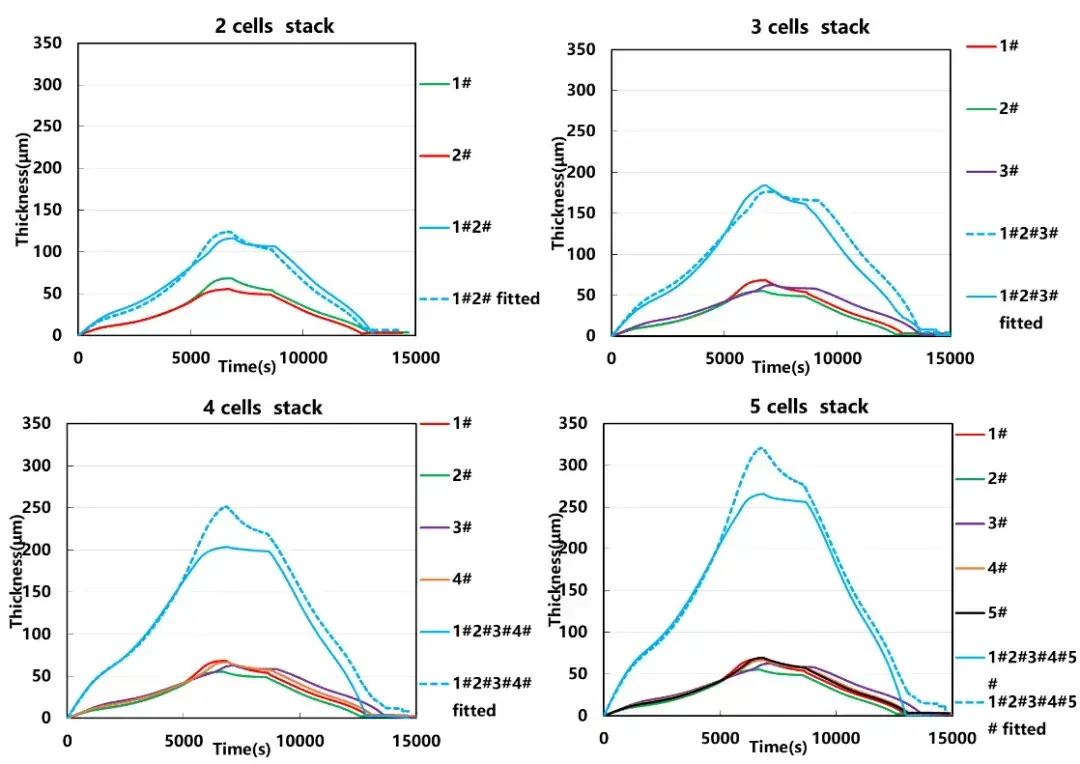

As shown in Figure 4, in order to simulate the interlayer between the single cells, a white PET film was pasted on the cells before testing. The superposition test method of cells is shown in Figure 5. Turn on the in-situ swelling analyzer (SWE2110), set the 200kg constant pressure mode, charge, and discharge in parallel, and test the swelling thickness changes of individual cells and stacked cells in situ, as shown in Figure 6: the solid line is the electric The actual swelling curve of the core, the dotted line is the fitted superposition curve (arithmetic sum). From the results, both the single cell and the stacked cell show the phenomenon of charge swelling and discharge contraction, which is mainly due to the structural swelling and contraction of graphite and ternary materials caused by the process of lithium deintercalation. As the number of superimposed cells increases, the overall swelling thickness of the module cell continues to increase, and the superimposed swelling curve of multi-cells (blue solid line) is basically consistent with the single-cell superposition arithmetic and swelling curve (blue dotted line), There are some differences only at the end of charge and discharge, which may be related to the poor consistency of each single battery cell, and as the number of stacked cells increases, the difference between the measured curve and the fitted curve is greater, which shows that The more multi-cell modules, the higher the requirements for the consistency of the monomers.

Figure 4. Schematic diagram of battery with PET film and Schematic diagram of cell superposition

Figure 5. Variation curves of swelling thickness of each battery cell and after superimposition

3.2 Exploration on the Relationship Between the Swelling Force of the Single cell and the Module cell

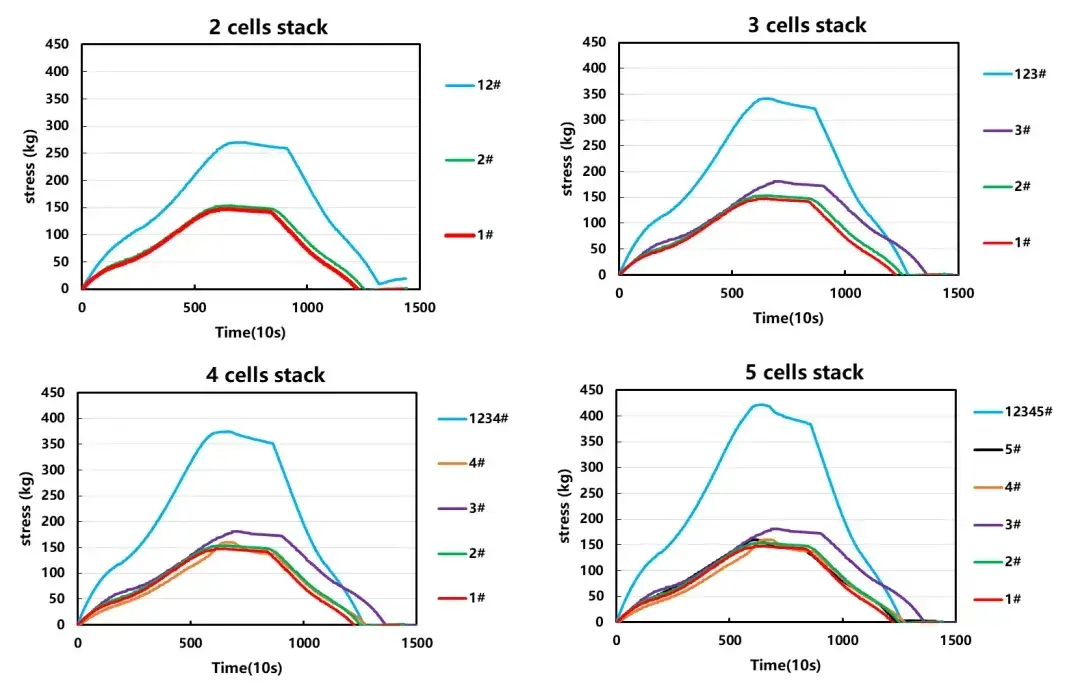

Set the constant gap mode, charge, and discharge in parallel, and test the swelling force changes of the single cell and the stacked cell in the process of charging and discharging in situ, as shown in Figure 7. From the results, as the number of stacked cells in the module increases, the total swelling force of the module continues to increase, but the absolute value of the swelling force of the module cell has no multiple relationship with the swelling force of the single cell. It is smaller than the sum of the swelling forces of multiple single cells, and the more cells are stacked, the greater the difference in absolute value. This may be the boundary condition for controlling the constant gap, which will make the cells in the module The state of the battery cell is different from that of a single battery cell when it is charged and discharged, which affects the electrochemical performance, and the reason for the difference needs to be further explored. The capacity of the single cells before grouping and the capacity of single cells after grouping can be taken into consideration and compared at the same time. The pressure after stacking does not increase linearly, which may be because the superimposed pressure of the cells after stacking reaches a critical value. Compressing the space between pole pieces or even more microscopic dimensions is bound to be reflected in battery performance!

Figure 6. Variation curve of swelling force of each battery cell and superposition

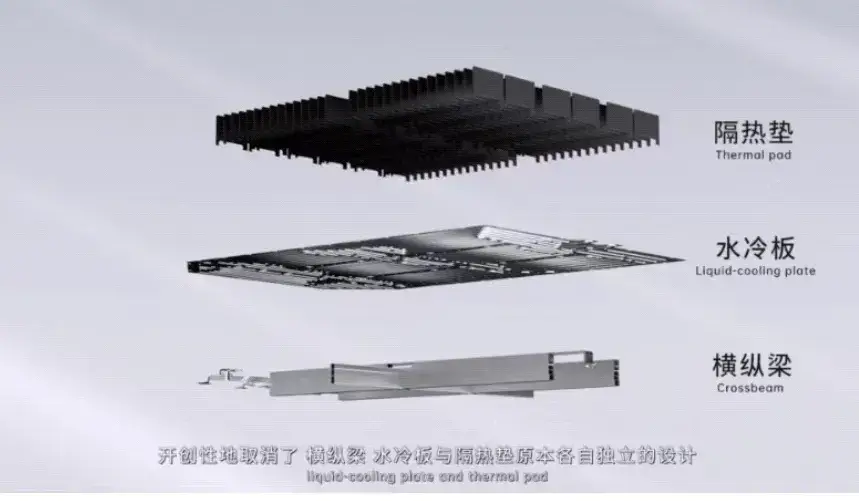

From the above results, the module or PACK is fixedly installed in the battery pack casing, and the gaskets between the single cells will have a relatively large impact on the overall force and swelling of the module. Excellent module cell design can eliminate the swelling of single cells. Recently, the Kirin battery launched by CATL integrates the needs of use, combining the horizontal and vertical beams, water-cooled plates, and heat insulation pads into one, and integrating them into a multi-functional elastic interlayer. A micro-bridge connection device is built in the interlayer, which can flexibly cooperate with the breathing of the battery core to expand and contract freely and improve the reliability of the battery life cycle.

Figure 8. Multi-functional elastic interlayer of Kirin battery in CATL

4. Summary

In this paper, the in-situ swelling analyzer (SWE) is used to analyze the swelling thickness and swelling force of the same system single cell and different numbers of module cells during the charging and discharging process. It is found that the swelling thickness of the module cells under constant pressure mode The change trend can be fitted by the single-cell arithmetic sum, but the simple arithmetic fitting method is not satisfied in the constant gap mode, which is different from the force of the single cell in the measurement mode of the two boundary conditions. The next step You can continue to explore the force model under different test modes and analyze the swelling process of the electrode in more detail.

5. References

[1] Yongkun Li, Chuang Wei, Yumao Sheng, Feipeng Jiao, and Kai Wu. Swelling Force in Lithium-Ion Power Batteries,Ind. Eng.Chem. Res,2020, 59, 27, 12313–12318.

[2] Oh K Y, Epureanu B I , Siegel J B , et al. Phenomenological force and swelling models for rechargeable lithium-ion battery cells[J]. Journal of Power Sources, 2016, 310(Apr.1):118-129.

[3] Martin Wünscha,Kaufmana, Dirk Uwe Sauer. Investigation of the influence of different bracing of automotive pouch cells on cyclic liefetime and impedance spectra. Journal of Energy Storage 21 (2019) 149–155.

[4] Qiu Shitao, Chen Chaohai, Jiang Jibing. Effect of foam performance on module cell swelling force. Guangdong Chemical Industry, 2020, 47(22): 1-3d

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.