-

iestinstrument

The Differences in Electrochemical and Mechanical Performance of LMFP-Blended Cathodes with Varied Ratios

1. Preface

In this paper, the resistivity, compaction density, and stress-strain curves of anode materials mixed with different ratios of LMFP and NCM under different pressures were investigated by using the Powder Resistivity & Compaction Density Meter (PRCD3100, IEST) and the differences in the electrical and mechanical performances of the anode materials with different mixing ratios were further analyzed.

With the growing market of new energy vehicles, the supply demand of lithium-ion batteries is also increasing rapidly. Lithium-ion batteries for automobiles have high requirements for energy density, cycle life, safety and cost, etc. Currently, the mainstream cathode materials for lithium batteries include lithium cobalt cobalt oxide (LCO), ternary materials (NCM) and lithium iron phosphate (LFP), etc. Although LCO and NCM cathode have high energy density, their cost and safety are inferior to LFP cathode, which has better stability and safety, but its energy density development is close to the limit. Although LFP anode has better stability and safety, the development of its energy density is close to the limit. Similar to LFP cathode, lithium manganese iron phosphate (LMFP) cathode also has better chemical stability and safety, and the doping of manganese can increase the charging voltage of the material to 4.1V, so that the theoretical energy density of the LMFP battery has been increased by 15-20% compared with that of LFP cathode. However, the LMFP anode at this stage is not perfect, and there are still problems such as voltage jump, low conductivity, and poor multiplicity performance.

In order to utilize the advantages of the above materials and also to meet different market demands, the strategy of hybrid cathode electrode has emerged [1,2]. By physically and mechanically mixing two (or more) cathode materials with complementary properties, and utilizing the advantages of other component materials to make up for their disadvantages while giving full play to the advantages of one component material, a lithium battery with good performance and moderate price can be prepared to meet the balanced requirements of cycle performance, range and safety. For example, H.S. Kim et al [2]. mixed NCM cathode and LCO cathode in different ratios and found that the reversible specific capacity and cycle stability of the battery improved significantly as the proportion of NCM in the components increased, but its multiplicity performance decreased sequentially. When the mixing ratio was 1:1, the multiplicity and cycle performance reached the dynamic optimum.

Different cathode materials have different operating voltages, so the synergistic effect between materials needs to be considered when mixing multiple active particles within a certain operating voltage range.The LMFP and NCM materials have similar discharge voltage windows, i.e., the electrochemical properties of both materials can be well utilized under the same voltage window. Therefore, the mixing of these two materials may have a better synergistic effect.

2. Test conditions

2.1 Test equipment:

Figure 1 shows the Powder Resistivity & Compaction Density Tester (PRCD3100, IEST), which can synchronously collect the resistivity, conductivity, compaction density and other parameters of the powder sample while applying different pressures to the powder sample (up to 5T) to assist researchers in studying the effects of different pressures on the electrochemical and mechanical properties of the powder sample.

Figure 1. Schematic diagram of the Powder Resistivity & Compaction Density Meter (PRCD3100, IEST) and the two testing principles of powder resistivity.

2.2 Experimental procedure:

① Prepare six different ratios of LMFP and NCM mixed anode materials, which are 1) 100% LMFP; 2) 80% LMFP + 20% NCM; 3) 60% LMFP + 40% NCM; 4) 40% LMFP + 60% NCM; 5) 20% LMFP + 80% NCM; and 6) 100% NCM;

② Within the range of 10~350MPa, apply pressure to the above six kinds of mixed cathode electrodes with different proportions in a step-step manner with 20MPa as the step-interval, and record the resistivity and thickness changes under different pressures in real time by utilizing the four-probe resistance test module and the thickness test module that comes with the PRCD3100, so as to get the resistivity & compaction density of the six kinds of mixed cathode electrodes with the change of the pressure ;

③ In the range of 10~350MPa, with 20MPa as the step interval, step pressurize the above 6 kinds of mixed cathode electrodes with different ratios to 350MPa firstly, and then step unpressurize them to 10MPa, and record the thickness change of the whole process synchronously, so as to obtain the stress-strain curve of these 6 kinds of mixed cathode electrodes.

3. Analysis of results

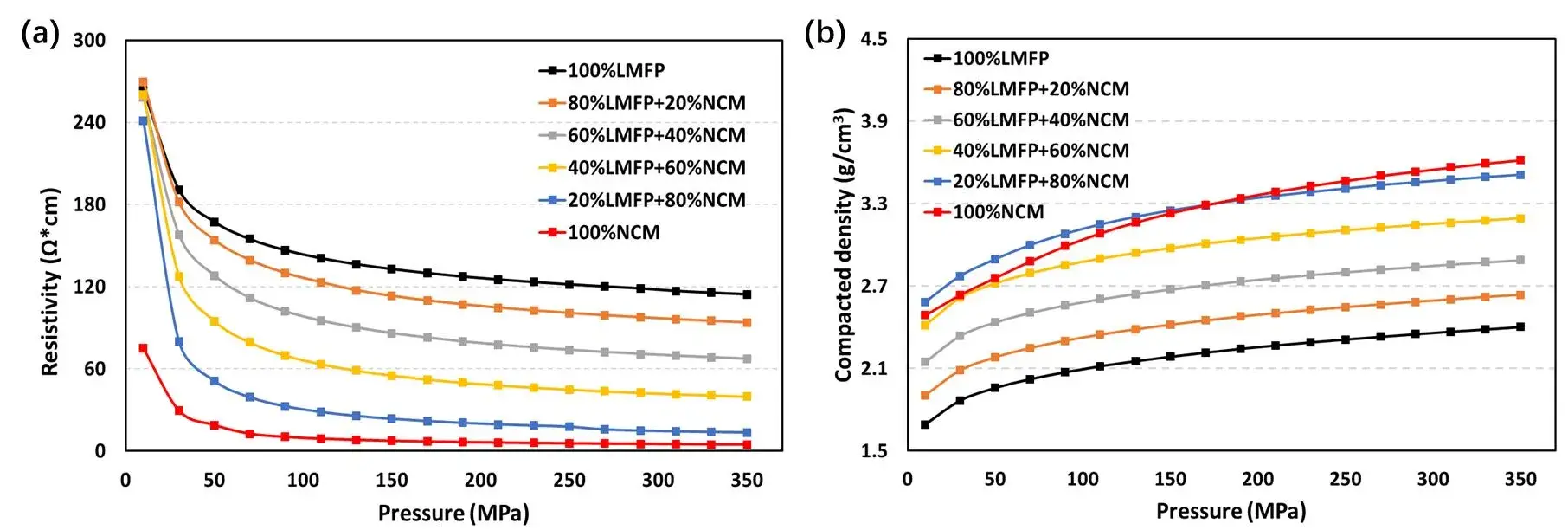

Figure 2 demonstrates the curves of resistivity (a) versus compaction density (b) with pressure for six different ratios of LMFP and NCM hybrid cathode materials. From Fig. 2(a), it can be seen that the electrical conductivity of all six cathode materials decreases gradually with the increase of pressure, indicating that the large pressure helps to improve the contact resistance between the powder materials, which in turn improves the electron transportation ability of the materials. In addition, the resistivity of 100% LMFP powder is the largest among the six both under small and large pressures, i.e., the conductivity of pure LMFP powder is the worst, which limits the multiplicative performance of the material. With the gradual addition of NCM powder, the resistivity of the hybrid positive electrode is also gradually decreasing throughout the test pressure range, i.e., the conductivity of the positive electrode material is gradually getting better with the addition of NCM powder until it approaches the electron transportation ability of pure NCM powder. In mixed particle materials, electrons are conducted through solid particles, and the material’s own conductivity, particle size distribution, and contact state between particles all affect the electronic conductivity. Typically, the electrode sheet contains active material, conductive carbon, and binder. In the current study, the effect of the type and proportion of conductive agent in the electrode sheet on the electronic conductivity of the electrode sheet is mainly considered, especially for positive electrodes, where conductive additives are used to ensure good electronic conductivity due to the low electronic conductivity of the active material. However, in addition to the conductive carbon, the type and volume fraction of the active material can have a similar effect on the conductivity. Therefore, the effect of the electronic conductivity of the active material itself on battery performance should also be emphasized. This hybrid material electrode can utilize the synergistic effect of the two, i.e., the NCM is utilized to avoid the disadvantage of the poor electrical conductivity of the LMFP powder.

From the trend of the compaction density with pressure in Figure 2(b), it can be seen that the compaction density of 100% LMFP powder is the smallest, and the compaction density of the hybrid cathode material is gradually increased with the continuous addition of NCM powder. The compaction density is also related to the mechanical properties and particle size distribution of the active particles. In the hybrid material, the two particles in the compression process, the mutual contact of the particles is closer, the small particles fill the gap of the large particles, and the void compaction is reduced; when the pressure continues to increase, the active particles are broken, and cracks are formed between the secondary particles. Generally speaking, in advance of not affecting the electrolyte infiltration and specific capacity play, the greater the compaction density of the cathode material and the smaller the electrode thickness, the higher the capacity of the battery, and the higher the battery volumetric energy density, the more it can meet the demand for lithium battery energy density in the market a few days ago.

In summary, the addition of NCM materials to LMFP cathode materials can effectively improve the electron transportation capacity and compaction density of LMFP materials. However, it is worth noting that, although in this study, the improvement effect of these two parameters shows a monotonically better trend with the continuous addition of NCM, it does not mean that the more NCM materials are mixed in, the better the performance of the hybrid anode is, which also needs to comprehensively evaluate the cycle performance, multiplication performance, safety performance, and cost advantage of the hybrid anode after it is prepared into a battery, and finally determine the optimal mixing ratio X.X. Zhao et al [3] prepared NCM and LMFP mixtures and assembled 18650 full batteries with NCM-LMFP mixtures as cathodes, and the overall performance of the batteries was better than that of single-material NCM or LMFP batteries, including superior multiplicity performance, good cycling stability, and high and low temperature performance.

Figure 2. (a) Resistivity variation curves and (b) compaction density variation curves with pressure for six different ratios of LMFP and NCM hybrid cathode materials.

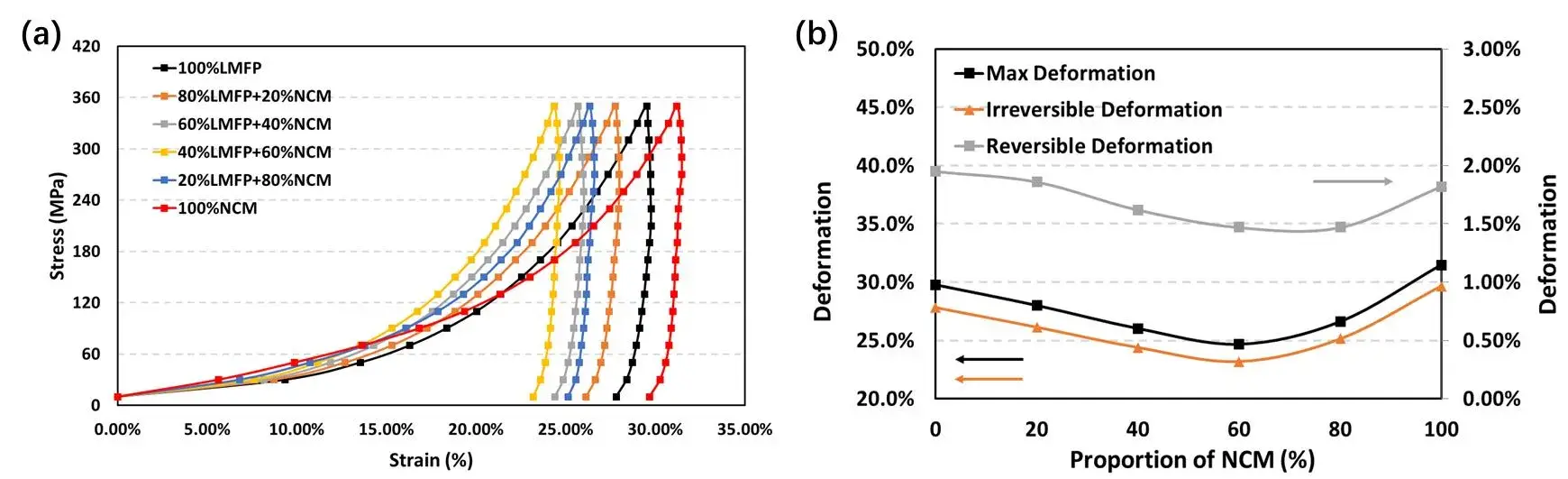

Figure 3(a) demonstrates the stress-strain curves of six different proportions of mixed anodes during pressurization and depressurization (pressure range of 10~350 MPa, with a step interval of 20 MPa) to assist in analyzing the differences in the mechanical properties of different mixed anodes. Firstly, it can be seen that the strains of the six mixed anode powders after unpressurization do not return to the origin, i.e., a certain proportion of irreversible deformation exists in all the mixed anode powders studied in this paper. Subsequently, the maximum deformation, irreversible deformation, and the change of reversible deformation with the proportion of NCM addition were counted for these six samples.

The results are shown in Figure 3(b). Whether it is the maximum deformation (black), irreversible deformation (orange) or reversible deformation (gray), the three curves show a U-shaped pattern, i.e., the deformation of pure LMFP and pure NCM powders is the largest, and the deformation of mixed powders is relatively small. The lowest point of all three appeared at 60%, i.e., the mixed positive electrode of 40% LMFP+60% NCM had the smallest deformation after pressure, and the smallest irreversible deformation. When preparing the electrodes, the thickness is a critical process index, and in order to ensure the controllable thickness of the final electrodes, it is generally desired to minimize the thickness rebound of the active material after being subjected to pressure. The stress-strain experiments in Fig. 3 show that the mechanical behaviors of the mixed positive electrodes with different ratios are different, and different process parameters need to be adjusted according to different mechanical feedbacks in the preparation process of the pole piece.

Figure 3. (a) Shows the stress-strain curves of six mixed positive electrodes with different ratios during pressurization and depressurization. (b) demonstrates the maximum deformation, irreversible deformation, and reversible deformation of the six hybrid anodes with the NCM addition ratio.

In addition, T. Liebmann et al [4] also conducted a systematic study on how the electrochemical properties of the components affect the behavior of hybrid electrodes for several mainstream cathode materials, i.e., olivine LFP, layered NCM, and spinel LMO. The results show that the basic electrochemical properties of the hybrid electrodes obey the physical mixture model and can be predicted accordingly based on the properties of the components with different mass fractions, including the thermodynamic properties, such as the equilibrium potential versus specific capacity curves, entropy distributions, and derived properties.

However, kinetic parameters, such as exchange current density and lithium diffusion coefficient in the active material are often a function of the state of charge, and these properties do not conform to the predictions of the physical model of the blends. It was also found that the microstructural properties of the blends produce different penetration networks of electrons and ions in the electrodes, which affect the battery performance. The conductivity and mechanical properties of the particles are the key parameters that determine the microstructural characteristics of the electrodes. Therefore, the work in this area deserves further in-depth study.

4. Summary

In this paper, the resistivity as well as the compaction density of six different ratios of LMFP+NCM hybrid anodes were tested under different pressures using the powder resistivity & compaction density tester (PRCD3100, IEST) and the changes in their mechanical properties were investigated. From the electrical properties, with the gradual addition of NCM powder, the resistive transport ability of the hybrid positive electrodes gradually becomes better; from the compaction density, the continuous addition of NCM powder is also conducive to the improvement of the overall compaction density of the hybrid positive electrode materials; from the stress-strain curves, the hybrid positive electrode with the composition of 40% LMFP+60% NCM has the smallest deformation under pressure and the irreversible type of deformation is also minimized.

However, it is worth noting that, in addition to the parameters studied in this paper, it is also necessary to comprehensively evaluate the cycle performance, multiplicity performance, safety performance and cost advantage of the hybrid anode after it is prepared into a battery before the optimal mixing ratio can be finally determined, so as to balance the market demand and production cost.

5. References

[1] T. Or, S.W.D. Gourley, K. Kaliyappan, A.P. Yu and Z.W. Chen, Recycling of mixed cathode lithium‐ion batteries for electric vehicles: Current status and future outlook. Carbon Energy 2 (2020) 6-43.

[2] H.S. Kim, S.I. Kim and W.S. Kim, A study on electrochemical characteristics of LiCoO2/LiNi1/3Mn1/3Co1/3O2 mixed cathode for Li secondary battery. Electrochimica Acta 52 (2006) 1457-1461.

[3] X.X. Zhao, L.W. An, J.C. Sun and G.C. Liang, LiNi0.5Co0.2Mn0.3O2-LiMn0.6Fe0.4PO4 mixture with both excellent electrochemical performance and low cost as cathode material for power lithium ion batteries, Journal of Electrochemical Society 165 (2018) A142-A148.

[4] T. Liebmann, C. Heubner, M. Schneider and A. Michaelis, Understanding kinetic and thermodynamic properties of blended cathode materials for lithium-ion batteries, Materials Today Energy, 22 (2021) 100845.

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.