-

iestinstrument

A Guide to Single Particles Compression Characteristics in Battery Materials

1. Background

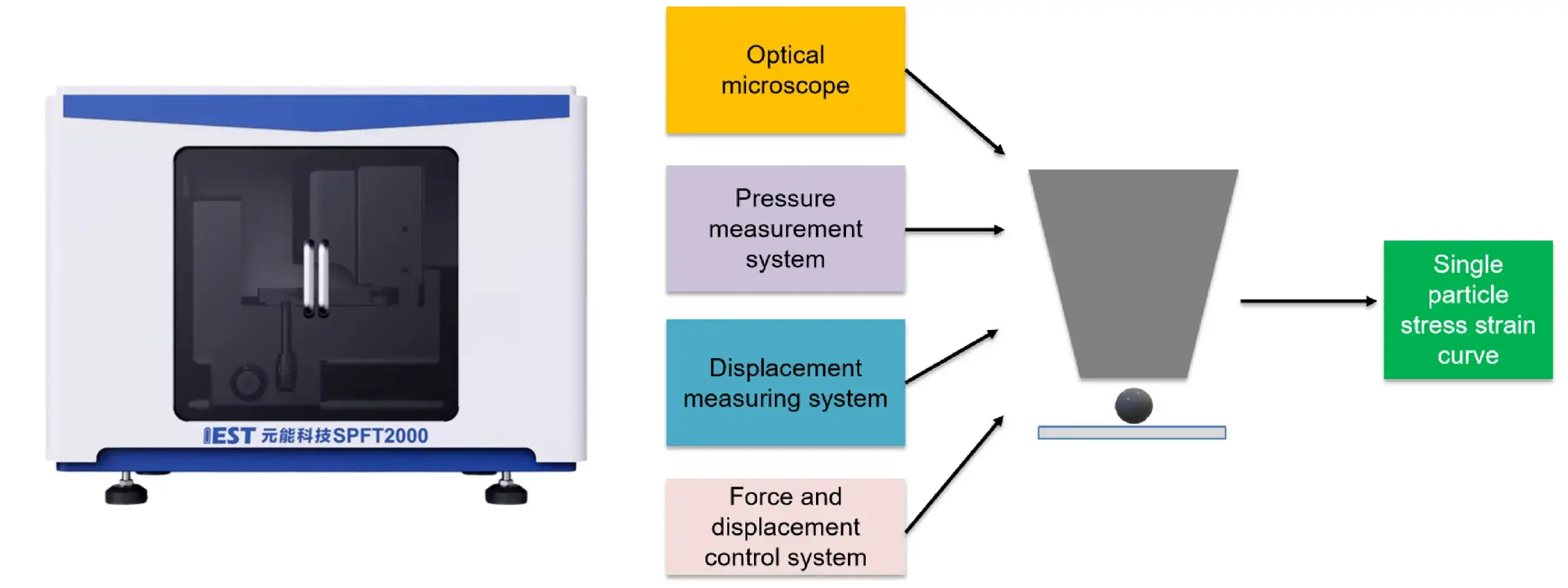

Understanding the mechanical behavior of individual material particles is crucial for advancing lithium-ion battery technology. The Single Particles Force properties Tester (SPFT) from IEST is specifically designed to characterize the mechanical properties of single cathode and anode particles, measuring key parameters such as crush force and crush strength. This system employs high-precision displacement control and force measurement to generate stress-strain curves during compression, with the point of fracture identified by a sharp change in the curve. Operators can simultaneously observe the particle’s morphological changes throughout the compression process via an integrated optical microscope.

Since its introduction, the SPFT has garnered significant interest within the battery R&D community. Its adoption is evidenced by the testing of over 380 samples from more than 70 institutions within a short timeframe. Based on this extensive dataset and relevant literature, we have consolidated a framework of characteristic compression curve models. These models describe the stress-strain relationship and reveal critical information about deformation mechanisms and fracture behavior of single particles.

2. The SPFT Methodology and Testing Protocol

Figure 1. (a) SPFT Device; (b) Test Mode with Controlled Displacement; (c) Bottom View of the Optical System

SPFT offers multiple testing modes, allowing operators to choose the appropriate mode based on sample type or specific testing requirements. Typically, we employ a controlled displacement mode to test stress (Figure 1b), where the probe compresses particles at a constant displacement rate. This mode measures the stress variation during particle compression. The displacement rate is typically set at 1 μm/s with displacement stability maintained within ±0.01 μm. The instrument automatically stops testing and saves data when the probe reaches the maximum displacement or set pressure limit.

Of particular note, SPFT utilizes a bottom optical system for imaging, allowing the testing software to synchronously record the entire process of particle compression, deformation, and fracturing (Figure 1c). Observing these changes provides crucial insights and guidance for analyzing stress-strain curves in single particles compression. This capability forms the core basis for establishing the models of single particles compression curves in this study.

2. Compression Characteristics Curve Models for Battery Particles

Single-particle load–displacement traces typically follow a characteristic sequence that can be parsed into mechanically meaningful stages. Based on a large sample set, we group observed behaviors into four representative curve types (A–D). Each type captures a distinct failure or deformation mechanism and therefore has value for particle screening and material qualification.

General stages commonly observed in a compression trace

-

Elastic / elastic–plastic regime: initial, near-linear rise in load with displacement.

-

Instability / crush point: a sudden load drop or peak that indicates fracture initiation (the crush force).

-

Post-crush behavior: rapid load reduction as fragments rearrange or the indenter contacts the substrate.

-

Substrate or packing response: after the particle is fully broken and compacted, the trace often rises again as the indenter loads the underlying substrate or compacted fragments.

Below we describe the four canonical curve types, link them to microstructural causes, and note measurable descriptors useful for battery particle characterization and particle compression studies.

Figure 2. Analysis of Single Particles Compression Curves of Lithium Battery Materials (A-D)

2.1 Model A: Ideal Brittle Fracture

Figure A represents the compression curve of an ideal particle: initially, the particle undergoes elastic-plastic deformation when compressed, exhibiting some degree of elastic behavior. When the particle reaches fracture, known as the crush point, the corresponding stress value is termed the crush force, indicating the stress at which the particle fractures or fails. Subsequently, as the particle breaks and releases most of its internal stresses, the stress rapidly decreases until the probe compresses the particle and substrate together. At this point, the curve rises again in a certain pattern, corresponding to the probe pressing against the substrate. Figure (a) shows the single particles compression curves of various particles of a ternary material we tested, which closely resemble the behaviors and characteristics shown in Figure 1.

Figure 3. (A-a) Single particle compression curves for different NCM particles.

2.2 Model B: Multi-Stage Fracture

This model is typical for large NCM or secondary granulated graphite particles. The curve features multiple plateaus following the initial fracture, corresponding to secondary or sequential crushing events. The shape of the curve from the origin to the first crush point provides insights into material brittleness. A steeper slope and shorter compression displacement indicate higher brittleness. The area under this portion of the curve represents the energy absorbed before failure (crush work), with lower values also suggesting a more brittle nature. Figure B-b demonstrates this behavior in large NCM particles.

Figure 4. (B-b) Single particle compression curves for large NCM particles.

Furthermore, the shape and compression displacement from zero to crush point marked in Figure B can provide characteristics of material brittleness. Under the same crush force conditions, a steeper curve indicates a quicker transition from elasticity to failure; a shorter compression displacement suggests greater brittleness as the material cannot withstand significant deformation before fracturing. The energy absorbed from zero to crush point, calculated as the area under the curve by integration, reflects the total energy input experienced by the particle before fracture, known as fracture energy or crush energy. Similarly, a smaller fracture energy indicates greater brittleness of the material.

2.3 Model C: Microstructural Defect Signatures

Type C traces display small, repeated micro-steps or “ripples” during the early part of the compression curve. Optical inspection typically shows no macroscopic fracture during these micro-events. Instead, the ripples indicate incremental rearrangements or micro-crack propagation associated with internal defects: pores, micro-voids, phase boundaries, or dislocations. Key interpretations:

-

Microstructural heterogeneity indicator: the presence and density of ripples correlate with defect populations.

-

History dependence: particles extracted from electrodes that experienced high compaction or long cycling often show more pronounced ripple patterns, suggesting accumulated damage.

-

Predictive value: a high ripple density can precede reduced crush force and lower fracture energy, signaling embrittlement.

Figure 5. (C-c) Single particle compression curves for NCM powder after compaction at different pressures.

Figure C shows the single particles compression curves of powder particles from the same ternary positive electrode material tested after compaction at different pressures. It is important to note that all tested particles were structurally intact, showed no signs of fracture under optical microscopy, and were approximately 18 μm in size. Comparing the compression curves of particles compacted at 100 MPa and 300 MPa, particles subjected to higher pressures exhibit phenomena similar to those seen in Figures 2.

2.4 Model D: Complex Heterogeneous Behavior

Figure D presents more complex compression curves observed in specific particles due to surface structural differences or irregularities. These curves exhibit both pronounced bends or large steps at the front end and bends or plateaus at the rear end. Additionally, the curve from the crush point to the substrate shows nonlinear attenuation. Such mechanical behaviors indicate a non-linear stress-strain relationship in the material, often reflecting significant variations between particles of the same material. Figure (d) shows the single particle compression curves of powder particles from two silicon-carbon materials we tested, closely resembling the behaviors and characteristics shown in Figure D.

Figure 6, D, d. Single Particles Compression Curves of Powder Particles from Two Silicon-Carbon Materials

3. Influence of Compaction History: Pre-pressing and Damage

We tested nominally identical particles after compacting the powder at different pressures (examples: 100 MPa vs 300 MPa) and observed systematic changes:

-

Reduced elastic modulus: particles pressed at higher pressure often show a lower initial slope, consistent with internal microcracking or densification-induced damage.

-

Lower crush force: high pre-pressures can reduce strength, likely because preexisting microcracks act as stress concentrators.

- Steps/Plateaus in Compression Curves: Internal defects in particles expand or new cracks form during compression, resulting in steps/plateaus in the compression curves, and the particle fracture process becomes more irregular.

These results underscore that processing history — such as calendering, electrode compression, or powder pressing — alters intrinsic particle mechanics and therefore must be considered during battery particle characterization.

4. Battery Particle Characterization Metrics and How to Report Them

For rigorous comparison across materials and processing conditions, report the following standardized metrics for each particle test:

-

Crush force (N) — peak load at first major fracture.

-

Crush displacement (μm) — displacement at the peak load.

-

Fracture energy (mJ) — integral of load vs. displacement up to crush.

-

Pre-crush slope / apparent elastic modulus (N·μm⁻¹ or GPa equivalent) — slope of the initial linear region.

-

Number of post-peak stages — count of plateaus/steps and their loads.

-

Ripple density — number of micro-steps per μm in the early loading regime.

-

Synchronized optical frames — include key frames at onset of visible damage, maximum fragmentation, and substrate contact.

Reporting these metrics together with particle size, morphology, and provenance (powder lot, prior calendering/pressing) provides a consistent dataset for both empirical comparison and model calibration.

5. Implications for electrode engineering and material selection

Single particle compression testing bridges microscale mechanics and electrode-level performance:

-

Particle fragility and electrode durability: brittle particles (low crush displacement and low fracture energy) are more likely to generate debris during mixing and calendering, which can increase active material isolation and impedance.

-

Processing limits: particles that show significant strength loss after modest pre-pressing suggest sensitivity to calendering; process windows should be adjusted accordingly.

-

Composite design: composite or coated particles with Type D behavior may require altered binder strategies to preserve integrity and contact.

-

Model input: the standardized metrics above are directly usable in discrete element method (DEM) or finite-element models that simulate particle breakage during electrode fabrication.

6. Conclusion

Analyzing the compression characteristics of single battery particles provides deep insights into their mechanical response, including crush strength, brittleness, and internal microstructure. This information is vital for material development, micro-scale simulation, and overall battery performance optimization. IEST remains committed to advancing battery particle characterization through instruments like the IEST SPFT, continuing to support innovation in lithium battery research and development.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.