-

iestinstrument

Amazing Discovery! Large Cylindrical Battery Expand Ten Times More Than Small Cylindrical Battery

1. Abstract

In the future market competition, the core advantages of large cylindrical batteries focus on high safety, excellent high-rate charge and discharge capabilities, top-notch energy density, and high cost-performance ratio. Their robust structural design provides exceptional structural rigidity, which has often been regarded as a guarantee for maintaining volume stability during battery charge and discharge cycles. However, upon closer examination, one might question: Can large cylindrical batteries truly maintain their volume without any change?

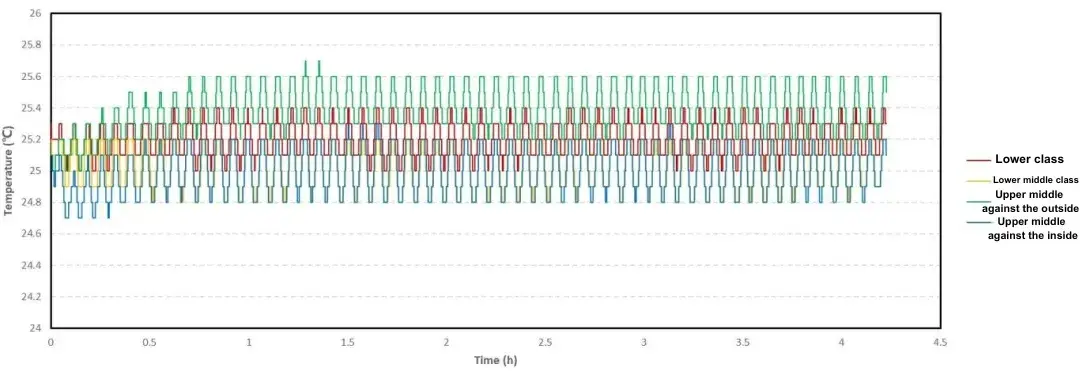

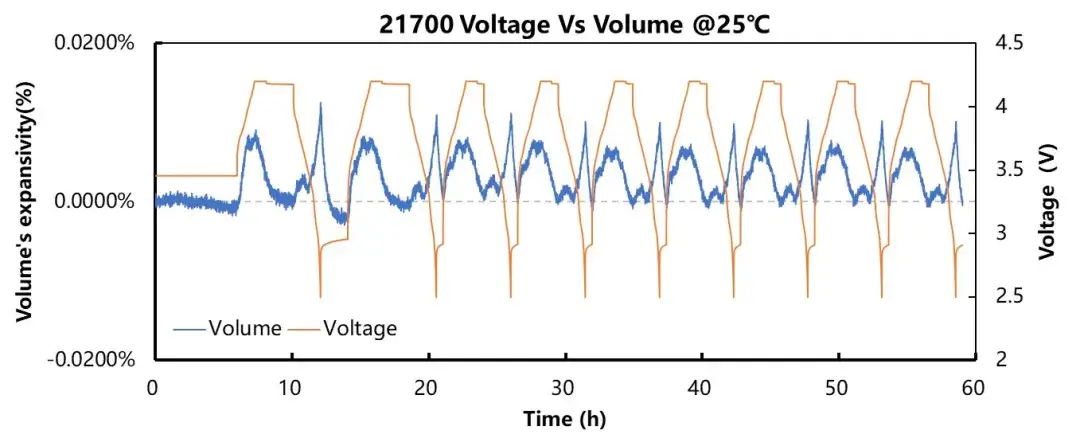

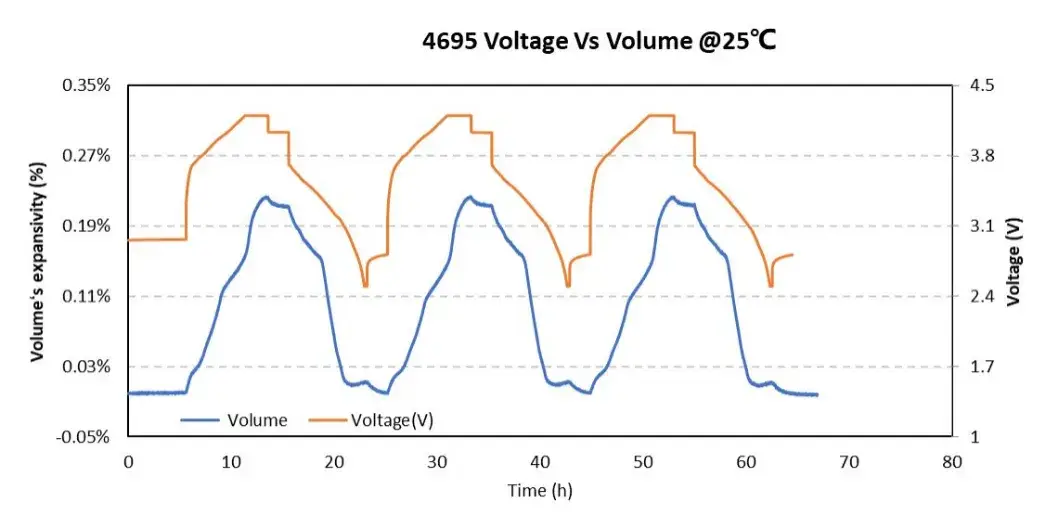

Through precise in-situ testing, we uncovered the truth: For example, with the 21700 model small cylindrical battery (using a ternary material system, with a capacity of 4.2Ah), the maximum volume change rate during the first three cycles at a 0.5C charge and discharge rate is only 0.013%, which is almost negligible. However, when we turn to the larger 4695 model cylindrical battery with a capacity of 33Ah (also based on the ternary system and charged and discharged at a 0.1C rate), the situation is different—the volume change rate increases significantly to 0.22%. Importantly, this volume change closely follows the fluctuations in the battery’s voltage curve, showing a high degree of consistency.

This finding not only reveals the subtle variations in volume stability of large cylindrical batteries but also highlights the nuanced relationship between these changes and battery performance. Particularly striking is the fact that the volume change of large cylindrical batteries far exceeds that of small cylindrical batteries, with a difference exceeding tenfold. This significant disparity presents new challenges and considerations for battery design, safety performance evaluation, and long-term stability.

In summary, while large cylindrical batteries lead the industry with their many advantages, their volume change characteristics should not be overlooked in the pursuit of optimal performance. Special attention and further research are needed, particularly in the areas of design optimization, safety management, and performance prediction.

2. Application Case

Large cylindrical batteries, such as Tesla’s 4680 cells, offer significant advantages in safety, lifespan, range, cost-effectiveness, and fast charging.

During cycling, batteries experience significant volume expansion due to factors such as the formation and growth of the solid-electrolyte interface (SEI), thermal expansion, and gas generation. This volume expansion not only increases internal stress between different parts of the battery but also introduces pressure between adjacent cells in the battery pack. Additionally, the continuous expansion and contraction cycles of the battery raise the risk of mechanical failure. Therefore, volume expansion is a key indicator for assessing structural and capacity degradation of batteries over long-term use. To gain a deeper understanding of the expansion and contraction characteristics of large cylindrical batteries, a comparative test between the 4695 model and the 21700 battery was conducted to more accurately evaluate the volume change characteristics of large cylindrical batteries and their impact on battery lifespan. The testing process involved imaging the batteries with an imaging system, and software processing was used to output the volume change rate and voltage relationship curves (Figure 1).

Figure 1. Testing Process

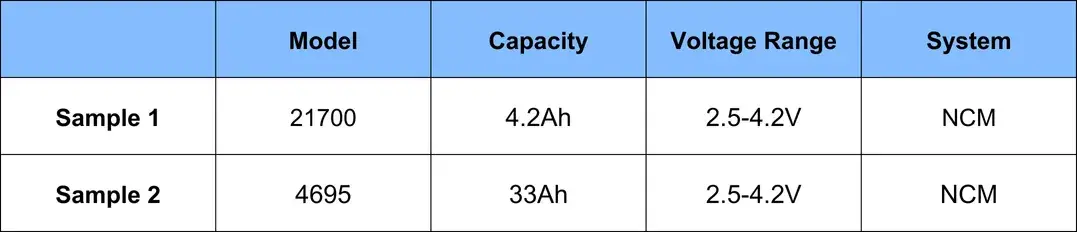

Table 1. Battery Sample Information:

Experimental instrument: IEST CCS1300 (Cylindrical Battery In-Situ Swelling Testing System)

Testing Conditions: Temperature: 25°C

Table 2. Battery Sample Charge and Discharge Steps

3. Results and Discussion

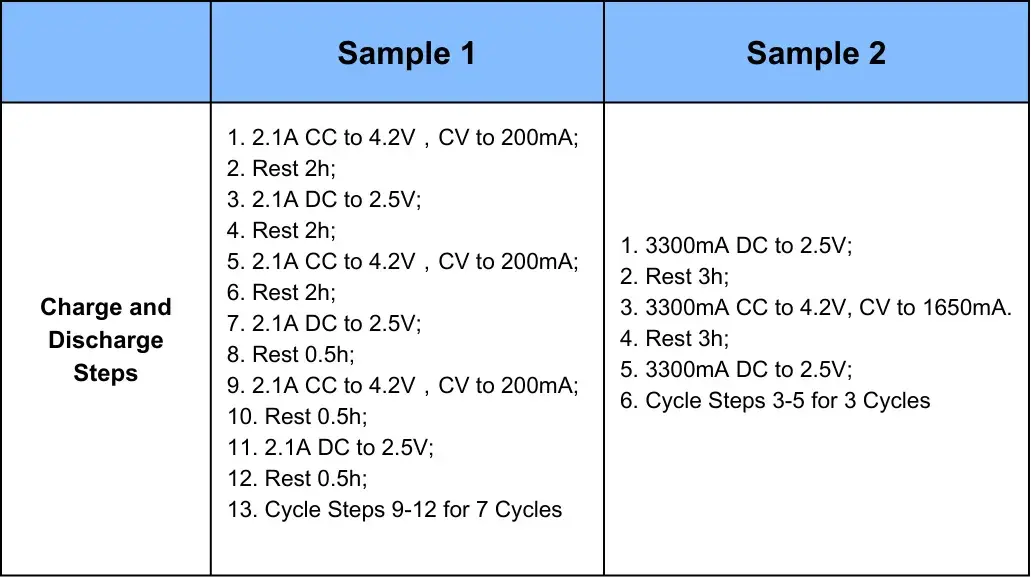

In battery testing or any experimental environment requiring precise temperature control, ensuring temperature uniformity is crucial. Currently, the temperature difference across all channels during testing remains within a fluctuation range of 25±1°C (Figure 2), meeting the temperature conditions.

Figure 2. Temperature Test Curve

Cylindrical batteries (whether the 21700 model or the 4695 model) do experience some volume change during charge and discharge, which is a normal phenomenon of battery operation. However, it is noteworthy that the maximum volume expansion of the 4695 cylindrical battery (0.22%, Figure 3) is significantly higher than that of the 21700 cylindrical battery (0.013%, Figure 4), exceeding the latter by more than ten times.

This difference in volume expansion may be caused by the following factors:

3.1 Battery Capacity and Structural Design

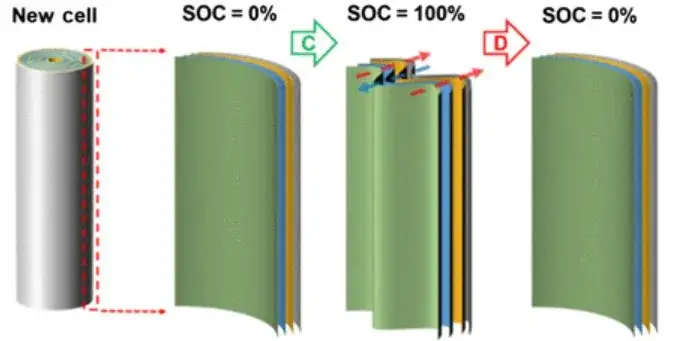

Unlike the flexible aluminum-plastic film casing of pouch cells, the rigid metal casing of cylindrical batteries hinders the release of stress generated by internal expansion. The non-uniform contact between the metal casing and the internal wound core can create small voids, leading to uneven stress distribution, as shown in Figure 5. The 4695 cylindrical battery, compared to the 21700 battery, has a larger capacity and a more complex structural design. A larger capacity means that the wound core has more layers, which can result in more uneven volume changes and greater internal stress, leading to more pronounced deformation of the battery’s metal casing. Additionally, the more complex structural design may result in weaker elasticity or buffering capability to cope with volume changes, exacerbating the phenomenon of volume expansion.

3.2 Material Properties

Different models of cylindrical batteries may use different electrode materials and electrolyte formulations. The expansion and contraction characteristics of these materials during charge and discharge may vary, leading to differences in the overall volume change of the battery. Additionally, the thickness and strength of the battery’s metal casing significantly affect the overall deformation of the battery. A thicker and stronger metal casing can withstand greater stress, resulting in smaller deformation.

3.3 Manufacturing Process

The manufacturing process of the battery also affects its volume stability. For example, factors such as the uniformity of electrode coating, the tightness of winding or stacking, and the seal integrity of the battery casing can all impact the battery’s volume change. Specifically, the assembly tightness of the cell (the gap between the wound core and the casing) plays a significant role. When the reserved space is larger, the battery can accommodate greater core deformation, resulting in less force on the casing and thus, smaller deformation of the battery.

3.4 Testing Conditions

Although the temperature difference across channels is within a controllable range, other testing conditions (such as charge and discharge rates, depth of discharge, and number of cycles) may also affect the battery’s volume change.

Figure 3. Volume & Voltage Change Curve of the 21700 Battery

Figure 4. Volume & Voltage Change Curve of the 4695 Battery

Figure 5. Schematic Diagram of Volume Change Mechanisms in Cylindrical Batteries

In the process of reducing costs and extending the lifespan of cylindrical batteries, key factors include the choice of casing material, casing thickness and design strength, the design of the gap between the bare cell and the casing, and the differences in expansion under various charge and discharge rates. Through rational design and optimization, along with comprehensive testing methods, the performance and safety of cylindrical batteries can be effectively enhanced.

4. Summary

In conclusion, the volume change of cylindrical batteries during charge and discharge is a complex phenomenon that requires the consideration of multiple factors for analysis and optimization. Through continuous research and improvements, we anticipate the development of more stable, safe, and high-performance cylindrical battery products in the future.

5. References

Wenxuan Jiang, Haoran Li, Sicong Wang, Sa Wang and Wei Wang,Dynamic Volumography of Cylindrical Li-Ion Battery Cells by Watching Its Breath During Cycling,CCS Chemistry. 2023; 5:1308–1317

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.