-

iestinstrument

Analysis of Lithium-Battery Powder Particle Mechanical Behavior and Irreversible Deformation During Compaction

1. Abstract

Particle-level mechanical properties control how electrode powders densify and how the electrode microstructure evolves during rolling and calendering. This study links single-particle compressive strength to bulk powder compaction behavior and irreversible deformation for representative cathode and anode materials. We used IEST Single Particle Force Testing System SPFT and powder resistivity & compaction (PRCD3100) instruments to quantify: single particle crush forces, stress–strain compaction curves, maximum and irreversible strain, and statistical distributions across material batches. The results demonstrate a clear causal relationship: weaker powder particles produce larger irreversible deformation under identical compaction protocols, with direct implications for porosity, ionic pathways and final electrode electrochemical performance.

2. Background

During the production of lithium-ion battery electrodes, particularly in the calendaring process, a certain degree of particle breakage is often inevitable. When the wet slurry—composed of active material powder, conductive agents, and binders—is coated onto the current collector, dried, and subsequently compressed by rollers to increase electrode density, the applied mechanical pressure can cause varying degrees of fracture or cracking in and between active material particles. This leads to irreversible deformation and a potential deterioration in material performance.

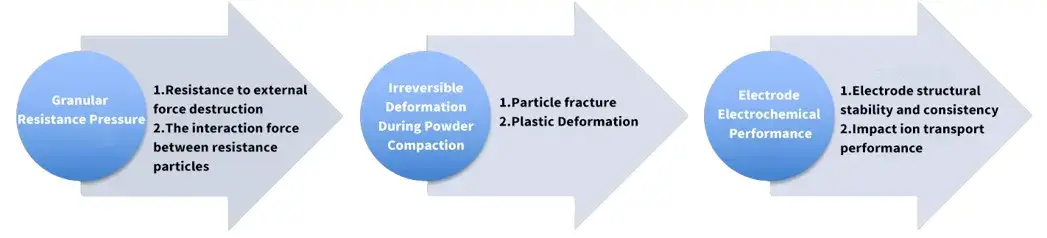

Figure 1. Influence of Particle Compressive Strength on Powder Compression and Electrochemical Performance of Electrodes

The crushing strength of individual battery material particles is intrinsically linked to the irreversible deformation observed when the corresponding powder is compressed (Figure 1). Crushing strength reflects a particle’s ability to resist destruction under external force, while irreversible deformation refers to the plastic deformation or fragmentation of powder particles during compression, resulting in a permanent change in shape that cannot be fully recovered.

First, single particles with high crushing strength are less prone to fracturing or plastically deforming under compression. Under identical calendaring conditions, stronger particles better maintain their structural integrity, minimizing irreversible deformation. This helps preserve electrode structure stability and uniformity, ultimately enhancing cell performance.

Second, the occurrence of irreversible deformation is closely tied to inter-particle interactions and contact states. During powder compression, changes in contact area and interaction forces between particles can induce plastic flow or breakage. High-strength particles are more resistant to these forces.

Furthermore, significant irreversible deformation can adversely affect electrode pore structure and ion transport properties. Excessive particle collapse may lead to pore closure, reducing ionic conductivity and harming electrochemical performance.

In summary, the crushing strength of individual particles profoundly influences the irreversible deformation of the powder bulk. Enhancing single-particle strength can minimize permanent deformation, preserve electrode structure, and boost cell performance. Therefore, understanding this cause-and-effect relationship is crucial in battery material design and manufacturing.

3. Testing Methodology

This study investigates the relationship between single-particle mechanical strength and bulk powder irreversible deformation for various cathode and anode materials. We characterized different NCM-type cathode materials, pure graphite anodes, and silicon-carbon composite anodes.

Two specialized instruments from IEST Instrument were employed:

-

Single Particle Mechanical Testing System (SPFT2000): Measures the crushing strength of individual active material particles.

-

Powder Resistivity & Compaction Density System (PRCD3100): Evaluates the compression behavior of powder samples, generating stress-strain curves.

The testing procedure for powder compression was standardized: pressure was applied from 10 to 200 (or 400) MPa in 10 (or 20) MPa increments, with a 10-second hold at each step.

Figure 2. Appearance and Functional Modules of the Single Particle Force Testing System SPFT

Figure 3. Schematic Diagram of the Appearance and Structure of the IEST PRCD Series

4. Case Studies & Results Analysis

4.1 Case 1: NCM Cathode Materials B1 vs. B2

Two NCM materials (B1 and B2), synthesized from different precursors but with identical median particle sizes (D50 = 9.5µm), were tested. The results of the single particle mechanical properties for both materials are shown in Figures 4(a) and 4(b).

-

Single-Particle Strength: The average crush force of B1 is 4.4mN, while that of B2 is 9mN, indicating a higher crush force for B2 compared to B1. Upon crush, the stress drops to zero for B1, whereas for B2, the force drops to 2mN. Additionally, after crush, B1 exhibits multiple plateaus on the force-displacement curve as the platen continues to compress, suggesting a faster structural breakdown and lower elasticity compared to B2. Moreover, during the platen compression process, some particles of B1 may undergo secondary crushing after initial fracture.

-

Powder Compression: By gradually increasing the pressure step by step until reaching the maximum pressure and then gradually releasing the pressure to the minimum, stress-strain curves for the powders of the two materials are obtained, as shown in Figures 4(c) and 4(d). From the slope of the stress-strain curve, it can be observed that the compression modulus of B2 is greater than that of B1, indicating that it is more resistant to compression. Numerically, both the maximum strain variable and irreversible strain variable of B1 are greater than those of B2, consistent with the difference in single particle crush force.

Figure 4. (a) Single particle crush curves for B1 and (b) B2 particles; (c) Stress-strain curves for powders of B1 and B2; (d) Comparison of the numerical distribution of single particle crush for B1 and B2 and irreversible deformation during powder compression.

4.2 Case 2: Graphite Anode Materials C1 vs. C2

Two pure graphite materials (C1, C2) with different production processes were analyzed (particle size ~6-8µm). Figure 5 shows the distribution of single particle crush forces for the two materials.

-

Single-Particle Strength: The crushing force distribution showed a clear difference: C1 ranged from 27-43 mN, while C2 was much weaker at 4-15 mN (Figure 5).

-

Powder Compression: The bulk powder test results were coherent: C1 (stronger particles) had a higher compression modulus and smaller maximum/irreversible strain values than C2 (weaker particles) (Figure 6). This demonstrates that powder composed of mechanically weak particles undergoes more significant and permanent deformation during compaction.

Figure 5. Distribution of single particle crush forces and schematic diagram of single particle crush before and after for particles of C1 and C2.

Figure 6. Stress-strain curves and strain variable numerical values for powders of C1 and C2.

4.3 Case 3: Silicon-Carbon Composite Anodes SC-1, SC-2, SC-3

Three Si-C composites with varying silicon content and slightly different structures were tested. Particles of two size ranges (~10µm and ~15µm) were selected for single-particle testing. The distribution of single particle crush forces is shown in Figure 7(a).

-

Single-Particle Strength: SC-2 showed slightly higher overall crushing forces than SC-1, and both were substantially stronger than SC-3. SC-1’s strength distribution was more uniform, while SC-2’s 15µm particles exhibited a wide strength range (22.2–65.4 mN) (Figure 7a).

-

Powder Compression: Due to its weaker particle compressive strength, SC-3 exhibits significantly larger maximum strain and irreversible strain during powder compression compared to the other two materials. Although the compressive strength of SC-2 particles is slightly higher overall than that of SC-1, differences in particle compressive consistency during powder compression may lead to effects such as the fracture of stronger particles due to weaker ones or stress concentration, or uneven compression affecting the recovery ability, resulting in similar compression performance and strain variables between SC-1 and SC-2 overall.

Figure 7. Distribution of single particle crush forces for different particles of SC-1, SC-2, and SC-3 (a), and stress-strain curves and strain variable numerical values for powder compression (b).

5. Discussion — Implications for Electrode Processing and Cell Performance

The experimental evidence supports several engineering conclusions that directly affect electrode manufacturing strategy:

-

Increase single-particle compressive strength where possible. Materials with higher per-particle crush force reduce particle fragmentation during calendering and rolling, limiting irreversible powder deformation and maintaining pore structure. This helps preserve ion-transport channels and homogeneity across the electrode.

-

Control particle-strength distribution, not just the mean. Batches with heterogeneous strength (wide distributions) produce localized breakage and stress concentrations that compromise bulk behavior. Supplier quality control should track particle mechanical property distributions in addition to particle size distributions.

-

Balance compaction targets with particle robustness. Aggressively targeting higher compaction density can backfire when particles are weak: increased crushing raises irreversible deformation, modifies pore topology and may reduce electrochemical active area. Instead, define calendering windows informed by particle mechanical data.

-

Material design strategies: For Si-C and other brittle systems, consider engineered microscale architectures (hollow, yolk-shell, coated, or graded particles) or binder/adhesive strategies that increase effective particle toughness to reduce fracture during densification.

6. Practical Recommendations For R&D and QC

-

Adopt single-particle testing (SPFT2000) early in powder qualification to screen candidate batches for crush-force distribution.

-

Use PRCD3100 compaction curves to map acceptable calendering regimes; monitor irreversible strain and set upper bounds for pressure based on the weakest acceptable batch.

-

Require supplier data on particle mechanical properties as part of incoming QA for active materials, not only particle size and surface area.

7. Conclusion

This study effectively links fundamental powder particle level properties to bulk powder behavior. By combining single-particle mechanical testing with powder compression analysis, we have demonstrated a direct causal relationship: materials comprised of stronger, more uniform individual particles exhibit significantly less irreversible deformation during powder compaction.

This insight is vital for electrode manufacturing. Enhancing the intrinsic mechanical strength and uniformity of active material particles can mitigate the risk of fracture and permanent deformation during calendaring and long-term battery cycling. This strategy directly contributes to maintaining electrode structural integrity, ensuring consistent porosity, and ultimately improving the performance and longevity of lithium-ion batteries.

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.