-

iestinstrument

Polystyrene Microspheres: Single-Particle Compression Properties and Particle Morphology

1. Background

Polystyrene microspheres (PS microspheres) represent a significant research focus in polymer science due to their unique physicochemical properties, which make them highly suitable for a variety of applications in biochemistry, sensing, catalysis, and more. These microspheres are synthesized through several methods—such as suspension polymerization, emulsion polymerization, and dispersion polymerization—each yielding variations in particle size, uniformity, and surface characteristics. These differences significantly influence not only the dispersion and adsorption behavior of PS microspheres but also their mechanical properties, particularly their compression properties.

This study reports single-particle compression tests on six PS microsphere variants (D50 ≈ 30 μm) using IEST’s Single Particle Force Test (SPFT) system. High-precision force–displacement traces were recorded together with bottom-view optical imaging to correlate crush forces with deformation modes and post-fracture morphology.

2. Testing instrument and methods

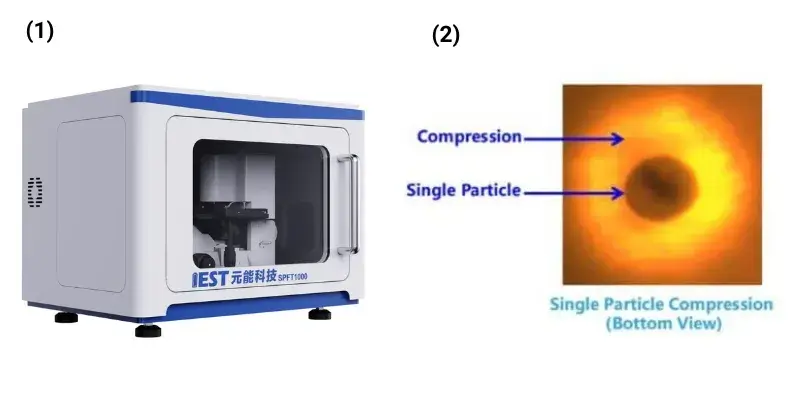

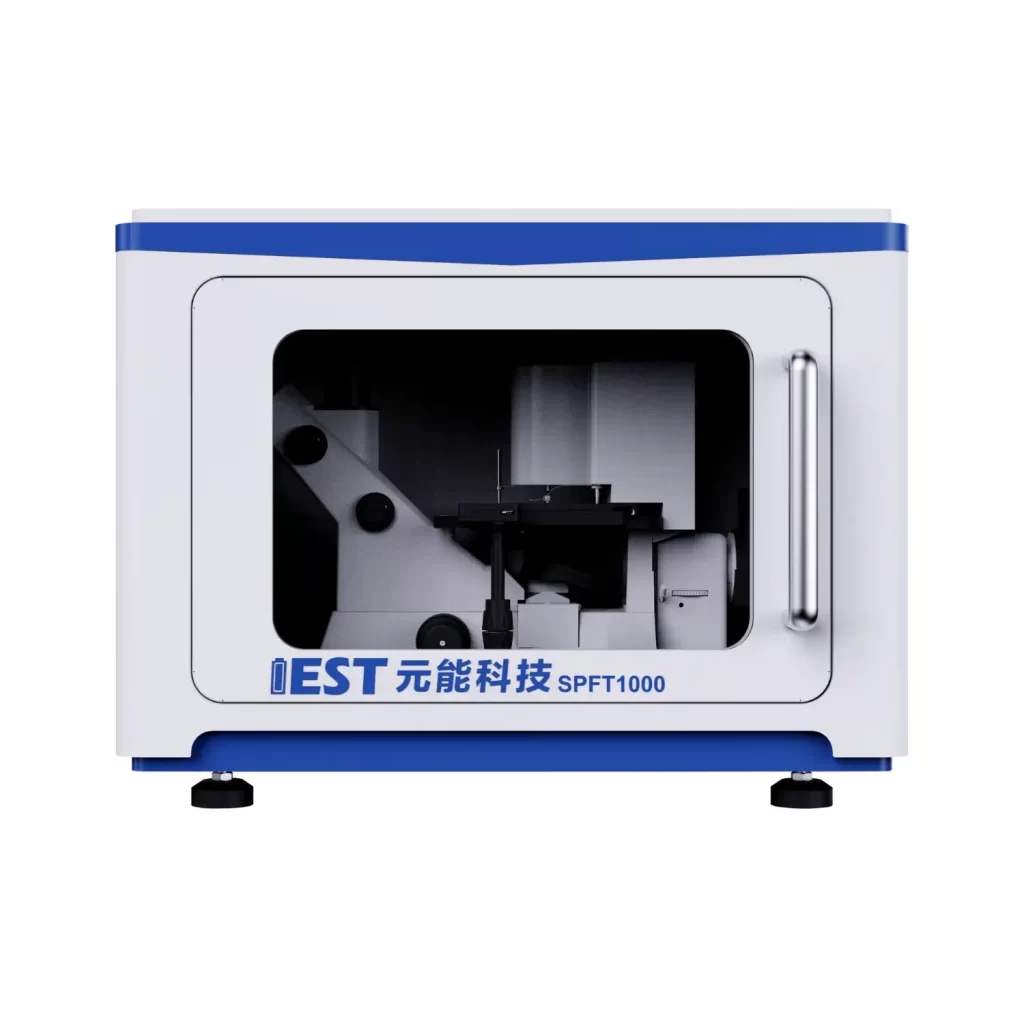

Figure 1. (a) Single Particle Force Properties Test System; (2) Bottom view of optical system

In order to deeply investigate the single particle compression resistance of Polystyrene microspheres, this paper adopts the SPFT (Single Particle Force Properties Test System) equipment from IEST for testing. The SPFT equipment is capable of controlling the displacement and measuring the pressure with high precision, so as to accurately capture the pressure-displacement curve of the indenter loaded onto a single particle. In addition, the IEST SPFT uses a bottom optical system for imaging, and the entire picture of the particle being compressed, deformed, and crushed can be synchronized in the test software. This device is particularly suitable for evaluating the compression resistance and crush force at the particle level of a material, and is essential for understanding the behavior of polystyrene microspheres during compression.

In this paper,six types of PS microspheres with particle size D50 around 30 μm were selected. The testing process followed strict standardized steps: first, the samples were prepared by ethanol dispersion to ensure uniform distribution of the particles; then, an optical microscope was used to locate the individual dispersed particles; then, the experimental parameters were configured and compression tests were executed; and the morphological changes of the particles before and after compression were observed and recorded during the testing process. More than five particles are usually tested per sample to ensure the reliability and statistical significance of the data.

3. Results Analysis

3.1 Compression curves and morphological changes of single particles

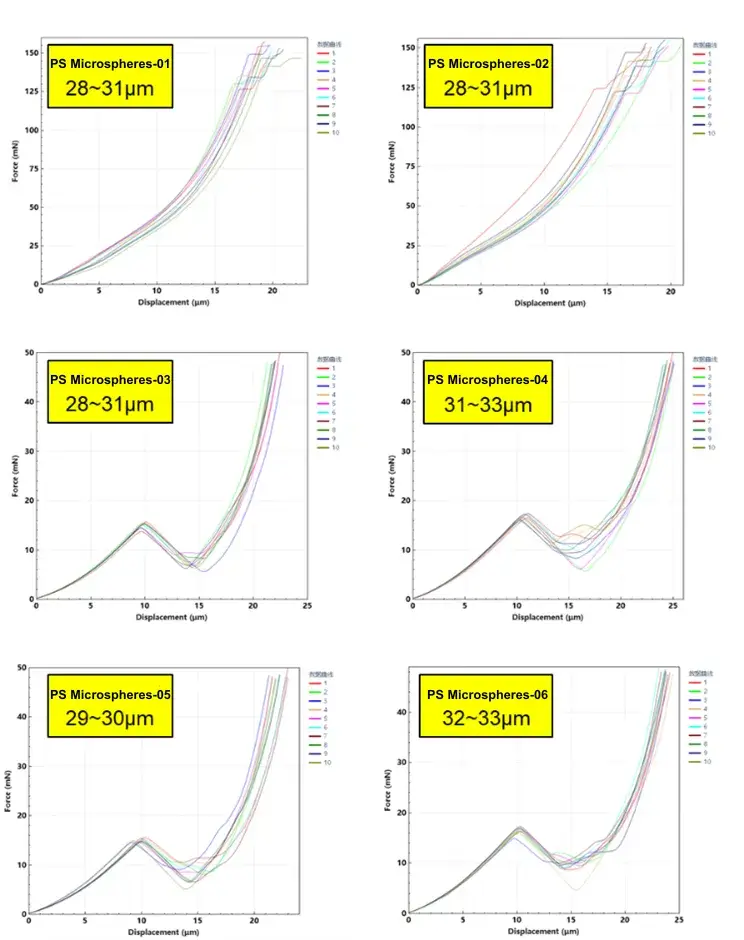

Figure 2. Single particle compression curves of six different Polystyrene microspheres

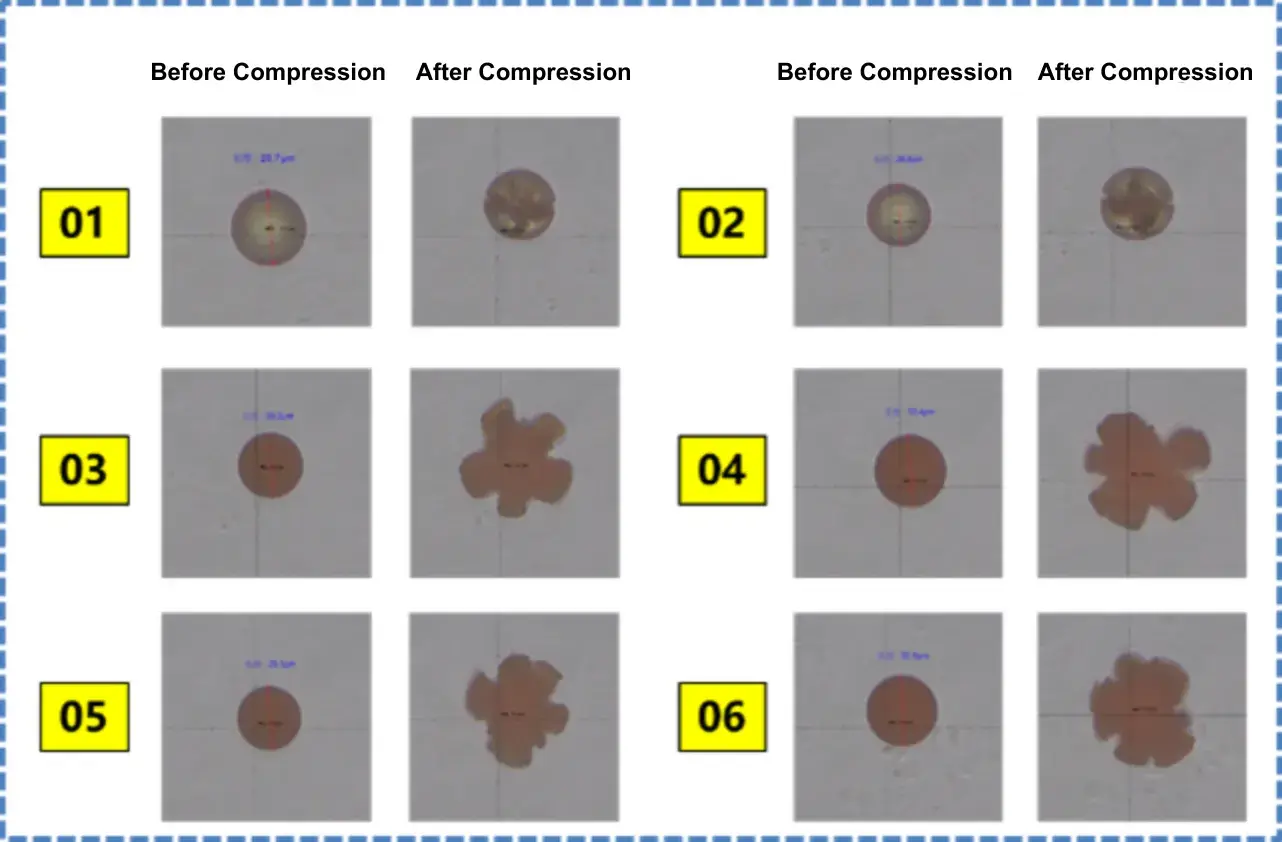

Figure 3. Animation of the single particle compression process of 6 different PS microspheres(above), The Polystyrene morphology before and after compression (below)

3.2 Comparison of crush force and compression strength

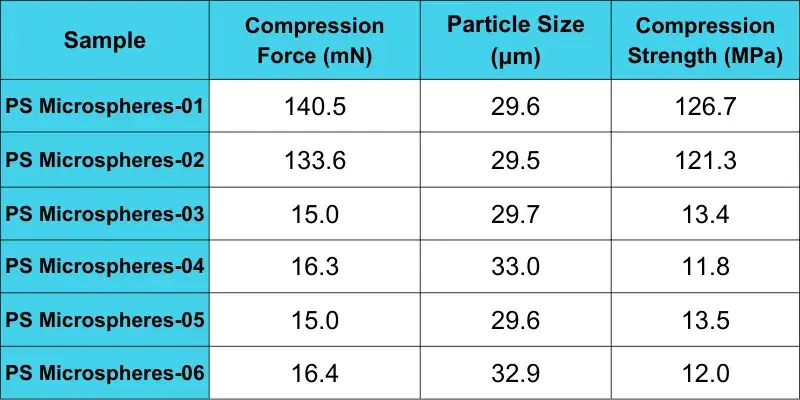

It can be seen from the results that the consistency of the curves of each sample tested in parallel for 10 times is relatively good. The overall crush force of the single particles of PS microspheres-01 and -02 are much larger than that of the other four microspheres.

According to the national standard GB/T 43091-2023 on the test method of powder compression strength, the compression strength of the particles can be calculated from the compression collapse force of single particles and the particle size of the particles, and the results of the average values are shown in Table 1. The compression strengths of PS microspheres-01 and -02 are nearly 10 times higher than that of the other 4 models of PS microspheres. Combined with the change in particle morphology during compression, it can be shown that there are significant differences in the crushing force and crushing behavior of different styles of microspheres.

Table 1. Single particle compression strength of six different PS microspheres

Some microspheres (e.g., -01 and -02) have extremely high compaction forces and are able to maintain a relatively intact particle morphology during compression, and even if they are subjected to a large amount of pressure, they will only suddenly disintegrate, but the disintegrated fragments will still be able to maintain a certain degree of structural integrity. These microspheres usually have a tight internal structure and high rigidity, making them able to respond quickly and produce violent deformation when subjected to external forces, but not easy to break completely. This property makes them potentially advantageous in applications where they need to withstand high stresses while maintaining structural integrity.

In contrast, other microspheres (e.g., -03 to -06) have relatively low crush forces, and they gradually deform during compression and eventually break up in a snowflake-like fashion, slowly spreading out on the slide. These microspheres usually have a looser internal structure and better toughness, and are capable of absorbing and dispersing the compressive stress to some extent. However, due to their fragile internal structure, they are prone to break down and form snowflake-like fragments when subjected to external forces. This characteristic makes them potentially more advantageous in application scenarios that require better dispersion and adsorption.

4. Characteristics of the force-displacement curves

4.1 Slope of the curve in the front section

By comparing the curve changes and slope characteristics of different microspheres before the point of compression and collapse, we can further analyze their deformation mechanisms and mechanical properties. Microspheres with high pressure collapse force usually have steeper compression curves, indicating a faster transition from elastic deformation to destruction. On the other hand, microspheres with low-pressure routing force may have more gentle compression curves, reflecting their gradual deformation and energy absorption in the compression process.

4.2 Stress response after compression collapse

From the curves, it can be seen that after the microspheres with high pressure collapse force were crushed, with the continuous downward pressure of the indenter, their stresses did not drop significantly at the short change of compression amount, and soon rose again (the indenter with the compression particles and the substrate). On the other hand, after the microspheres with low-pressure collapse force were crushed, with the continuous downward pressure of the indenter, there was a significant drop and fluctuation at the short change of compression amount. This again suggests that microspheres with high pressure routing forces are able to maintain some structural integrity after disintegration due to the robustness of their internal structure, allowing the stress level to not decay significantly.

5. Practical Implications & Recommendations

-

Material selection: Choose high-crush-force PS microspheres for structural or compressive load applications; choose low-crush-force, high-toughness variants for adsorption and dispersion use cases.

-

Quality control: Single-particle SPFT testing offers rapid QA to detect batch variability in mechanical strength that bulk tests might miss.

-

Design guidance: For composite or packed systems, incorporate particle crush behavior into packing density and porosity models—fragmentation changes interparticle contacts and transport properties.

6. Summary

The SPFT system of IEST provided detailed insights into the compression properties and failure mechanisms of various PS microspheres. The study revealed marked differences in crush resistance, deformation behavior, and post-fracture response, correlating with internal structure and material rigidity. These findings enhance the understanding of polystyrene microsphere mechanics and offer valuable guidance for selecting appropriate microsphere types based on application-specific requirements—whether for high-strength durability or superior dispersion and adsorption.

7. Related Testing Equipment Recommendation

Application:

- Testing the crushing strength of battery material particles

- Can be used to evaluate the pressure resistance of the material

- Guide the rolling process

- Materials with high mechanical strength will have better subsequent cycle stability

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.