-

iestinstrument

Molten-Salt Crystal-Facet Engineering for High-Performance Single-crystal Nickel-Rich Cathodes

1. Article Information

Equipment used: IEST Single Particle Force Properties Test System(SPFT2000)

First Author: Hongyun Zhang

Corresponding Authors: Jinyang Dong*, Yuefeng Su*, Lai Chen*

Affiliation: Beijing Institute of Technology; Beijing Institute of Technology Chongqing Innovation Center; Lenovo (Beijing) Co., Ltd.

2. Research Background

Nickel-rich layered oxide cathodes (LiNixCoyMn1-x-yO2, x≥0.5, NCM) are ideal candidates for lithium-ion batteries due to their high energy density and low cost. However, they suffer from structural instability, sluggish lithium-ion transport, and capacity degradation, particularly under high-voltage cycling conditions. Conventional polycrystalline materials experience performance decay due to structural degradation such as microcracks. While single-crystal materials (SC-NCMs) can eliminate grain boundaries and suppress microcrack formation, the synthesis of large single crystals typically requires high temperatures, which often leads to increased oxygen vacancy defects and cationic disordering. Crucially, the uncontrolled exposure of crystal facets significantly impacts ionic transport kinetics and mechanical stability, presenting a bottleneck for enhancing the overall performance of single crystal nickel-rich cathodes. Current research faces dual challenges: breaking through the limitations of low-temperature synthesis processes for single crystals and establishing quantitative structure-property relationships between facet control and electrochemical performance. Therefore, developing innovative methods for precise facet control in single crystal nickel-rich cathodes is of significant scientific importance and engineering value.

3. Research Overview: A Molten-Salt Strategy for Superior Performance

Recently, a team led by Prof. Yuefeng Su, Assoc. Prof. Lai Chen, and Postdoc Jinyang Dong from Beijing Institute of Technology proposed a molten-salt-mediated facet engineering strategy, successfully synthesizing a single crystal nickel-rich cathode material LiNi0.83Co0.11Mn0.06O2 (denoted SC-B) with preferentially exposed (104) facets. By modulating the molten salt anions (replacing KCl with KBr), the proportion of (104) facet exposure in the single crystals was appropriately increased. The (104) facet not only facilitates rapid lithium-ion diffusion but also suppresses oxygen vacancy formation and mechanical stress accumulation. SC-B exhibits a capacity retention of 82.11% after 600 cycles, a significant improvement compared to SC-C (>65% capacity decay), along with excellent rate capability (159.8 mAh g⁻¹ at 10C). This work, entitled “Molten-salt-mediated crystal facet engineering for high-performance single crystal nickel-rich cathode materials in lithium-ion batteries,” has been published in the international journal Nano Energy.

4. The Facet Engineering Breakthrough: From Theory to Synthesis

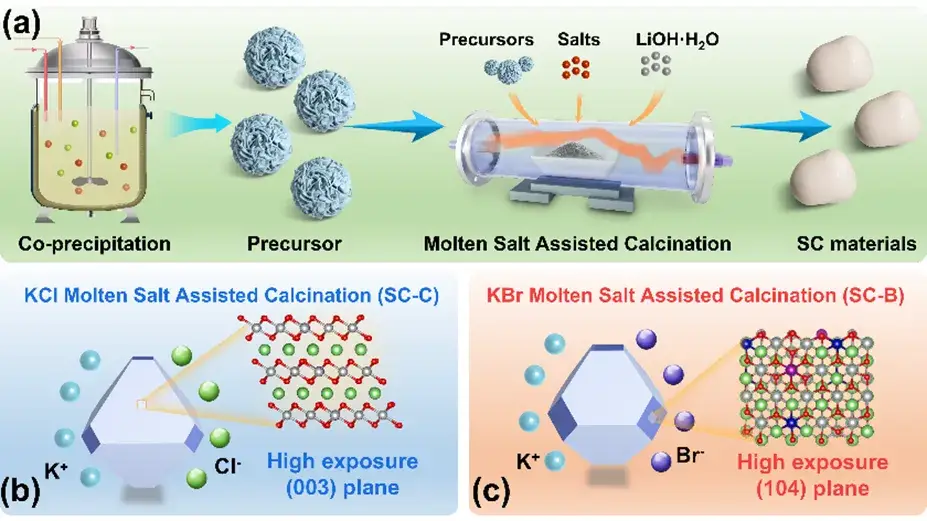

The team’s strategy centered on using different molten salts to direct crystal growth. By replacing KCl with KBr, they leveraged the selective adsorption of bromide ions (Br⁻) to promote the exposure of the (104) crystal facet over the more common (003) facet (Figure 1).

Figure 1. Schematic of single-crystal materials prepared in different molten-salt systems.

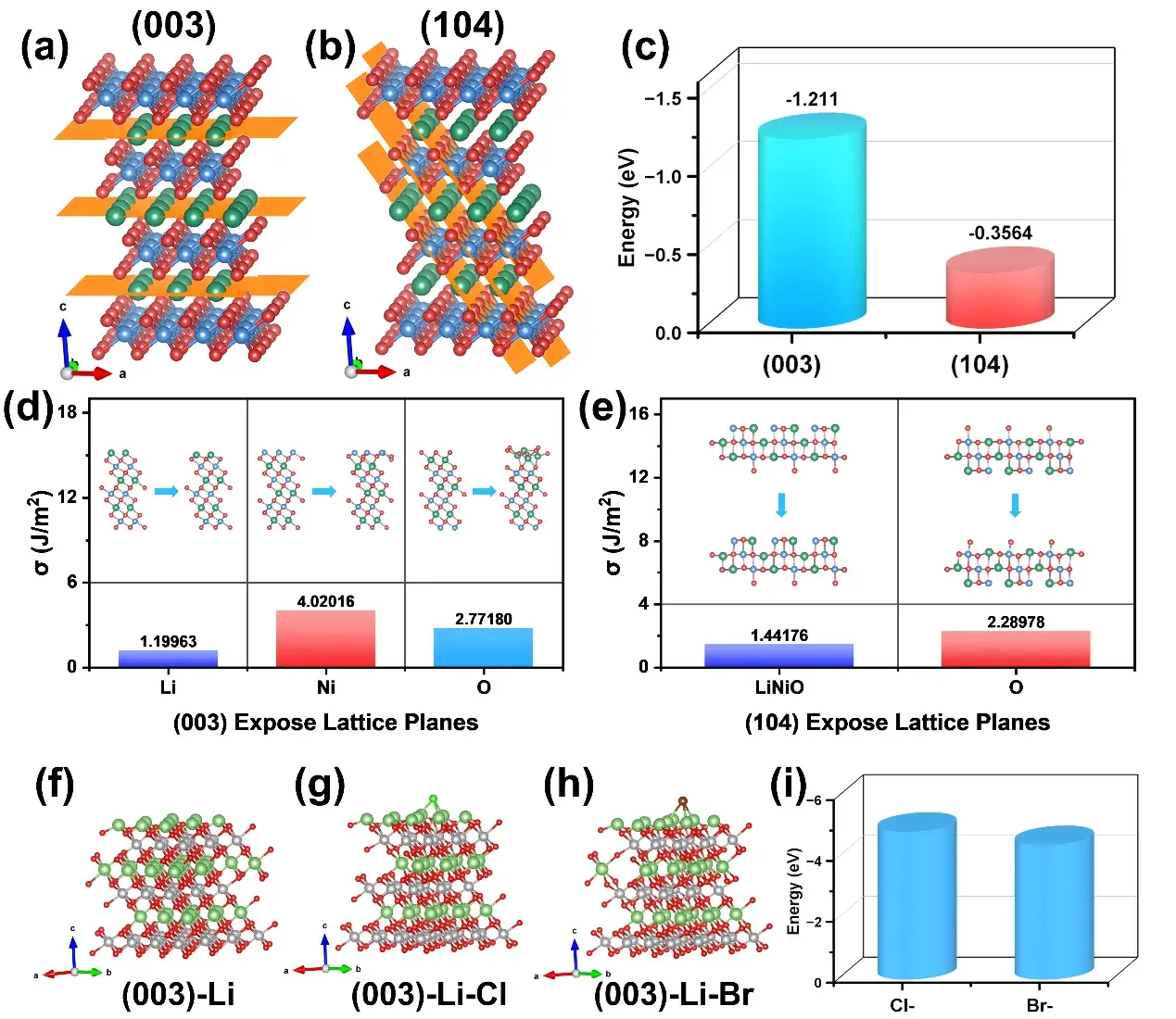

Density functional theory (DFT) calculations systematically revealed the fundamental mechanism underlying facet stability differences: the (104) facet exhibits a higher oxygen vacancy formation energy (-0.3564 eV) compared to the (003) facet (-1.211 eV), effectively inhibiting lattice oxygen loss during high-voltage cycling. In-depth investigation into the anion-selective adsorption mechanism within the molten salt system revealed that Br⁻ ions preferentially promote (104) facet exposure by modulating crystal growth kinetics, while Cl⁻ tends to stabilize the (003) facet. Combined Wulff construction predictions and experimental characterizations validated the thermodynamic stability advantage of the (104)-LiNiO configuration (surface energy: 1.44 J/m²), providing theoretical guidance for facet engineering(Figure 2).

Figure 2. DFT calculation results revealing the thermodynamic stability of different facets.

5. Key Findings: Enhanced Structure, Mechanics, and Electrochemistry

5.1 Optimized Structure and Mechanical Robustness

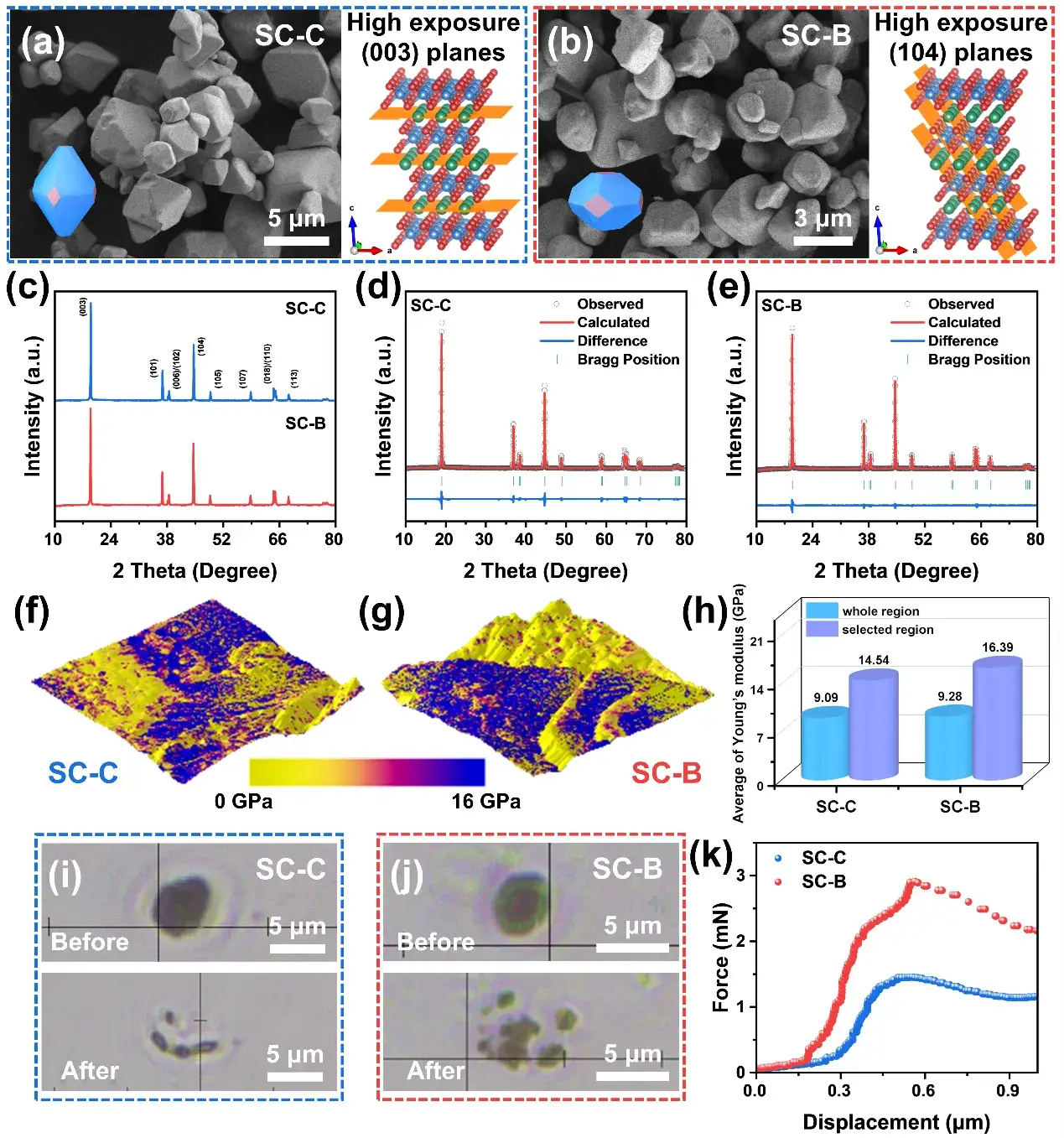

Material characterization confirmed the success of the facet engineering. Rietveld refinement showed an expanded interlayer spacing in SC-B, facilitating lithium-ion diffusion. Crucially, mechanical properties were significantly enhanced.

-

Atomic Force Microscopy (AFM) measured an average Young’s modulus of 16.39 GPa for SC-B, a 12.7% increase over the control material SC-C (14.54 GPa).

-

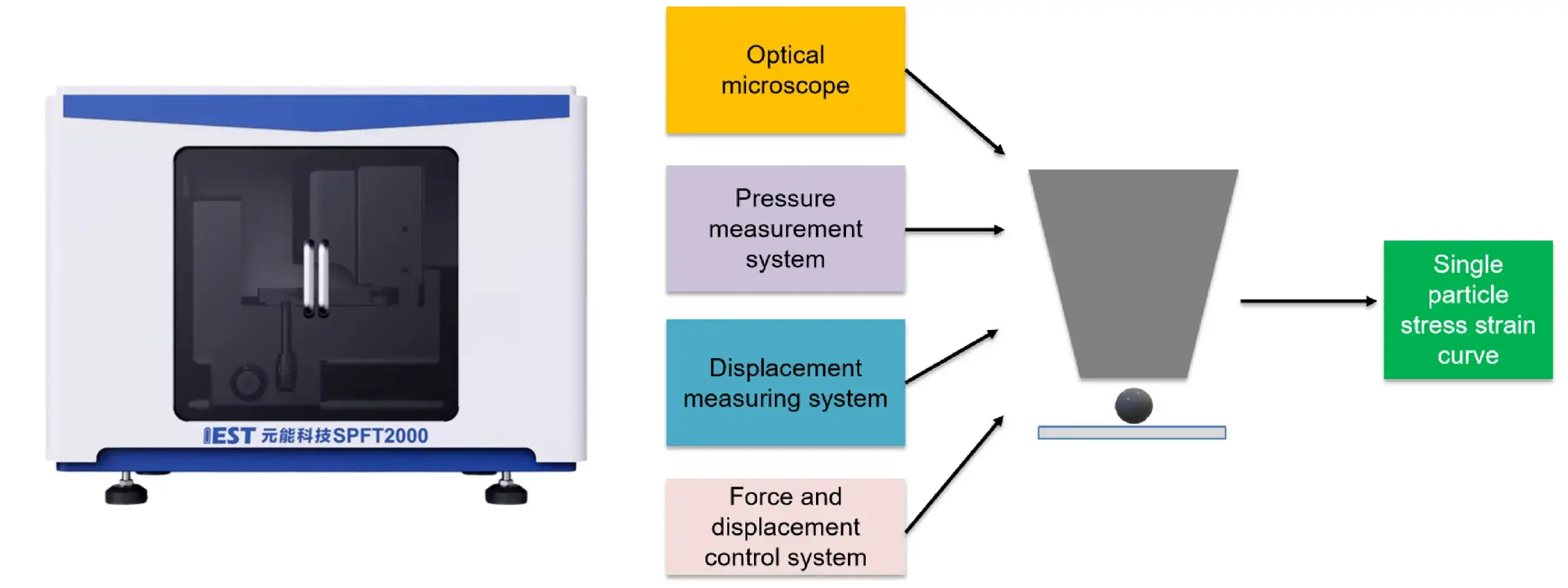

Using IEST Single Particle Mechanical Performance Test System (SPFT2000), the researchers further confirmed SC-B’s higher compressive strength (Figure 3). This mechanical robustness supports the use of higher electrode compaction densities (>3.8 g cm⁻³).

- X-ray photoelectron spectroscopy (XPS) analysis showed an increased Ni³⁺/Ni²⁺ ratio and reduced oxygen vacancy concentration on the SC-B surface, explaining the enhanced material stability at the molecular level.

Figure 3. Morphological, structural, and mechanical performance analysis.

5.2 Electrochemical Kinetics and Phase-transition Behavior Linked to Crystal Facet

-

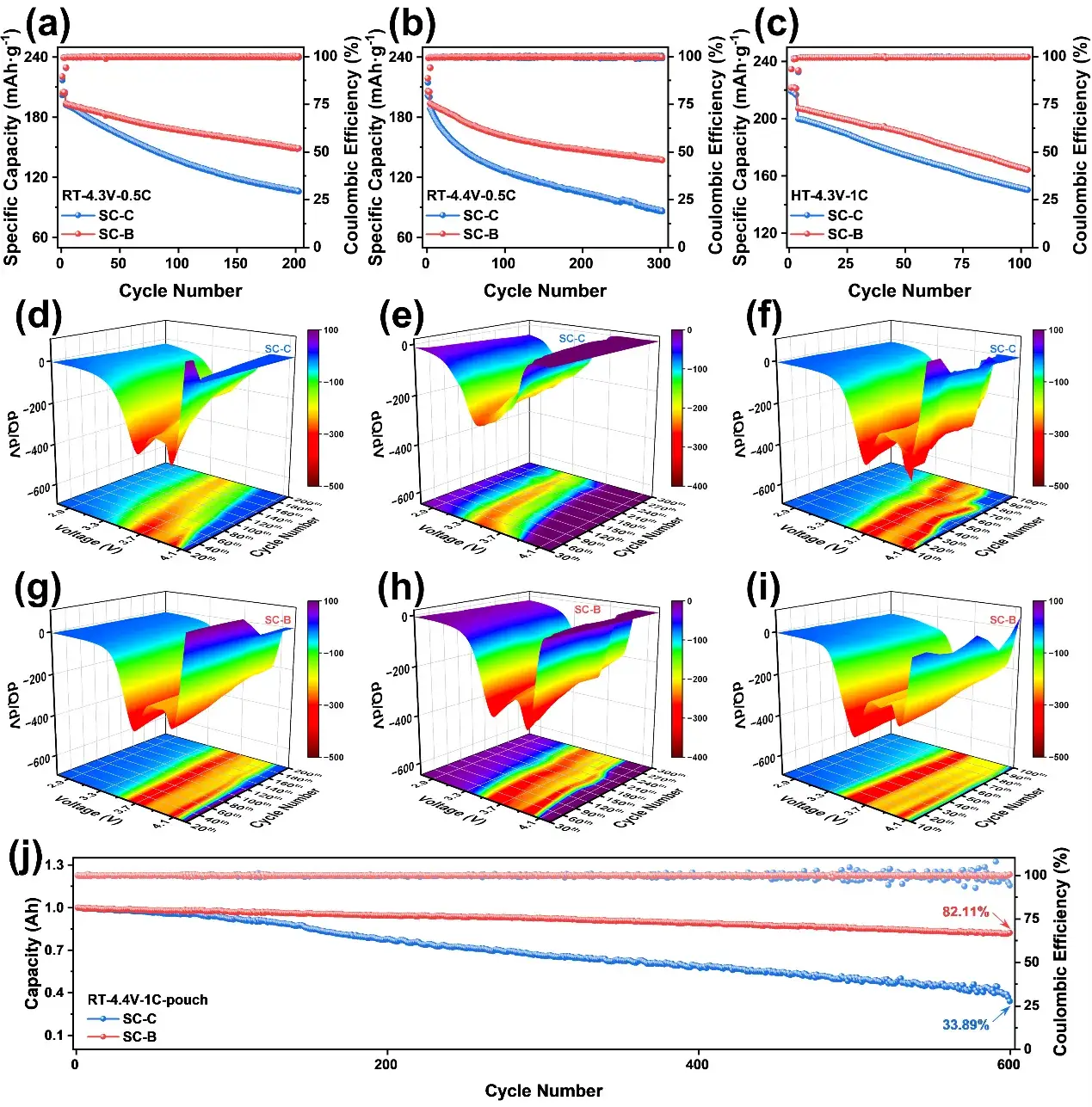

Systematic electrochemical testing revealed the favorable kinetics of SC-B: it delivered a discharge capacity of 159.8 mAh g⁻¹ at a high rate of 10C, a 36% improvement over SC-C (117.5 mAh g⁻¹).

-

Galvanostatic intermittent titration technique (GITT) tests concurrently demonstrated an enhanced lithium-ion diffusion coefficient for SC-B, confirming the positive role of the (104) facet in promoting ion migration.

- In situ X-ray diffraction (XRD) characterization unveiled critical structural evolution: during the H2-to-H3 phase transition, SC-B exhibited a reduced lattice contraction compared to SC-C, effectively mitigating structural degradation triggered by c-axis collapse.

- After 300 cycles at 4.4 V, SC-B maintained a capacity retention of 70.57% (136.9 mAh g⁻¹), significantly improved over SC-C’s 45.57% (85.9 mAh g⁻¹), demonstrating the efficacy of facet engineering in enhancing high-voltage stability.

Figure 4. Electrochemical performance of the materials.

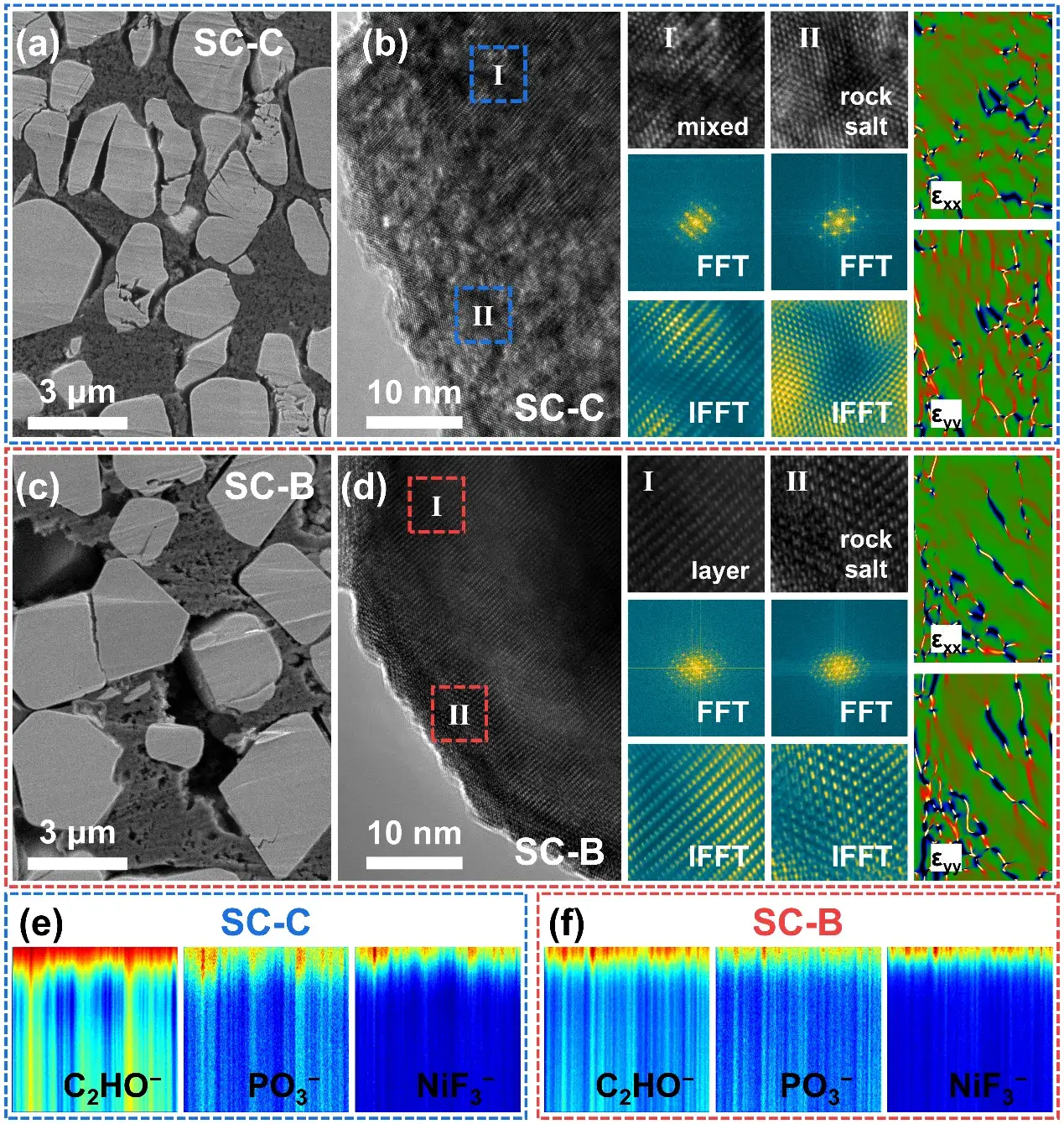

5.3 Mitigated Degradation and Stress Accumulation

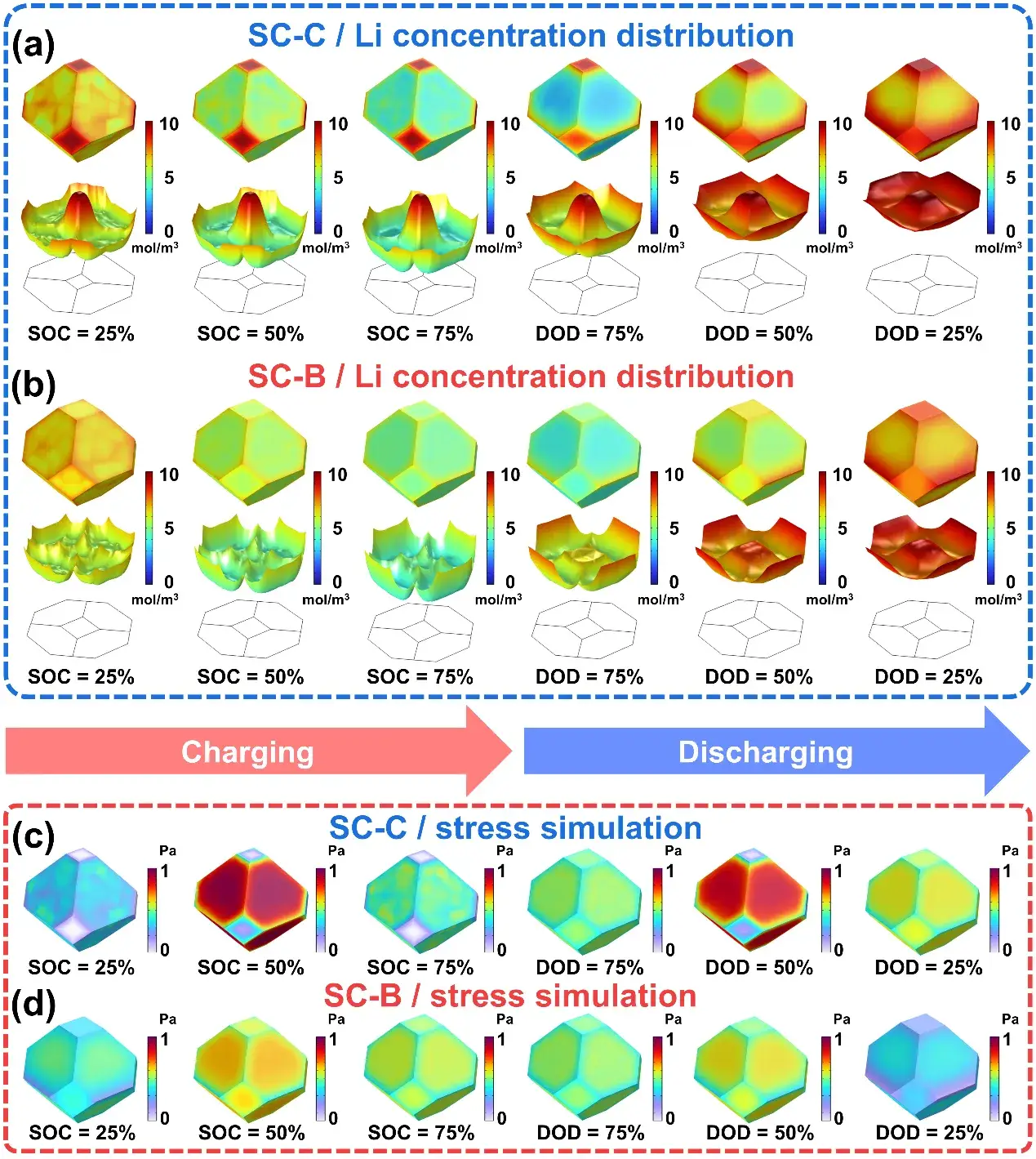

Multiscale characterization techniques provided deep insights into the cycling stability mechanism: high-resolution transmission electron microscopy (HRTEM) analysis revealed severe rock-salt phase formation on the surface of cycled SC-C, while SC-B formed only a thin ~10 nm surface reconstruction layer. Geometric phase analysis (GPA) indicated reduced stress accumulation in SC-B compared to SC-C, confirming the stress-relieving effect of (104) facet exposure. Time-of-flight secondary ion mass spectrometry (TOF-SIMS) showed reduced surface side reaction products on SC-B, indicating that the facet engineering design suppresses detrimental interfacial reactions. COMSOL Multiphysics simulations further validated these findings: SC-B exhibited improved lithium-ion distribution uniformity and reduced stress concentration, revealing the structural basis for its superior long-term cycling stability.

Figure 5. TEM and TOF-SIMS analysis of cycled electrode materials.

Figure 6. Finite element simulation results.

6. Manufacturing implications — Compaction, Electrode Processing and Pack Design

Because SC-B tolerates higher compaction density (>3.8 g·cm⁻³) and has improved particle-level toughness, electrode engineers can consider tighter calendering windows to raise volumetric energy density without proportionally increasing mechanical failure modes. However, process windows should be validated at cell scale because higher compaction can alter ionic pathways and slurry behavior. The improved Ni³⁺/Ni²⁺ surface balance and reduced oxygen vacancies also suggest fewer side reactions during formation, potentially simplifying formation protocols and post-formation aging.

7. Conclusion

This work successfully achieved structural optimization and performance breakthroughs in single crystal nickel-rich cathodes through a molten-salt-mediated facet engineering strategy. The synthesized SC-B material exhibits three core advantages: excellent rate capability (159.8 mAh g⁻¹ at 10C), enhanced structural stability (average Young’s modulus: 16.39 GPa), and superior long-term cycling stability (82.11% capacity retention after 600 cycles). This study establishes a quantitative structure-property relationship linking facet control, structural stability, and electrochemical performance, providing novel design principles and technical pathways for developing high-energy-density, long-lifetime lithium-ion battery cathodes.

8. Acknowledgements

This work was supported by the National Key R&D Program of China (2021YFB2401800), the National Natural Science Foundation of China (22179008, 21875022), the Beijing Nova Program (20230484241), the China Postdoctoral Science Foundation (2024M754084), and the Special Funding of China Postdoctoral Science Foundation (GZB20230931). Technical support from IEST Instrument is gratefully acknowledged.

9. Reference Details

10. Related Test Equipment Recommendation

You may want to learn about our equipment: IEST Single Particle Mechanical Properties Test System(SPFT)

IEST Single Particle Property Testing System(SPFT Series) provides high-precision (0.1 mN / 10 nm) compression and fracture testing for 5–50 µm battery electrode particles, quantifying micro-scale mechanical properties and failure mechanisms under controlled pressure to evaluate the material’s pressure resistance and guide the calendering process, particle design, densification, and electrode process optimization.

Application:

- Testing the crushing strength of battery material particles

- Can be used to evaluate the pressure resistance of the material

- Guide the rolling process

- Materials with high mechanical strength will have better subsequent cycle stability

Subscribe Us

Contact Us

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.